Technique for producing high-strength copper covered steel conductor for coaxial cable inner core wire

A coaxial cable and production process technology, applied in the field of high-strength copper-clad steel conductors, can solve the problem of high yield limit, reduce environmental pollution, improve tensile strength, and eliminate internal stress.

Active Publication Date: 2010-11-24

ZHEJIANG PUJIANG BAICHUAN IND

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the technical defects in the production process of the existing high-strength copper-clad steel conductor for the inner core wire of the coaxial cable. Production process of high-strength copper-clad steel conductors for coaxial cable inner core wires that can reduce pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

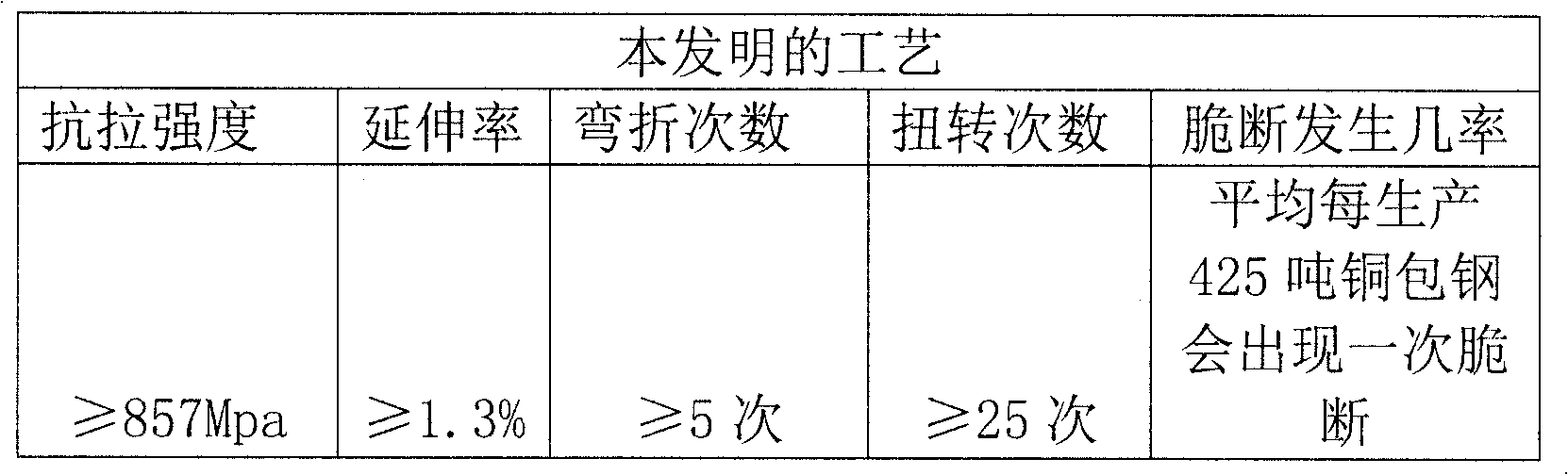

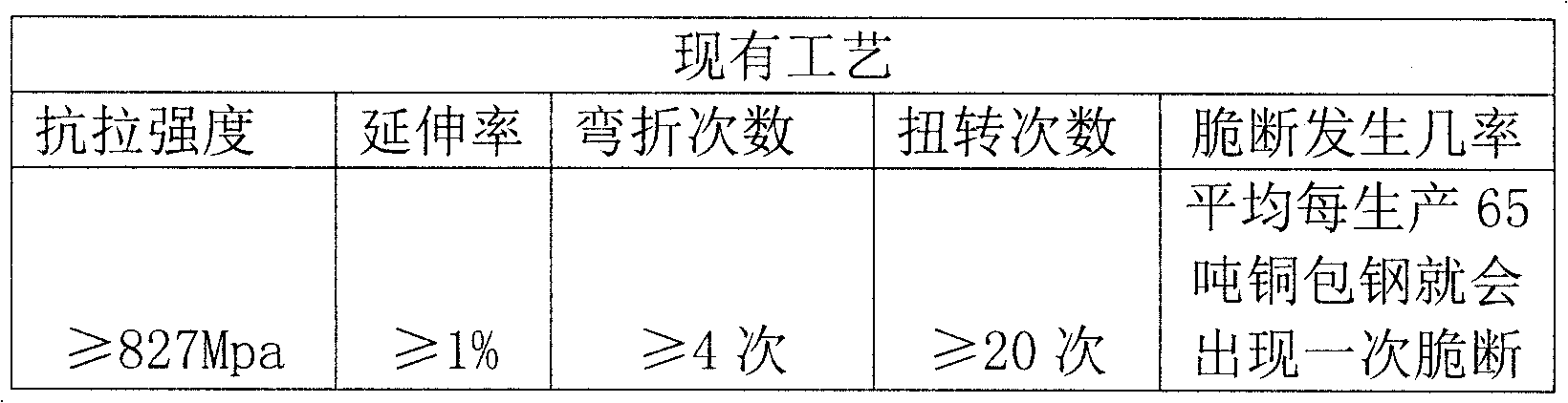

The invention relates to a high-strength copper-clad steel conductor. A production technique of a high-strength copper-clad steel conductor used for an inner core wire of a coaxial cable is characterized by comprising the following steps: rough drawing, medium temperature tempering, oxide layer removal, fine drawing, treatment before electro-deposition, acid electrolysis, washing, pretreatment ofelectro-deposition, washing, thick treatment of the electro-deposition, washing, oxidation protection, drying, tank wire drawing, washing, oxidation protection, drying and collecting lines and tray filling. Physical properties such as tensile strength, elongation, small reduction of area and bending times of the high-strength copper-clad steel conductor produced by the technique are enhanced.

Description

Production process of high-strength copper-clad steel conductor for inner core wire of coaxial cable technical field The invention relates to a high-strength copper-clad steel conductor, in particular to a production process for a high-strength copper-clad steel conductor used for the inner core wire of a coaxial cable. Background technique The high-strength copper-clad steel conductor for the inner core wire of the coaxial cable is a new type of bimetal composite material made of high-quality low-carbon steel wire base material with a diameter of 6.5mm as the base material, which is electrodeposited and drawn. This product not only has the electrical conductivity and high-frequency performance of copper, but also has the toughness of steel. Compared with the traditional pure copper wire, it has the advantages of light weight, low cost, and various performance indicators are higher than or similar to pure copper wire. A good substitute for pure copper wire. It has been wid...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01B1/02H01B13/00

Inventor 张荣良

Owner ZHEJIANG PUJIANG BAICHUAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com