Special steel pipe for CO2 (carbon dioxide) air conditioner compressor casing and processing process of special steel pipe

A technology for air-conditioning compressors and steel pipes, which is applied in the direction of pipes, rigid pipes, mechanical equipment, etc., and can solve the difficulties of thickening the plate and raising the height of the shell, the difficulty of bending and rolling the thick plate into a cylinder, and the inability to meet mass production, etc. problems, to achieve the effect of saving raw materials, simple structure and high production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

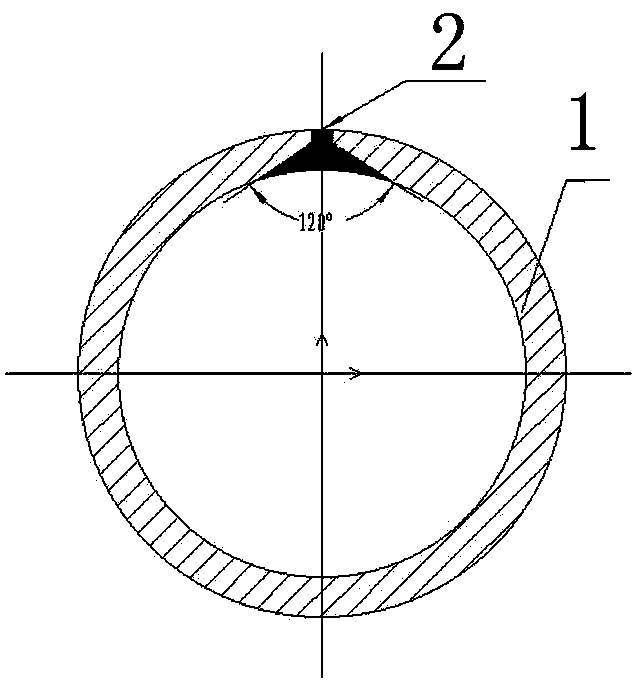

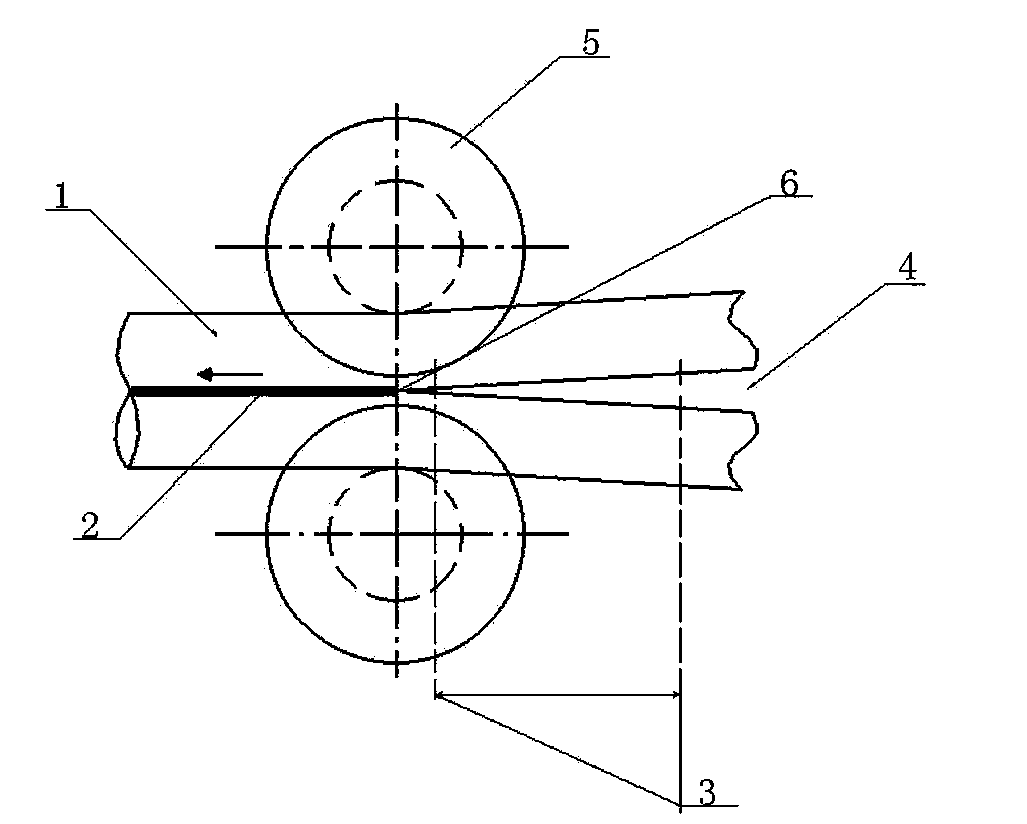

[0028] Such as figure 1 As shown, including steel pipe 1 and steel pipe weld 2.

[0029] The invention adopts the high-quality steel coil SS400 produced by Baosteel, whose thickness tolerance is controlled at ±0.10mm, and the surface quality of the steel coil is smooth, flat and free of scars. The steel coil is cut into the required steel strip according to the specified width, and the joints on both sides of the steel strip are welded into steel pipes, and rolled into the steel pipes required for the shell in the forming area of the high-frequency welding machine.

[0030] a CO 2 A processing method for special steel pipes for air-conditioning compressor shells; including the following process steps:

[0031] 1. The material of the steel coil is selected as: SS400, and the tolerance of its thickness is controlled at ±0.10mm. The surface quality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com