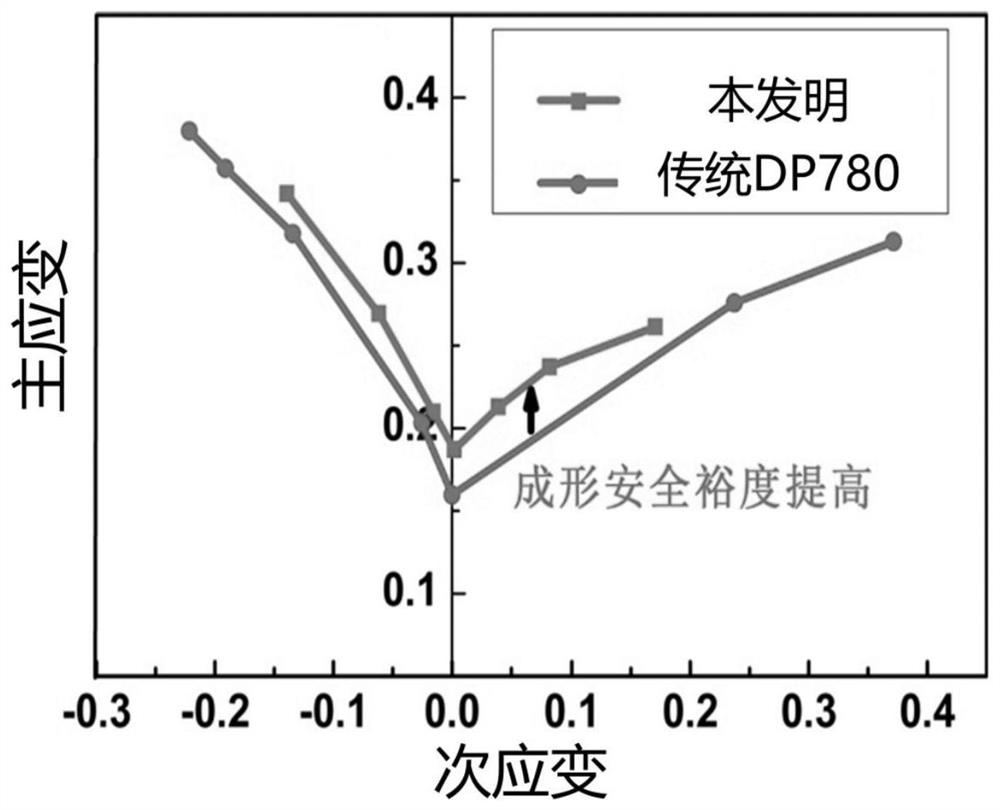

780MPa-grade hot-dip galvanized dual-phase steel with enhanced formability and manufacturing method thereof

A manufacturing method, dual-phase steel technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve problems such as difficult forming, improve surface quality, improve formability, and inhibit austenite decomposition and the effect of carbide formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

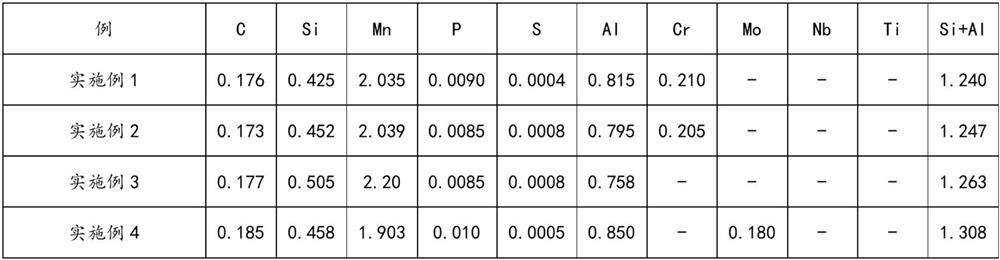

[0108] The present invention is a 780MPa-level enhanced formability hot-dip galvanized dual-phase steel, the chemical composition of the dual-phase steel includes in mass fraction:

[0109] C: 0.16%~0.2%, Si: 0.35%~0.65%, Mn: 1.8%~2.3%, Al: 0.7%~1.0%, P≤0.01%, S≤0.003%, Si+Al≥1.2%, the rest Fe and unavoidable impurities;

[0110] Further, the chemical composition of the dual-phase steel also includes any one of the following elements in terms of mass fraction:

[0111] Cr: 0.16% to 0.25%, Mo: 0 to 0.3%.

[0112] The chemical composition of each embodiment of the present invention and comparative example is as shown in table 1:

[0113] The chemical composition (wt.%) of each embodiment of table 1 and comparative example

[0114]

[0115]

[0116] A method for manufacturing a 780MPa-level enhanced formability hot-dip galvanized dual-phase steel of the present invention has the following steps:

[0117] (1): According to the chemical composition ratio of 780MPa enhance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com