Al-Mg-Si-Cu alloy and preparation method thereof

An alloy and percentage technology, applied in the field of Al-Mg-Si-Cu alloy and its preparation, can solve the problems of surface roughness and cracking, achieve high elongation, improve material elongation, and eliminate negative effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

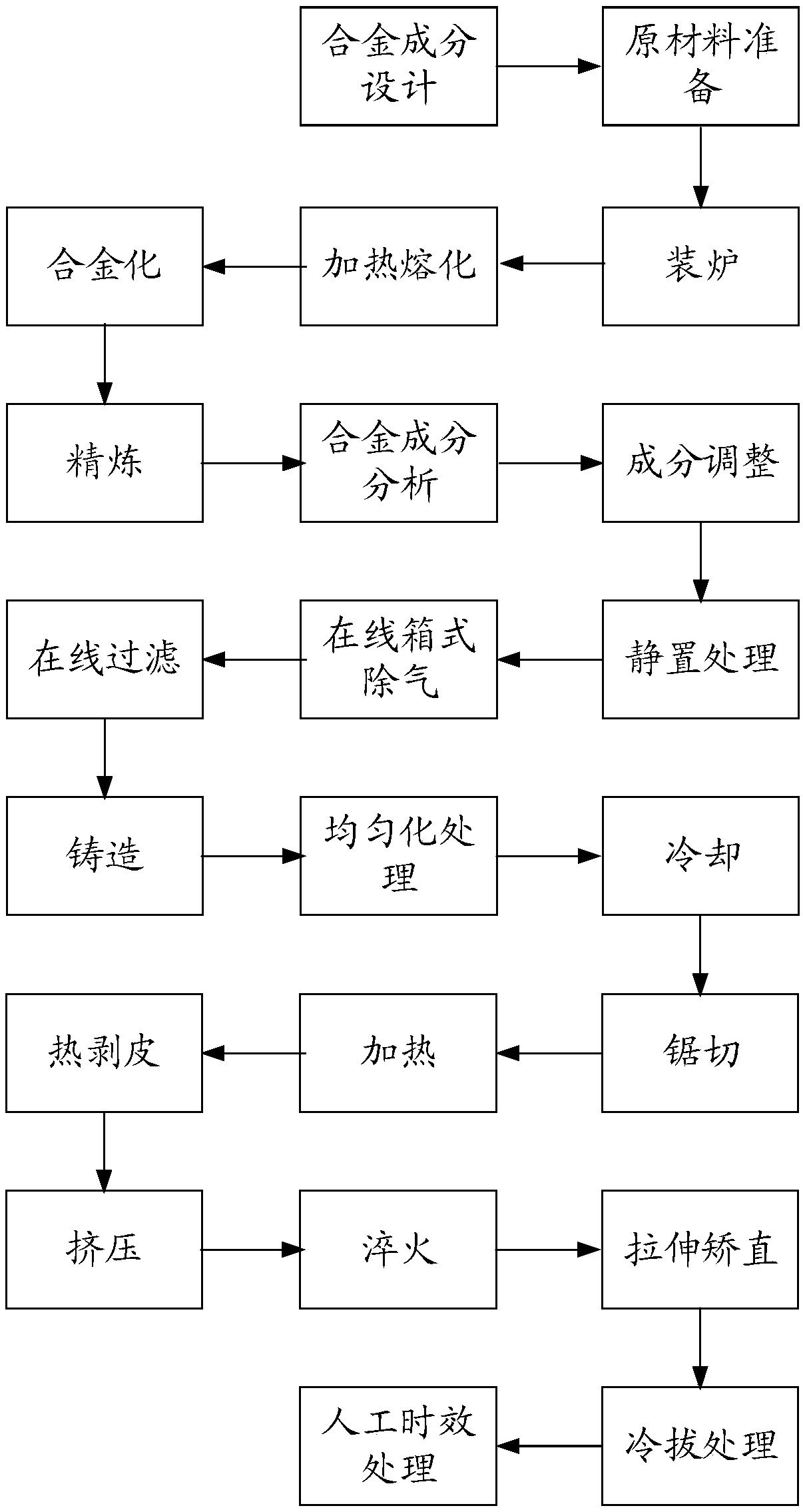

Method used

Image

Examples

Embodiment 1-4

[0037] A kind of Al-Mg-Si-Cu alloy described in the present embodiment 1-4, by mass percentage, includes the components as shown in Table 1, and the individual content of other impurities should not exceed 0.05%, and the total amount should not exceed 0.15% , the balance being Al.

[0038] components

Example 1

Example 2

Example 3

Example 4

Si

0.65%

0.70%

0.68%

0.60%

Mg

1.00%

1.10%

1.00%

1.05%

Fe

0.06%

0.10%

0.09%

0.10%

Cu

0.20%

0.15%

0.16%

0.13%

Cr

0.06%

0.08%

0.08%

0.04%

mn

0.03%

0.003%

0.01%

0.05%

Zn

0.08%

0.10%

0.12%

0.07%

Ti

0.02%

0.03%

0.03%

0.02%

Mn+Cr%

0.09%

0.083%

0.09%

0.09%

[0039] Table 1

[0040] The raw materials for preparing the above-mentioned Al-Mg-Si-Cu alloy are as follows:

[0041] Aluminum ingots: Al99.7 aluminum ingots are used, and the mass percentage of A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com