Ultraviolet (UV) curing silicon steel insulating coating and preparation method thereof

A technology of insulating coatings and ultraviolet light, which is applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems that have not been found and reported in use, and achieve the effects of increasing curing rate, reducing VOC content, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

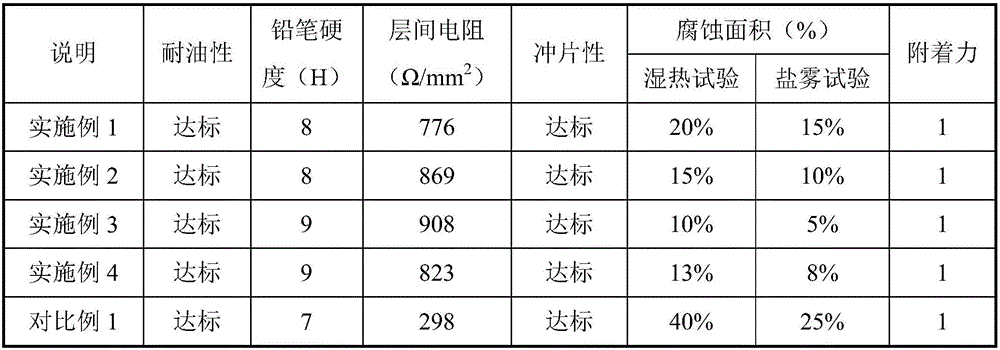

Examples

Embodiment 1

[0025] A kind of preparation method of ultraviolet curing silicon steel insulation coating specifically comprises the following steps:

[0026] 1) Take polyurethane prepolymer (model: T52, Xiamen Aikema Chemical Co., Ltd.) and epoxy resin prepolymer (model: NPEL-128, Henan Zepu Chemical Products Co., Ltd.) respectively, and the mass ratio is 1:1 , with a total weight of 130g, 45g of methyl methacrylate, mixed in the reactor, heated to 60°C, and stirred at a speed of 500r / min for 60min for later use;

[0027] 2) Take an appropriate amount of deionized water in another reactor (the amount of deionized water added accounts for 20-40% of the total mass of the insulating coating, and the amount of deionized water added in this embodiment is 300g), and add a silicone dispersant 5g (Model: SN-5040, Zhongya, Taiwan), after stirring evenly, add 50g of nano-silica (Model: TSP, Nanjing Tianxing New Material Co., Ltd.), 30g of nano-titanium dioxide (Model: EFU-G100, Shanghai EFU Industri...

Embodiment 2

[0030] A kind of preparation method of ultraviolet curing silicon steel insulation coating specifically comprises the following steps:

[0031] 1) Take polyurethane prepolymer (model: T52, Xiamen Aikema Chemical Co., Ltd.) and isocyanate prepolymer (model: TDI-80, Jiangyin Zhuqing Chemical Co., Ltd.) respectively, with a mass ratio of 1:0.8 and a total weight of 150g, 45g ethyl methacrylate, add to the reactor and mix, heat to 60°C, stir at 500r / min for 60min and set aside;

[0032] 2) Take an appropriate amount of deionized water (250g) in another reactor, add 11g of silicone dispersant (model: SN-5040, Taiwan Zhongya), stir well and then add 40g of nano silicon dioxide (model: TSP, Nanjing Tianxing New Material Co., Ltd.), nano-titanium dioxide 40g (model: EFU-G100, Shanghai Yifu Industrial Co., Ltd.), nano-barium sulfate 20g (model: micro, Shanghai Jinghong Industrial Co., Ltd.), aluminum dihydrogen phosphate 55g and Dihydrogen zinc phosphate 35g, 1200r / min high-speed stir...

Embodiment 3

[0035] A kind of preparation method of ultraviolet curing silicon steel insulation coating specifically comprises the following steps:

[0036]1) Take epoxy resin prepolymer (model: NPEL-128, Henan Zepu Chemical Products Co., Ltd.) and isocyanate prepolymer (model: TDI-80, Jiangyin Zhuqing Chemical Co., Ltd.) respectively, and the mass ratio is 1: 1. The weight is 120g in total, 50g of vinyl acetate is added to the reactor and mixed, heated to 60°C, stirred at a speed of 500r / min for 60min, and then set aside;

[0037] 2) Take an appropriate amount of deionized water (350g) in another reactor, add 12g of silicone dispersant (model: SN-5040, Taiwan Zhongya), stir well and then add 45g of nano silicon dioxide (model: TSP, Nanjing Tianxing New Material Co., Ltd.), nano-titanium dioxide 45g (model: EFU-G100, Shanghai Yifu Industrial Co., Ltd.), nano-barium sulfate 25g (model: micro, Shanghai Jinghong Industrial Co., Ltd.), aluminum dihydrogen phosphate 50g and Zinc dihydrogen pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com