A chemical tempering method for ultrathin unequal-thickness glass

A chemical tempering and non-uniform thickness technology, which is applied in the tempering of glass, glass manufacturing equipment, manufacturing tools, etc., to achieve the effect of excellent bending performance, high bending times, and small bending radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

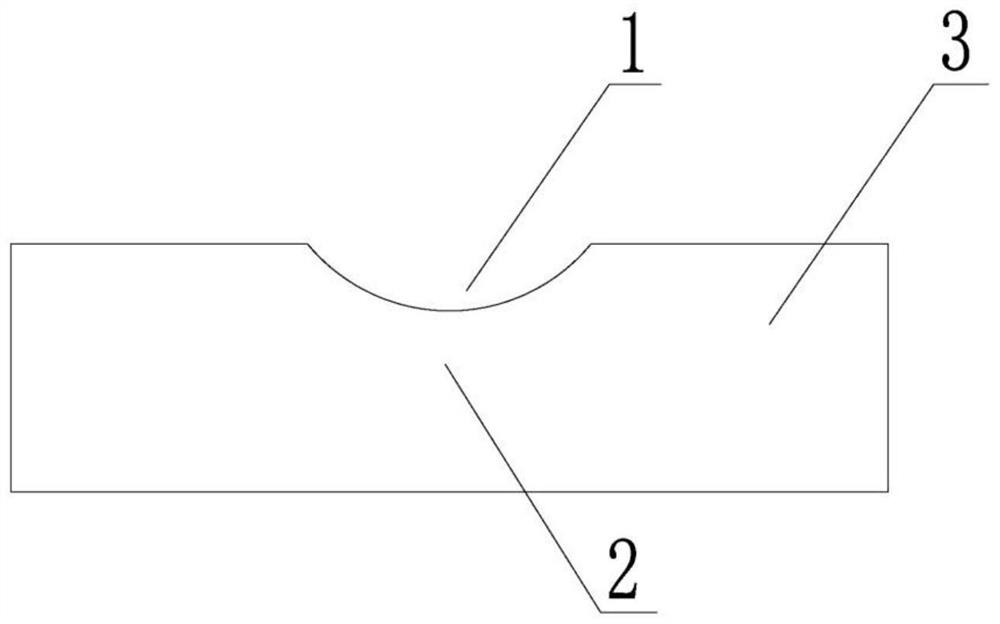

Image

Examples

Embodiment 1

[0043] The method for chemically tempering the above non-equal thickness glass comprises the following steps:

[0044] 1) Coating of the non-equal thickness area: After covering the surface of the non-equal thickness area 3 of the non-equal thickness glass with PET film protection, the upper surface of the non-equal thickness area 2 of the non-equal thickness glass is protected by coating. The film used The material is silicon dioxide, and the thickness of the coating is

[0045] 2) Chemical tempering: put 98-100% solid potassium nitrate into the chemical tempering tank, and heat the chemical tempering tank through the resistance wire heating system at a heating temperature of 450-470°C for 24-48 hours to chemically toughen The solid potassium nitrate in the tank is melted from solid to liquid to form a molten salt solution.

[0046] Put the non-equal thickness glass into the preheating furnace to heat, the preheating temperature is 370-400℃, put the non-equal thickness gla...

Embodiment 2

[0050] The difference from Example 1 is that the thickness of the coating film on the upper surface of the non-equal thickness region is The film material used is indium tin oxide. Put the non-equal thickness glass after coating into the preheating furnace for heating. The preheating temperature is 370-400°C. ℃, soaking for 10-60min, tempering is completed, after cooling, film peeling, cleaning, drying, inspection and packaging in the later stage, it will leave the factory.

[0051] After the above chemical tempering treatment, the thickness of the stress layer in the equal thickness zone 3 is 10-11μm, the stress value after tempering is 650-700MPa, the pen-down impact strength of the equal thickness zone is 46-48cm, and the pencil hardness is 7H; non-equal thickness The thickness of the stress layer in the non-uniform thickness area is 6-7μm, the stress value is 500-560MPa, the pen-down impact strength of the non-uniform thickness area is 28-30cm, and the pencil hardness is ...

Embodiment 3

[0053] The difference from Embodiment 1 and Embodiment 2 is that the thickness of the coating film on the upper surface of the non-equal thickness region is The film material used is antimony tin oxide. Put the non-equal thickness glass after coating into the preheating furnace for heating. The preheating temperature is 370-400°C. ℃, soaking for 10-60min, tempering is completed, after cooling, film peeling, cleaning, drying, inspection and packaging in the later stage, it will leave the factory.

[0054] After the above chemical tempering treatment, the thickness of the stress layer in the equal thickness area is 11-12μm, and the stress value after tempering is 700-750MPa; the pen-down impact strength of the equal thickness area is 46-50cm, and the pencil hardness is 7H; the non-equal thickness area The thickness of the stress layer is 7-8μm, the stress value after tempering is 550-600MPa, the pen-down impact strength is 28-30cm, and the pencil hardness is 3H; the bending rad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com