Machining process of rotation-torsion threaded copper pipe

A processing technology and threaded pipe technology, which is applied in the field of copper processing technology for twisted threaded pipes, can solve the problems of unstable molding quality, slow production speed, and low bending times, reduce processing costs and material costs, and improve production efficiency , Improve the effect of compressive strength and bending times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

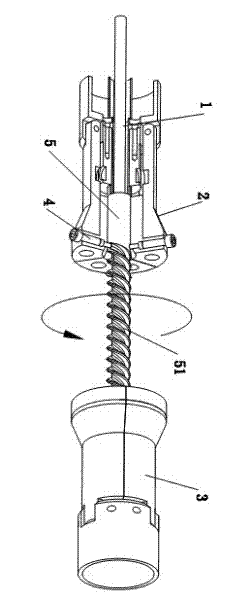

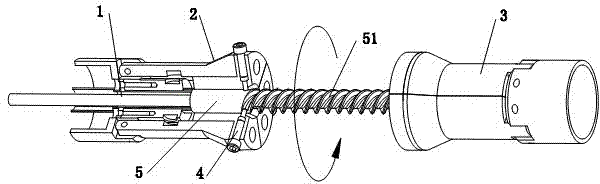

[0012] It is a processing technology of twisted threaded tube copper. The copper tube with wall thickness T=0.7±0.03mm is selected. The state of the copper tube is TP2Y2, which is No. 2 deoxidized phosphorus copper with 99.90% copper and a hardness of 90-100HV. , HV refers to the Vickers hardness; then use a metal cutting machine to cut the processed copper tube, cut it into the same length of copper tube to be processed, clean and dry with water-soluble cleaning agent; the feature of the present invention is to The copper pipe 5 to be processed after drying is sent to the threaded pipe machine place through the conveying device, such as figure 1 As shown, and penetrate the mandrel 1 in the copper pipe to be processed, one end of the copper pipe to be processed and the mandrel is clamped in the first chuck 3 of the threaded pipe machine and fixed, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com