Anode material used for lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, active material electrodes, etc., can solve problems such as unsatisfactory rate performance, low electronic conductivity, and limitations on the practical application of lithium zinc titanate, and achieve cycle and Good rate performance, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

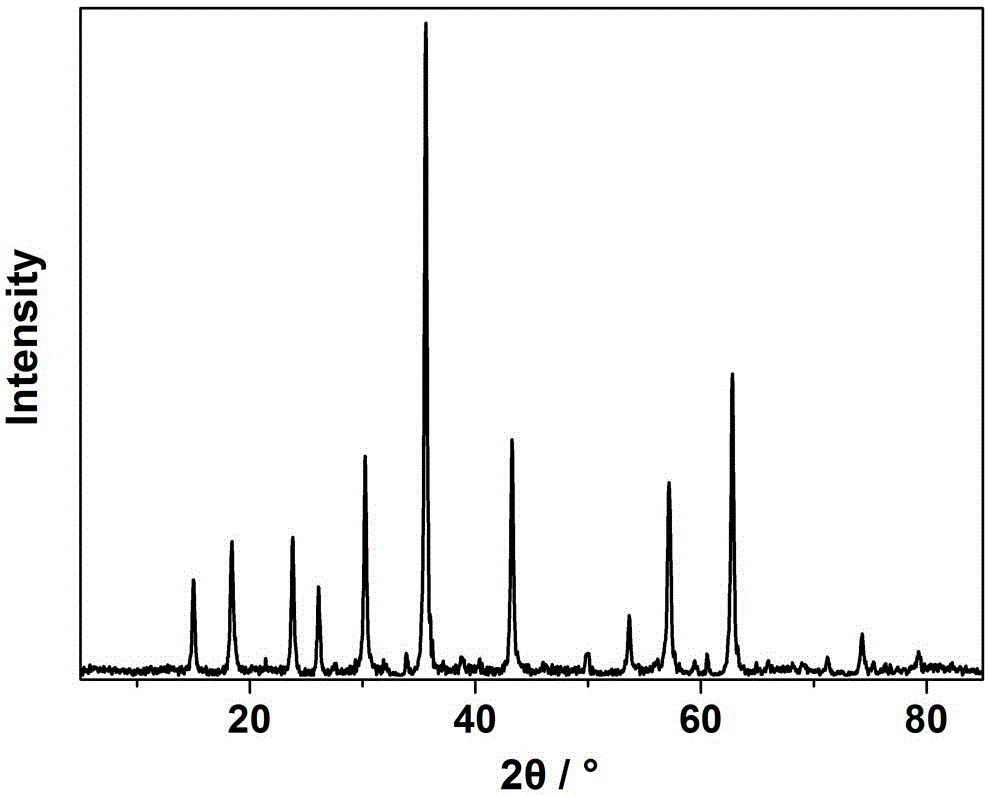

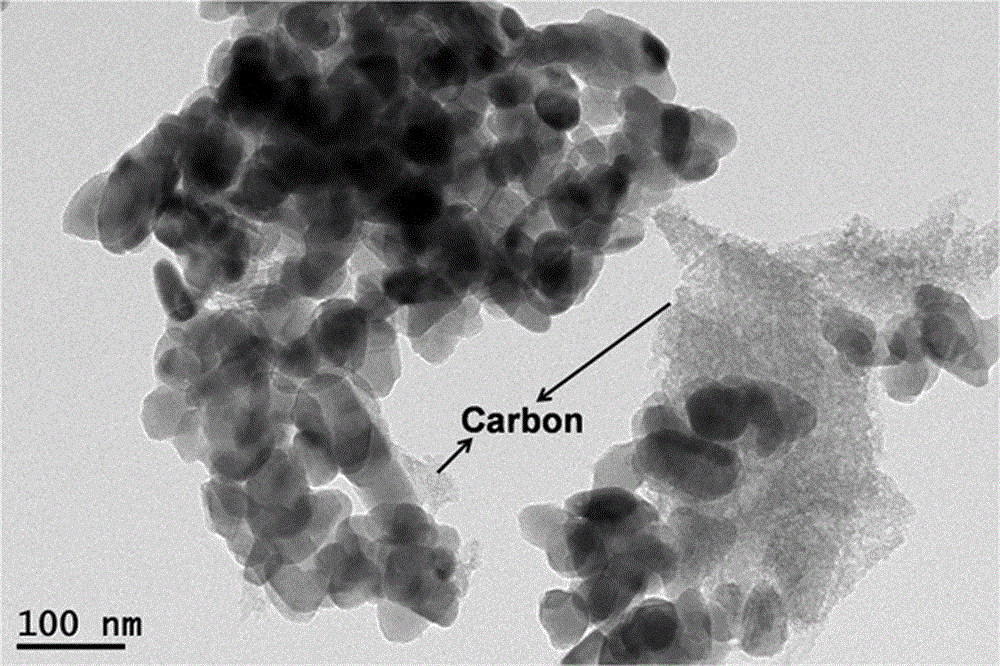

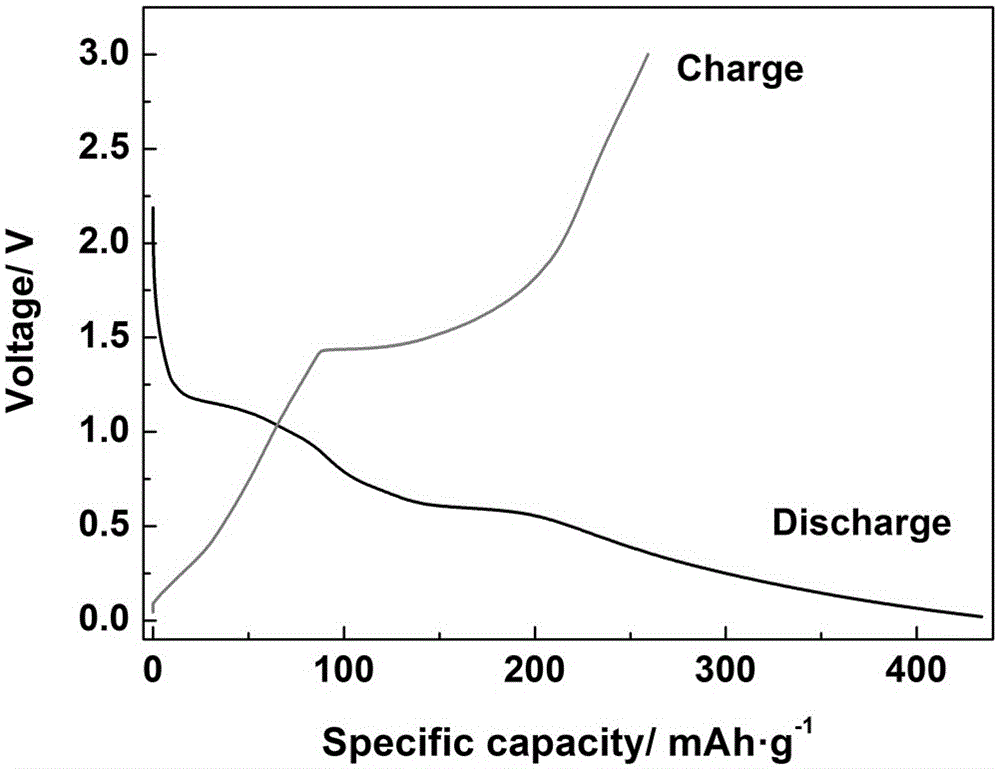

[0045] see Figure 1~3 , a negative electrode material for a lithium ion battery, the molecular formula of the negative electrode material is Li 2 ZnTi 3 o 8 C-N, from lithium salt, zinc source and titanium source according to the amount of material ratio n Li :n Zn :n Ti =2.2:1:3 mixed and sintered, the zinc source is a porous MOF material containing Zn, C and N elements.

[0046] The lithium salt is Li 2 CO 3 .

[0047] Described porous MOF material is ZIF-8, and molecular formula is Zn(MeIM) 2 ·(DMF)·(H 2 O) 3 , sod topology.

[0048] The titanium source is a mixture of MIL-125 (Ti) and anatase titanium dioxide, and the molecular formula of the MIL-125 (Ti) is Ti 8 o 8 (OH) 4 -(O 2 C-C 6 h 4 -CO 2 ) 6 .

[0049] The preparation method of above-mentioned negative electrode material, comprises the steps:

[0050] Step A, Li 2 CO 3 , ZIF-8, MIL-125(Ti) and anatase TiO 2 Ball milling and mixing for 3 hours to obtain the precursor, wherein calculated acco...

Embodiment 2

[0059] see Figure 4~6 , a negative electrode material for a lithium ion battery, the molecular formula of the negative electrode material is Li 2 ZnTi 3 o 8 C-N, from lithium salt, zinc source and titanium source according to the amount of material ratio n Li :n Zn :n Ti =2.4:1:3 mixed and sintered, the zinc source is a porous MOF material containing Zn, C and N elements.

[0060] The lithium salt is LiOH·H 2 O and LiNO 3 mixed lithium salts.

[0061] Described porous MOF material is ZIF-8, and molecular formula is Zn(MeIM) 2 ·(DMF)·(H 2 O) 3 , sod topology.

[0062] The titanium source is MIL-125 (Ti) and rutile TiO 2 The mixture, the MIL-125 (Ti) molecular formula is Ti 8 o 8 (OH) 4 -(O 2 C-C 6 h 4 -CO 2 ) 6 .

[0063] The preparation method of above-mentioned negative electrode material, comprises the steps:

[0064] Step A, LiOH·H 2 O and LiNO 3 Mixed lithium salts, ZIF-8 and MIL-125(Ti) and rutile TiO 2 Ball milling and mixing for 2 hours to obtain...

Embodiment 3

[0073] see Figure 7-9 , a negative electrode material for a lithium ion battery, the molecular formula of the negative electrode material is Li 2 ZnTi 3 o 8 C-N, from lithium salt, zinc source and titanium source according to the amount of material ratio n Li :n Zn :n Ti =2.4:1:3 mixed and sintered, the zinc source is a porous MOF material containing Zn, C and N elements.

[0074] The lithium salt is LiOH·H 2 O and LiNO 3 mixed lithium salts.

[0075] Described porous MOF material is ZIF-8, and molecular formula is Zn(MeIM) 2 ·(DMF)·(H 2 O) 3 , sod topology.

[0076] The titanium source is NH 2 -MIL-125(Ti) and rutile TiO 2 a mix of the NH 2 -MIL-125(Ti) molecular formula is Ti 8 o 8 (OH) 4 -(O 2 C-C 6 h 4 -NH 2 -CO 2 ) 6 .

[0077] The preparation method of above-mentioned negative electrode material, comprises the steps:

[0078] Step A, LiOH·H 2 O and LiNO 3 mixed lithium salts, ZIF-8, NH 2 -MIL-125(Ti) and rutile TiO 2 Ball milling and mixing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com