Method and system for tin crystal nucleus in-situ deposition through aluminum foil surface sol-gel method

A surface sol-gel, in-situ deposition technology, applied in electrolytic capacitors, electrical components, circuits, etc., can solve the problems of suboptimal pores, large influence of crystal nucleus distribution, limited specific capacitance improvement, etc., and achieve small size. , uniform distribution, the effect of reducing corrosion and thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

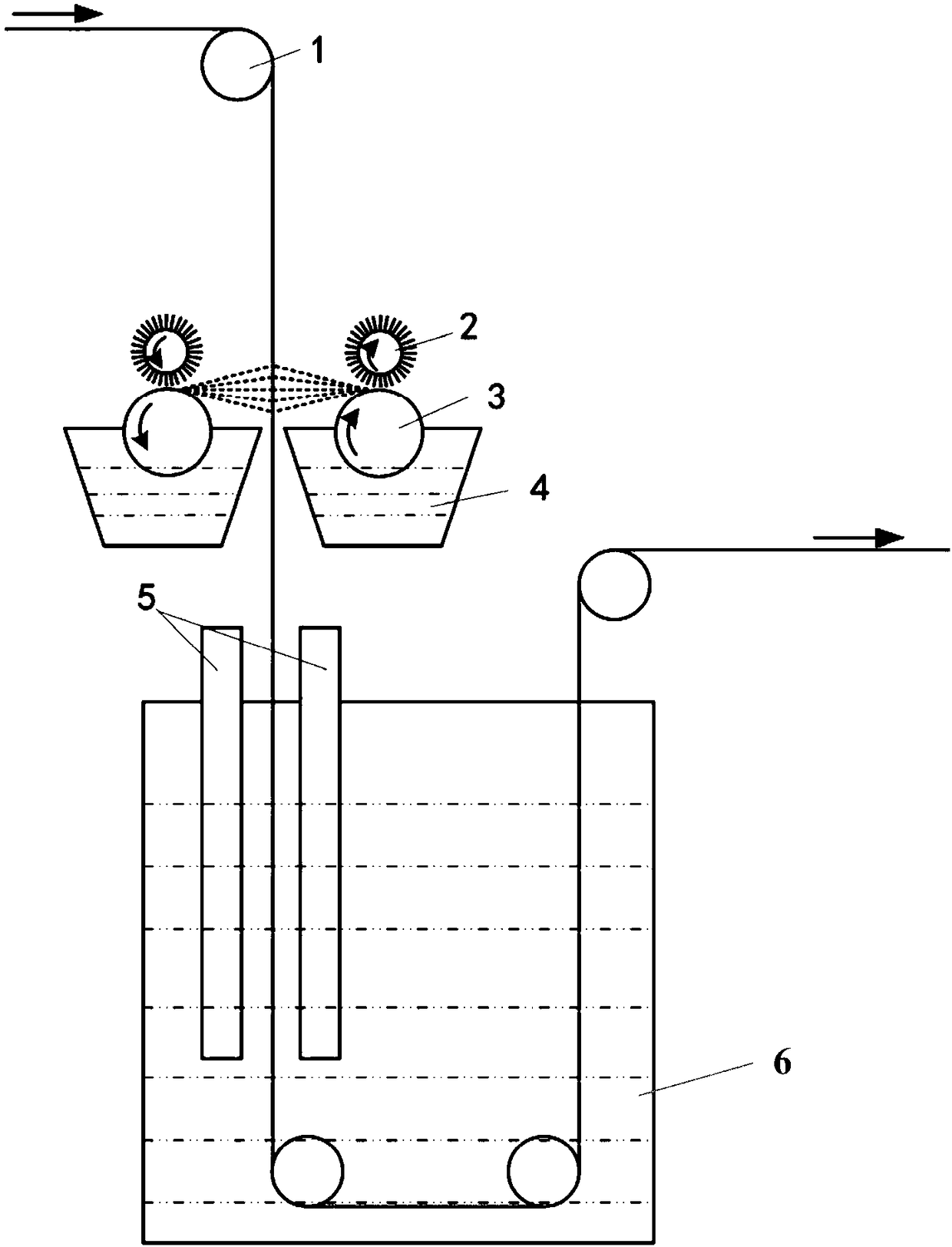

[0033] Such as figure 1 The shown system for in-situ deposition of tin nuclei by sol-gel method on the surface of aluminum foil is composed of an aluminum foil conveying device, a sol-spraying device arranged in sequence along the conveying direction of the aluminum foil, and an in-situ electrochemical dissolution deposition device for aluminum foil.

[0034] The sol throwing device is composed of two sets of sol throwing mechanisms arranged oppositely, and there is a space for the aluminum foil to pass between the two sets of sol throwing mechanisms. Both sets of sol throwing mechanisms include a sol tank 4 filled with tin sol solution, a feeding roller 3 and a bristle roller 2 with bristles arranged from bottom to top. The middle and lower parts of the feeding roller 3 are soaked in the tin sol solution. The bristles of the roller 2 are in contact with the peripheral surface of the feeding roller 3, and the bristles of the brush roller 2 and the feeding roller 3 rotate in th...

Embodiment 2

[0039] (1) The finished aluminum foil is recrystallized and annealed to form an Al with a purity of 99.99%, a thickness of 110 μm, a {100} surface texture occupancy of more than 95%, and trace amounts of Fe, Si, Cu, Zn, Ga, Mn on the surface and Aluminum foil not enriched with Pb.

[0040] (2) Pretreat the aluminum foil after recrystallization annealing in a solution containing 1.5mol / L sodium carbonate + 0.5mol / L sodium silicate + 1mol / L sodium hydroxide. The pretreatment temperature is 60°C and the time is For 20s, remove the dense oxide film formed after recrystallization annealing on both surfaces of the aluminum foil.

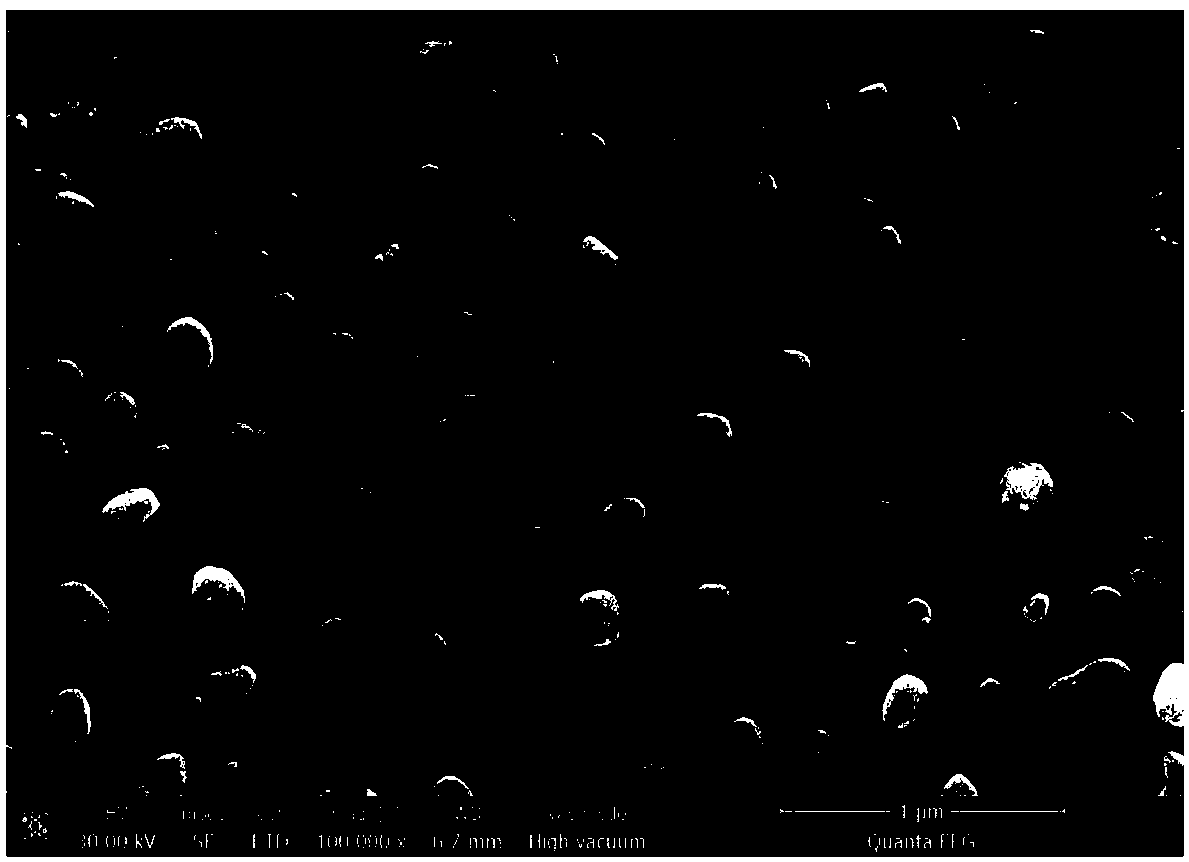

[0041] (3) throwing 0.1mol / L tin sol to the two surfaces of the pretreated aluminum foil, the temperature of the throwing sol is 40°C, the time is 10s, and the speed ratio between the brush roller 2 and the feeding roller 3 is 2, thus A uniform tin hydroxide sol layer with colloidal thickness is formed on both surfaces of the aluminum foil.

[0042] (4) ...

Embodiment 3

[0047] (1) The finished aluminum foil is recrystallized and annealed to form an Al with a purity of 99.99%, a thickness of 110 μm, a {100} surface texture occupancy of more than 95%, and trace amounts of Fe, Si, Cu, Zn, Ga, Mn on the surface and Aluminum foil not enriched with Pb.

[0048] (2) The aluminum foil after the recrystallization annealing treatment is pretreated in a solution containing 1.5mol / L sodium carbonate+0.5mol / L sodium silicate+1mol / L sodium hydroxide+0.2mol / L sodium citrate, The pretreatment temperature is 60° C. and the time is 20 s to remove the dense oxide film formed after recrystallization annealing on both surfaces of the aluminum foil.

[0049] (3) throwing 0.1mol / L tin sol to the surface of the pretreated aluminum foil, the temperature of the throwing sol is 40°C, the time is 10s, and the speed ratio between the brush roller 2 and the feeding roller 3 is 3, thus in A uniform tin hydroxide sol layer with colloidal thickness is formed on both surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com