Annealing method for total nitrogen produced cold-rolled non-oriented electrical steel

A technology of grain-oriented electrical steel and nitrogen, applied in the field of steel rolling production, can solve the problems of high energy consumption, increased production cost, long process, etc., and achieves saving coating liquid usage, good insulation and punching properties, and saving gas consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

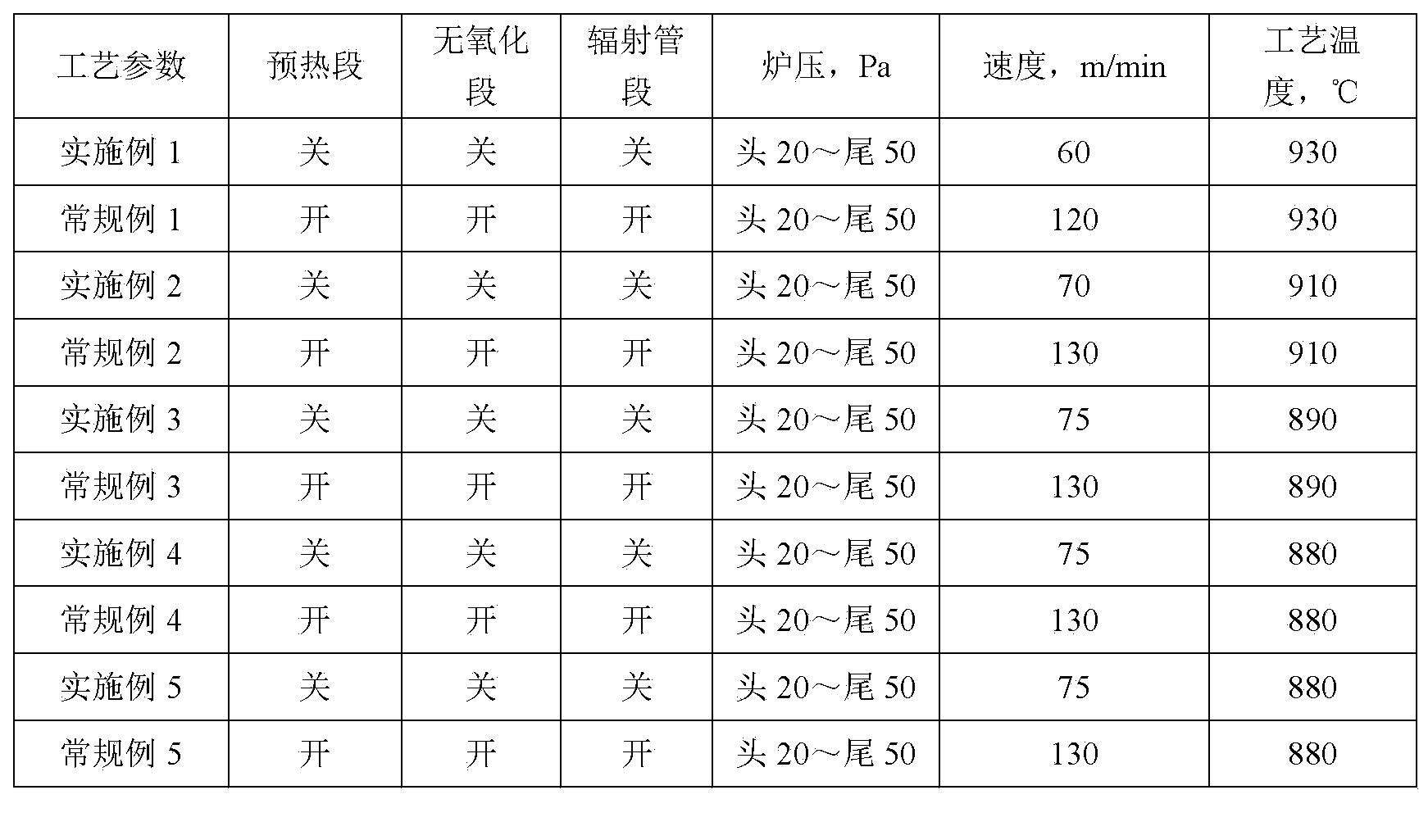

[0017] Describe below in conjunction with specific embodiment:

[0018] The present invention adopts a horizontal continuous annealing furnace. The annealing furnace has a total length of 295m, consisting of 2 sections of preheating furnace (PH), 5 sections of non-oxidizing heating furnace (NOF), 5 sections of radiant tube heating furnace (RTF), 14 sections of soaking furnace (SF), and circulating protective gas cooler (RJC), the furnace shell is an airtight welded structure.

[0019] 1) Close the preheating furnace section, non-oxidizing heating furnace section, and radiant tube heating furnace section to keep them in the shutdown state.

[0020] 2) Turn on the soaking furnace section, and when the process temperature is 850-950°C, pass in nitrogen for purging, and control the furnace pressure to 20-50MPa.

[0021] 3) The main purpose of controlling the strip speed to 50~120 m / min and the flow rate of the circulating gas cooler is to control the plate temperature to 650°C t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com