Vertical drying and curing process for non-oriented silicon steel low-temperature chromium-free environment-friendly insulating coating

A vertical drying and insulating coating technology, which is applied to coatings, manufacturing tools, and devices for coating liquid on the surface, etc. It can solve problems such as polluted water sources, toxicity and hazards of hexavalent chromium, and achieves convenient operation and excellent performance. The effect of insulation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions and effects of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

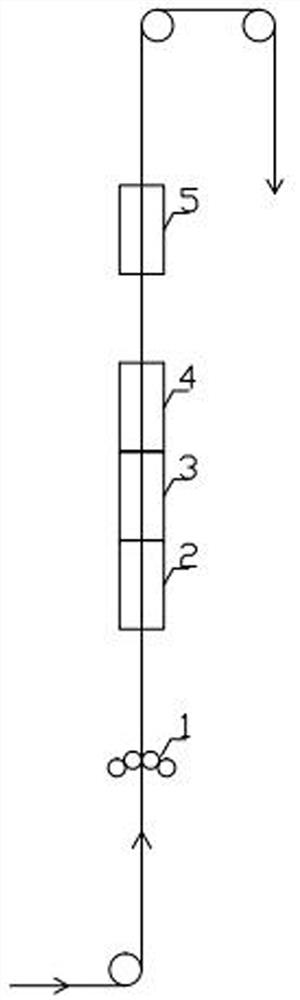

[0025] The vertical drying and curing process of the non-oriented silicon steel low-temperature chromium-free environmental protection insulating coating in the embodiment of the present invention is completed in a vertical galvanizing unit. The cold-rolled non-oriented silicon steel coil with a thickness of 0.5mm is firstly recrystallized and annealed in a vertical annealing furnace, then passed through a coating machine 1 to coat a low-temperature chromium-free environmental protection insulating coating, and then heated in a vertical drying furnace for a section 2 , The second section of vertical drying furnace heating 3, the third section of vertical drying oven heating 4, and the cooling section 5 are dried and solidified, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com