Manufacturing process of waterproof crazy horse leather

A manufacturing process and leather technology, applied to special surfaces, pre-treated surfaces, and devices for coating liquids on surfaces, etc., can solve the problems of reducing the number of times of bending and using crazy horse leather, shortening the service life, etc., and improving the waterproof effect , a wide range of options, and the effect of improving the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

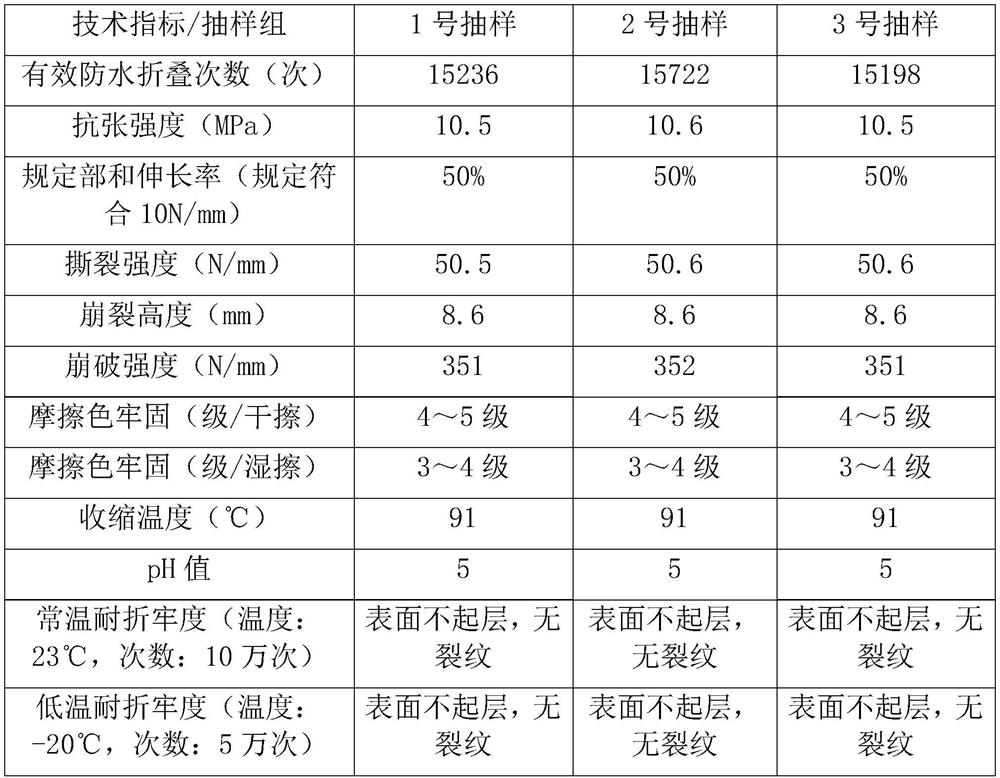

[0040] A kind of waterproof crazy horse leather manufacturing process provided in this embodiment is to use two-layer cowhide as the main material, and by bonding wet base on the surface of the two-layer cowhide, and spraying film to fix it, the obtained crazy horse leather can have Approximate the feel and effect of the first layer of cowhide, including the following steps:

[0041] Step 1 is to prepare materials, take a suitable size of two-layer cowhide that has been waterproofed, and carry out the pretreatment of washing, processing and drying to clean the surface pollutants of the second-layer cowhide to ensure smooth post-processing. After the two-layer cowhide is waterproofed, and the characteristics of the leather itself to isolate water molecules can ensure that the processed Crazy Horse Leather has good waterproof performance. At the same time, a certain amount of Pu glue, DMF (dimethylformamide) solvent and wood fiber powder were prepared as raw materials for the we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com