Preparation process of polyimide-aluminum composite foil

A polyimide, preparation technology, applied in the field of electrode foil manufacturing, can solve the problems of reduced structural strength, increased production cost, placed in a vacuum environment or an inert gas environment, etc., to achieve high dielectric constant and capacitance, Effect of improving bending strength and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

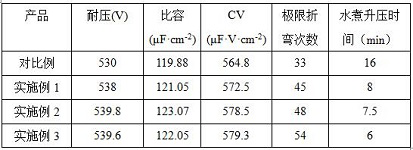

Examples

Embodiment 1

[0037] The preparation process of polyimide-aluminum composite foil includes the following steps:

[0038] S1. Heat treatment stage: place aluminum foil with a purity of not less than 99.9% in an oven for heat treatment, the temperature is controlled at 480-520 °C, and the duration is controlled at 3-5min;

[0039] S2, cooling stage: the aluminum foil processed in step S1 is placed in the air to cool naturally;

[0040] S3, corrosion foil preparation stage; the aluminum foil treated in step S2 is immersed in a corrosion acid solution to form corrosion pores on its surface; the corrosion acid solution used is hydrochloric acid 11.03mol / L: sulfuric acid 7.5mol / L=2:1 Mix the solution, and the temperature is controlled at 50 ~ 70 ℃;

[0041] S4, the preparation stage of the reaming foil; the etched foil obtained in step S3 is placed in the reaming liquid to ream the corroded pores, and the pore diameter of the etched porosity after the treatment is not less than 0.1 μm; the reami...

Embodiment 2

[0055] The preparation process of polyimide-aluminum composite foil includes the following steps:

[0056] S1. Heat treatment stage: place aluminum foil with a purity of not less than 99.9% in an oven for heat treatment, the temperature is controlled at 480-520 °C, and the duration is controlled at 3-5min;

[0057] S2, cooling stage: the aluminum foil processed in step S1 is placed in the air to cool naturally;

[0058] S3, corrosion foil preparation stage; the aluminum foil treated in step S2 is immersed in a corrosion acid solution to form corrosion pores on its surface; the corrosion acid solution used is hydrochloric acid 11.03mol / L: sulfuric acid 7.5mol / L=2:1 Mix the solution, and the temperature is controlled at 50 ~ 70 ℃;

[0059] S4, the preparation stage of the reaming foil; the etched foil obtained in step S3 is placed in the reaming liquid to ream the corroded pores, and the pore diameter of the etched porosity after the treatment is not less than 0.1 μm; the reami...

Embodiment 3

[0069] The preparation process of polyimide-aluminum composite foil includes the following steps:

[0070] S1. Heat treatment stage: place aluminum foil with a purity of not less than 99.9% in an oven for heat treatment, the temperature is controlled at 480-520 °C, and the duration is controlled at 3-5min;

[0071] S2, cooling stage: the aluminum foil processed in step S1 is placed in the air to cool naturally;

[0072] S3, corrosion foil preparation stage; the aluminum foil treated in step S2 is immersed in a corrosion acid solution to form corrosion pores on its surface; the corrosion acid solution used is hydrochloric acid 11.03mol / L: sulfuric acid 7.5mol / L=2:1 Mix the solution, and the temperature is controlled at 50 ~ 70 ℃;

[0073] S4, the preparation stage of the reaming foil; the etched foil obtained in step S3 is placed in the reaming liquid to ream the corroded pores, and the pore diameter of the etched porosity after the treatment is not less than 0.1 μm; the reami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com