Method for performing multi-level quality-lifting on mixed organic solid waste based on molten salt

A solid waste and organic solid technology, applied in the fields of solid waste removal, chemical instruments and methods, furniture waste recycling, etc., can solve the problems of graded utilization of unfavorable products and high processing costs, and achieve high-value utilization and multi-level Effect of low upgrading temperature, degree of homogenization and improved fuel properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

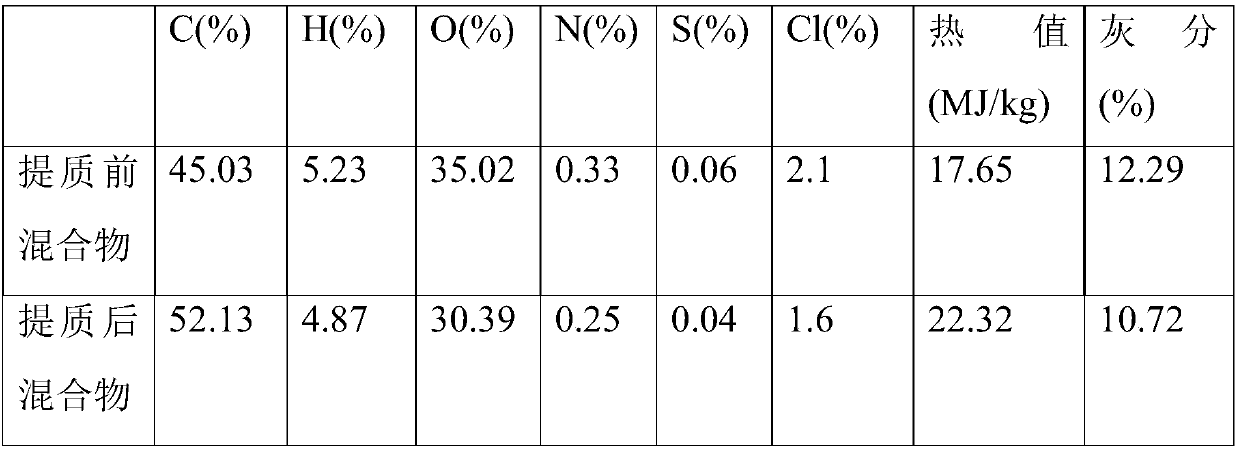

Embodiment 1

[0025] (1) Drying of solid waste: The mixture of sycamore bark and polypropylene (PP) was placed in an oven at 110° C. until the moisture content decreased to 20%.

[0026] (2) Introduction and penetration of hot molten salt: molten salt is made of NaNO 3 -KNO 3 -NaNO 2 Mix according to the mass fraction of 7%-53%-40% (melting point is 142°C), and obtain after heating and melting. The solid waste obtained in step (1) is sent into molten salt, and the liquid molten salt is ensured to penetrate into the mixed solid waste.

[0027] (3) Heating, aeration and acid-base modulation: heating the molten salt through an external heat source, and maintaining the internal reaction temperature of the molten salt at 350°C through program control; adding an acid-base regulator 15% NaOH to the molten salt while feeding it into the reaction chamber. The atmosphere required is air + 5% water vapor.

[0028] (4) Classification of mixture: after PP is melted, the sycamore bark is pressed to t...

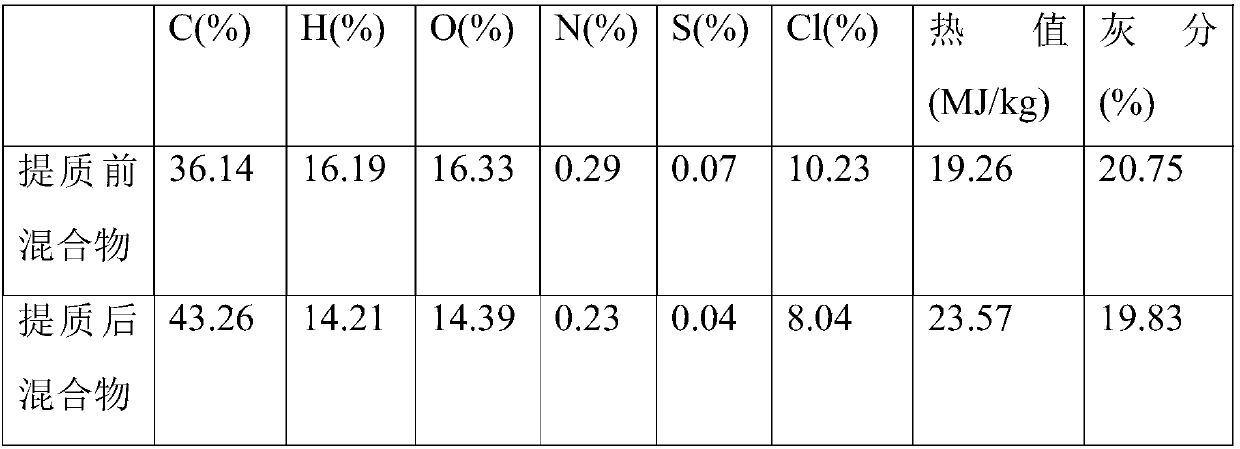

Embodiment 2

[0035] (1) Drying of solid waste: The mixture of disposable wooden chopsticks, A4 paper, and polyvinyl chloride (PVC) was placed in an oven at 100°C until the moisture content was reduced to 25%.

[0036] (2) Introduction and penetration of hot molten salt: molten salt is made of KNO 3 -LiNO 3 -Ca(NO 3 ) 2 According to the mass fraction of 50%-80%-0%-25%-10%-45%, mix (melting point below 80°C), and obtain after heating and melting. The solid waste obtained in step (1) is fed into molten salt, and the liquid molten salt is ensured to penetrate into the mixed solid waste.

[0037] (3) Heating, aeration and acid-base modulation: heating the molten salt through an external heat source, and maintaining the internal reaction temperature of the molten salt at 250°C through program control; adding an acid-base regulator 10% NaOH+5% CaOH to the molten salt, At the same time, the atmosphere required for the reaction, ie, air, was introduced.

[0038] (4) Classification of mixture: ...

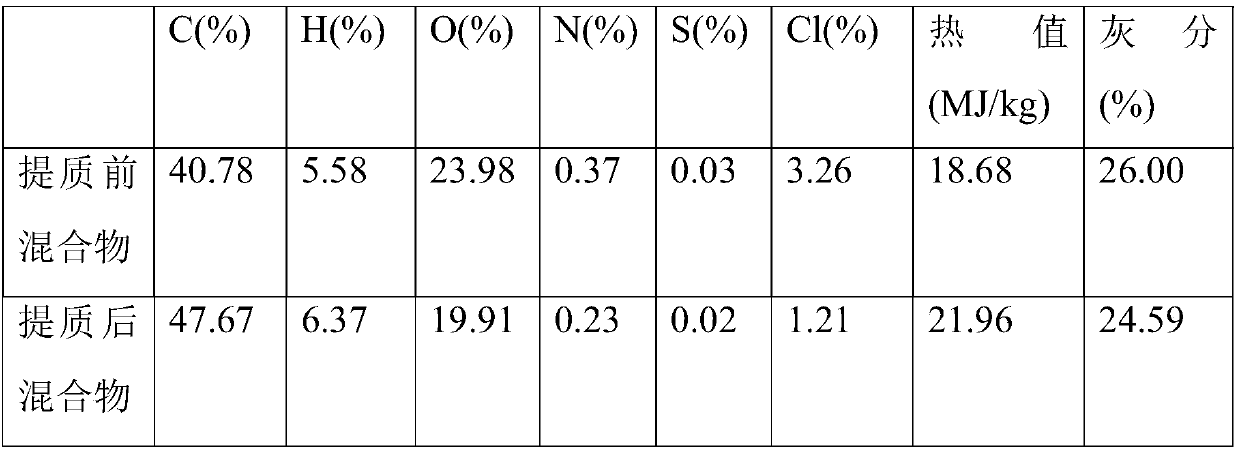

Embodiment 3

[0045] (1) Drying of solid waste: The mixture of express carton, old clothes, polyethylene (PE) was placed in an oven at 105°C until the moisture content was reduced to 22%.

[0046] (2) Introduction and permeation of hot molten salt: The molten salt is mixed with Na-NO3-KNO3-LiNO3-Na NO2 in a mass fraction of 14.2%-50.5%-17.5%-17.8% (melting point is 99°C). The solid waste obtained in step (1) is sent into molten salt, and the liquid molten salt is ensured to penetrate into the mixed solid waste.

[0047] (3) Heating, aeration and acid-base modulation: heating the molten salt through an external heat source, and maintaining the internal reaction temperature of the molten salt at 150°C through program control; adding an acid-base regulator 5% CaOH to the molten salt, and feeding the reaction The required atmosphere is air + 20% water vapor.

[0048] (4) Classification of the mixture: After the PE is melted, the sycamore bark is pressed to the bottom of the reactor by using a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com