Technological process for selective plating copper on through holes of flexible multiple layered printing circuit board

A technology of multi-layer printing and process method, which is applied in the direction of electrical connection formation of printed components, etc., can solve the problems of inflexibility and poor bending of flexible multi-layer printed circuit boards, so as to increase the number of bending times and increase flexibility. degree, the effect of increasing the folding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

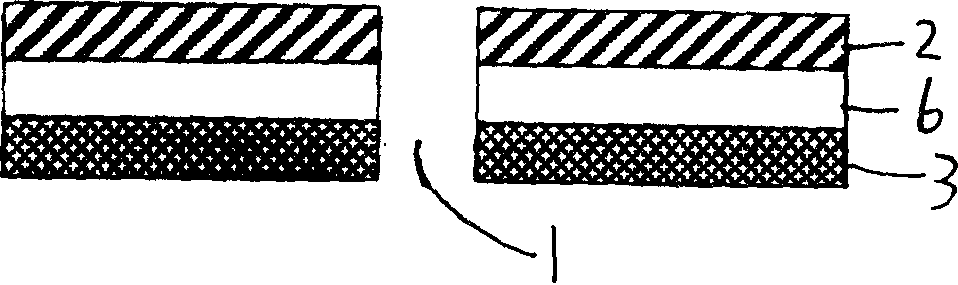

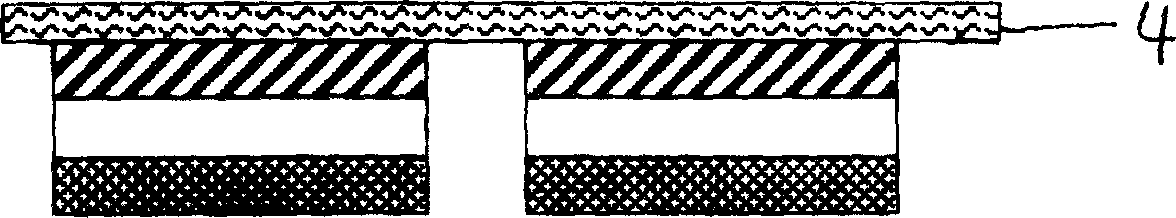

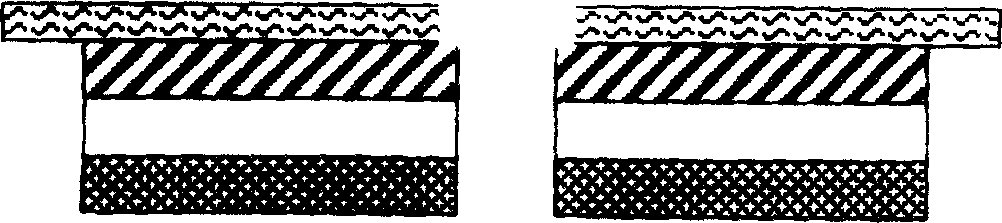

[0019] Example: see Figure 1 to Figure 5 , a process method for selective copper plating of via holes in flexible multilayer printed circuit boards, which is completed in the following steps: ①. Through-hole electroplating: through-hole electroplating is performed on flexible multilayer printed circuit boards with via holes drilled ; ②. Lamination: A layer of dry film is laminated on the flexible multilayer printed circuit board after through-hole plating; ③. Exposure: Use the principle of film exposure to expose the dry film at the position of the via hole, and the dry film at other positions Reserve; ④. Imaging: develop the via hole ring on the copper foil, that is, remove the dry film on the via hole; ⑤. Copper plating: At this time, except for the position of the via hole ring, other Some parts are covered with dry film, so that when electroplating, only the via holes are electroplated; ⑥. Stripping: peel off the dry film with the principle of chemical liquid reaction.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com