Copper alloy and preparation method and application thereof

A technology for preparing copper alloys and raw materials, applied in the direction of contact parts, etc., can solve the problems of medium strength and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

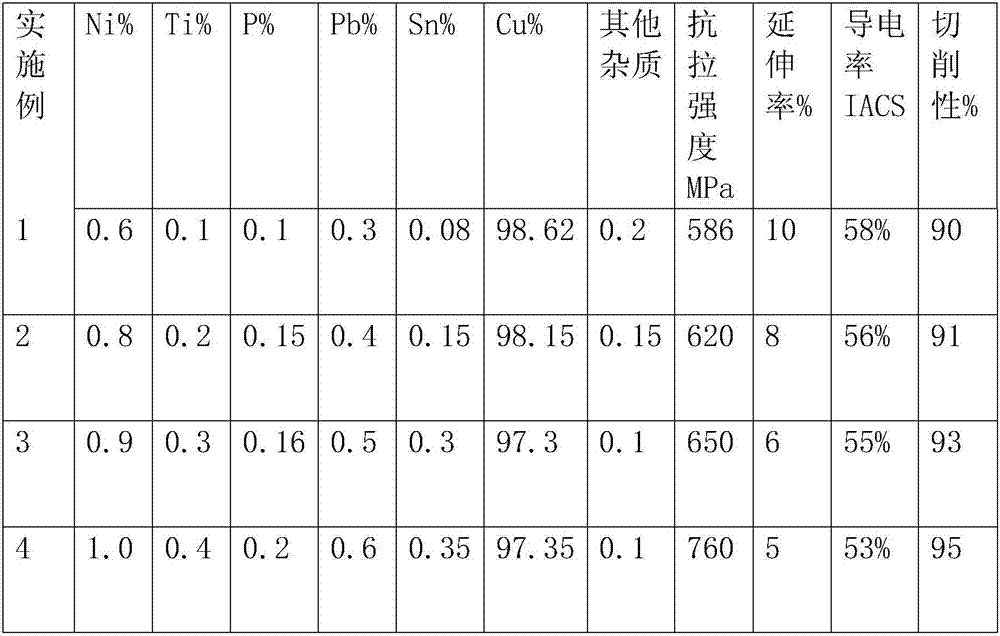

Examples

Embodiment 1

[0019] Raw materials: by weight fraction, take 98.62 parts of copper, 0.6 part of nickel, 0.1 part of titanium, 0.1 part of phosphorus, 0.3 part of lead, 0.08 part of tin, and 0.2 part of other unavoidable impurities.

[0020] Horizontal continuous casting process: Put the raw materials of the above components into the melting furnace for alloying. The melting sequence of the melting in the melting furnace is that copper is added first, and the temperature of the melting furnace rises to 1080°C. After the copper is melted, nickel and lead are added, followed by tin, titanium and phosphorus. After the melt is alloyed, keep it at 1080°C for 20 minutes, and put it into the holding furnace through the launder, and the temperature of the holding furnace is controlled at 1200°C. The copper alloy liquid is gradually solidified after being cooled by the crystallizer, and drawn out by the traction device. The traction device automatically controls the traction process by the motor. T...

Embodiment 2

[0023] Take 98.15 parts of copper, 0.8 parts of nickel, 0.2 parts of titanium, 0.15 parts of phosphorus, 0.4 parts of lead, 0.15 parts of tin, and 0.15 parts of other unavoidable impurities.

[0024] Horizontal continuous casting process: Put the raw materials of the above components into the melting furnace for alloying. The melting sequence of the melting in the melting furnace is that copper is added first, and the temperature of the melting furnace rises to 1200°C. After the copper is melted, nickel, lead, tin, titanium and phosphorus are added. After the melt is alloyed, it is kept at 1200°C for 20 minutes, and then put into the holding furnace through the launder, and the temperature of the holding furnace is controlled at 1300°C. The copper alloy liquid is gradually solidified after being cooled by the crystallizer, and drawn out by the traction device. The traction device automatically controls the traction process by the motor. The traction method is repeated pull-s...

Embodiment 3

[0027] Raw materials: Take 97.74 parts of copper, 0.9 parts of nickel, 0.3 parts of titanium, 0.16 parts of phosphorus, 0.5 parts of lead, 0.3 parts of tin, and 0.1 parts of other unavoidable impurities.

[0028] The horizontal continuous casting process is the same as in Example 1.

[0029] Cold drawing process: Stretch from 20mm in diameter to 10mm in diameter, solid solution at 740°C, then stretch to 8mm in diameter, age at 460°C, and stretch to 3mm in diameter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com