Nb-contained high-strength high-tenacity low-density steel for automobile and preparation method thereof

A high-toughness, low-density steel technology, applied in the field of metal materials, can solve the problems of low-density steel being easily corroded and oxidized, poor controllability of the second phase, and restricted wide application, etc., to achieve excellent corrosion resistance, reliable method, improved The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

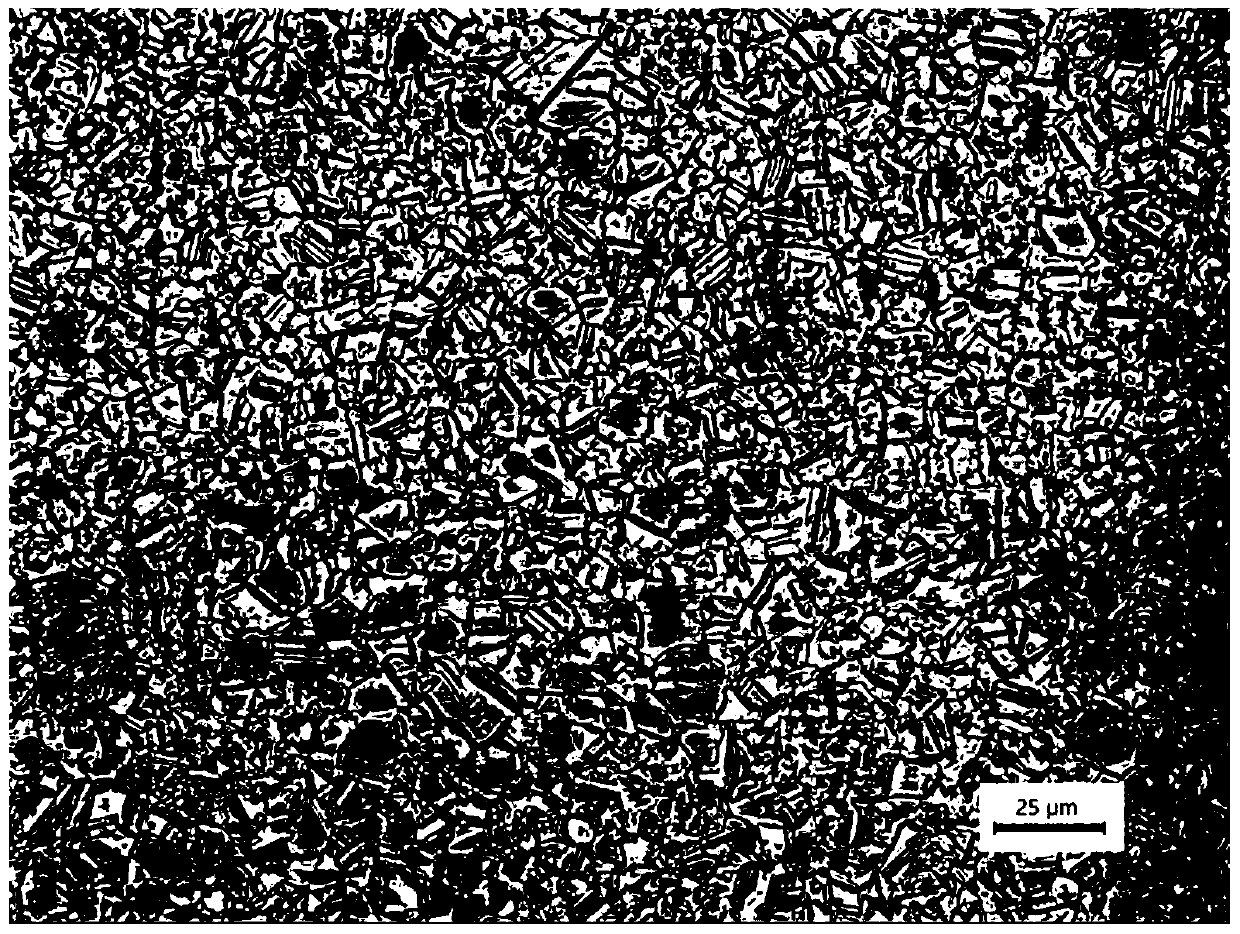

Image

Examples

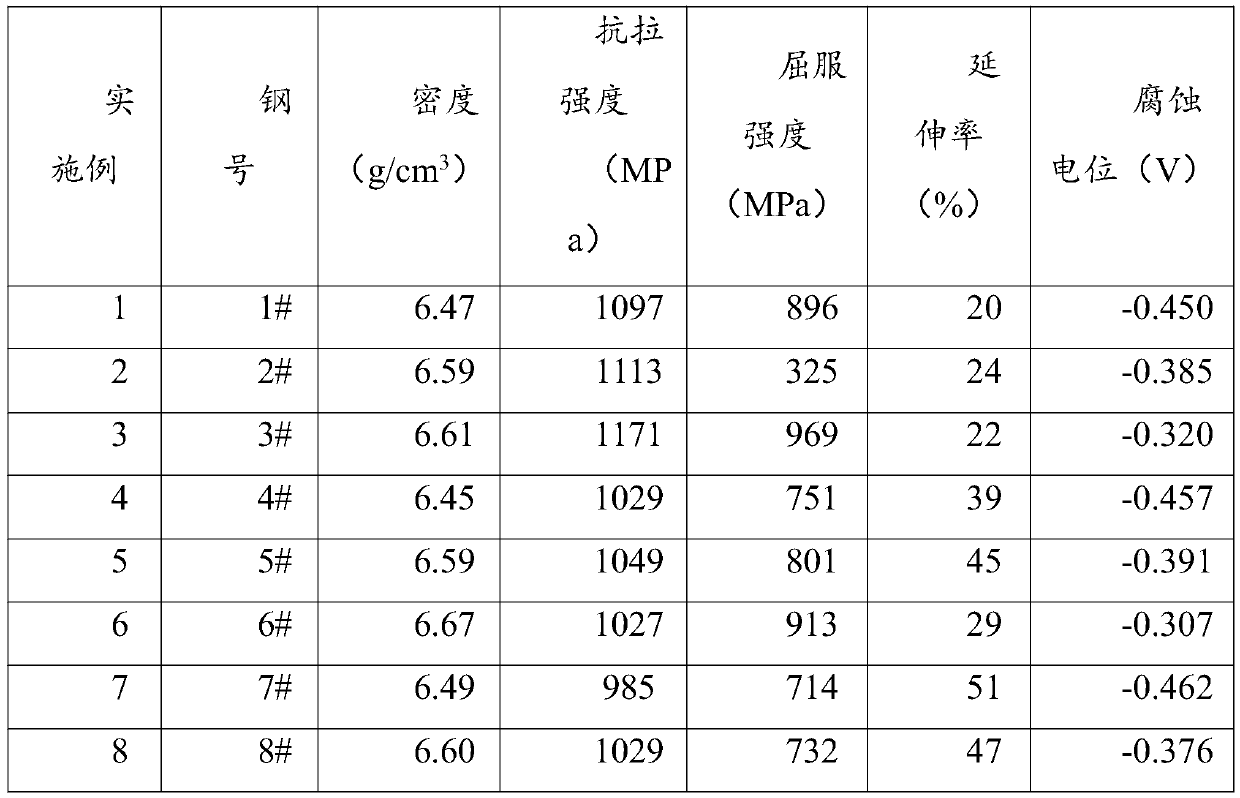

Embodiment 1

[0046] The present embodiment provides a kind of preparation method of Nb-containing low-density steel for automobile, specifically comprises the following steps:

[0047] Step 1. Smelting: According to the mass percentage corresponding to 1# steel in Table 1, weigh raw materials with a purity greater than 99.5, carry out vacuum melting in a vacuum induction furnace under the condition of vacuum degree <50Pa, and heat until the alloy raw materials are completely melted and the surface of the molten pool After no bubbles escape, heat it at 1600°C for 1 hour under the protection of argon to refine and fully alloy, then cast and cool at room temperature to obtain a steel ingot.

[0048] Step 2, homogenization treatment: the steel ingot prepared in step 1 was placed in a heating furnace, kept at a constant temperature of 1200° C. for 30 minutes, and cooled to room temperature with the furnace to obtain a homogenized steel ingot.

[0049] Step 3, forging treatment: the steel ingot ...

Embodiment 2

[0055] The present embodiment provides a kind of preparation method of Nb-containing low-density steel for automobile, specifically comprises the following steps:

[0056] Step 1, smelting: according to the mass percentage corresponding to 2# steel in Table 1. Weigh raw materials with a purity greater than 99.5, conduct vacuum melting in a vacuum induction furnace under the condition of a vacuum degree of <50Pa, heat until the alloy raw materials are completely melted and no bubbles overflow from the surface of the molten pool, then keep warm for 1 hour at 1600°C under the protection of argon for refining and fully alloyed, then cast and cooled at room temperature to obtain a steel ingot.

[0057] Step 2, homogenization treatment: the steel ingot prepared in step 1 was placed in a heating furnace, kept at a constant temperature of 1200° C. for 30 minutes, and cooled to room temperature with the furnace to obtain a homogenized steel ingot.

[0058] Step 3, forging treatment: t...

Embodiment 3

[0064] The present embodiment provides a kind of preparation method of Nb-containing low-density steel for automobile, specifically comprises the following steps:

[0065] Step 1, smelting: according to the mass percentage corresponding to 3# steel in Table 1. Weigh raw materials with a purity greater than 99.5, conduct vacuum melting in a vacuum induction furnace under the condition of a vacuum degree of <50Pa, heat until the alloy raw materials are completely melted and no bubbles overflow from the surface of the molten pool, then keep warm for 1 hour at 1600°C under the protection of argon for refining and fully alloyed, then cast and cooled at room temperature to obtain a steel ingot.

[0066] Step 2, homogenization treatment: the steel ingot prepared in step 1 was placed in a heating furnace, kept at a constant temperature of 1200° C. for 30 minutes, and cooled to room temperature with the furnace to obtain a homogenized steel ingot.

[0067] Step 3, forging treatment: t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com