Chromium-free insulating coating, electrical sheet material and preparation method thereof

A technology for insulating coatings and electrical steel, applied in the direction of epoxy resin coatings, coatings, and devices for coating liquid on the surface, etc., can solve problems such as poor performance, achieve excellent heat resistance, reduce curing temperature, and optimize process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

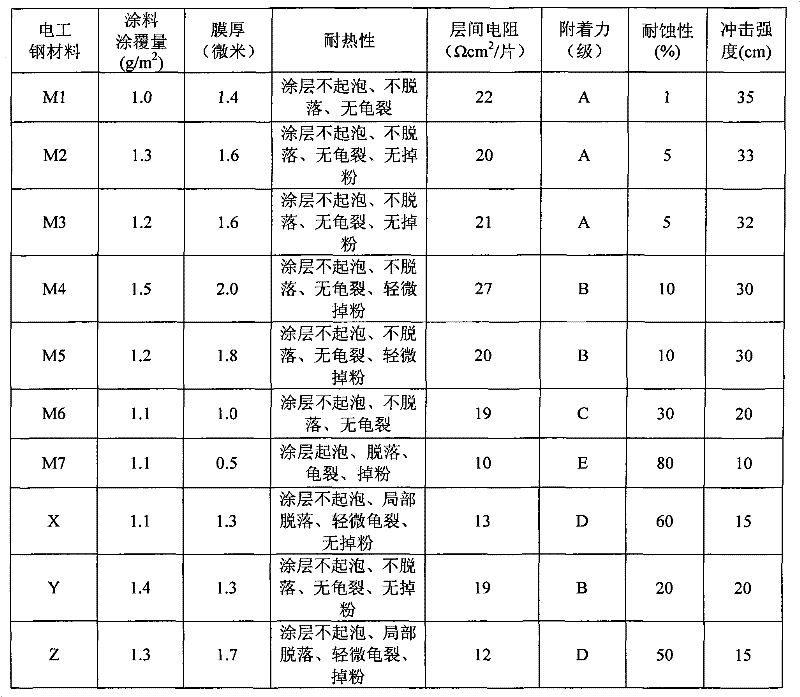

Examples

preparation example Construction

[0036]According to the preparation method of the above-mentioned electrical steel material provided by the present invention, the electrical steel material includes an electrical steel substrate and a coating attached to the electrical steel substrate, the coating is a cured product of the above-mentioned chromium-free insulating coating, the The method includes: curing the chromium-free insulating paint on the electrical steel substrate, and the curing temperature is not higher than 250°C.

[0037] According to the preparation method of the above-mentioned electrical steel material provided by the present invention, in order to make the coating reach the above-mentioned thickness, the amount of the chromium-free insulating coating is 1.0-3.0 grams relative to the surface of the electrical steel substrate per square meter, preferably 1.5-2.5 grams.

[0038] According to the preparation method of the above-mentioned electrical steel material provided by the present invention, b...

Embodiment 1

[0048] Under stirring conditions, add 20kg of deionized water and 42kg of styrene-acrylic emulsion (purchased from Nantong Shengda, brand SD588, solid content of 48% by weight, viscosity of 500-1500mPa·s , particle size is 50-80nm), 33kg aluminum dihydrogen phosphate and 5kg silica sol (particle size is 20-30nm, as SiO 2 , the concentration is 30% by weight), and after stirring for 30 minutes, a uniform and stable dispersion system is obtained, which is the chrome-free insulating coating P1 of the present invention.

[0049] Clean the cold-rolled non-oriented electrical steel strip (50PW800 produced by Panzhihua Iron and Steel Group Co., Ltd.) with an alkaline degreasing cleaning solution at 55°C. The alkaline degreasing cleaning solution is PA50-A1 degreasing solution with a concentration of 15% by weight, and the consumption of the alkaline degreasing cleaning solution per square meter of steel strip is 30Kg. Then it is cleaned with a rinsing liquid, which is deionized wate...

Embodiment 2

[0052] Under stirring conditions, add 10Kg of deionized water and 69Kg of styrene-acrylic emulsion (purchased from Nantong Shengda, brand SD800, solid content of 48% by weight, viscosity of 500-1500mPa·s ), 20Kg calcium dihydrogen phosphate and 7Kg water glass (modulus is 2.5, with SiO 2 , the concentration is 30% by weight), and after stirring for 30 minutes, a uniform and stable dispersion system is obtained, which is the chrome-free insulating coating P2 of the present invention.

[0053] Clean the cold-rolled non-oriented electrical steel strip (50PW800 produced by Panzhihua Iron and Steel Group Co., Ltd.) with an alkaline degreasing cleaning solution at 55°C. The alkaline degreasing cleaning solution is PA50-A1 degreasing solution with a concentration of 15% by weight, and the consumption of the alkaline degreasing cleaning solution per square meter of steel strip is 30Kg. Then it is cleaned with a rinsing liquid, which is deionized water, and the amount of the rinsing l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com