Low-carbon ferrite soft magnetic stainless steel and production method thereof

A technology of soft magnetic stainless steel and a production method, which is applied in the field of iron and steel smelting to achieve the effects of improving weldability and soft magnetic properties, expanding the scope of use, and increasing the content of Si element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

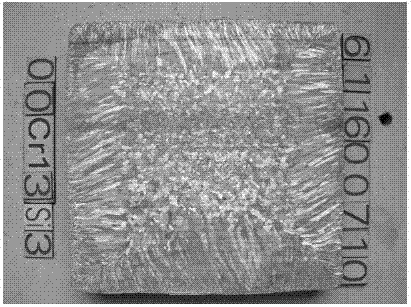

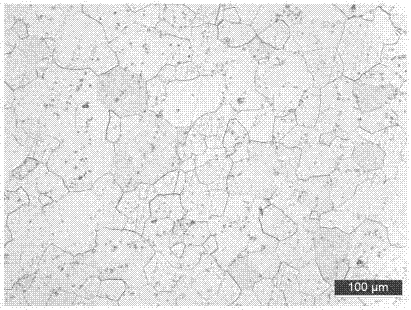

Image

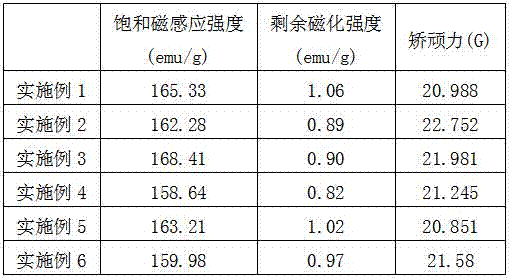

Examples

Embodiment 1

[0021] The chemical composition and production method of low carbon ferritic soft magnetic stainless steel are as follows:

[0022] Chemical composition and mass percentage of low carbon ferritic soft magnetic stainless steel: C: 0.02%, Si: 2.7%, Mn: 0.35%, P: 0.018%, S: 0.01%, Cr: 13.9%, Ni: 0.2% , Mo: 0.25%, V: 0.08%, Ti: 0.10%, N: 0.019%, and the balance is Fe and unavoidable impurity elements.

[0023] The production method of low-carbon ferritic soft magnetic stainless steel includes dephosphorization of molten iron, smelting in AOD furnace, refining in LF furnace, continuous casting, rolling, annealing, and pickling. The specific steps are as follows:

[0024] 1) Hot metal dephosphorization process: hot metal dephosphorization treatment, the main chemical components and mass percentages of the dephosphorized hot metal are: C: 3.2%, Si: 0.015%, P: 0.015%, and the temperature of the hot metal is 1260°C.

[0025] 2) AOD furnace smelting process:

[0026] The dephosphorize...

Embodiment 2

[0035] The chemical composition and production method of low carbon ferritic soft magnetic stainless steel are as follows:

[0036] Chemical composition and mass percentage of low carbon ferritic soft magnetic stainless steel: C: 0.02%, Si: 2.85%, Mn: 0.27%, P: 0.016%, S: 0.01%, Cr: 14.00%, Ni: 0.24% , Mo: 0.24%, V: 0.15%, Ti: 0.04%, N: 0.015%, and the balance is Fe and unavoidable impurity elements.

[0037] The production method of low-carbon ferritic soft magnetic stainless steel includes dephosphorization of molten iron, smelting in AOD furnace, refining in LF furnace, continuous casting, rolling, annealing, and pickling. The specific steps are as follows:

[0038] 1) Hot metal dephosphorization process: hot metal dephosphorization treatment, the main chemical components and mass percentages of the dephosphorized hot metal are: C: 3.1%, Si: 0.018%, P: 0.015%, and the temperature of the hot metal is 1265°C.

[0039] 2) AOD furnace smelting process:

[0040] The dephosphoriz...

Embodiment 3

[0049] The chemical composition and production method of low carbon ferritic soft magnetic stainless steel are as follows:

[0050] Chemical composition and mass percentage of low carbon ferritic soft magnetic stainless steel: C: 0.030%, Si: 2.50%, Mn: 0.50%, P: 0.014%, S: 0.01%, Cr: 13.50%, Ni: 0.23% , Mo: 0.24%, V: 0.08%, Ti: 0.06%, N: 0.17%, the balance is Fe and unavoidable impurity elements

[0051] The production method of low-carbon ferritic soft magnetic stainless steel includes dephosphorization of molten iron, smelting in AOD furnace, refining in LF furnace, continuous casting, rolling, annealing, and pickling. The specific steps are as follows:

[0052] 1) Hot metal dephosphorization process: hot metal dephosphorization treatment, the main chemical components and mass percentages of the dephosphorized hot metal are: C: 3.3%, Si: 0.017%, P: 0.012%, and the temperature of the hot metal is 1255°C.

[0053] 2) AOD furnace smelting process:

[0054] The dephosphorized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com