Transformer silicon steel sheet and preparation method thereof

A technology for silicon steel sheets and transformers, applied in coatings and other directions, can solve the problems of high preparation cost, insufficient control of hysteresis loss, etc., and achieve the effects of excellent mechanical properties, improved service life and performance, and high hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The above-mentioned preparation method of a transformer silicon steel sheet is carried out according to the following steps:

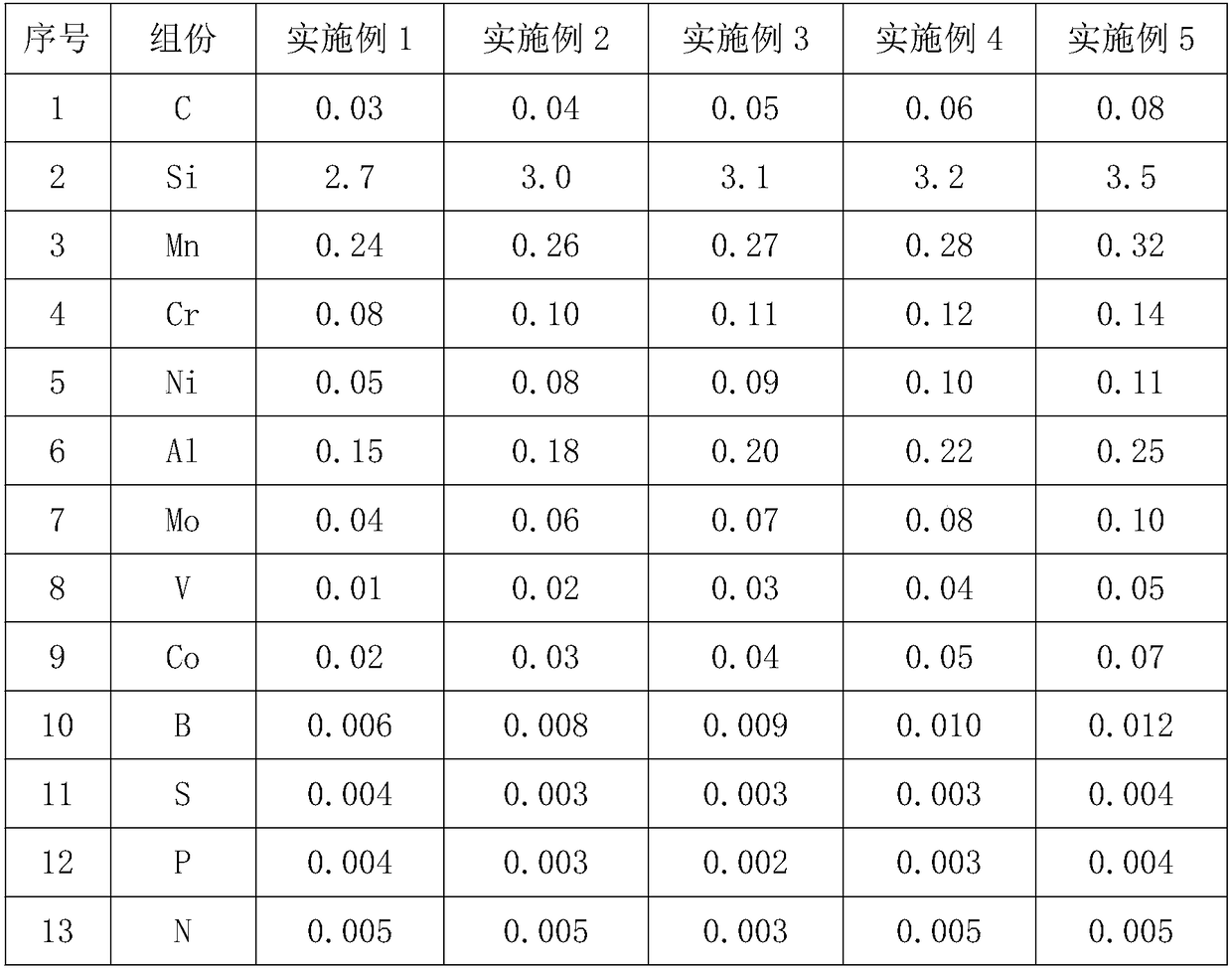

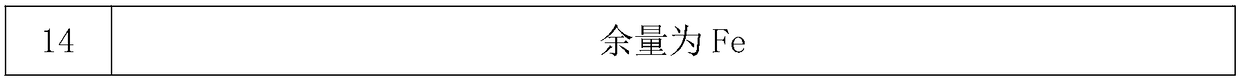

[0033] Step 1: Put industrial raw materials into the melting furnace for smelting to obtain molten steel, blow argon outside the furnace and feed wire for refining after being released from the furnace, adjust and control the content of chemical components in the molten steel as shown in Table 1 above, where the argon pressure 0.4MPa, the inner diameter of the pressure pipe is 10mm, and the argon blowing time is 30min;

[0034] Step 2: Cast the molten steel into rough silicon steel sheets, place the rough silicon steel sheets on a hot rolling mill and roll them into semi-finished silicon steel sheets. The hot rolling of semi-finished silicon steel sheets includes the following four processes:

[0035] (1) Heating and heat preservation: keep the semi-finished silicon steel sheet at a temperature of 370°C for 1.5h; then raise the temperature to 58...

Embodiment 2

[0043] The above-mentioned preparation method of a transformer silicon steel sheet is carried out according to the following steps:

[0044] Step 1: Put industrial raw materials into the melting furnace for smelting to obtain molten steel, blow argon outside the furnace and feed wire for refining after being released from the furnace, adjust and control the content of chemical components in the molten steel as shown in Table 1 above, where the argon pressure The pressure is 0.4MPa, the inner diameter of the pressure pipe is 10mm, and the argon blowing time is 32min;

[0045] Step 2: Cast the molten steel into rough silicon steel sheets, place the rough silicon steel sheets on a hot rolling mill and roll them into semi-finished silicon steel sheets. The hot rolling of semi-finished silicon steel sheets includes the following four processes:

[0046] (1) Heating and heat preservation: heat the semi-finished silicon steel sheet at a temperature of 375°C for 1.5h; then raise the t...

Embodiment 3

[0054] The above-mentioned preparation method of a transformer silicon steel sheet is carried out according to the following steps:

[0055] Step 1: Put industrial raw materials into the melting furnace for smelting to obtain molten steel, blow argon outside the furnace and feed wire for refining after being released from the furnace, adjust and control the content of chemical components in the molten steel as shown in Table 1 above, and the argon pressure is 0.4 MPa, the inner diameter of the pressure pipe is 11mm, and the argon blowing time is 35min;

[0056] Step 2: Cast the molten steel into rough silicon steel sheets, place the rough silicon steel sheets on a hot rolling mill and roll them into semi-finished silicon steel sheets. The hot rolling of semi-finished silicon steel sheets includes the following four processes:

[0057] (1) Heating and heat preservation: heat the semi-finished silicon steel sheet at a temperature of 380°C for 2 hours; then raise the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com