Flexible plate connecting method and ultrasonic probe

A flexible board and ultrasonic technology, applied in the field of ultrasonic probes, can solve problems such as inability to meet bending requirements, and achieve the effect of increasing the force area, improving reliability, and increasing the number of bending times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is attached Figure 1-3 The present invention is described in detail.

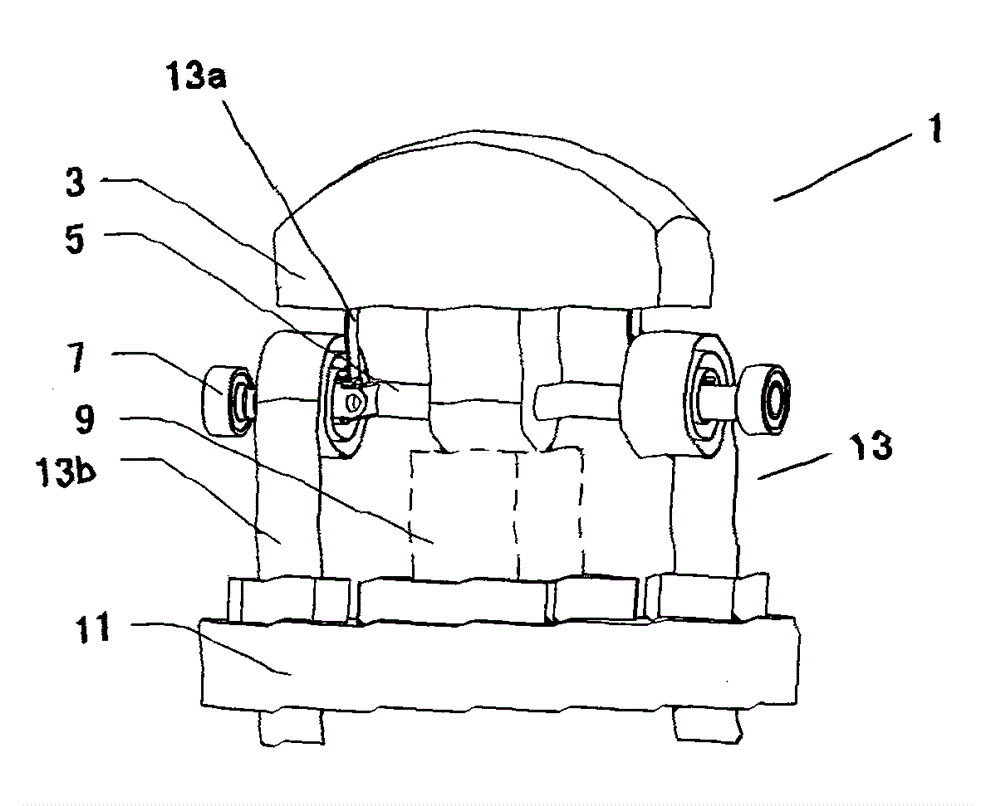

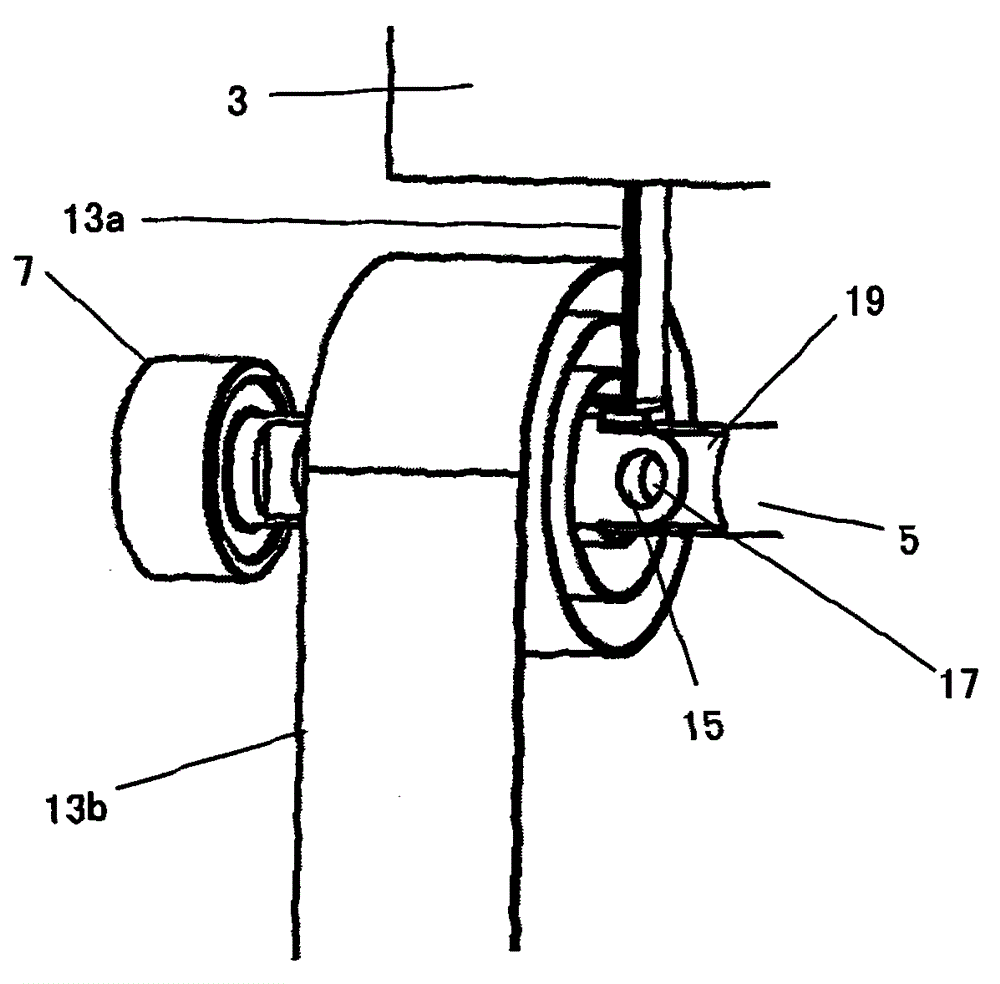

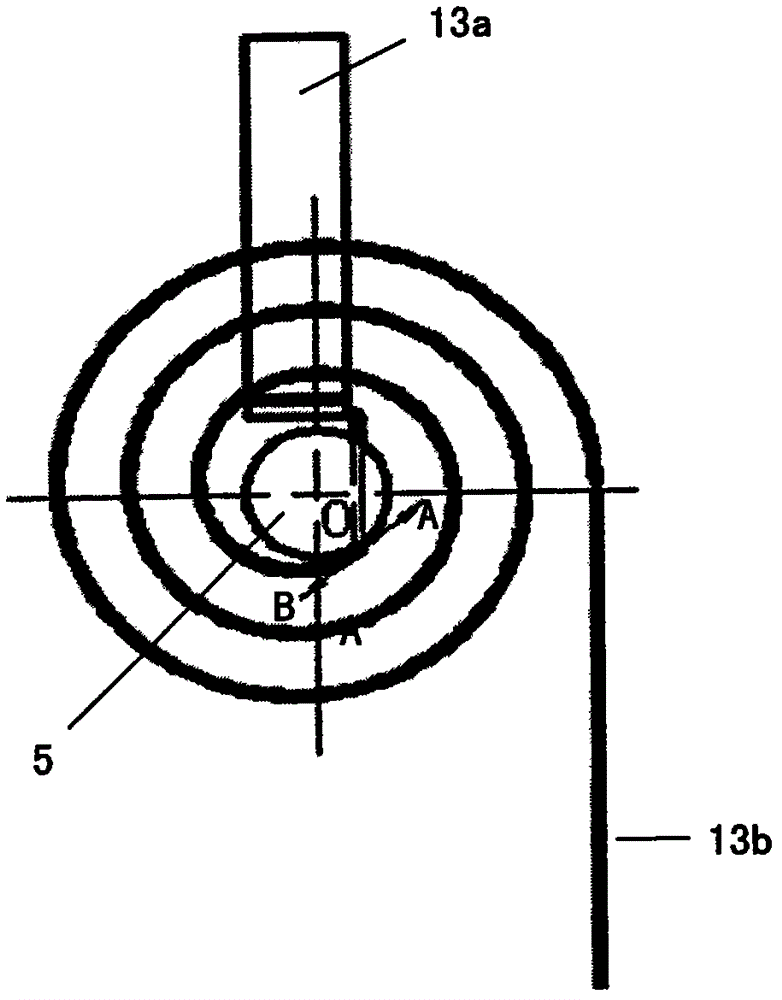

[0025] figure 1 The ultrasonic probe of the ultrasonic system according to the present invention is schematically shown, wherein the casing is removed to clearly show its inner structure. Such as figure 1 As shown, the ultrasonic probe 1 includes an ultrasonic sound head 3 in which a plurality of ultrasonic transducer elements are arranged for generating incident ultrasonic waves and receiving reflected ultrasonic waves. The ultrasonic probe 1 also includes a rotating shaft 5 to which the ultrasonic head 3 is fixed and reciprocally rotates (or swings) therewith, and the rotating shaft 5 is rotatably fixed to a frame housing (not shown) through a bearing 7 . The rotating shaft 5 can rotate reciprocally at high speed under the driving action of the driving mechanism 9 in any suitable known manner, and the driving mechanism 9 preferably includes a stepping motor. In addition to the ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com