Patents

Literature

58results about How to "Increase the number of bends" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technological process for selective plating copper on through holes of flexible multiple layered printing circuit board

ActiveCN1798484AGood flexibilityIncrease the number of bendsPrinted element electric connection formationCopper platingCopper foil

The method includes: 1) plates through-hole on the flexible multilayer circuit board on which the through-hole is drilled; 2) presses a dry film on the flexible multiplayer circuit board whose through-holes are plated; 3) light exposing method is used to indicate the location of the through-hole; 4) develops the image of through-hole on the copper foil to distinguish the location of through-hole from the other area covered by the dry film; 5) plates the through hole with copper; 6) remove the dry film by using chemical agent. The flexible multilayer circuit board can bear 60,000-100,000 times of bending.

Owner:CHUNHUA TECHNOLOGICAL KUSN

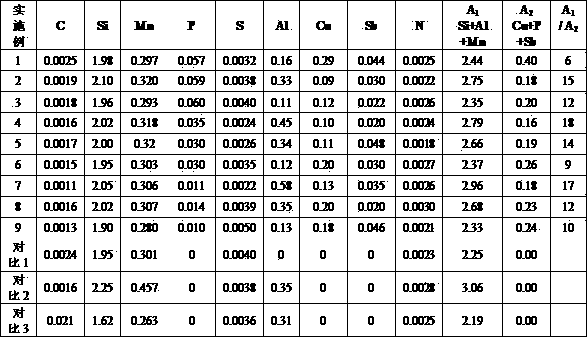

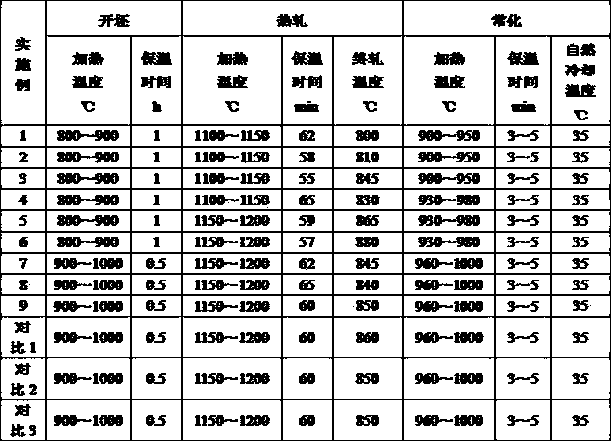

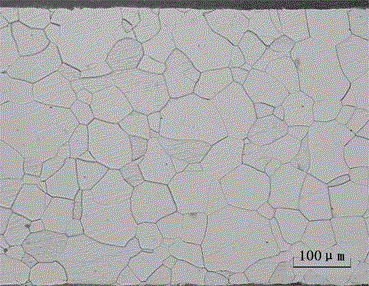

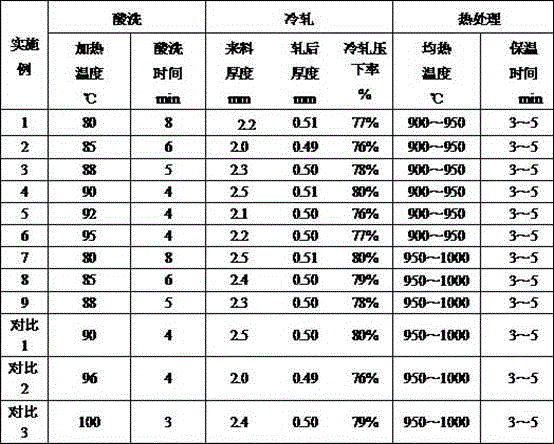

Non-oriented electrical steel for efficient motor and production method

The invention relates to non-oriented electrical steel for an efficient motor. The non-oriented electrical steel for the efficient motor is prepared from the chemical components in percentage by weight: less than or equal to 0.0030% of C, 1.9-2.1% of Si, 0.28-0.32% of Mn, 0.10-0.60% of Al, 0.01-0.06% of P, less than or equal to 0.0050% of S, 0.10-0.30% of Cu, 0.02-0.05% of Sb and less than or equal to 0.0030% of N. The production process comprises the following steps: smelting; cogging; repeatedly forging to obtain square billets; heating; hot-rolling; normalizing; pickling; cold-rolling; and thermally heating. By controlling the total weight of main alloy elements (Si+Al+Mn) and auxiliary elements (Cu+P+Sb), favorable effects of elements in physical metallurgy are fully exerted. By researching the composite effect of elements (Cu+P+Sb) on silicon steel organization structure and magnetism, partial (Si+Al) is replaced by (Cu+P). On the one hand, the inflection time of a normalized plate can be improved and on the other hand, the punching property of a finished plate is improved. The non-oriented electrical steel for the efficient motor excellent in magnetic property and good in punching effect is developed.

Owner:武汉钢铁有限公司

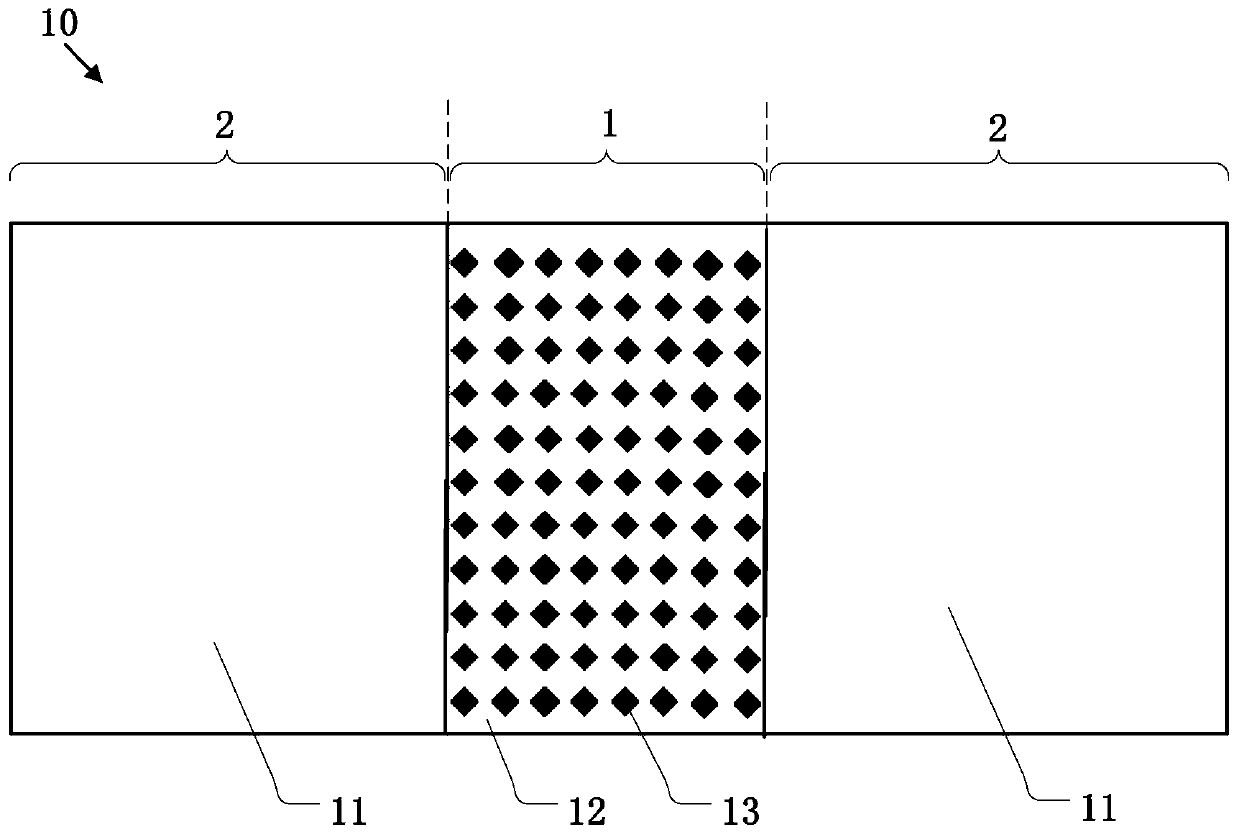

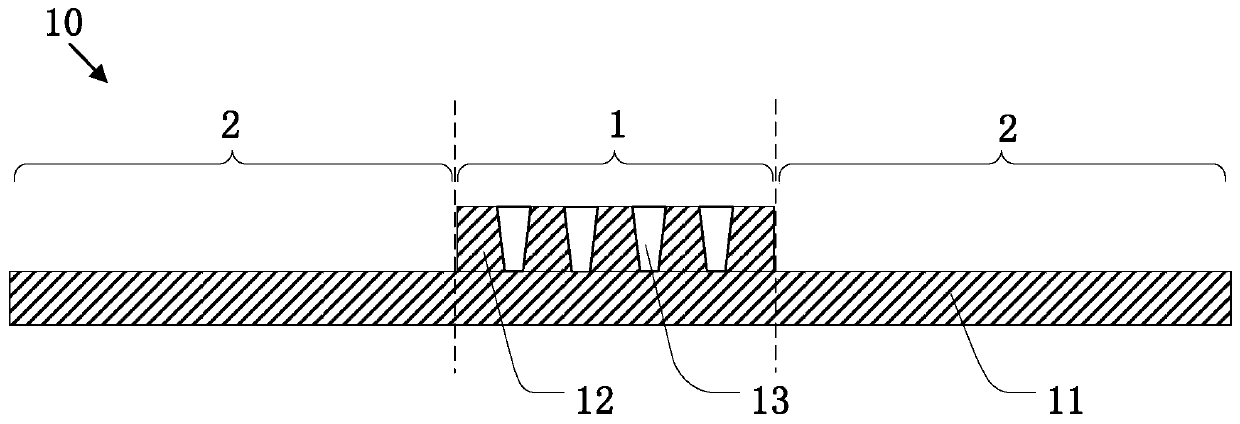

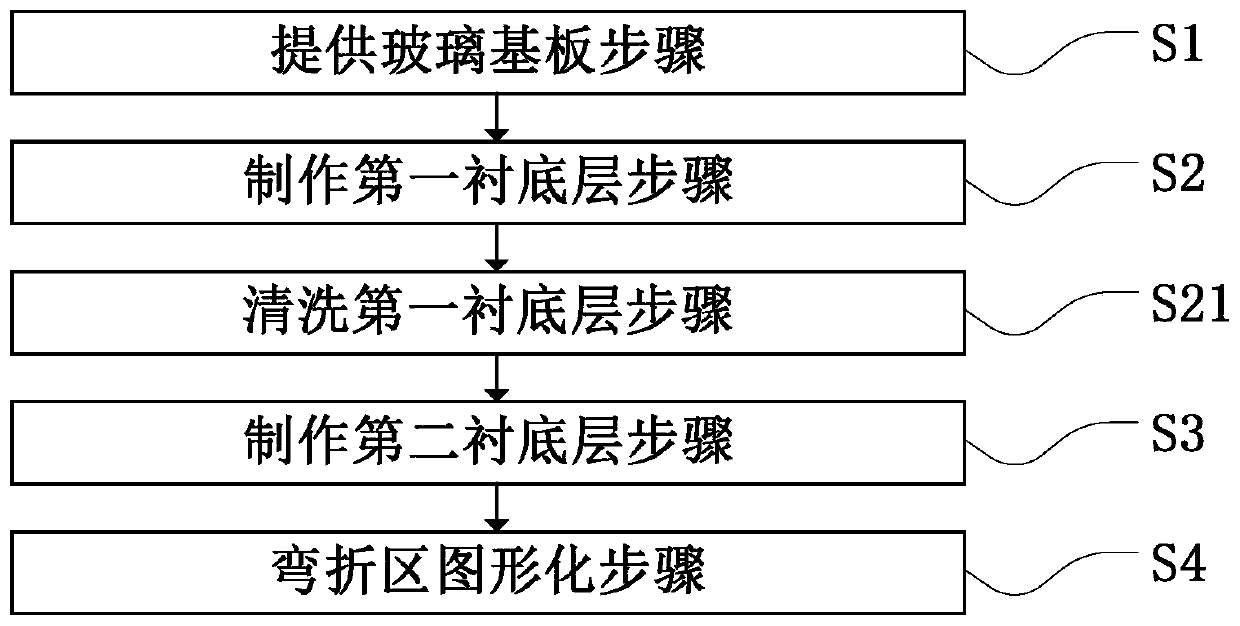

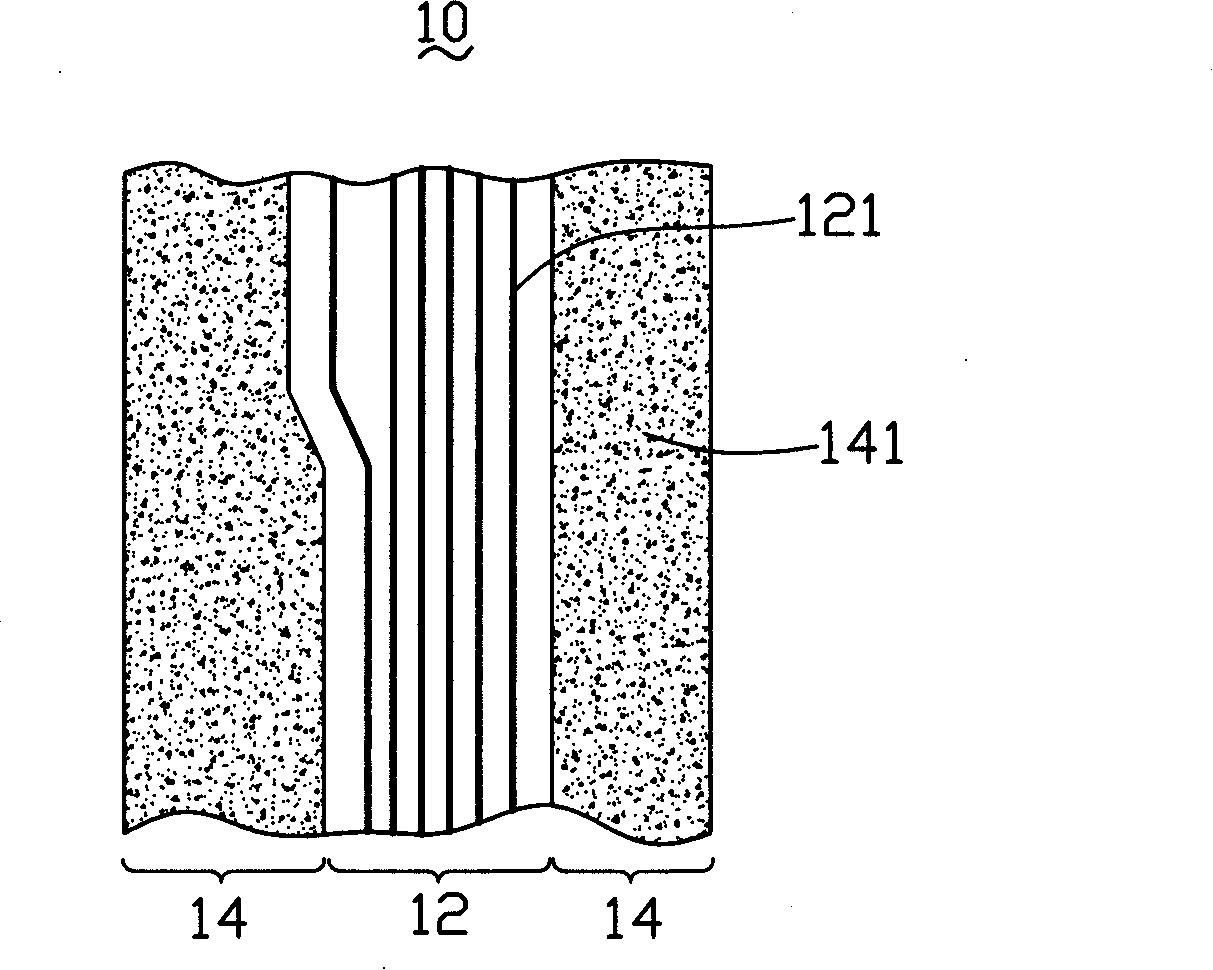

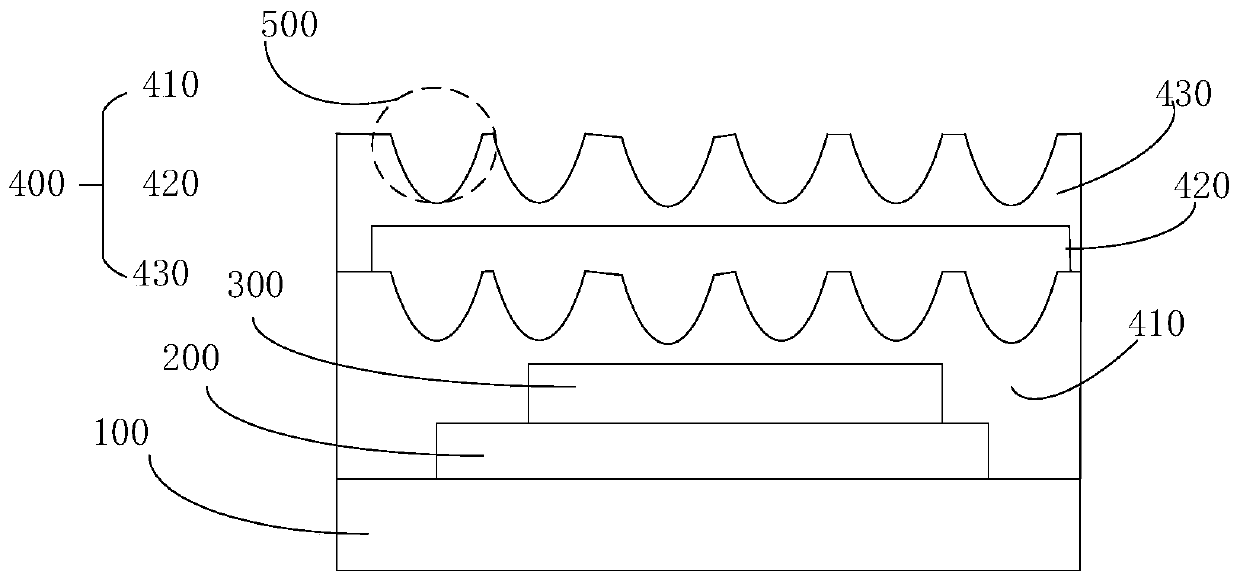

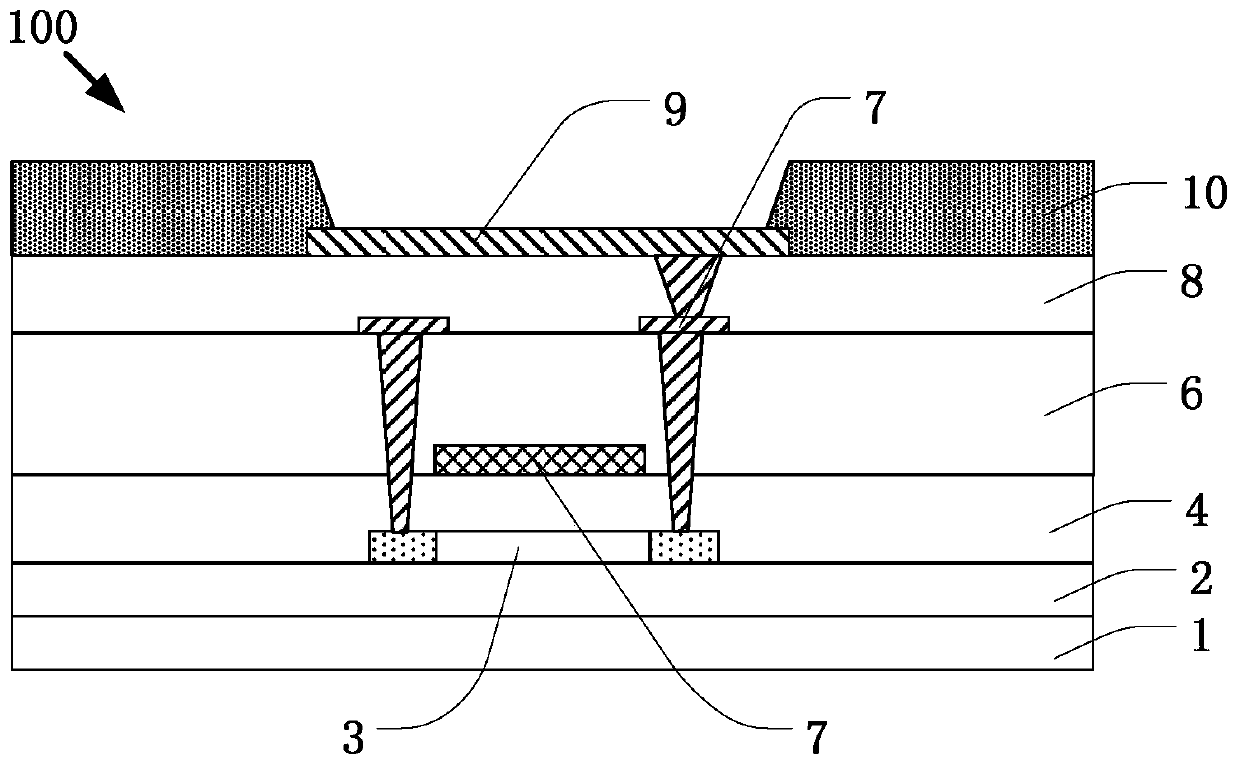

Flexible substrate, flexible display panel and manufacturing method thereof

InactiveCN110649070AIncrease the number of bendsImprove impact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingManufacturing engineeringMechanical engineering

The invention provides a flexible substrate, a flexible display panel and a manufacturing method of the flexible substrate. The flexible substrate is provided with a bending area and a non-bending area, wherein the non-bending region comprises a first substrate layer, the bending area comprises the first substrate layer and a second substrate layer arranged on one side of the first substrate layer, and a plurality of grooves distributed in an array mode are formed on the second substrate layer and used for dispersing tension and stress generated when the bending area is bent. The manufacturingmethod of the flexible substrate comprises steps of providing the glass substrate, manufacturing the first substrate layer, manufacturing the second substrate layer and patterning the bending area. The flexible display panel comprises the flexible substrate, an array substrate, a light-emitting layer and a polaroid. The flexible substrate is advantaged in that tension and stress generated duringbending are dispersed through grooves, so the tension and stress generated during bending are reduced, the bending frequency of the second substrate layer can be increased, certain stiffness can be kept, and thereby the bending resistance and the impact resistance are enhanced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

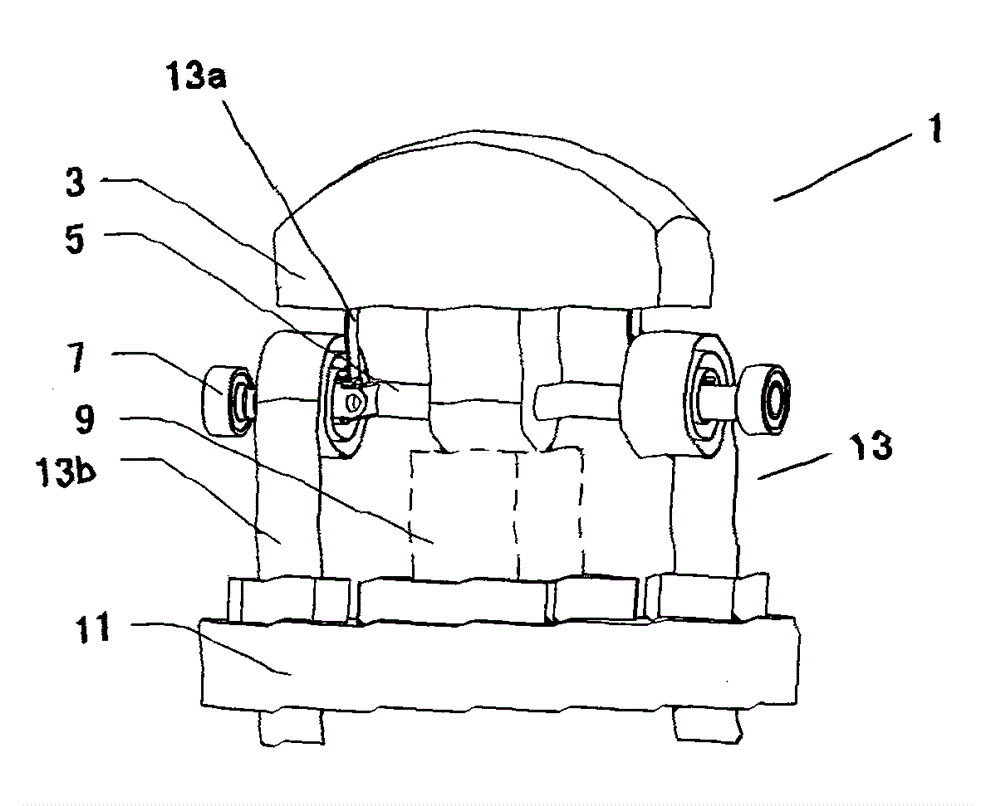

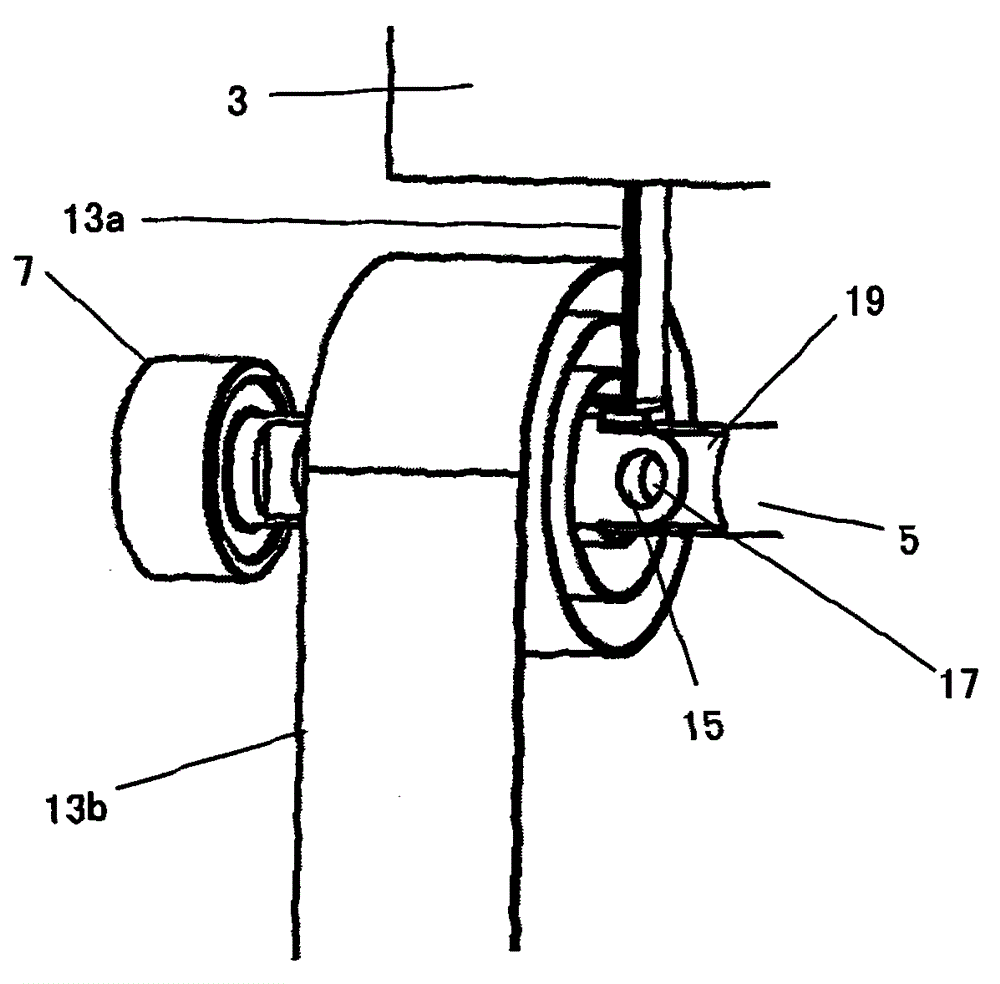

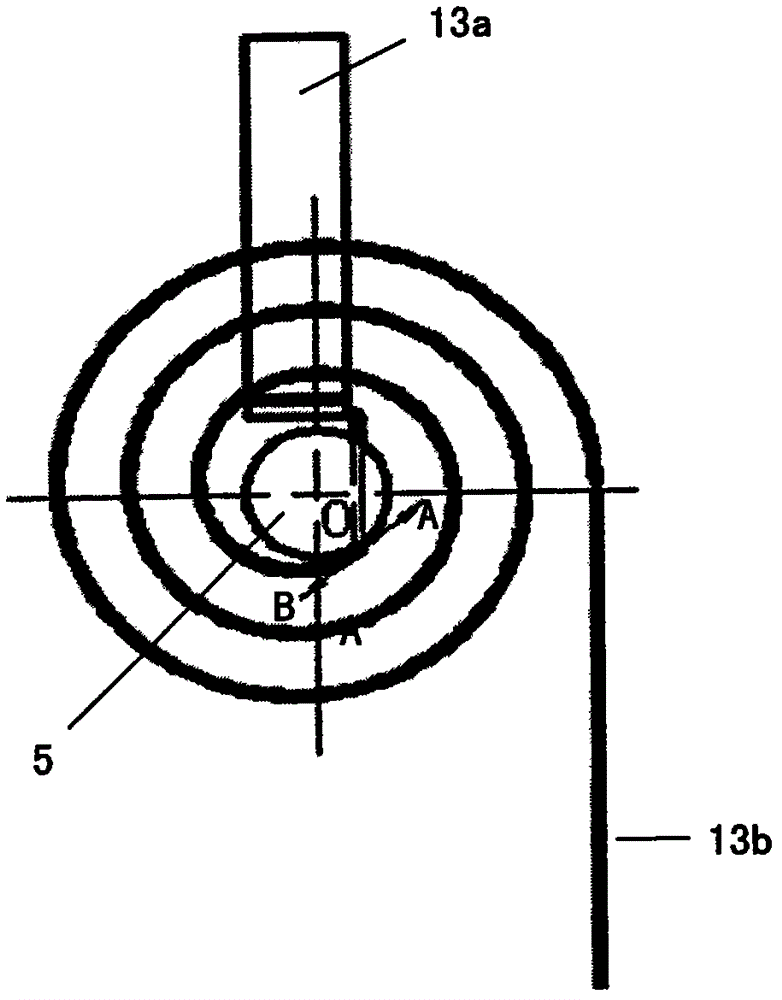

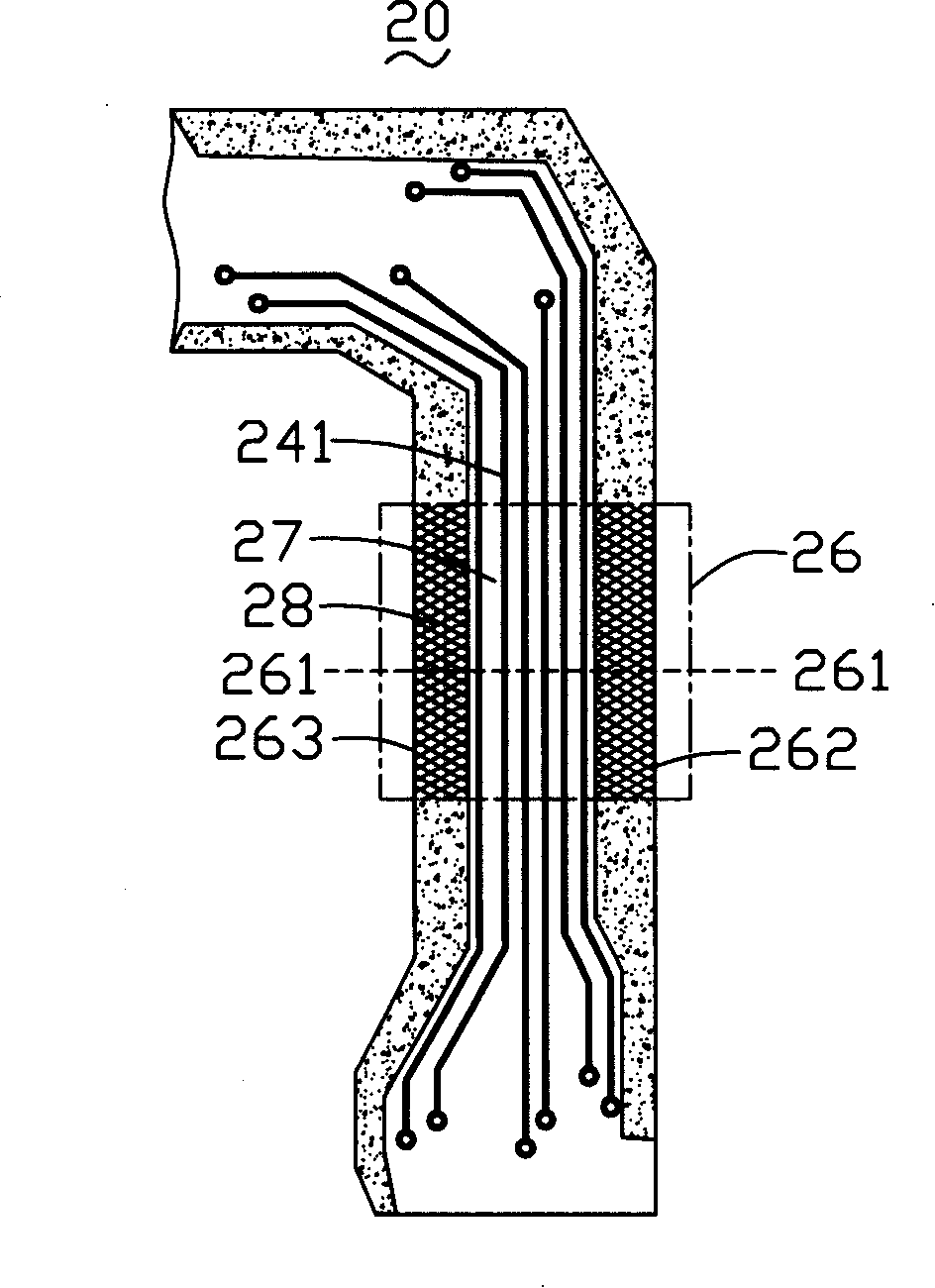

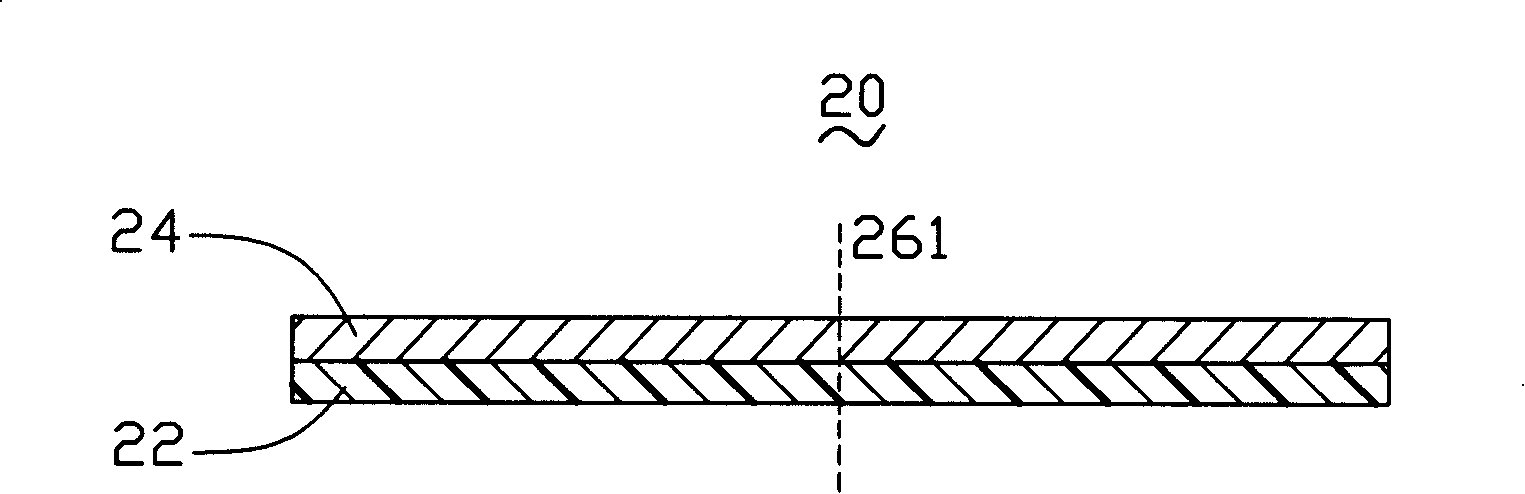

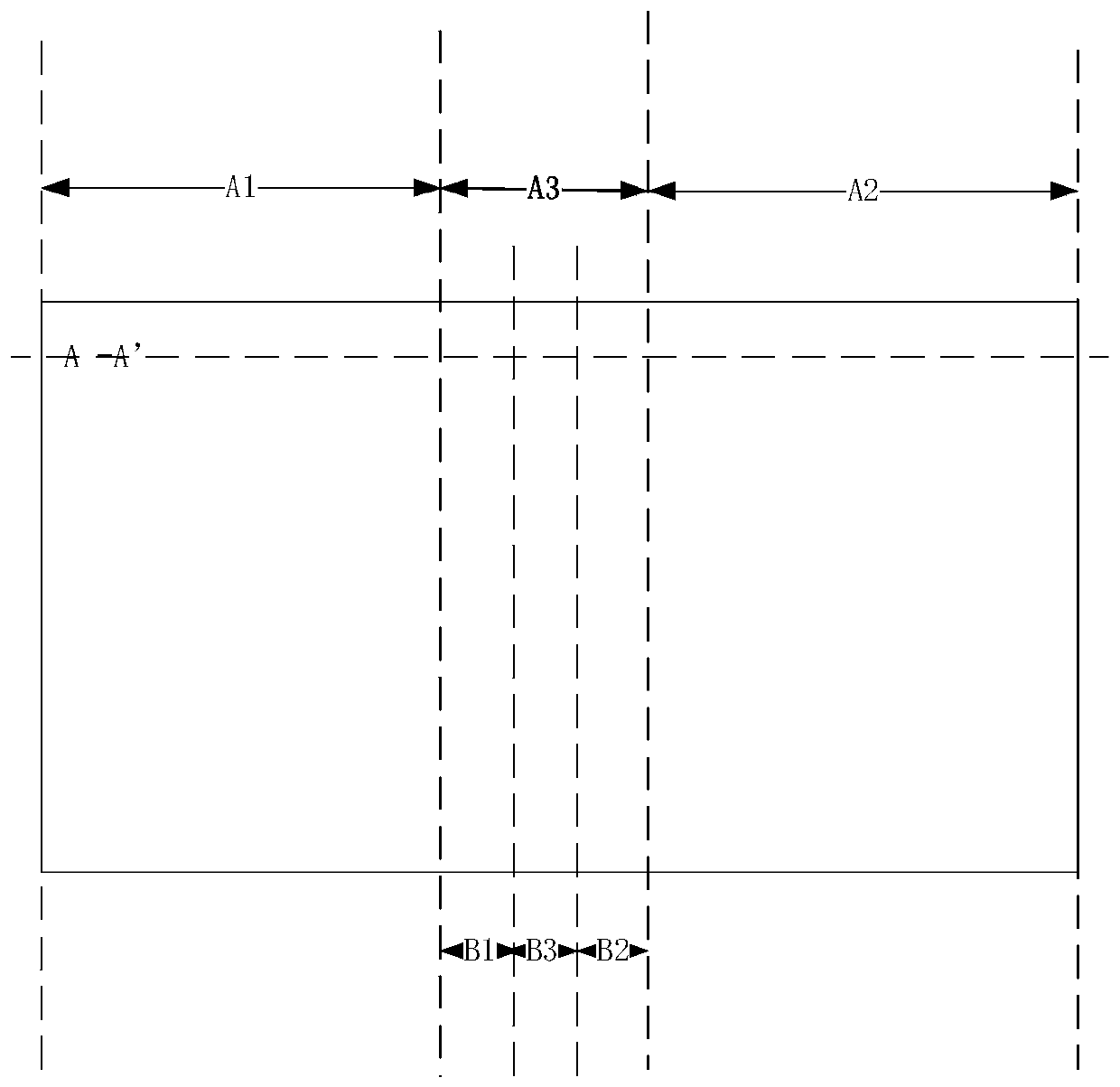

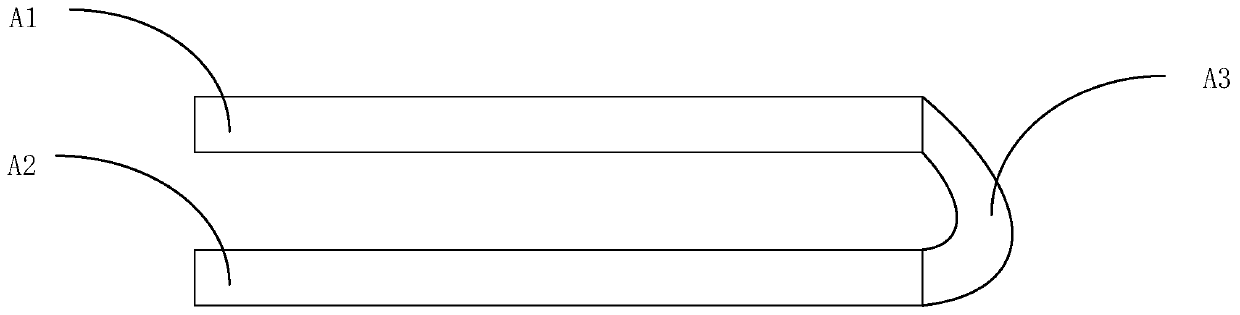

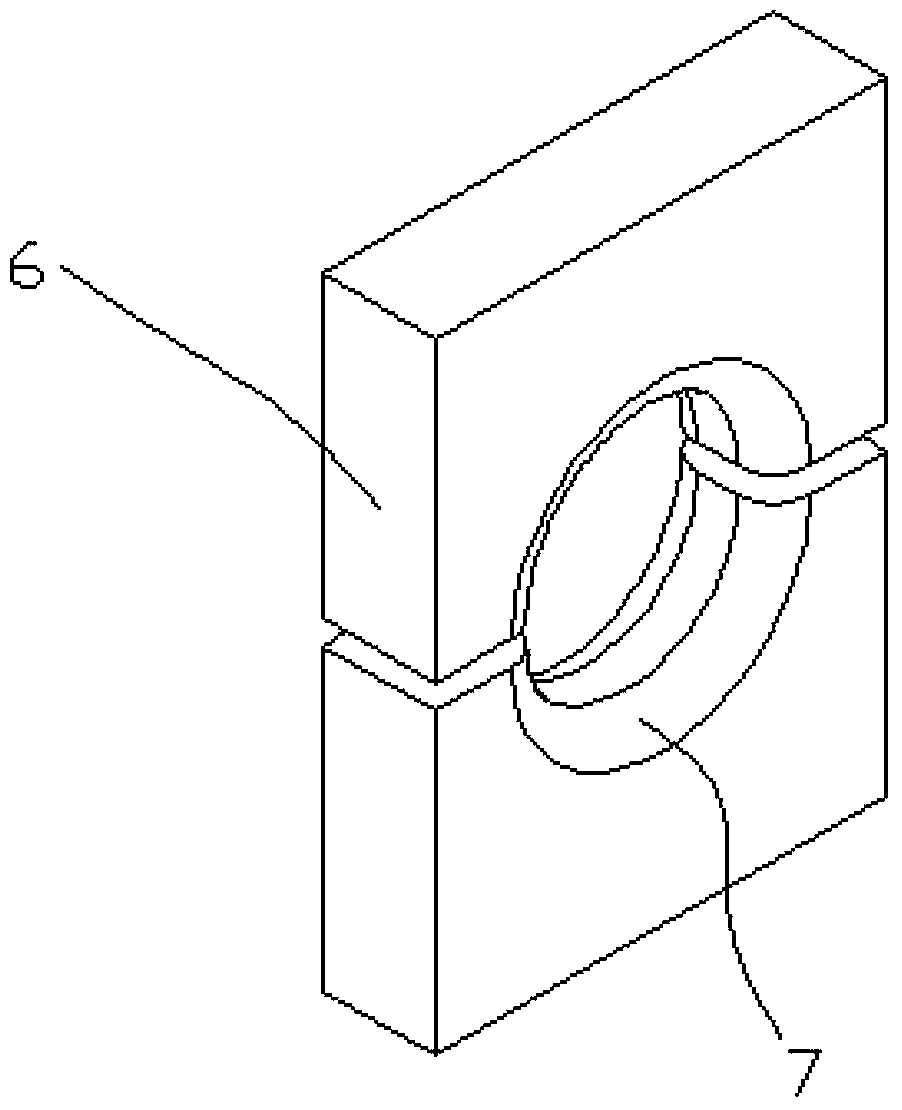

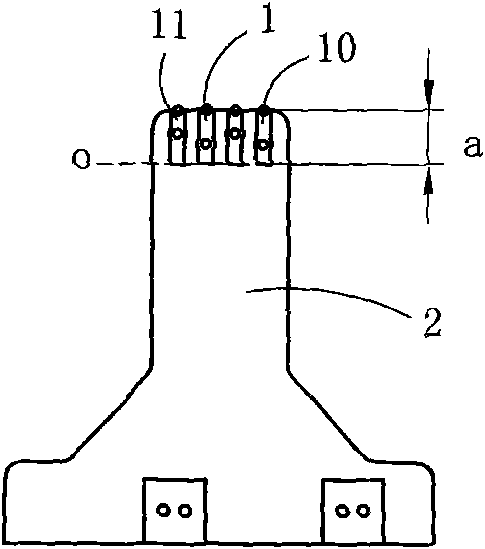

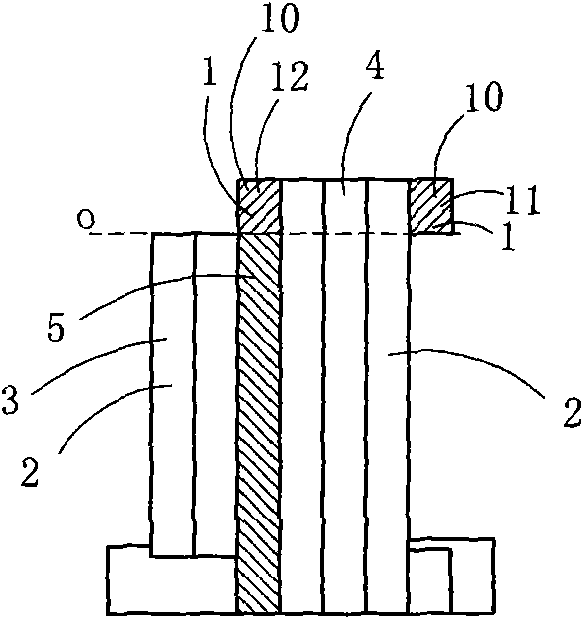

Flexible plate connecting method and ultrasonic probe

InactiveCN102802353AIncrease the bearing areaIncrease the number of bendsMaterial analysis using sonic/ultrasonic/infrasonic wavesSound producing devicesEngineeringUltrasound probe

Owner:PHILIPS ULTRASOUND SHANGHAI CO LTD

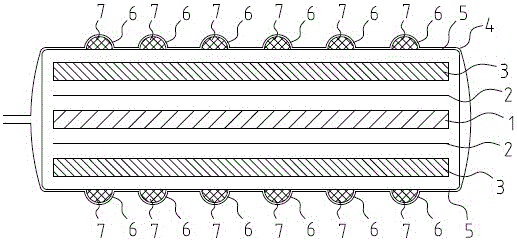

Flexible lithium ion battery

ActiveCN106252737AEasy to bendReduce breakageCell electrodesFinal product manufactureElectrical batteryPole piece

The invention discloses a flexible lithium ion battery. The flexible lithium ion battery comprises an electrical core and an outer packaging film which is wrapped outside the electrical core; flexible membranes are arranged between the outer packaging film and the upper surface of the electrical core and between the outer packaging film and the lower surface of the electrical core, and cover the upper surface and the lower surface of the electrical core, a plurality of buffer bulges are arranged between at least one piece of the flexible film and the outer packaging film, and concave pits are formed in the buffer bulges and correspond to the inner surface of the outer packaging film. The buffer bulges are added on the surface of the electrical core, and have certain elasticity, and the whole battery takes precedence over a pole piece to be extruded by a bending stress while bending, thereby protecting power falling and fracture of the pole piece for bearing an excessively high stress to increase the bending times of the battery.

Owner:APOWER ELECTRONICS CO LTD

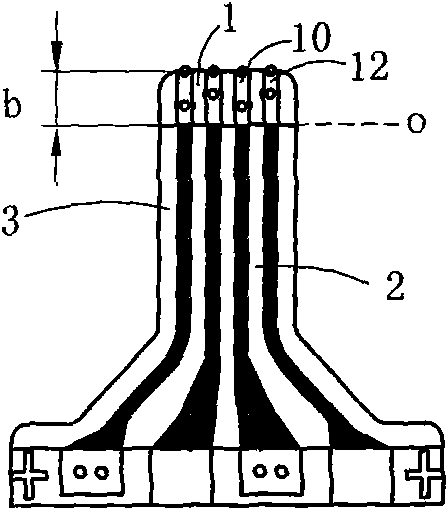

Flexible printing circuit board

InactiveCN101222815AReduce stressImprove bending performancePrinted electric component incorporationPrinted circuit aspectsCopperGround line

The invention relates to a soft printing circuit board which comprises a bending part. The bending part is provided with a wiring area of earth wires in which a plurality of copper areas are evenly distributed in a pattern design. Bending the soft printing circuit board can facilitate the dispersion of stress, effectively reduce the stress produced when the soft circuit board is bent and avoid breaking earth wires and signals wires so as to improve the bending performance of the soft printing circuit board.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Flexible display panel

InactiveCN111430432AIncrease the number of bendsReduce stressSolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayMechanical engineering

The invention discloses a flexible display panel. The flexible display panel comprises a bending area and plane display areas located on the two sides of the bending area., t The flexible display panel comprises a flexible substrate, an array substrate, a light-emitting function layer and a packaging layer which are arranged in a stacked mode, and in the bending area, a stress release structure isformed on the packaging layer in the bending direction. When the flexible display panel is bent, a a stress release space is provided for the flexible display panel by arranging the stress release structure in the bending direction of the packaging layer, so that the effects of reducing stress generated during bending and increasing the bending frequency of the flexible display panel are achieved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

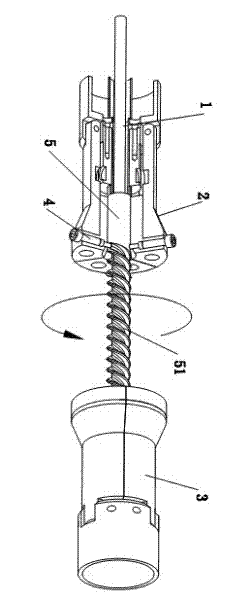

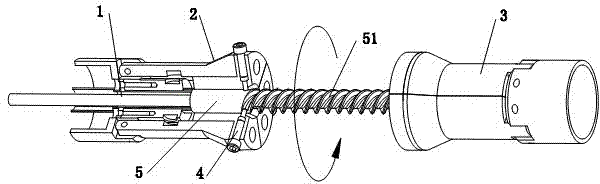

Machining process of rotation-torsion threaded copper pipe

The invention relates to a machining process of a rotation-torsion threaded copper pipe, which comprises the following steps of: selecting a copper pipe with the wall thickness T of 0.7 + / -0.03mm, wherein the copper pipe is in a state of TP2Y2 and has the hardness of 90 to 100HV; and then cutting the processed copper pipe by using a metal cutting machine so as to cut the processed copper pipe into copper pipes to be processed with the same length, cleaning the copper pipes to be processed by using a water-soluble cleaning agent and drying the copper pipes to be processed. The machining process is characterized in that the dried copper pipes to be processed are fed into a threaded pipe machine through a conveying device, core rods are inserted into the copper pipes to be processed; one ends of the copper pipes to be processed and one ends of the core rods are clamped in a first chuck of the threaded pipe machine, one ends of the copper pipes are fixed firmly, the other ends of the copper pipes to be processed are clamped in a second chuck of the threaded pipe machine and can rotate, three pressing pit needles are distributed at the position of the second chuck of the threaded pipemachine, the walls of the copper pipes to be processed are radially pressed by the three pressing pit needles, the stresses at the positions of the thread forming initial ends of the copper pipes to be processed are changed and the three pit needles extend towards the other ends along with the rotation of the second chuck to form three spiral grooves, so that screw threads are formed; and then the copper pipes to be processed are cleaned by using the water-soluble cleaning agent, are dried, are subjected to vacuum annealing to be in a soft state TP2M and are checked and packaged. The machining process has the advantages of high production efficiency, stable quality of the produced products, a large number of bending times and the like.

Owner:佛山市顺德区精艺万希铜业有限公司

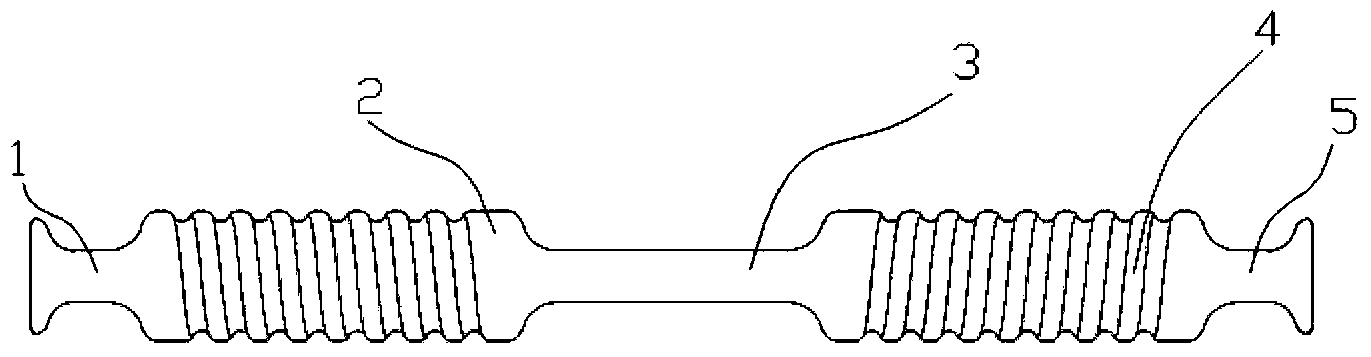

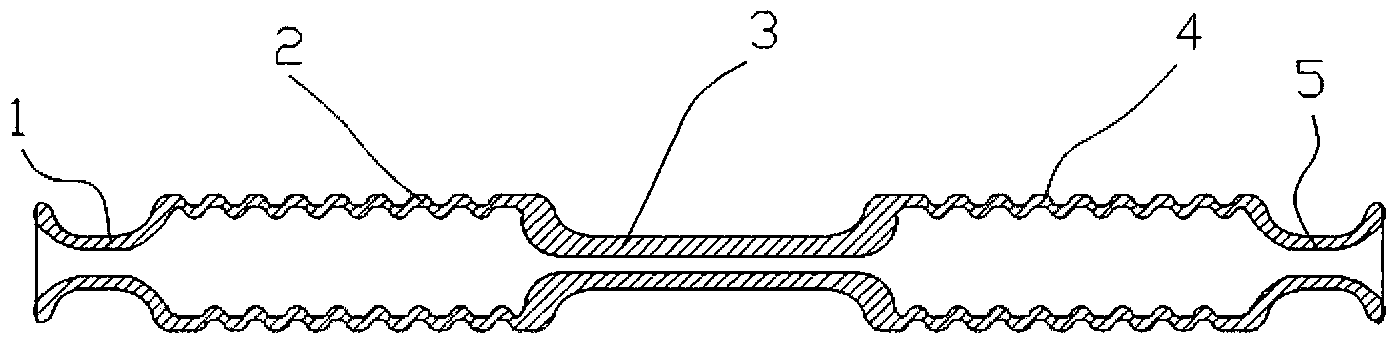

Different-diameter joint-free corrugated connecting pipe and manufacturing method thereof

The invention discloses a different-diameter joint-free corrugated connecting pipe and a manufacturing method thereof. The different-diameter joint-free corrugated connecting pipe is of an integrated structure, and sequentially comprises a first port (1), a first corrugated pipe (2), an unthreaded pipe (3), a second corrugated pipe (4) and a second port (5). The outer diameter of the unthreaded pipe (3) is smaller than that of each of the first corrugated pipe (2) and the second corrugated pipe (4). The wall thickness of the unthreaded pipe (3) is larger than that of each of the first corrugated pipe (2) and the second corrugated pipe (4). The different-diameter joint-free corrugated connecting pipe is of the integrated structure and free of leakage, and the pipe wall of an unthreaded pipe section is thicker than the pipe walls of corrugated pipe sections, so that the different-diameter joint-free corrugated connecting pipe is less prone to bending and deforming during mounting, and normal circulation of media in the pipe can be ensured.

Owner:泰州市恒立管业制造有限公司

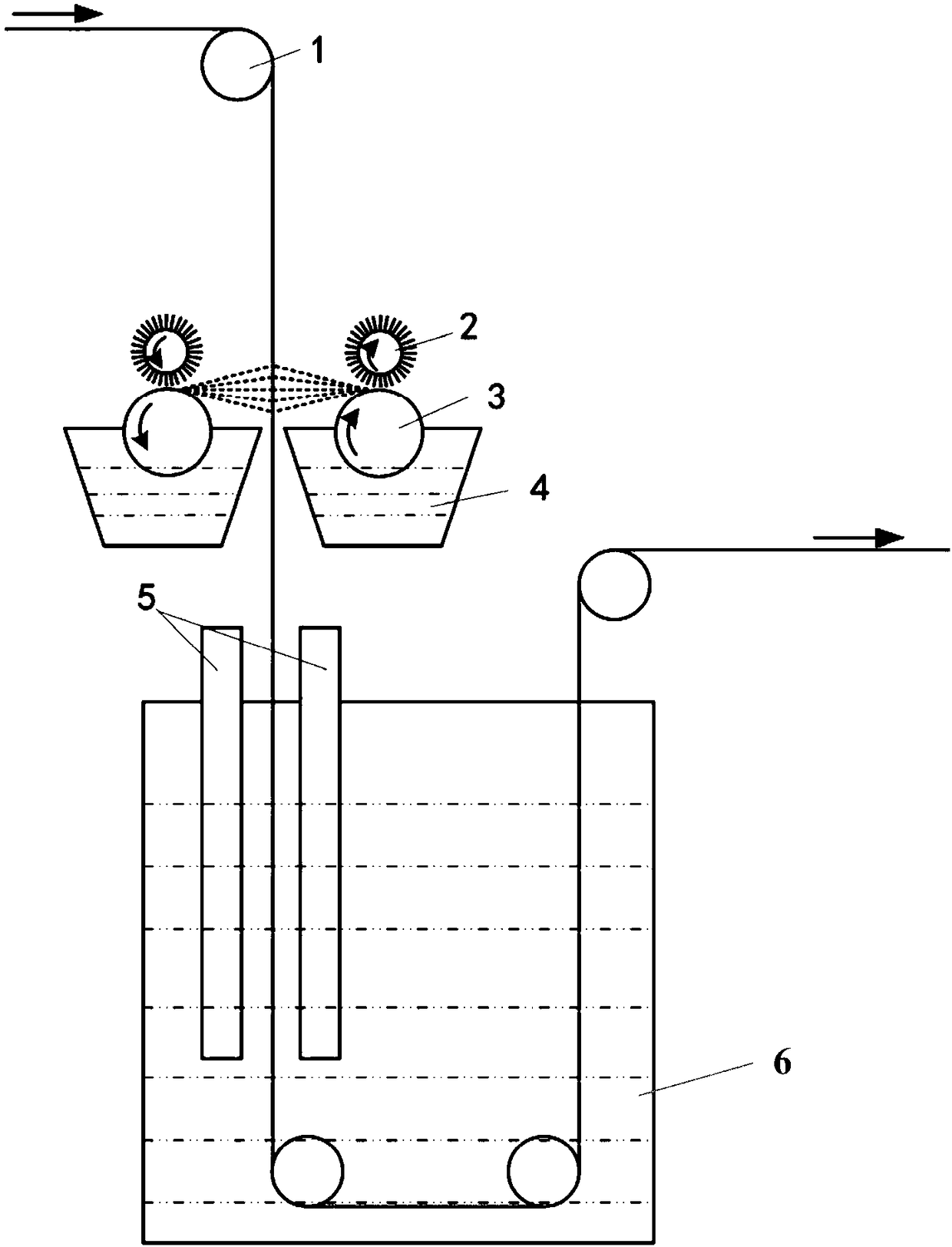

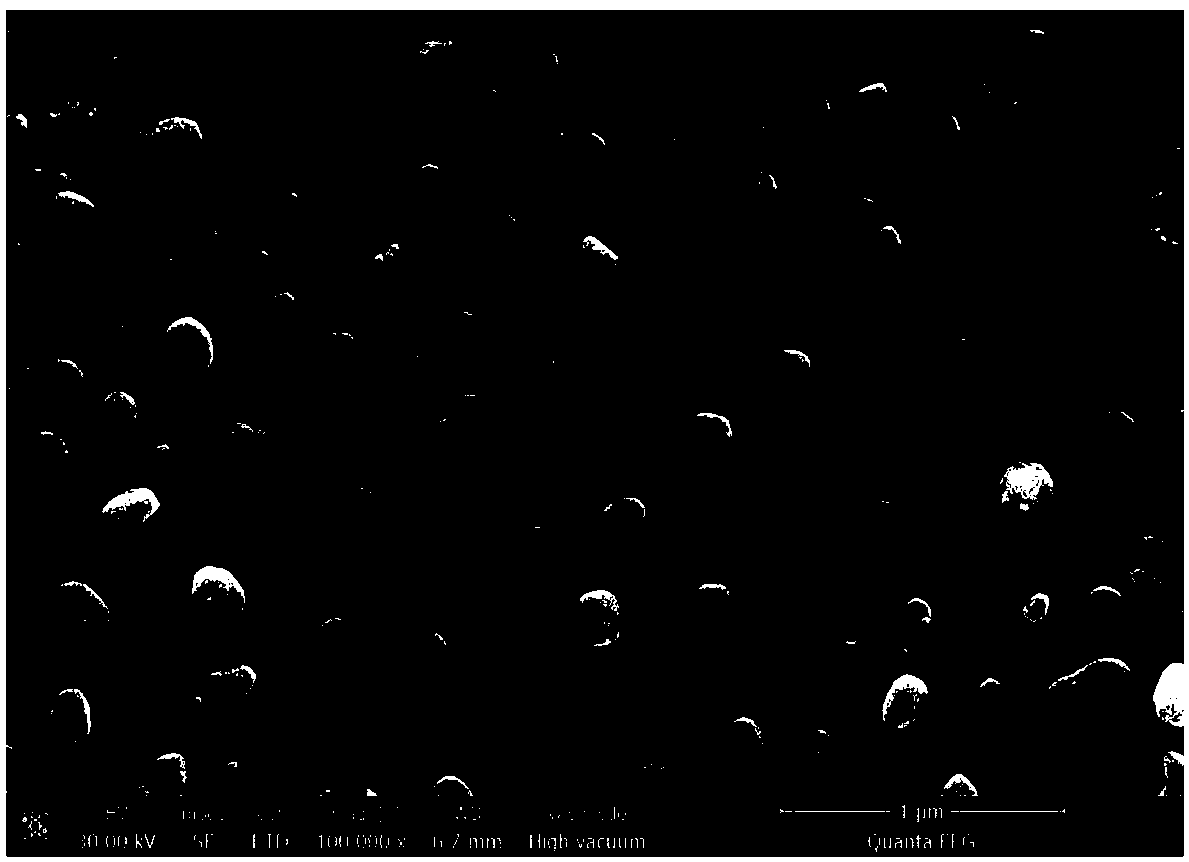

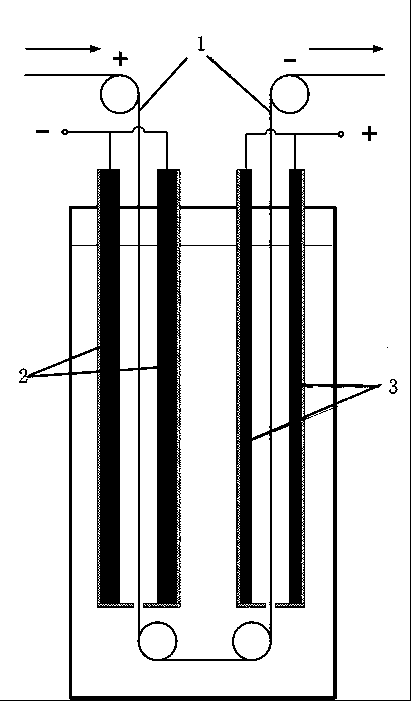

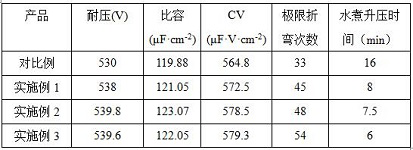

Method and system for tin crystal nucleus in-situ deposition through aluminum foil surface sol-gel method

ActiveCN108085721AEvenly distributedSmall sizeElectrolytic capacitorsGraphite electrodePre treatment

The invention discloses a method for tin crystal nucleus in-situ deposition for medium-high-voltage anodes through a high-purity aluminum foil surface sol-gel method. The method includes the steps that firstly, an aluminum foil finished product is subjected to recrystallization annealing treatment, so that the {100} surface texture occupation rate is lager than 95%, the surface of the finished product comprises trace Fe, Si, Cu, Zn, Ga and Mn and is not enriched with Pb, and the purity of Al is 99.99%; secondly, the aluminum foil is pretreated in an alkaline solution to remove an oxidation film on the surface of the aluminum foil; thirdly, the surface of the pretreated pure aluminum foil is coated with a soil solution to form a uniform tin hydroxide sol layer; fourthly, a graphite electrode serves as an anode and the aluminum foil serves as a cathode to conduct in-situ electrochemical dissolving deposition, and nano tin crystal nucleuses are deposited on the surface of the aluminum foil in situ. The invention further discloses a system suitable for the method. The nano tin crystal nucleuses are small in size, and distribution is not influenced by rolling marks and defects on the surface of the aluminum foil and accordingly is more uniform.

Owner:广西广投正润新材料科技有限公司

A kind of non-oriented electrical steel for high-efficiency motor and its production method

The invention relates to non-oriented electrical steel for an efficient motor. The non-oriented electrical steel for the efficient motor is prepared from the chemical components in percentage by weight: less than or equal to 0.0030% of C, 1.9-2.1% of Si, 0.28-0.32% of Mn, 0.10-0.60% of Al, 0.01-0.06% of P, less than or equal to 0.0050% of S, 0.10-0.30% of Cu, 0.02-0.05% of Sb and less than or equal to 0.0030% of N. The production process comprises the following steps: smelting; cogging; repeatedly forging to obtain square billets; heating; hot-rolling; normalizing; pickling; cold-rolling; and thermally heating. By controlling the total weight of main alloy elements (Si+Al+Mn) and auxiliary elements (Cu+P+Sb), favorable effects of elements in physical metallurgy are fully exerted. By researching the composite effect of elements (Cu+P+Sb) on silicon steel organization structure and magnetism, partial (Si+Al) is replaced by (Cu+P). On the one hand, the inflection time of a normalized plate can be improved and on the other hand, the punching property of a finished plate is improved. The non-oriented electrical steel for the efficient motor excellent in magnetic property and good in punching effect is developed.

Owner:武汉钢铁有限公司

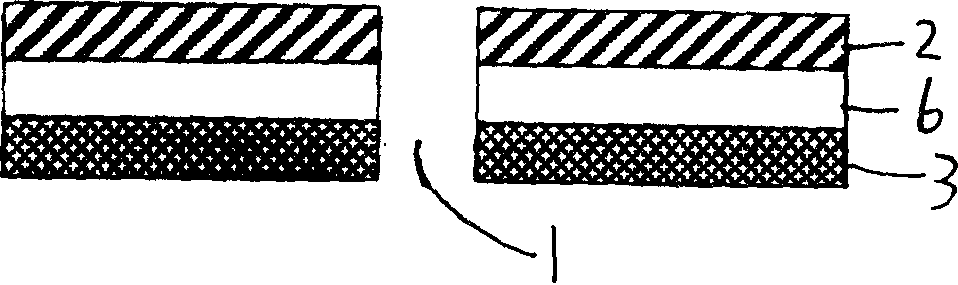

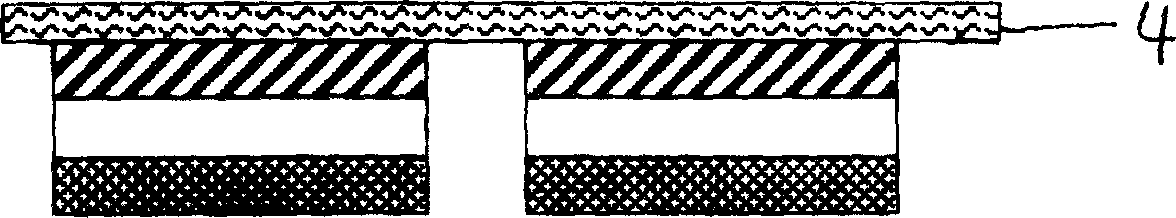

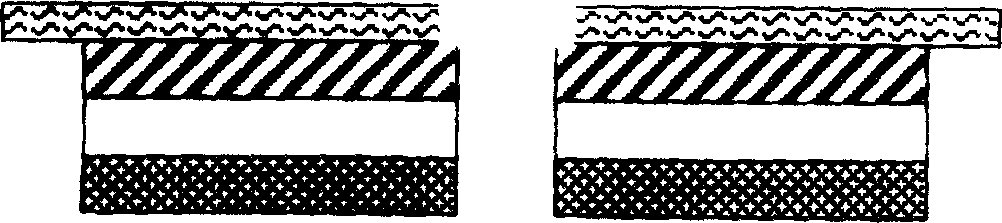

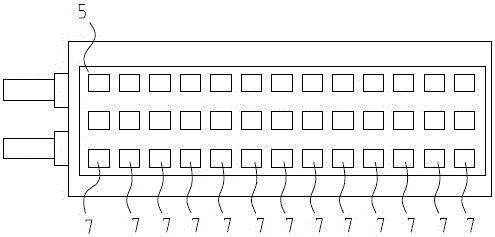

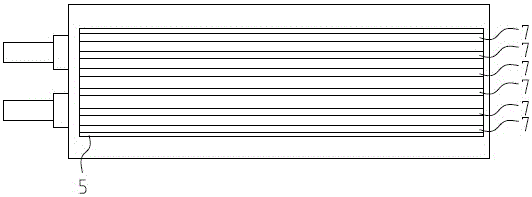

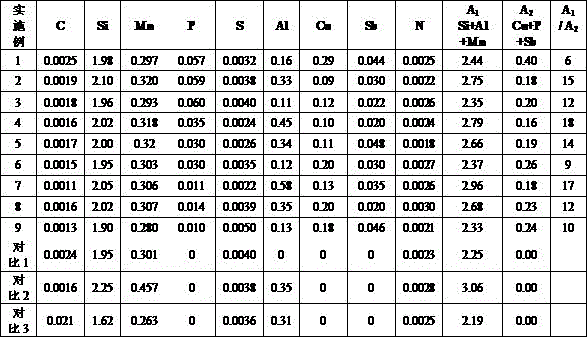

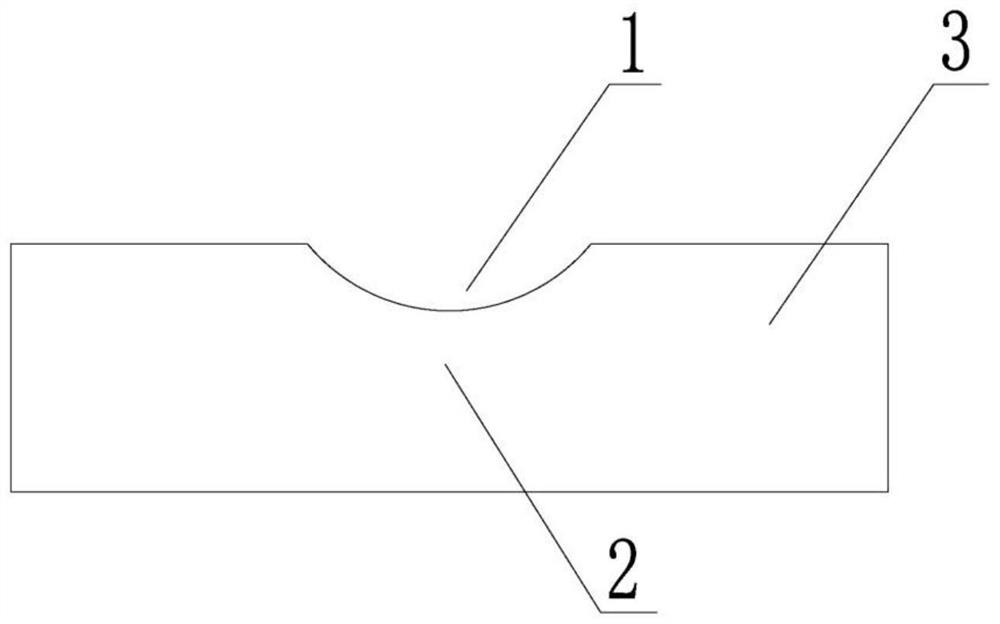

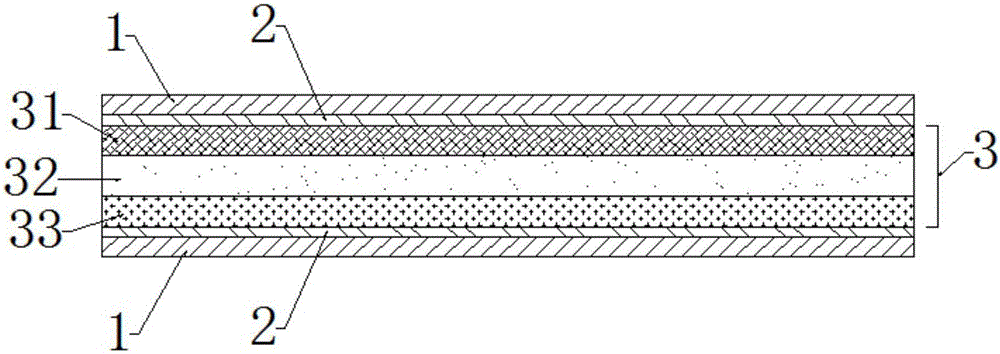

High rupture resistant rigid-flex printed circuit board (PCB)

ActiveCN106332446ARigid-flex eliminationIncrease the number of bendsPrinted circuit assemblingPrinted circuit aspectsInter layerPrinted circuit board

The invention relates to a high rupture resistant rigid-flex printed circuit board (PCB). The high rupture resistant rigid-flex printed circuit board is characterized in that an interlayer of the rigid-flex printed circuit board is a polyimide layer, a PCB rigid board portion is arranged on the inner side of the polyimide layer, and a FPC (flexible printed circuit) flexible board portion is arranged on the outer side of the polyimide layer; an L2 circuit board, an upper cover membrane, an upper layer prepreg, an upper FR4 layer, an L1 circuit board and an upper resistance welding layer are sequentially overlapped on the upper surface of the interlayer from bottom to top; an L3 circuit board, a lower cover membrane, an lower layer prepreg, a lower FR4 layer, an L4 circuit board and a lower resistance welding layer are sequentially overlapped on the lower surface of the interlayer; the upper FR4 extends outwards 0.2mm relative to the upper layer prepreg, the lower FR4 layer extends outwards 0.2mm relative to the lower layer prepreg, a concave is formed in the rigid-flex junction, rigid-flex combination is removed, and the number of bending times is increased.

Owner:江西弘信柔性电子科技有限公司

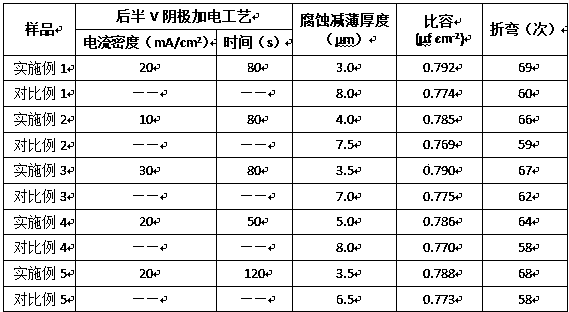

Power-up protection method of hole generating corrosion second half V cathode of middle-high voltage electronic aluminum foil

ActiveCN108754594AImprove uniformityIncrease specific volumeElectrolytic capacitorsElectricityThinning

Provided is a power-up protection method of a hole generating corrosion second half V cathode of middle-high voltage electronic aluminum foil. After the aluminum foil is subjected to pretreatment andfirst-stage first half V hole generating corrosion, first-stage second half V cathode power-up protection is carried out, and after the aluminum foil enters a second half V, the cathode is subjected to constant-current protection treatment for 30 s to 120 s until the aluminum foil exceeds the liquid surface of the second half V, wherein the current density ranges from 5 mA / cm<2> to 30 mA / cm<2>. According to the method, after first-stage hole generating corrosion, second half V cathode power-up protection is added, the hole regenerating and hole combining phenomena of the aluminum foil are obviously reduced, and the surface corrosion thinning thickness of the aluminum foil is reduced by 37.5% to 67.5% compared with a traditional method; and hole generating density, the aperture of generatedholes, the hole generating uniformity and other indexes are good and about 2% higher than those of aluminum foil obtained through the traditional method, the material and thickness of the foil are kept uniform, and the bending frequency is increased by 5-10 times compared with the traditional aluminum foil.

Owner:新疆广投桂东电子科技有限公司

Flexible panel and device with display panel

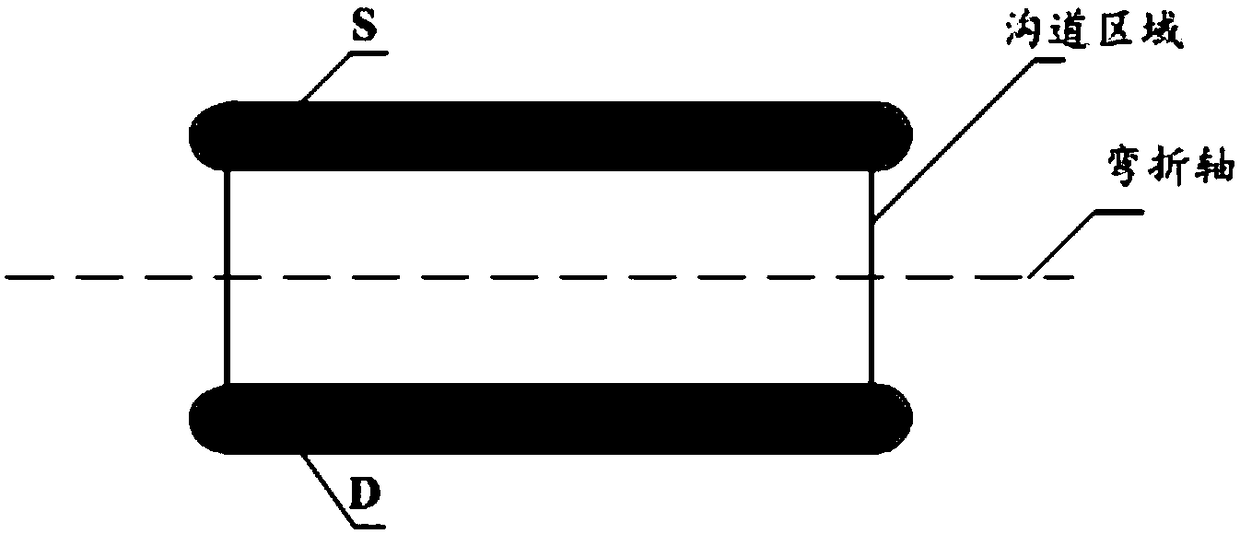

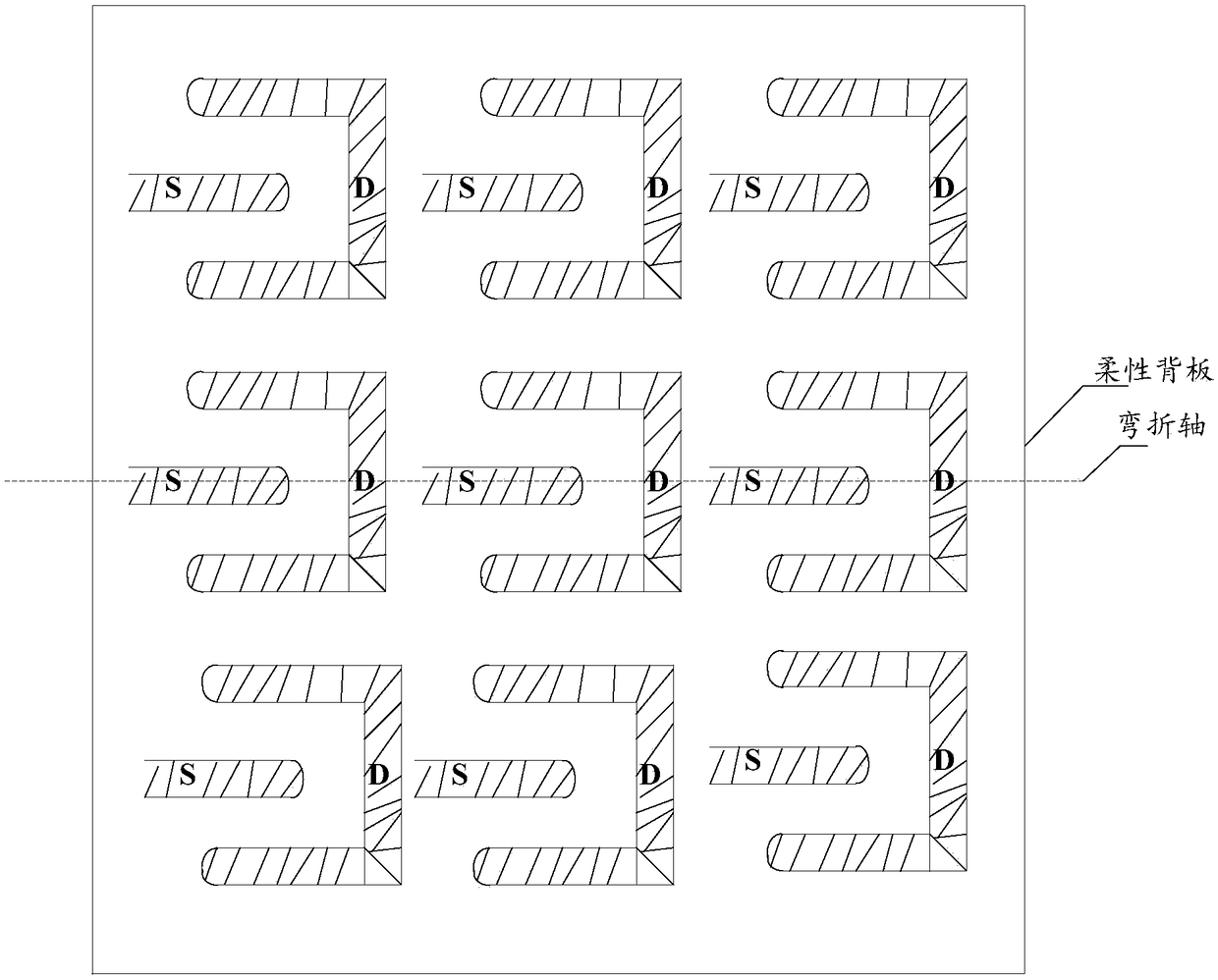

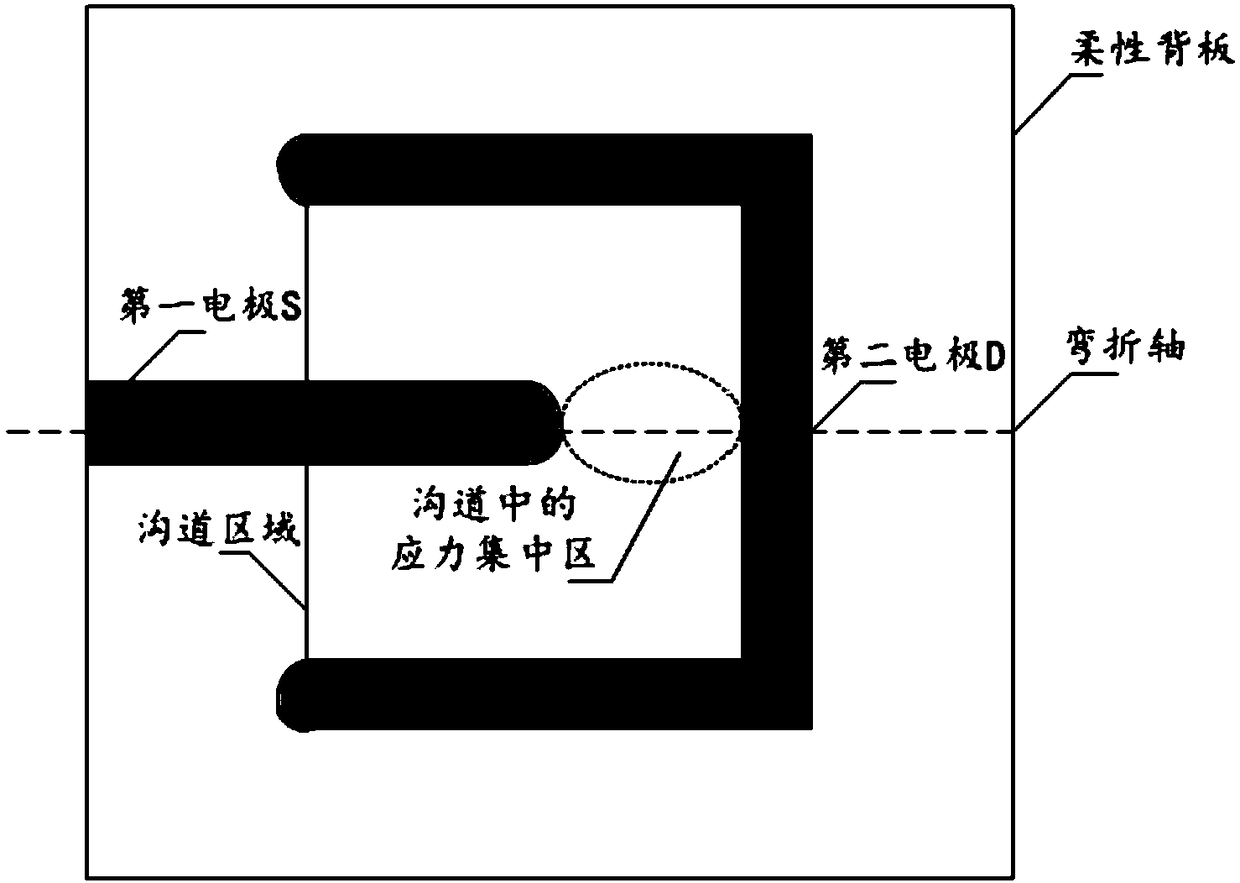

ActiveCN108962980AWeaken electrical degradationIncrease the number of bendsSolid-state devicesSemiconductor devicesBackplaneEngineering

The invention discloses a flexible panel and a device with a display panel. The flexible panel includes a flexible backplane and a plurality of thin film transistors arranged in multiple arrays on theflexible backplane. Each thin film transistor includes a first electrode and a second electrode which are paired as a source and a drain, and a channel region is formed between the first electrode and the second electrode. The flexible panel has a bending axis, and at least one of the first electrodes and the second electrodes of the multiple thin film transistors arranged along the bending axisoverlaps with the bending axis. The channel regions of the multiple thin film transistors arranged along the bending axis are non-uniform channels. Therefore, the electrical degradation of thin film transistors caused by stress can be weakened, the number of bending times of the flexible panel can be increased, and the service life of the flexible panel can be improved.

Owner:YUNGU GUAN TECH CO LTD

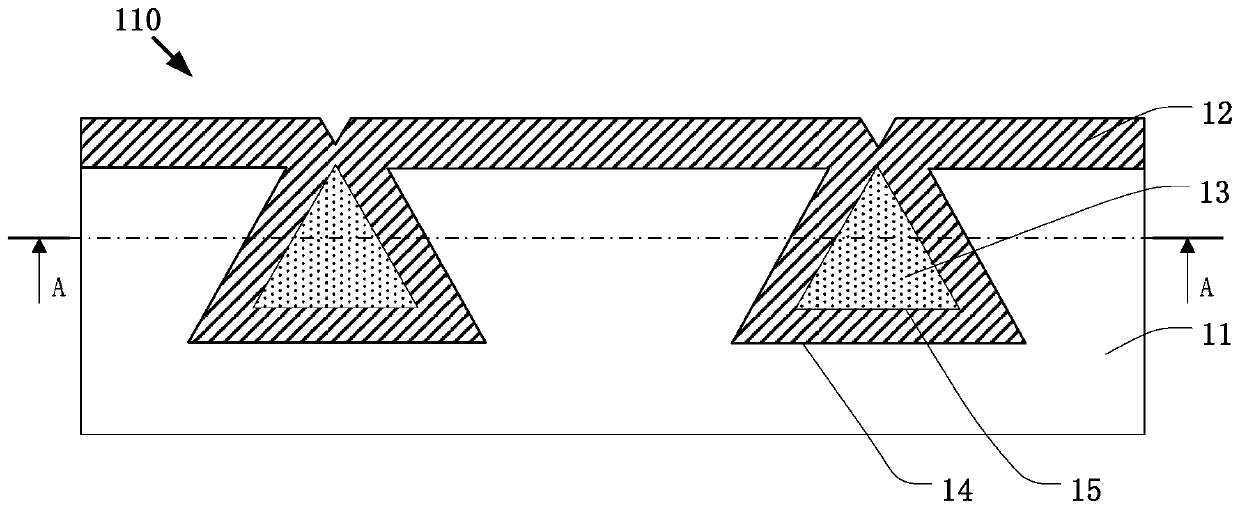

Buffer structure, display panel and manufacturing method of buffer structure

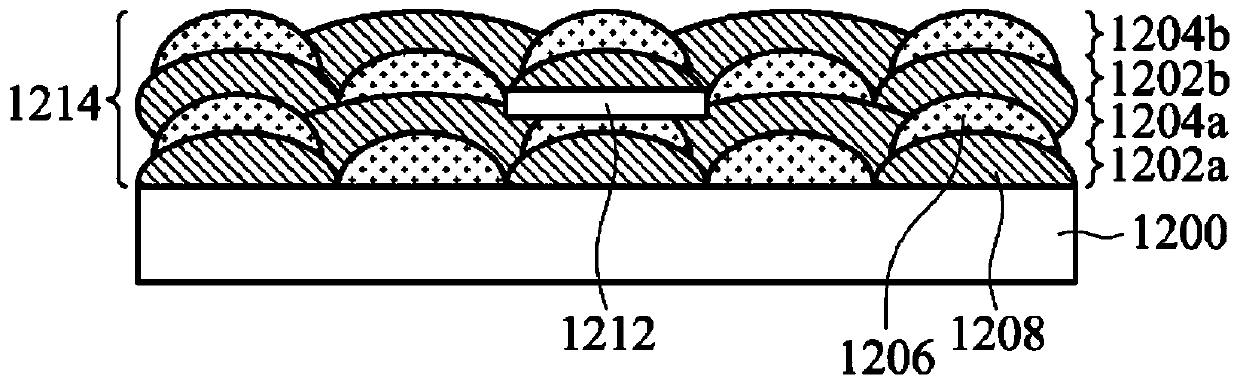

ActiveCN110429064AIncrease the number of bendsDoes not affect barrier abilitySemiconductor/solid-state device detailsSolid-state devicesCapillary channelOxygen

The invention provides a buffer structure, a display panel and a manufacturing method of a buffer structure. The display panel includes at least one buffer structure including a first inorganic layer,a second inorganic layer, and an organic layer. Trapezoidal grooves arranged at intervals are arranged at the surface of one side of the first inorganic layer, the second inorganic layer is arrangedon the surface of one side, provided with the trapezoidal grooves, of the first inorganic layer, covers the surface of the inner side of the trapezoidal grooves and connected at the groove mouths to form a capillary channel; and the organic layer fills the capillary channel. The manufacturing method of a buffer structure comprises the steps of: manufacturing an inorganic layer, a second inorganiclayer and an organic layer. The bending stress of the inorganic layers can be effectively relieved by allowing the organic layer to penetrate the inorganic layers, and the number of times of bending of the display panel is improved without influence of the inorganic layers on the barrier property of water and oxygen.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

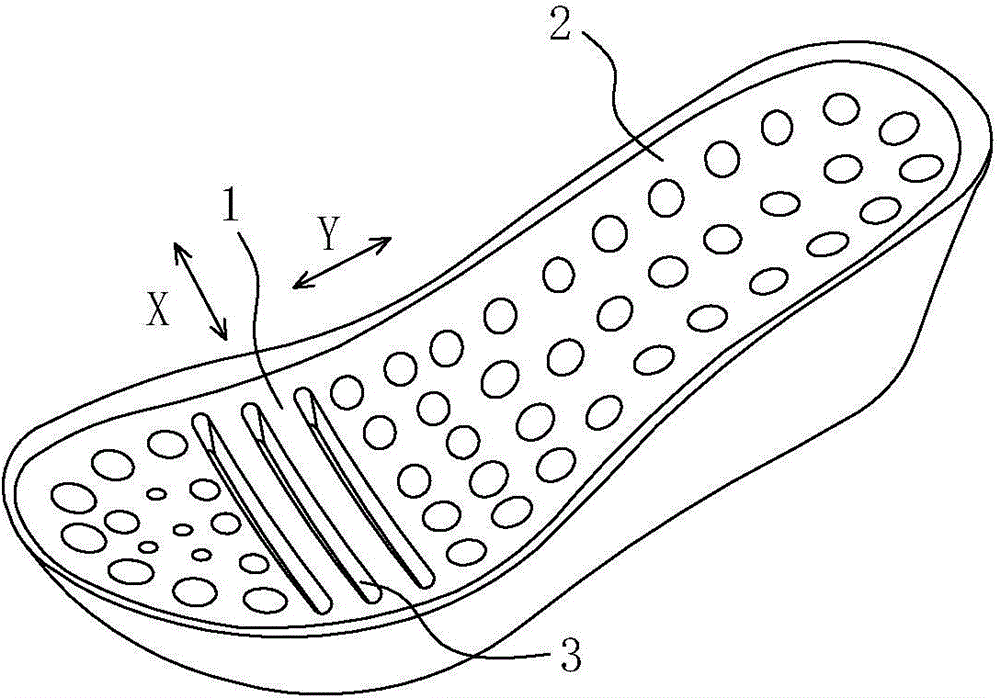

Bending-proof shoe outsole

InactiveCN104872924AImprove shock resistanceIncrease the number of bendsSolesTransverse grooveEngineering

The invention discloses a bending-proof shoe outsole. The bending-proof shoe outsole comprises a front sole part and a rear heel part, wherein three transverse grooves which are transversely designed are formed in the front sole part; the three transverse grooves are distributed at intervals towards the longitudinal direction. After the technical scheme is adopted, compared with the prior art, the technical scheme has the following advantages that the transverse grooves are designed in the front sole part which drives a human body to move, and the anti-vibration performance of the bending-proof shoe outsole can be increased; meanwhile, the bending frequency of the bending-proof shoe outsole can be increased, and the service life is prolonged.

Owner:佛山市南方鞋材有限公司

Bending-resistant flexible printed circuit board

InactiveCN101778532AImprove bending resistanceIncrease the number of bendsElectrical connection printed elementsShear stressFlexible circuits

The invention discloses a bending-resistant flexible printed circuit board. The bending-resistant flexible printed circuit board comprises a finger area and a flexible circuit area, wherein the front surface and the back surface of the finger area are provided with fingers; and the connecting line at the junction of a front finger area and the flexible circuit area is staggered from that of a back finger area and the flexible circuit area. The shear stress lines on the front surface and the back surface are different during bending the bending-resistant flexible printed circuit board, which enhances the bending resistance.

Owner:浙江近点电子股份有限公司

A chemical tempering method for ultrathin unequal-thickness glass

InactiveCN113336429AUniform stressGood bending propertiesGlass tempering apparatusVitrificationIon exchange

A chemical tempering method for ultrathin unequal-thickness glass belongs to the technical field of chemical tempering methods for ultrathin glass, and comprises the following steps: 1) covering the surface of an equal-thickness area of the unequal-thickness glass with a PET film for protection, and then coating the upper surface of the unequal-thickness area of the unequal-thickness glass with a film for protection; 2) putting the coated unequal-thickness glass into a tempering liquid for tempering treatment, so that the stress layer thickness of a tempered unequal-thickness area is 6-8 microns, the stress value is 500-600MPa, the stress layer thickness of a tempered uniform-thickness area is 10-12 microns, and the stress value is 650-750MPa; and (3) carrying out film stripping, cleaning, drying, inspection, packaging and delivery on the tempered unequal-thickness glass cooled to normal temperature. The method has the beneficial effects that the non-uniform-thickness area of the unequal-thickness glass is subjected to film coating protection, so that an effect of blocking part of ion exchange in the chemical tempering process is achieved, so that the ultra-thin glass has excellent bending performance, high impact resistance and scratch resistance.

Owner:芜湖东信光电科技有限公司

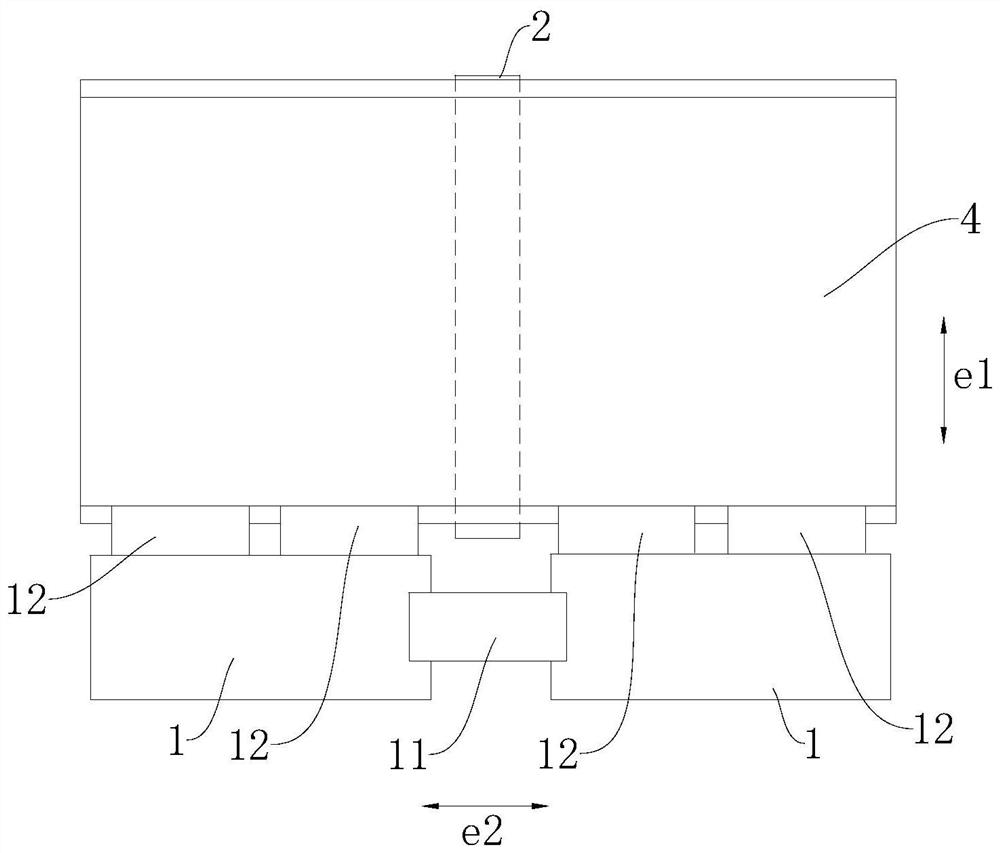

Connecting assembly of electronic equipment and electronic equipment

PendingCN113014709AIncrease the number of bendsImprove stabilityTelephone set constructionsFlexible circuitsEngineering

The invention discloses a connecting assembly of electronic equipment and the electronic equipment. A machine body of the electronic equipment comprises two sub-machine bodies and a connecting assembly connected between the two sub-machine bodies, wherein main boards of the two sub-machine bodies are connected through a flexible circuit board. The connecting assembly comprises a rotating connecting mechanism and a plurality of shaping device sets, wherein the rotating axis of the rotating connecting mechanism extends in the first direction. Each shaper set comprises at least one shaper, the multiple shaper sets are arranged on the rotary connecting mechanism and arranged at intervals in the second direction, and each shaper can stretch out and draw back in the third direction; the third direction is parallel to the thickness direction of the machine body, the second direction is perpendicular to the first direction and the third direction, and the flexible circuit board is suitable for being wound at the free end of the shaper and between two adjacent shaper groups. According to the connecting assembly provided by the embodiment of the invention, the bending frequency of the electronic equipment can be effectively improved, the stability and reliability of the electronic equipment are improved, and the service life is prolonged.

Owner:BOE TECH GRP CO LTD +1

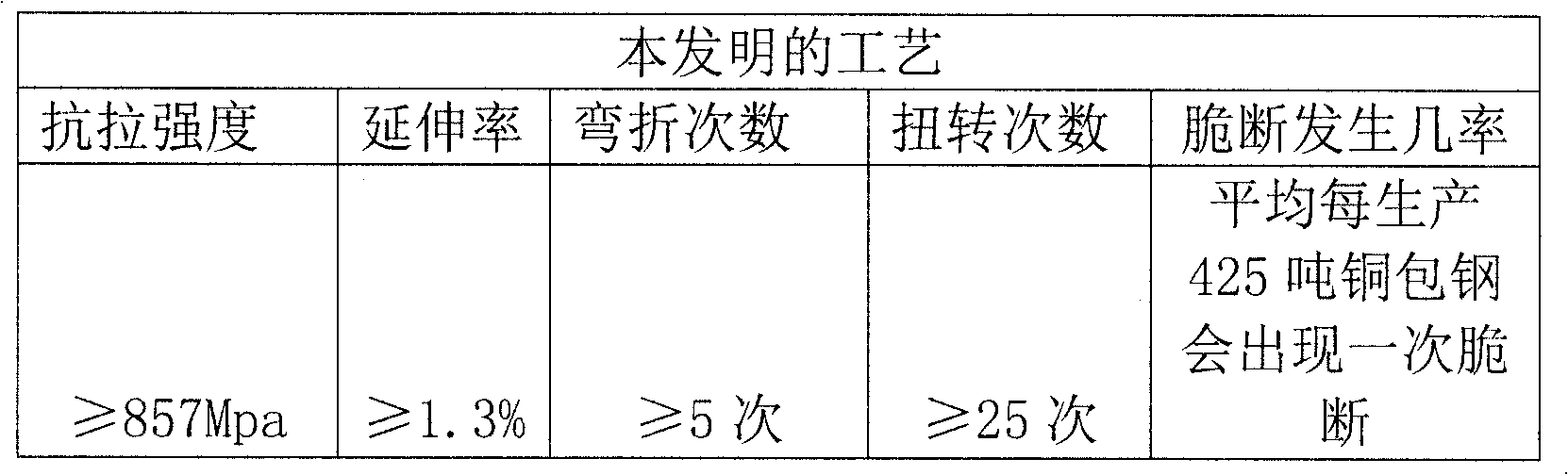

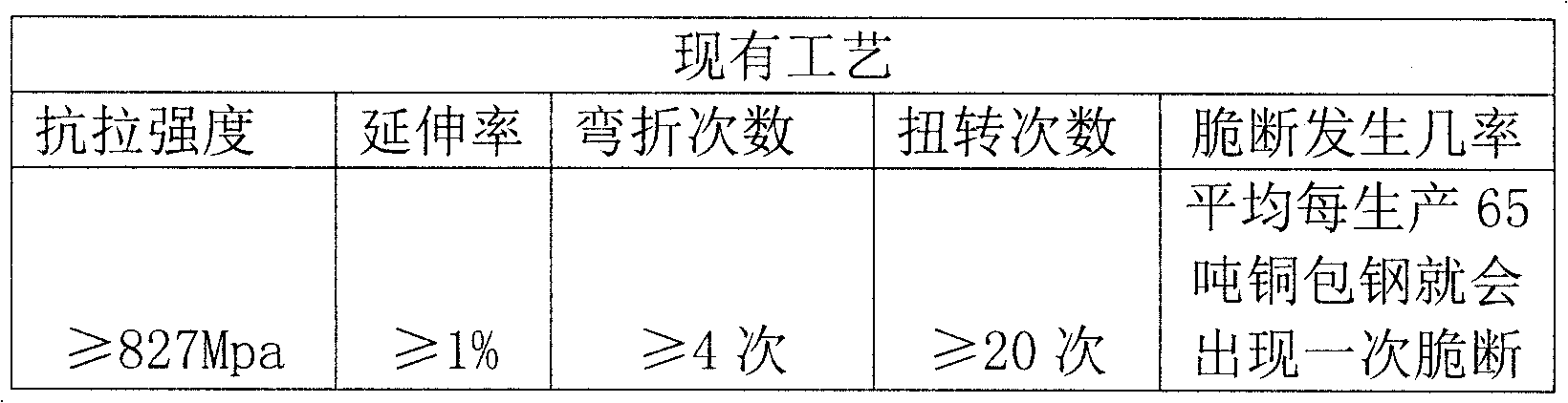

Technique for producing high-strength copper covered steel conductor for coaxial cable inner core wire

ActiveCN101303923BEliminate internal stressHigh tensile strengthMetal/alloy conductorsCable/conductor manufactureElectrical conductorElectrolysis

The invention relates to a high-strength copper-clad steel conductor. A production technique of a high-strength copper-clad steel conductor used for an inner core wire of a coaxial cable is characterized by comprising the following steps: rough drawing, medium temperature tempering, oxide layer removal, fine drawing, treatment before electro-deposition, acid electrolysis, washing, pretreatment ofelectro-deposition, washing, thick treatment of the electro-deposition, washing, oxidation protection, drying, tank wire drawing, washing, oxidation protection, drying and collecting lines and tray filling. Physical properties such as tensile strength, elongation, small reduction of area and bending times of the high-strength copper-clad steel conductor produced by the technique are enhanced.

Owner:ZHEJIANG PUJIANG BAICHUAN IND

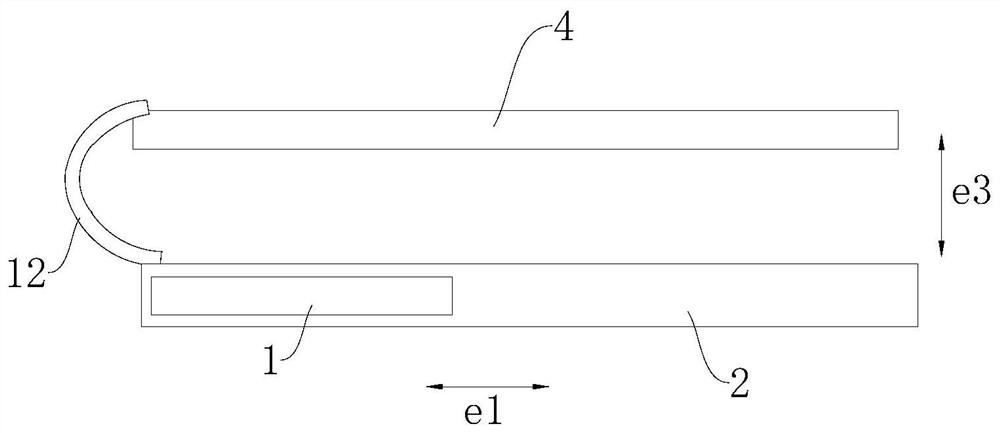

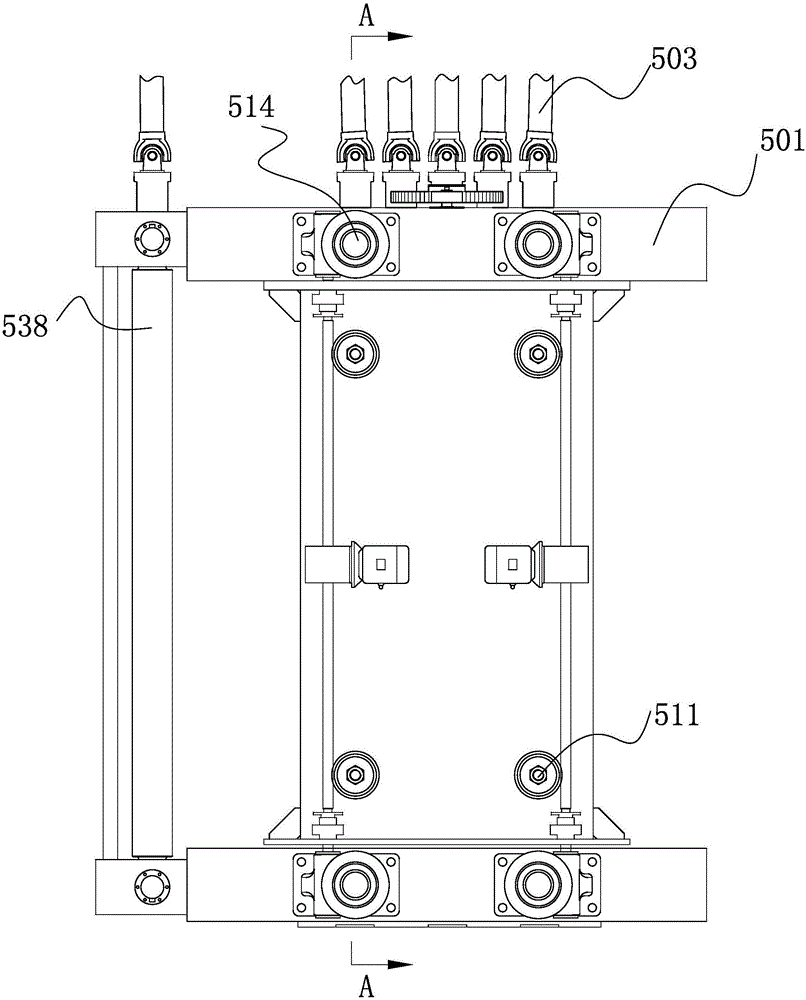

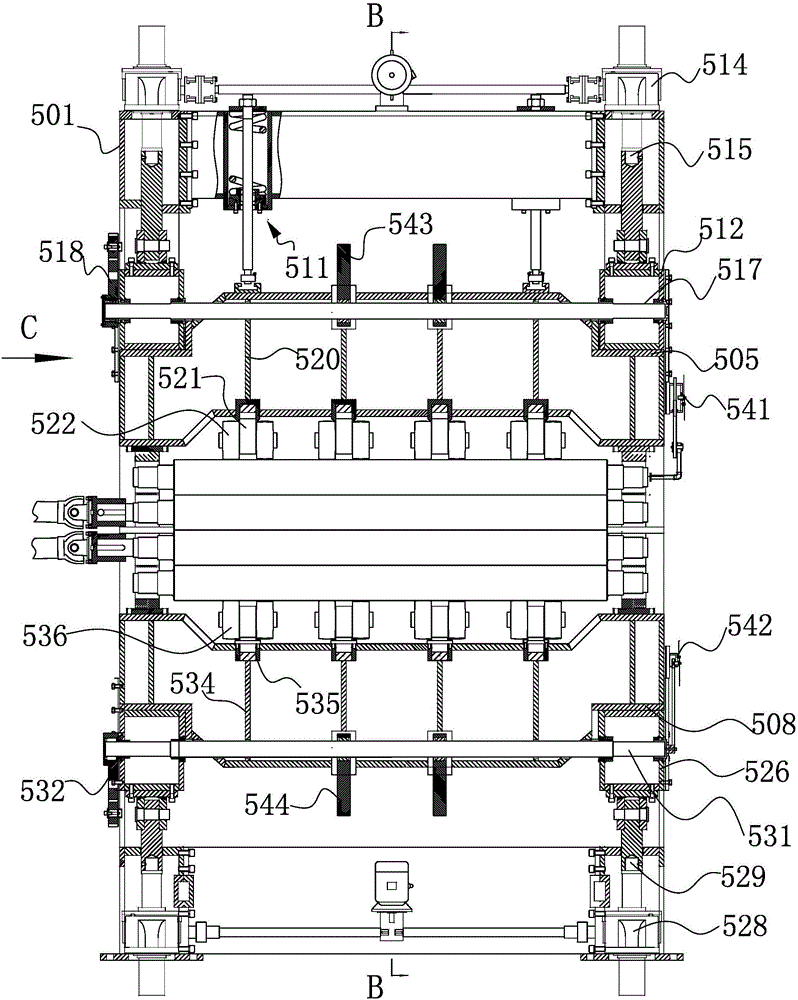

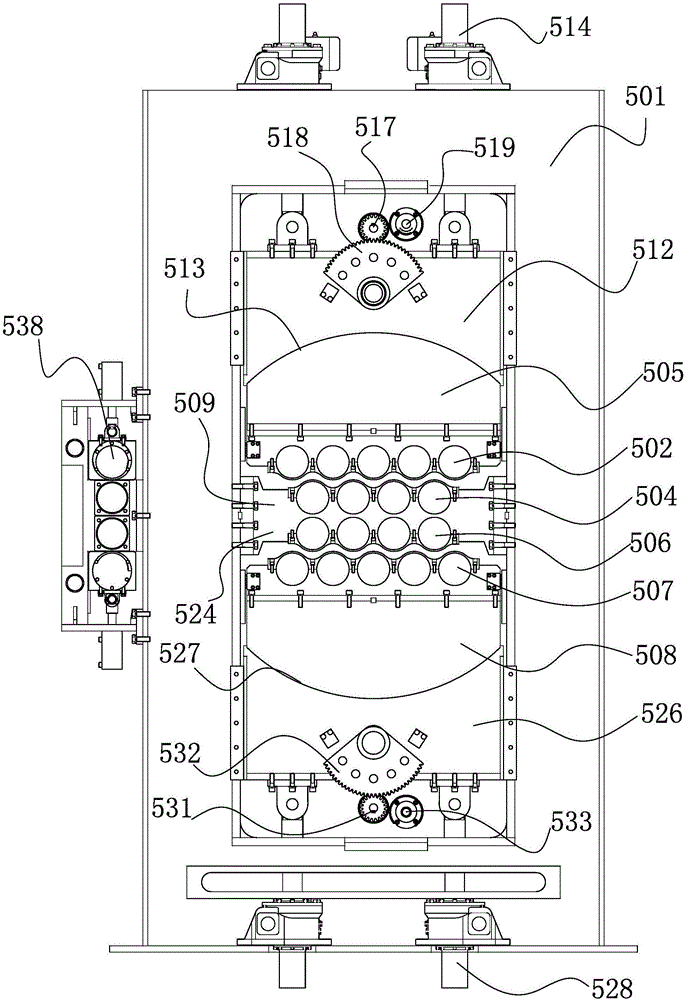

Double-layer composite board leveling machine

The invention discloses a double-layer composite board leveling machine, and relates to leveler equipment. The double-layer composite board leveling machine comprises a portal frame, and an upper-layer leveling roller system and a lower-layer leveling roller system arranged on the portal frame; the upper-layer leveling roller includes an upper roller system upper leveling roller, and an upper roller system lower leveling roller driven by a power device; the upper roller system upper leveling roller is arranged on an upper movable cross beam of the portal frame; the lower-layer leveling roller system includes a lower roller system upper leveling roller and a lower roller system lower leveling roller driven by a power device; and the lower roller system lower leveling roller is arranged on a lower movable cross beam of the portal frame. The double-layer composite board leveling machine can synchronously level an upper double-metal composite board and a lower double-metal composite board, is high in production efficiency, and reduces the production cost.

Owner:山东易川新材料科技股份有限公司

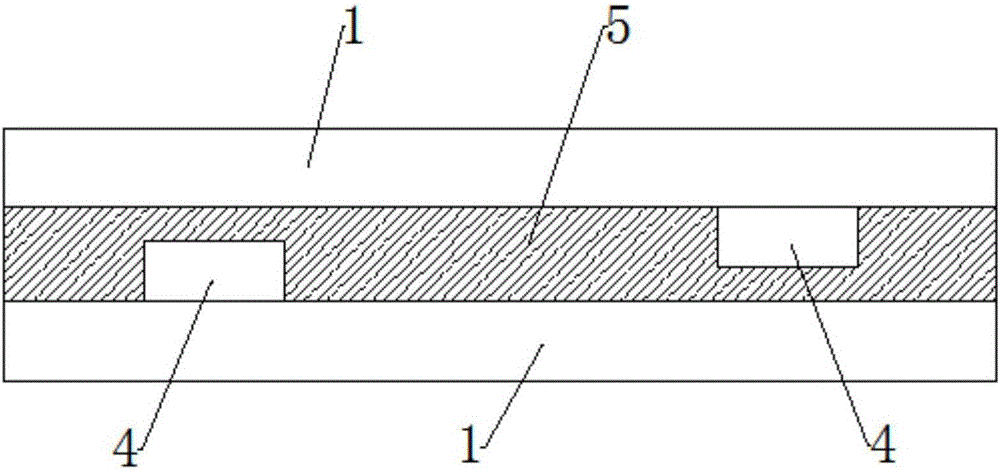

Gel electrolyte, battery cell containing same, paper shell battery and preparation method of paper shell battery

PendingCN106785027ALower internal resistanceAvoid short circuitFinal product manufactureSecondary cellsInternal resistanceBiochemical engineering

The invention provides a gel electrolyte, a battery cell containing the same, a paper shell battery and a preparation method of the paper shell battery. A paper shell thin lithium ion battery comprises a shell, a corrosion-resistant layer and a battery cell, wherein the corrosion-resistant layer is arranged on an inner wall of the shell, the battery cell is packaged in the shell, the shell material is gas-tight paper, a positive pole plate of the battery cell comprises a first substrate and a positive paste layer, a negative pole plate of the battery cell comprises a second substrate and a negative paste layer, the positive paste layer and the negative paste layer are both in close contact with the gel electrolyte, a tab is integratedly formed at one side, right opposite to the gel electrolyte, of each of the first substrate and the second substrate, and the two tabs both extend out of the shell. In the paper shell thin lithium ion battery provided by the invention, the gas-tight paper is used as outer package of the battery cell, the corrosion-resistant layer is arranged between the gas-tight paper and the battery cell, the internal resistance of the battery can be increased, the battery weight is reduced, the specific capacity is improved, and the bending frequency of the battery is increased.

Owner:HUINENG TIANJIN TECH DEV CO LTD

Preparation process of polyimide-aluminum composite foil

ActiveCN114724859AFirmly attachedImprove bending strengthElectrolytic capacitorsBenzoic acidDiaminodiphenyl ether

The invention relates to a polyimide-aluminum composite foil preparation process which comprises the following steps: an aluminum foil heat treatment stage, an aluminum foil cooling stage, a corrosion foil preparation stage, a chambering foil preparation stage, a polyimide composite layer preparation stage, a surface cleaning stage and a drying treatment stage. In the preparation stage of the polyimide composite layer, a pre-treatment solution is formed by mixing 4, 4 '-diaminodiphenyl ether, N, N-dimethylacetamide and ammonium tetra-n-hexyl benzoate, and a post-treatment solution is formed by mixing sulfuric acid, hydrochloric acid, 4, 4'-diaminodiphenyl ether, N, N-dimethylacetamide and ammonium tetra-n-hexyl benzoate. Therefore, the formed polyimide composite layer can be stably attached to the outer surface of the corrosion foil, so that the bending strength of the electrode foil can be improved; and the polyimide composite layer filled in the corrosion hole channel can be tightly combined with the aluminum residual core into a whole, so that the formed electrode foil is ensured to have relatively high dielectric constant and capacitance.

Owner:NANTONG HAIXING ELECTRONICS +2

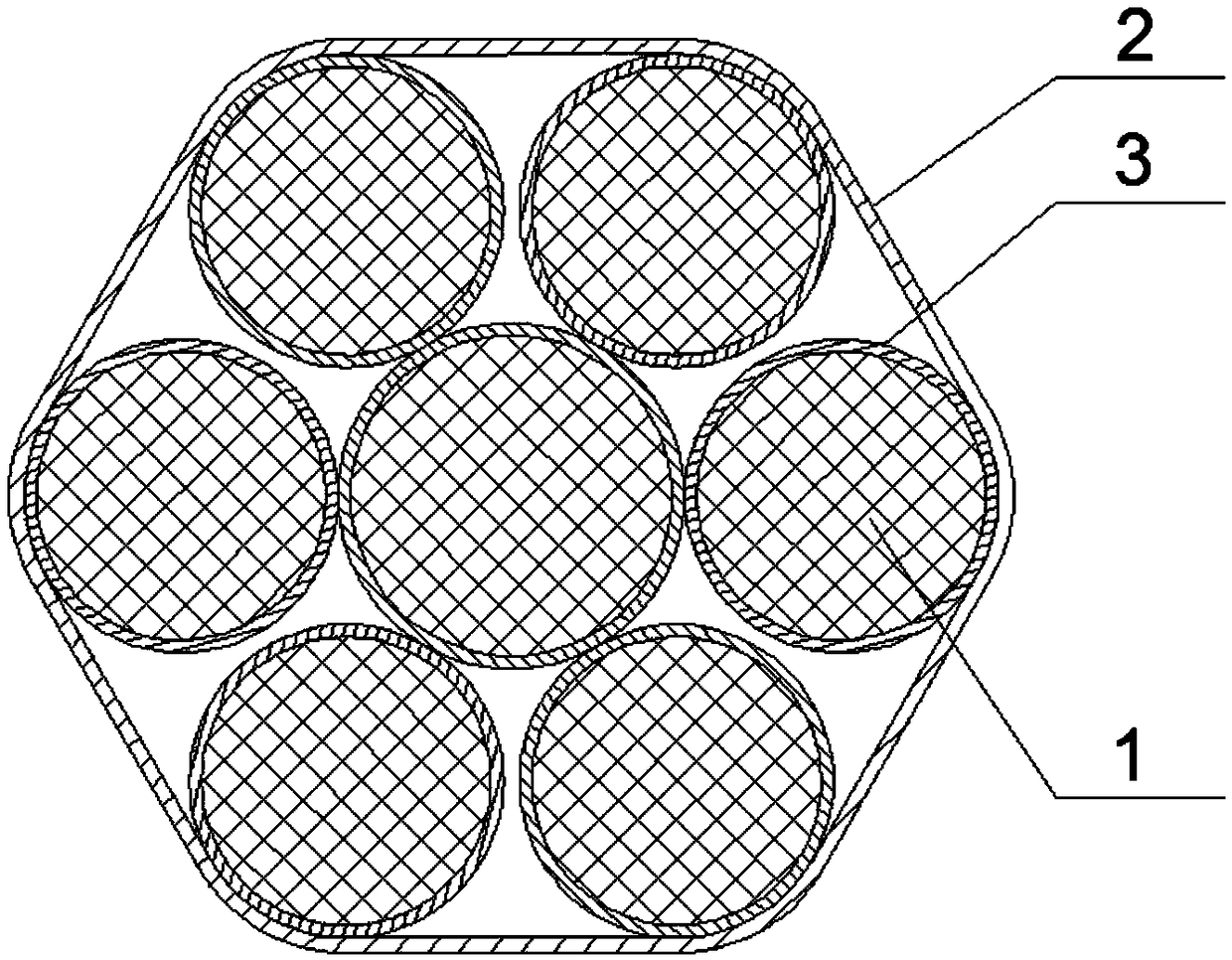

Processing method of drag chain cable conductor

InactiveCN110718333AIncrease the number of bendsEven by forceNon-insulated conductorsDetails of conductive coresElectrical conductorCopper wire

The invention discloses a processing method of a drag chain cable conductor, comprising the following steps: a plurality of copper wires with the elongation of more than or equal to 18% are selected;a strand is formed by standing 2-3 copper wires, multiple strands are taken to wrap the periphery of a hollow first reinforcing wire to obtain a wire unit, and the first reinforcing wire is arranged in the center of the strands; a plurality of wire units are arranged at the inner periphery of a drag chain cable conductor; and the wire units are firstly bundled and then re-stranded, and a second reinforcing wire is additionally arranged at the center of the compound strand. The mode of wire bundling and then compound stranding is conducive to maintaining the stability of the conductor structure, ensuring that the conductor is evenly stressed during bending, avoiding mechanical stress concentration and prolonging the bending fatigue life of the conductor. The reinforcing wires are added to the central positions of the strands and the compound strand to improve the bending strength of the whole conductor, increase the gaps between the single copper wires and reduce the stress effect during bending, so as to prolong the bending fatigue life of the conductor. Therefore, the bending frequency of the cable is greatly increased, and the comprehensive strength of the cable is high.

Owner:广东金联宇电缆实业有限公司

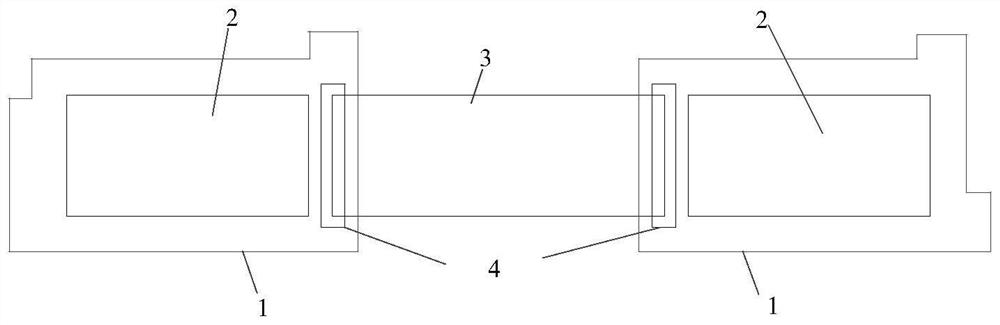

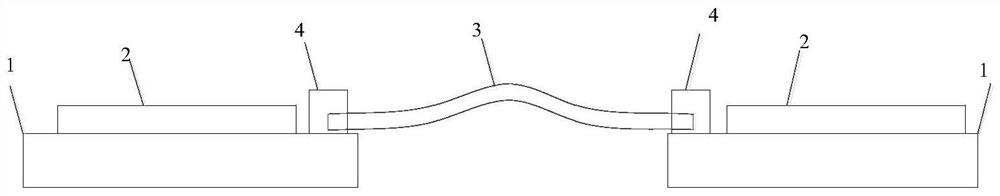

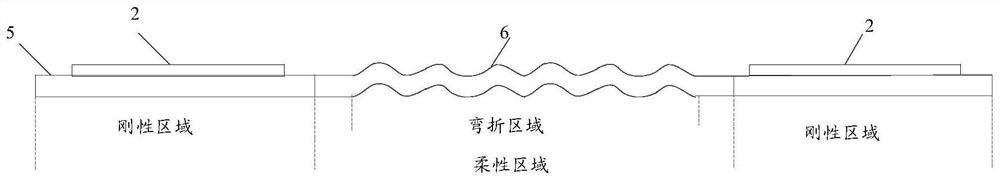

Circuit board and display device

PendingCN113242643AIncrease the number of bendsImprove reliabilityPrinted circuits structural associationsIdentification meansWave structureDisplay device

The invention discloses a circuit board and a display device. The circuit board comprises at least one flexible base layer and a metal circuit layer which are arranged in a laminated mode, rigid areas and a flexible area, wherein the rigid areas are located on the two sides of the flexible area, rigid base materials are arranged on the rigid areas, at least part of the flexible area is arranged to be of a wave structure to form a bending area, and the wave structure extends towards the rigid area. According to the embodiment of the invention, the integrated board with the soft and hard structure is arranged, and at least part of the flexible area is arranged to be of the wave structure to form the bending area, so that the circuit board can achieve the accumulation and release of stress through tiny tensile compression deformation by utilizing the wave structure similar to a spring in the folding, bending or flattening process, and high bending times of the circuit board in the bending area can be ensured; and the soft and hard integrated structure can prevent the soft board from being damaged due to pulling during assembling, bending and pulling, so that the reliability of the circuit board in a folded product is improved.

Owner:BOE TECH GRP CO LTD +1

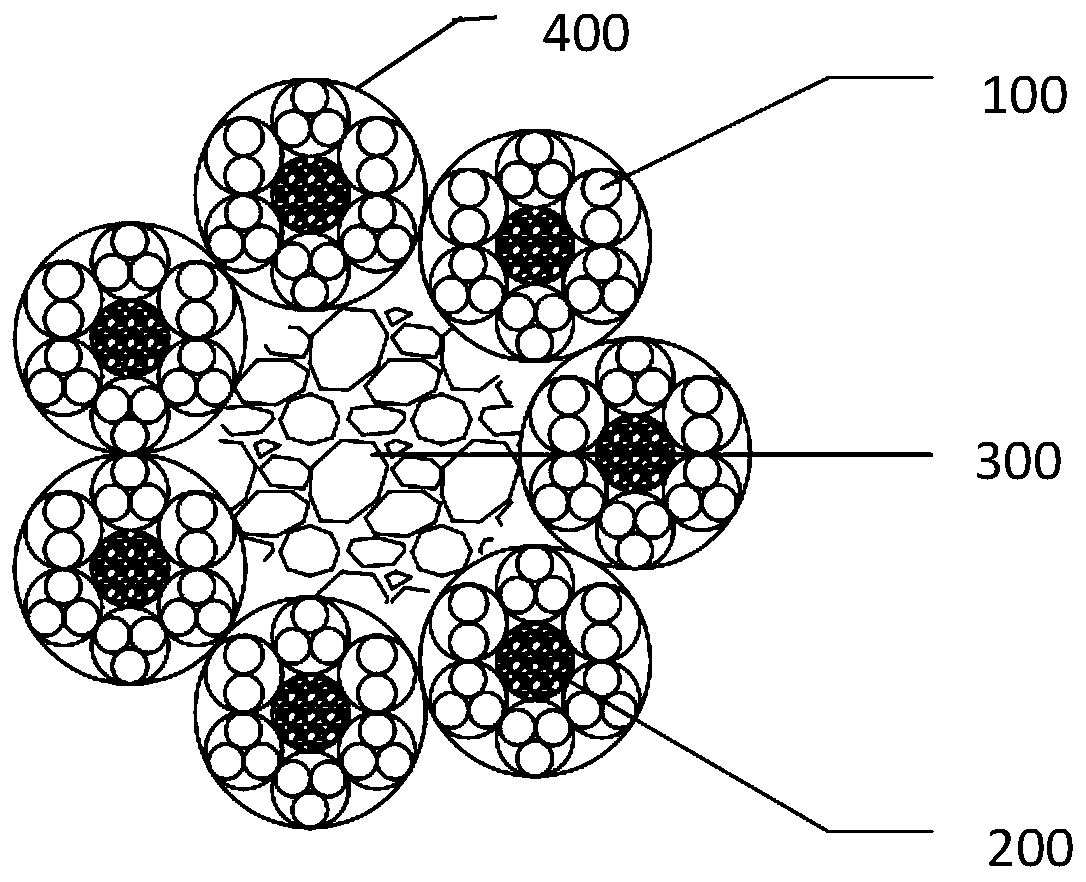

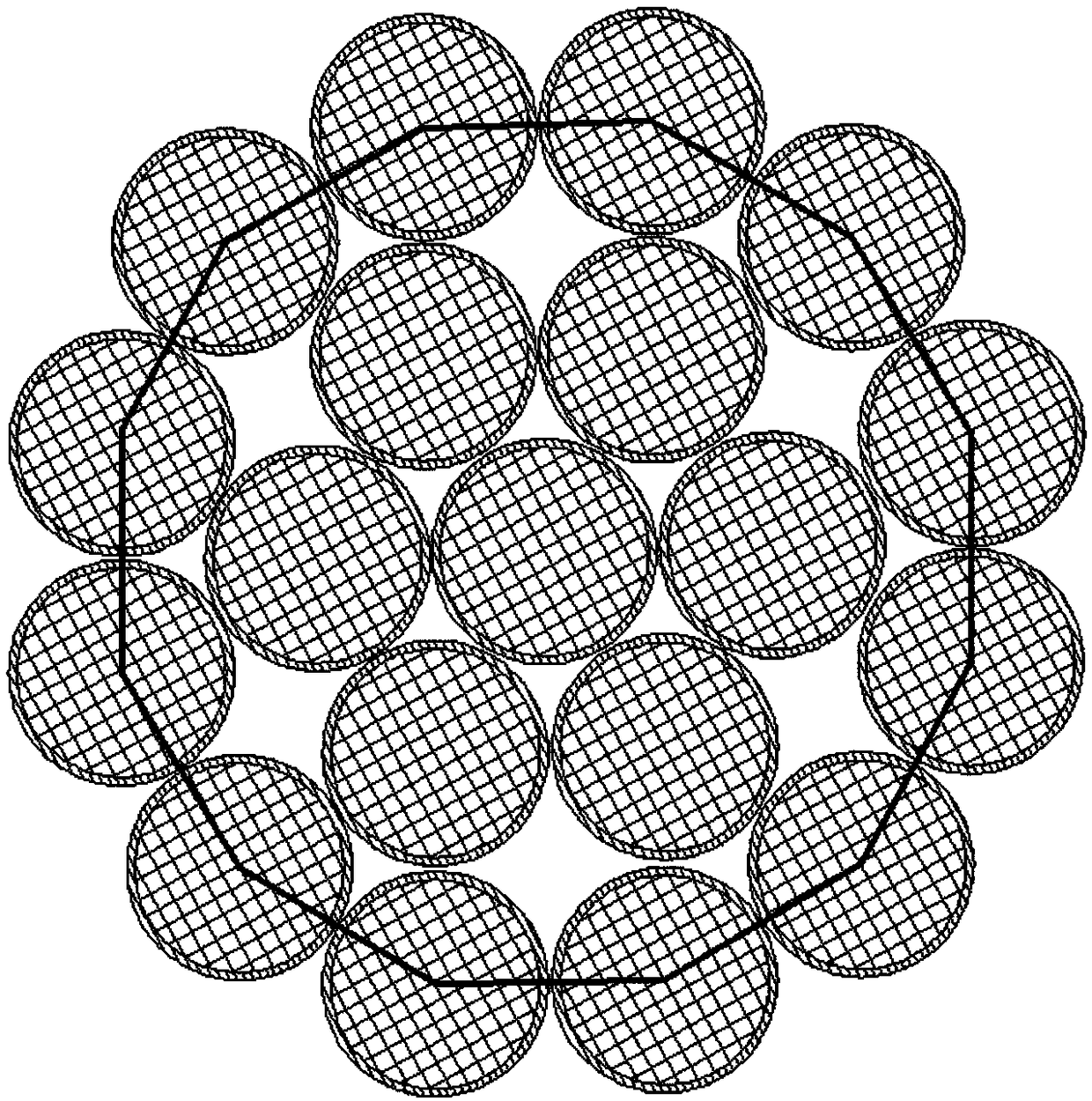

Aerial lead super-soft multi-strand combined carbon fiber mandrel and manufacturing process thereof

PendingCN109360672ALarge bending angleIncrease the number of bendsSingle bars/rods/wires/strips conductorsConductive materialFiberAluminum foil

The invention relates to an aerial lead super-soft multi-strand combined carbon fiber mandrel which comprises one group of circular cross section carbon fiber composite cores. Axes of single carbon fiber composite cores in a carbon fiber composite core group are parallel, axis ligatures of the peripheral carbon fiber composite cores in the carbon fiber composite core group form a regular polygon structure, and an aluminum foil or tinfoil wrapping layer is arranged on the periphery of the carbon fiber composite core group. The mandrel overcomes the shortcomings of the prior art and is fixed bythe aluminum foil wrapping layer in a core wire combined manner, bending and winding performance of the mandrel is improved, strength is improved, heat and humidity resistance and ozone and ultraviolet aging performances are improved, use stability and reliability is remarkably improved, the mandrel can serve as a separate product to be prefabricated, a separate module is provided for lead preparation, and a production process is simplified.

Owner:HEBEI SILICON VALLEY CHEM CO LTD +1

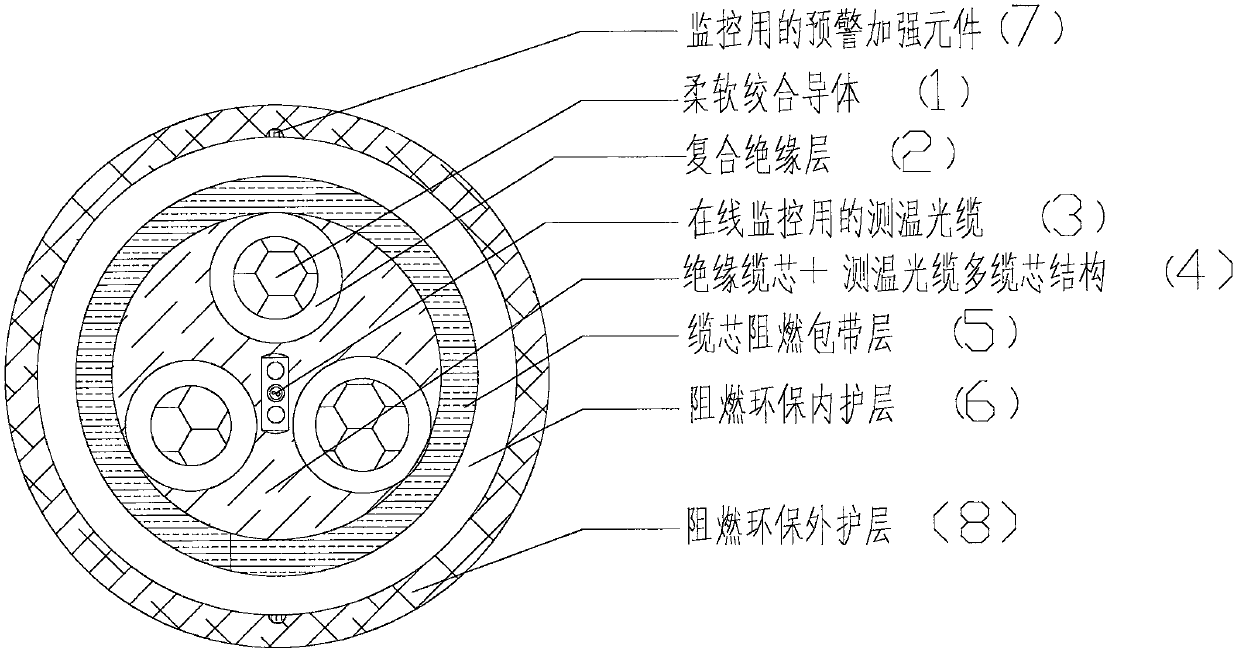

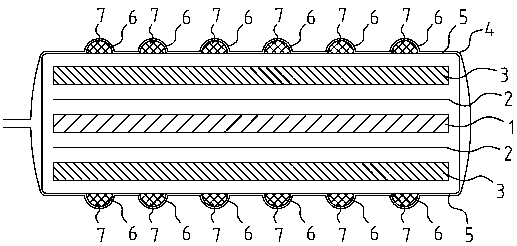

Monitoring type fireproof cable

PendingCN111048249AImprove integrityOvercome production difficultiesPower cables with screens/conductive layersFlexible cablesAmpacityProtection layer

The invention relates to a monitoring type fireproof cable. The cable sequentially comprises a temperature measuring optical cable, an insulating cable core, a cable core flame-retardant wrapping tapelayer, a flame-retardant environment-friendly inner protection layer and a flame-retardant environment-friendly outer protection layer from the inner layer to the outer layer, wherein the insulatingcable core comprises a flexible stranded conductor and a composite insulating layer wrapping the flexible stranded conductor; and the parts among the temperature measuring optical cable, the insulating cable core and the cable core flame-retardant wrapping tape layer are filled with an insulating filler. According to the invention, the flame-retardant and fire-resistant performance of the cable istruly improved, the reactive loss of the cable is reduced, and the current-carrying capacity of the cable is increased; the special multi-level monitoring structure is adopted, the operation condition of the cable under the high-load condition can be monitored online in real time, early warning information can be sent out in time when the cable is affected by the outside, and large property lossis avoided.

Owner:HANGZHOU HONGYAN CABLE +1

An electrochemical corrosion process for medium and high voltage anode foil production

ActiveCN110164696BFoil surface quality is stableIncrease specific volumeElectrolytic capacitorsElectrochemical corrosionHigh voltage

The invention discloses an electrochemical corrosion process for the production of medium and high voltage anode foil, which comprises the following steps: A. Pretreatment: put the aluminum foil into a mixed solution of sodium hydroxide and potassium hydroxide at a temperature of 35-45°C, Soak for 40-60s; B. Pores: Put the pretreated aluminum foil into a mixed solution containing 10-15% hydrochloric acid and 35-45% sulfuric acid by mass at a temperature of 65-75°C to control the corrosion current density 250-400mA / cm2, carry out the hole corrosion for 100-120s; C, expand the hole: wash the aluminum foil after the hole with deionized water, put it into the aluminum foil with a temperature of 80-90°C and a mass percentage of 11-15%. In the nitric acid solution, control the hole expansion current to 50-150mA / cm2, and carry out hole expansion for 9-12 minutes; D, post-treatment; E, drying. The electrochemical corrosion process of the present invention has a simple process and is easy to control the process, and can effectively ensure stable foil surface quality of the produced medium and high voltage anode foil, and has both high specific volume and high strength.

Owner:ZHEJIANG FENGCHUAN ELECTRONICS TECH

A flexible lithium-ion battery

ActiveCN106252737BEasy to bendReduce breakageCell electrodesFinal product manufactureElectrical batteryEngineering

A flexible lithium-ion battery, comprising an electric core and an outer packaging film wrapped outside the electric core; a flexible film is arranged between the outer packaging film and the upper surface and the lower surface of the electric core, and the flexible film covers the On the upper surface and the lower surface, at least one piece of flexible film and the outer packaging film are provided with several buffer protrusions, and the inner surface of the outer packaging film is provided with pits corresponding to the buffer protrusions. A buffer protrusion is added on the surface of the battery cell. The buffer protrusion has a certain degree of elasticity. When the battery as a whole is bent, it will be squeezed by the bending stress prior to the pole piece, thereby protecting the pole piece from powder shedding due to excessive stress. Fracture, increasing the number of times the battery is bent.

Owner:APOWER ELECTRONICS CO LTD

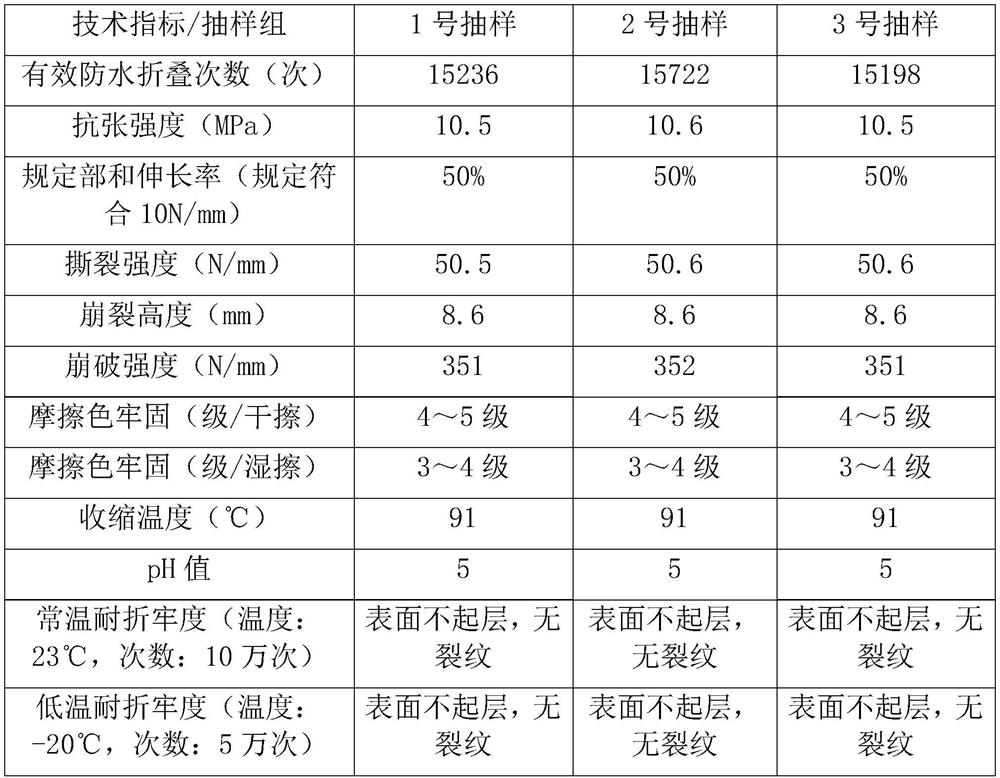

Manufacturing process of waterproof crazy horse leather

InactiveCN113695211AImprove waterproof performanceWon't breakPretreated surfacesCoatingsFiberAdhesive

The invention discloses a manufacturing process of waterproof crazy horse leather, and relates to the technical field of leather surface treatment. The process comprises the steps of material preparation, surface smoothing treatment, wet-process material treatment, wet-process base production, attachment and post-treatment to obtain the crazy horse leather, wherein a wet-process material comprises 30D polyurethane, 35D polyurethane, a DMF (dimethyl formamide) solvent and wood fiber powder, a produced wet-process material base uses guide cloth as a carrier, and the wet-process material base is stripped from the guide cloth and then bonded to cow split leather through a water-based adhesive. According to the process, the prepared wet-process base layer is attached to the waterproof split leather in a mold transfer manner, the damage to a waterproof layer on the leather surface caused by direct high-temperature coating is avoided, the number of bending times in effective waterproof use of the crazy horse leather is guaranteed, and compared with a traditional method, the number of bending times is increased by nearly one time and reaches 15000. Besides, the cow split leather can be used as a raw material for production, so that compared with a traditional method of using cow top grain leather, the production cost is greatly reduced, and the problem of raw material shortage in the industry is solved.

Owner:晋江国泰皮革有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com