Flexible printing circuit board

A technology of flexible printed circuit and conductive layer, which is applied in the direction of printed circuit, printed circuit, printed circuit parts, etc., can solve the problems of long time and high production cost of flexible printed circuit board, and achieve the improvement of bending performance and saving production Cost, effect of preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The flexible printed circuit board provided by the embodiment of the technical solution will be further described below in conjunction with the accompanying drawings.

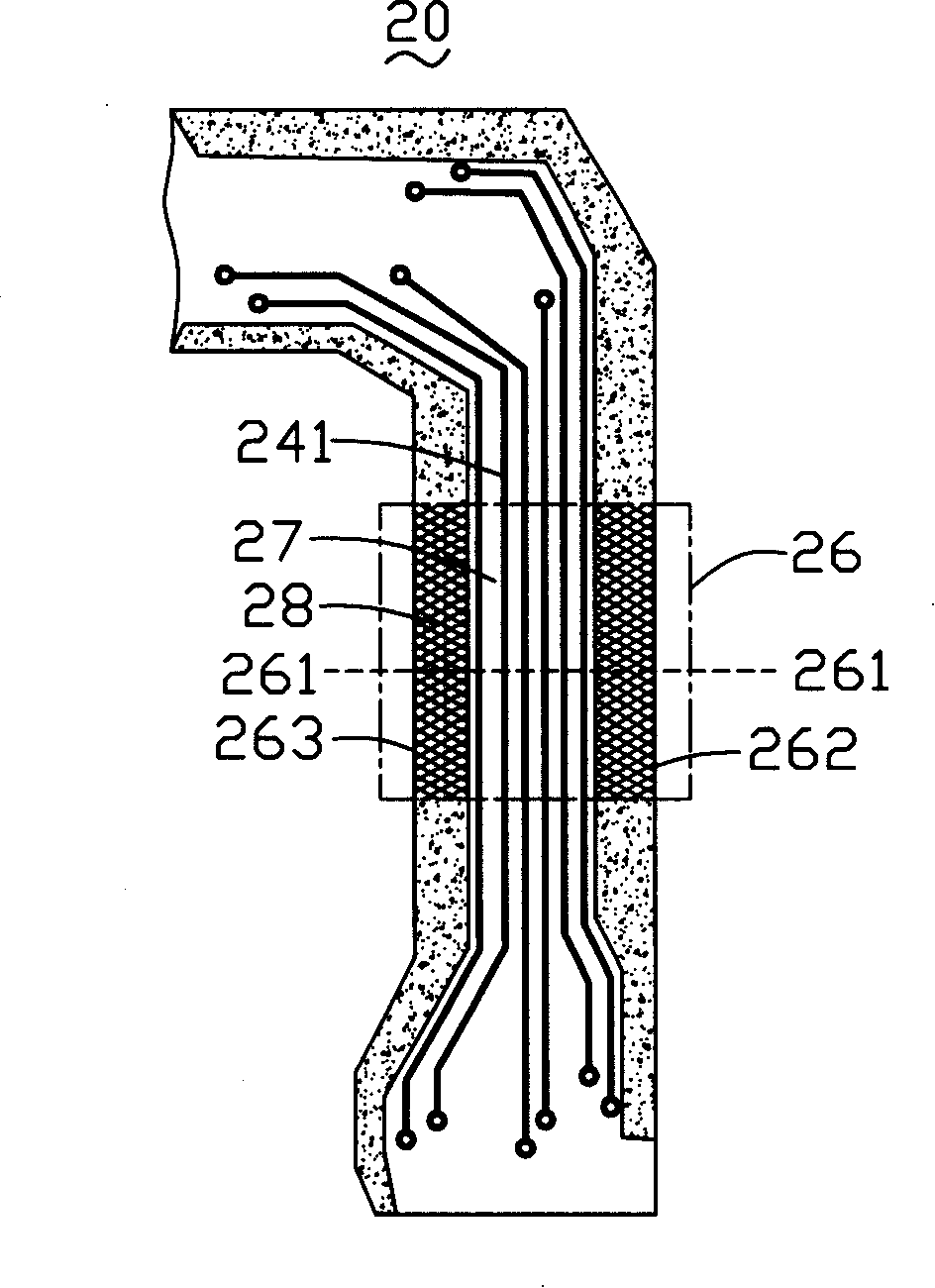

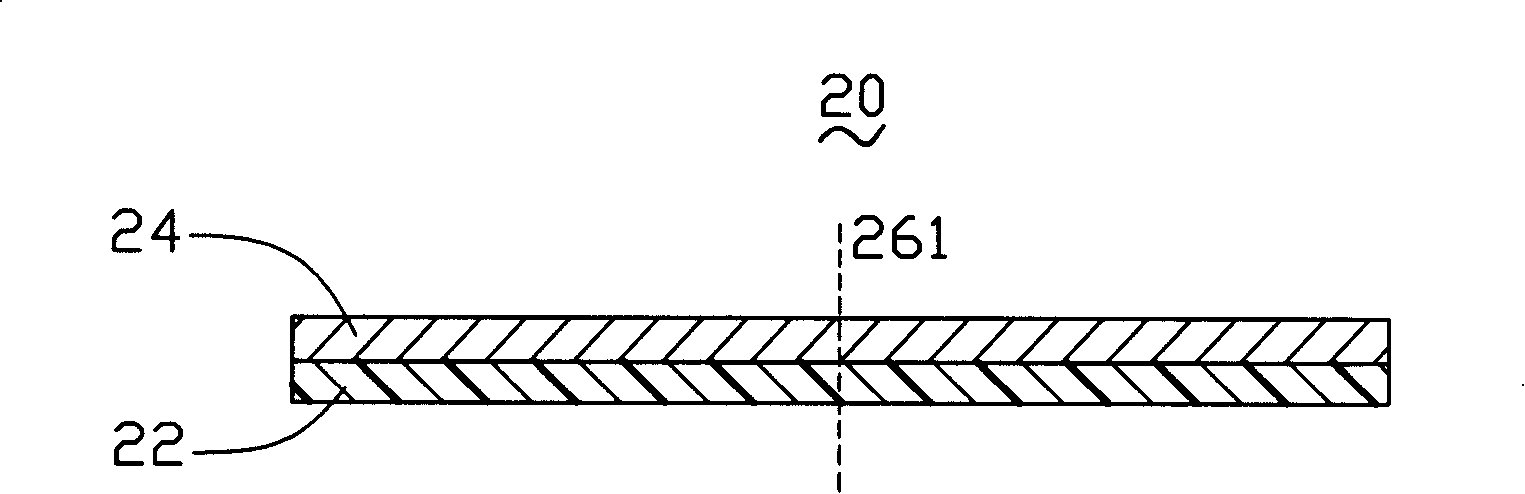

[0020] see figure 2 and image 3 Embodiment 1 provides a flexible printed circuit board 20, the flexible printed circuit board 20 is a single-layer printed circuit board composed of a base material layer 22 and a copper conductive layer 24. The flexible printed circuit board 20 has a bending portion 26 that can be bent along a bending line 261 . The bent portion 26 has a first edge 262 and a second edge 263 . The bent portion 26 includes a signal line wiring area 27 and a ground line wiring area 28 . The signal line wiring area 27 and the ground line wiring area 28 are located on the same copper conductive layer 24 , and the ground line wiring area 28 surrounds the signal line wiring area 27 . In this embodiment, the bending portion 26 of the flexible printed circuit board 20 includes two ground wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com