Power-up protection method of hole generating corrosion second half V cathode of middle-high voltage electronic aluminum foil

A technology of electronic aluminum foil and power-on protection, which is applied in the direction of electrolytic capacitors, circuits, capacitors, etc., can solve problems affecting the performance of aluminum foil, etc., and achieve the effect of low cost, thickness maintenance, and good indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

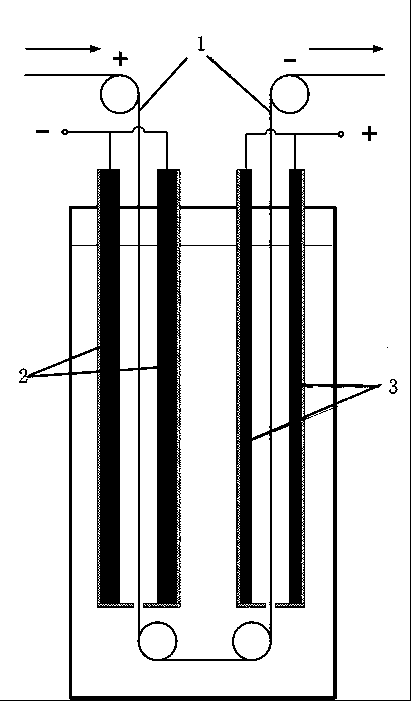

Image

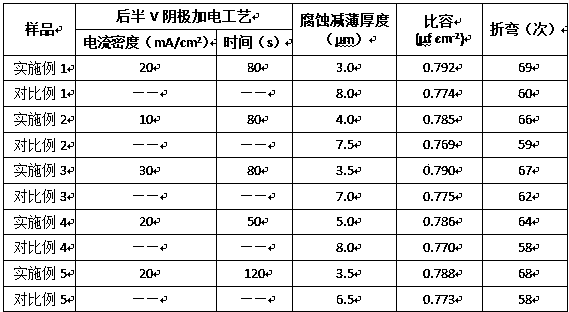

Examples

Embodiment 1

[0032] A method for half-V cathodic power-on protection after hole corrosion of medium and high voltage electronic aluminum foil, comprising the following steps:

[0033] (1) Pretreatment: The aluminum foil is soaked in a mixed solution containing 3% hydrochloric acid and 35% sulfuric acid at a temperature of 80°C for 120 s;

[0034] (2) The first half V porosity corrosion of the first level: the aluminum foil after pretreatment enters the porosity corrosion solution at a temperature of 75 ° C, and the applied current density is 600 mA cm -2 The direct current is carried out porosity corrosion 80 s, and described porosity corrosion solution is the mixed solution that contains mass percent and is 3% hydrochloric acid and 35% sulfuric acid;

[0035] (3) Cathodic energization protection in the second half V of the first level: After the first half V is corroded, the aluminum foil enters the second half V, and the cathode is subjected to constant current protection treatment for 8...

Embodiment 2

[0041] A method for half-V cathodic power-on protection after hole corrosion of medium and high voltage electronic aluminum foil, comprising the following steps:

[0042] (1) Pretreatment: The aluminum foil is immersed in a mixed solution containing 5% hydrochloric acid and 30% sulfuric acid at a temperature of 75°C for 100 s;

[0043] (2) The first half V porosity corrosion of the first level: the aluminum foil after pretreatment enters the porosity corrosion solution at a temperature of 70°C, and the applied current density is 500 mA cm -2 The direct current is carried out porosity corrosion 120 s, and described porosity corrosion solution is the mixed solution that contains mass percent and is 5% hydrochloric acid and 30% sulfuric acid;

[0044] (3) Cathodic energization protection for the second half V of the first level: After the first half V is corroded, the aluminum foil enters the second half V, and the cathode is subjected to constant current protection treatment for...

Embodiment 3

[0050] A method for half-V cathodic power-on protection after hole corrosion of medium and high voltage electronic aluminum foil, comprising the following steps:

[0051] (1) Pretreatment: The aluminum foil is immersed in a mixed solution containing 5% hydrochloric acid and 30% sulfuric acid at a temperature of 85 °C for 60 s;

[0052] (2) The first half V porosity corrosion of the first level: the aluminum foil after pretreatment enters the porosity corrosion solution at a temperature of 80 °C, and the applied current density is 800 mA cm -2 The direct current is carried out porosity corrosion 60 s, and described porosity corrosion solution is to contain the mixed solution that mass percent is 5% hydrochloric acid and 30% sulfuric acid;

[0053] (3) Cathodic energization protection in the second half V of the first level: After the first half V is corroded, the aluminum foil enters the second half V, and the cathode is subjected to constant current protection treatment for 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com