Patents

Literature

33 results about "Bactericidin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

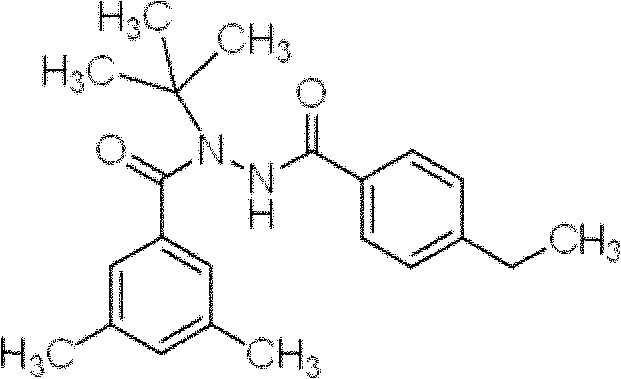

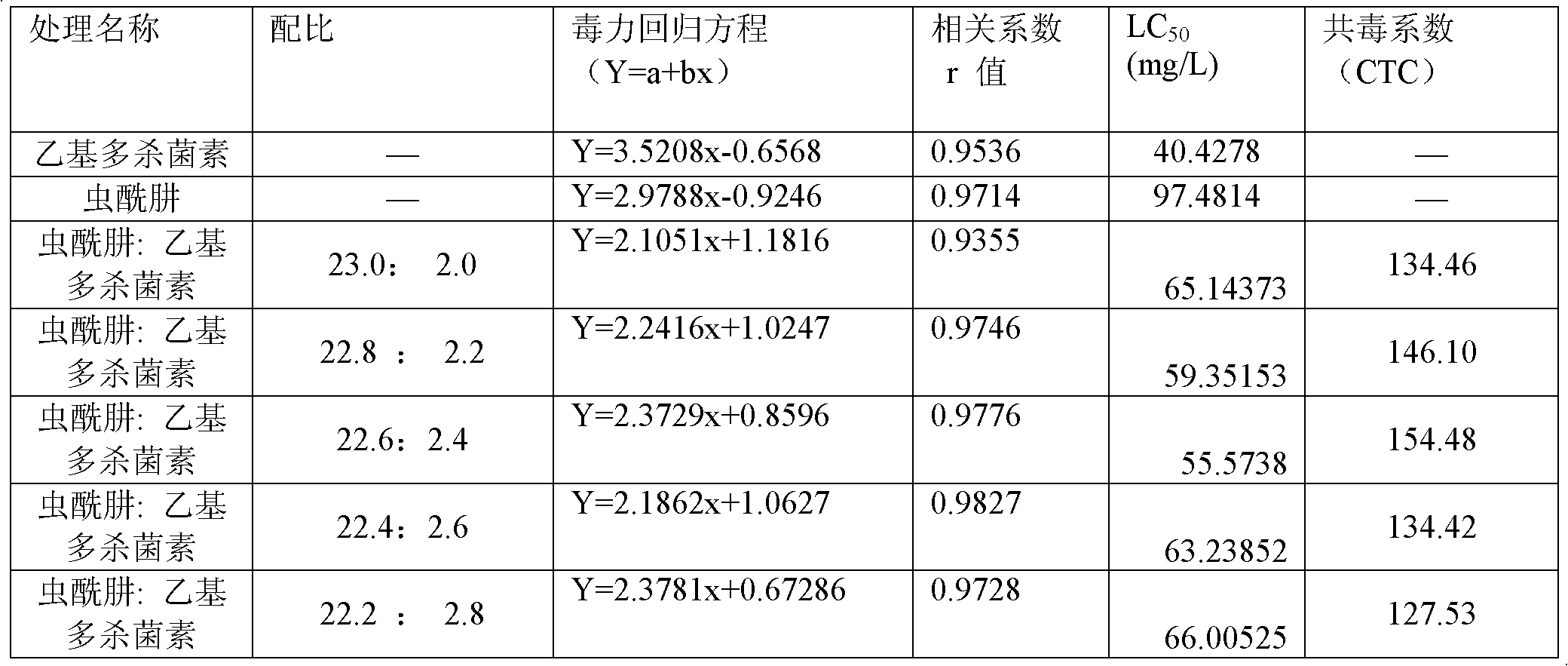

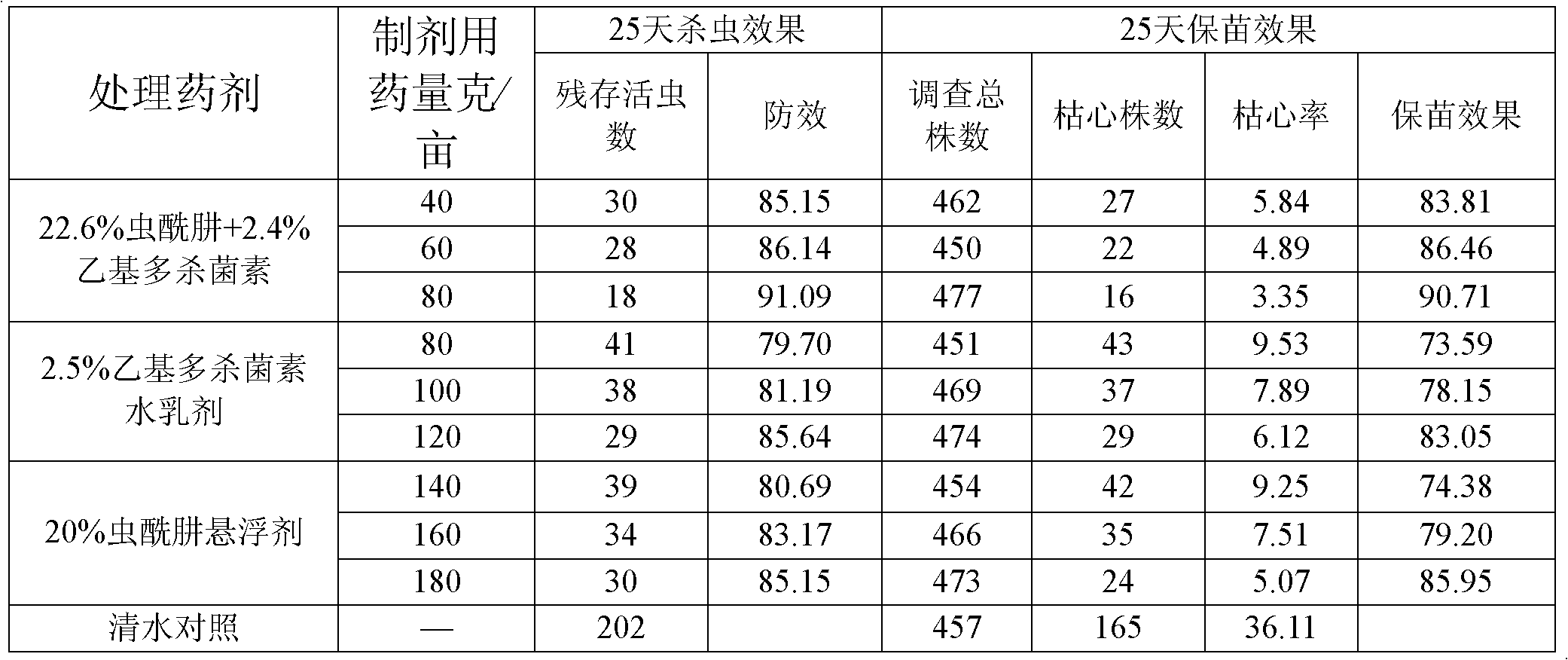

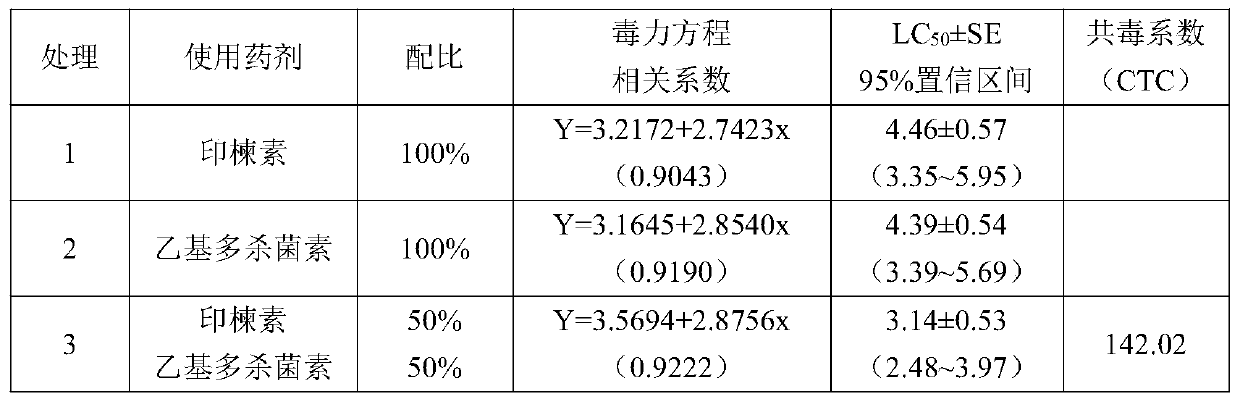

Ethyl pleocidin and tebufenozide-containing insecticidal composition

The invention discloses an ethyl pleocidin and tebufenozide-containing insecticidal composition and a preparation method and application thereof. The insecticidal composition is characterized by comprising ethyl pleocidin, tebufenozide and other aids, wherein a weight ratio of the ethyl pleocidin to the tebufenozide is 1:300-1:1. The insecticidal composition can be applied to the prevention and control of chewing and piercing-sucking type pests, mites and the like, and has the advantages of wide application range, low cost and good effect. Experiments prove that the composition has the obvious synergistic effect, and reports on mixing the ethyl pleocidin and the tebufenozide do not occur at home and abroad, so the insecticidal composition is provided.

Owner:HAILIR PESTICIDES & CHEM GRP

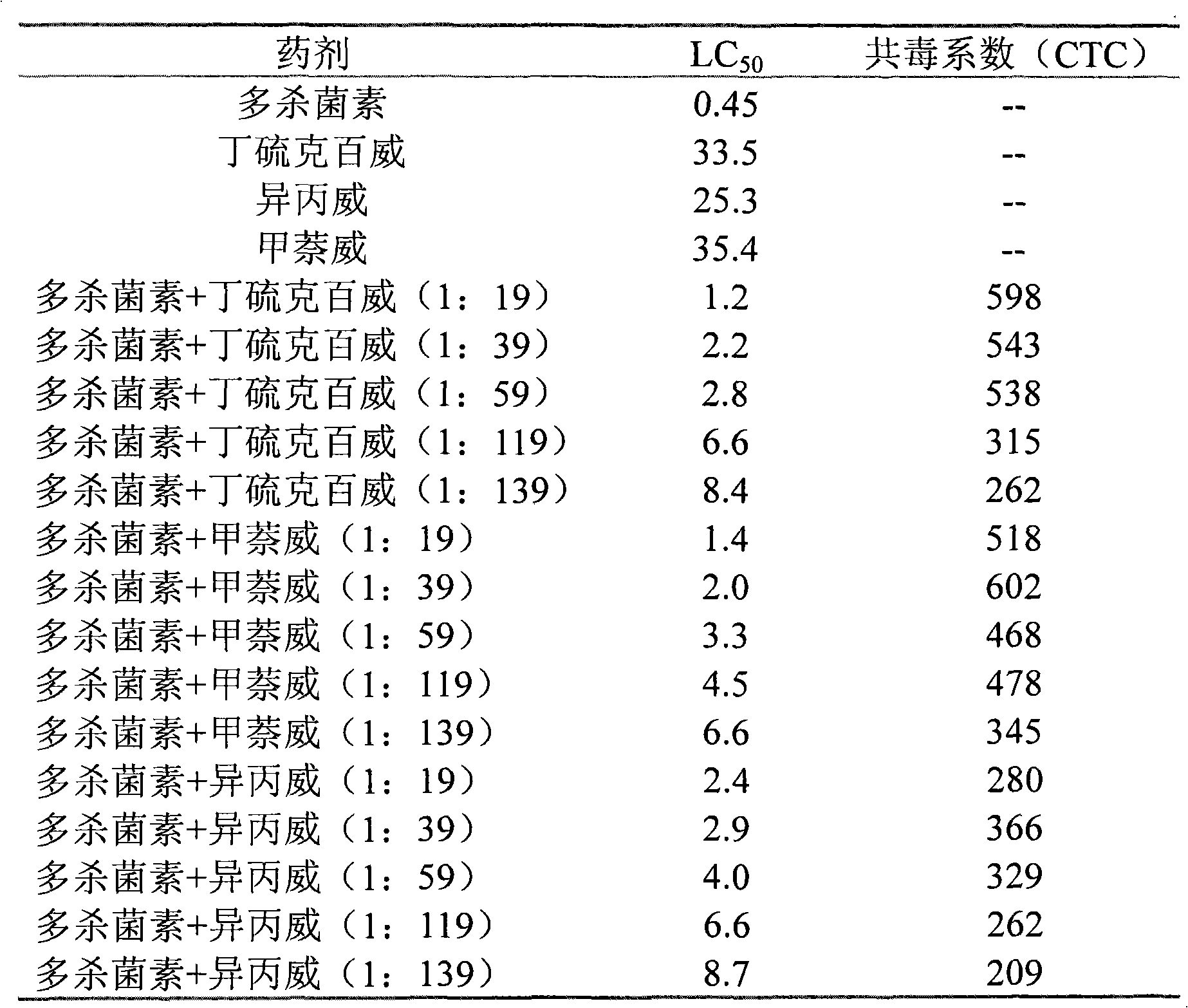

Agricultural chemical composition containing multiple bactericidins and carbamate inecticides

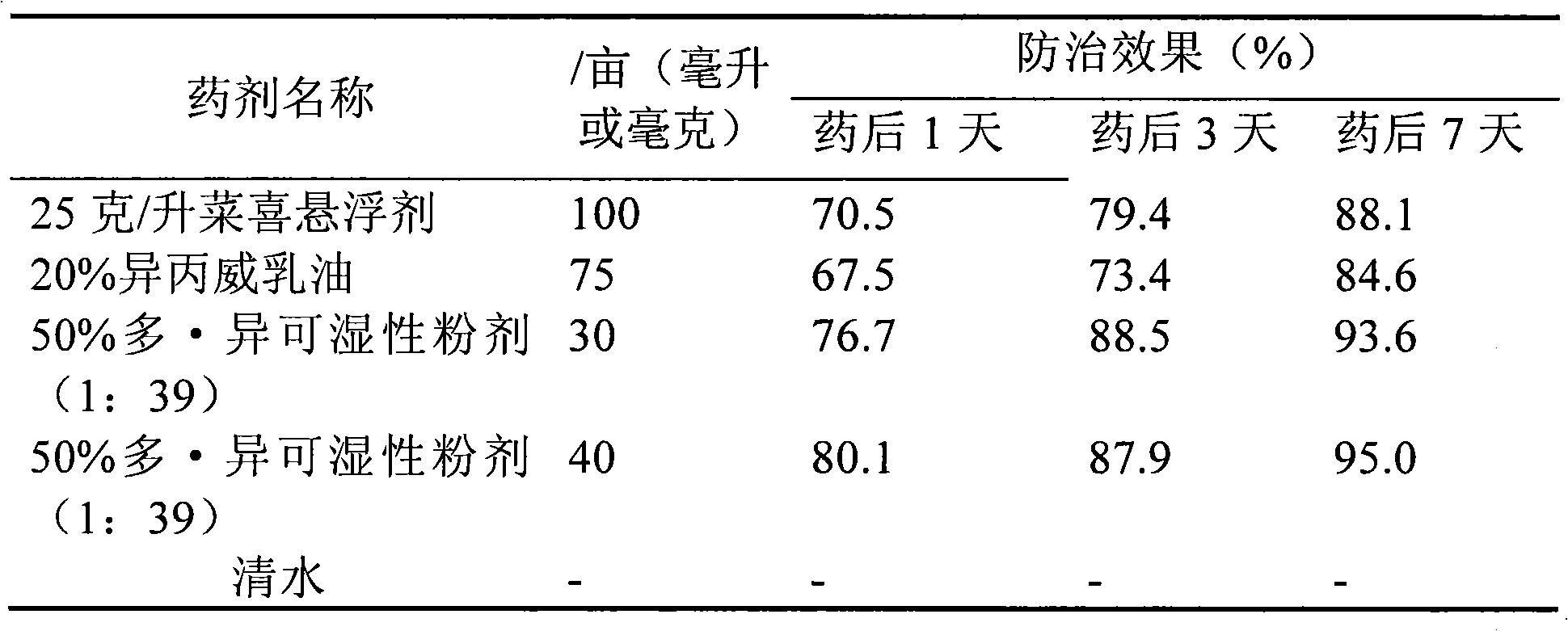

The invention relates to a pesticide composition, in particular to a pesticide composition containing dosis efficax synergism pesticide of pleocidin and carbamates, wherein the weight ratio of the pleocidin and the carbamates is selected preferably (1:0.1)-(1:200), more preferably (1:1)-(1:150) and most preferably (1:19)-(1:139).

Owner:CHINA AGRI UNIV

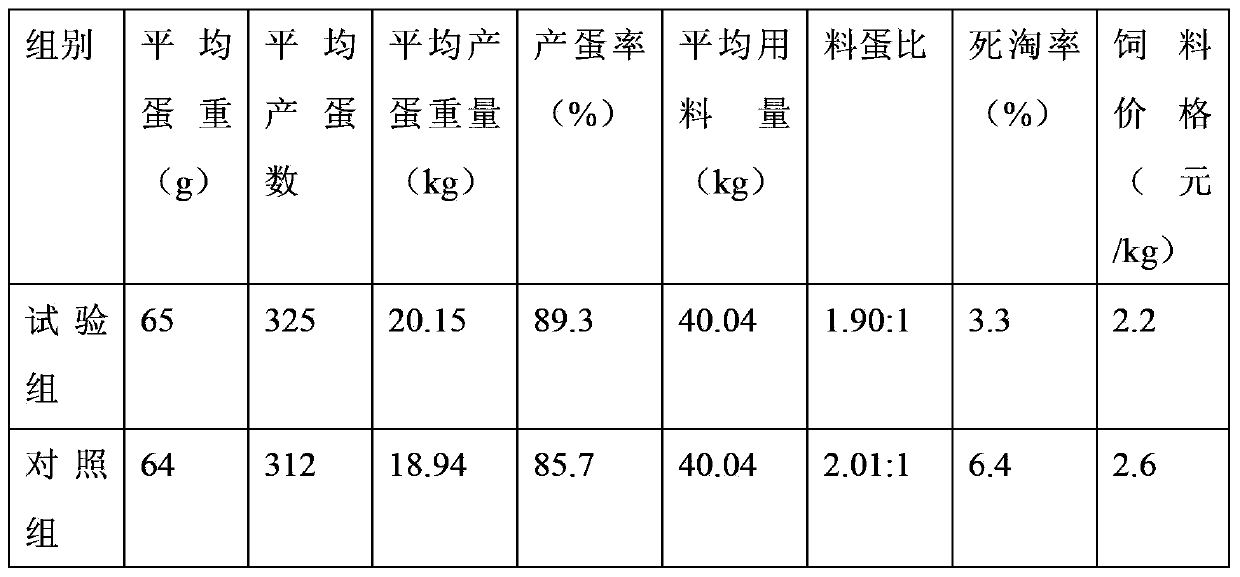

Laying hen pellet feed and preparation method thereof

ActiveCN103416636AInhibition of growth and reproductionImprove immunityAnimal feeding stuffPlant hormoneAnimal science

The invention discloses laying hen pellet feed and a preparation method thereof. The laying hen pellet feed comprises the following components in parts by weight: 30-50 parts of maize, 10-30 parts of soybean meal, 2-6 parts of bran, 4-14 parts of kudzu vine, 6-18 parts of peanut straw, 2-8 parts of pine needle power, 3-11 parts of stone power and 0.1-0.5 part of salt. The invention further discloses the preparation method of the laying hen pellet feed. The kudzu vine and the peanut straw rich in protein and amino-acid are added to a formula of the laying hen pellet feed. The maize and the soybean meal contain considerable calcium, which can greatly reduce the rate of egg breaking during the later period of egg-laying. The pine needle power contains considerable amino-acid and microelements, and is used for substituting for traditional feed additives, in addition, the pine needle power also contains biological active substances including plant hormone, plant bactericidin, unknown growth factors and the like, which can detoxify and kill inserts, restrain the growth and propagation of harmful microorganisms in organisms, and improve the immunity of the organisms, so as to improve the output and quality of eggs.

Owner:佛山播恩生物科技有限公司

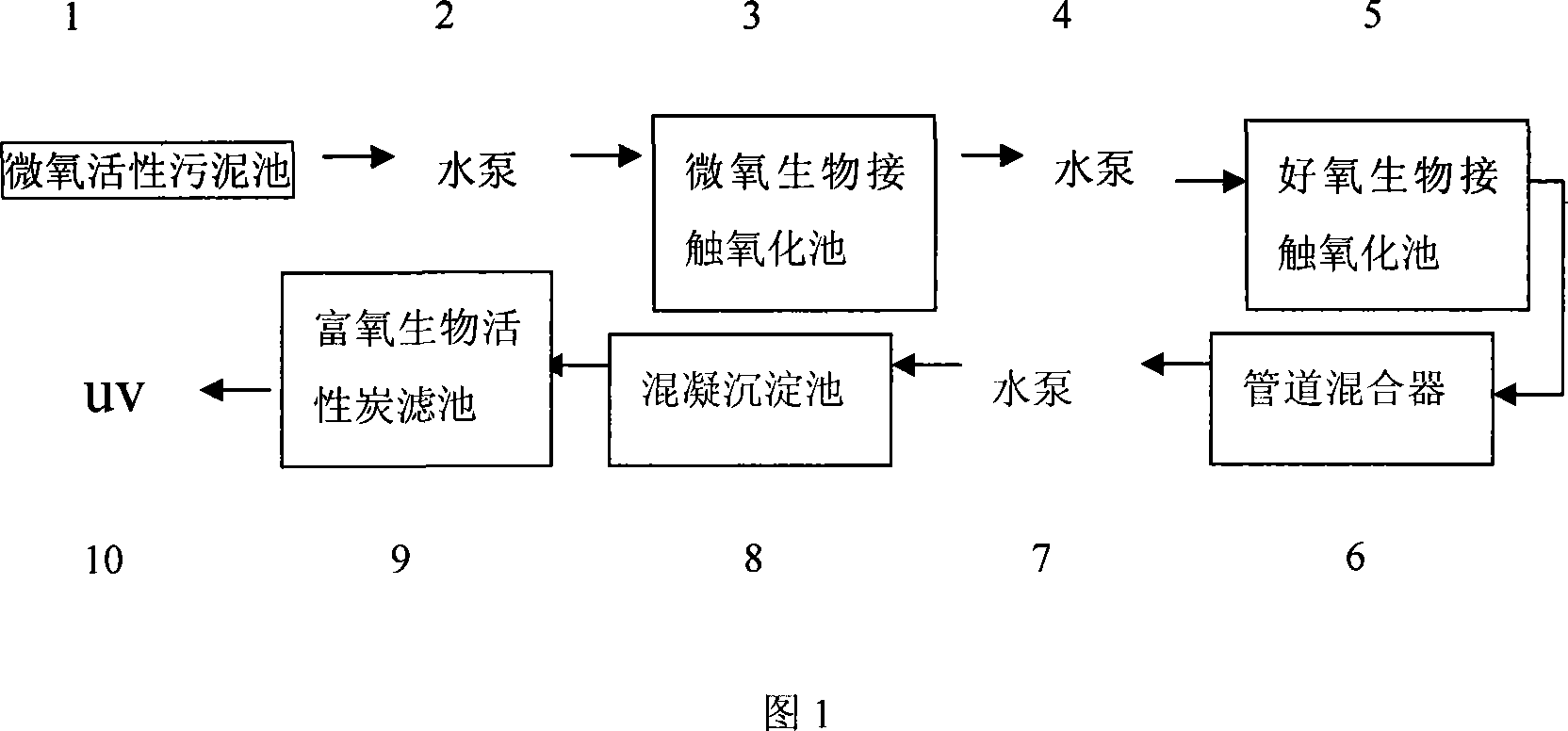

Process method for dimethyl ether production wastewater recycled for cooling water

InactiveCN101172744AWith biodegradable functionAchieve reflowTreatment using aerobic processesWater/sewage treatment by irradiationActivated sludgeBactericidin

The invention relates to a processing method for recovering the organic waste water exhausted from the dimethyl enther procedure to be used for industry circulation cooling water, and adopts the integrated system technique of anoxic activated sludge pool-anoxic biological contact oxidation pond-oxygen biological contact oxidation pond-coagulation sedimentation tank-oxygenrich biological activated carbon filtrating pool-UV bactericidin disposal technique. The biological contact oxidation pond adopts a biological filling and micropore aerating system. The anoxic biological contact oxidation degrades the organic matter under the condition of DO is 0.5 to 1.0 mg / L, and the oxygen biological contact oxidation effectively eliminates CODcr under the condition of the DO is 2 to 4mg / L. The outputted water from the oxygen biological contact oxidation pond is used for eliminating the suspended matter by coagulating and precipitation, and further is deeply processed through oxygenrich biological activated carbon filtrating pool to eliminate suspended matter and organic matter, and is finally sterilized through uv to be repeatedly used as circulation cooling water makeup water. Compared with the normal anaerobic technique, the anoxic biological processing technique eliminates the producing of the peculiar smell of H2S, and compared with the aerobic technique, the aeration quantity is reduced, the powder consumption is saved, and the anoxic biological processing technique is a new technique of biological processing. The method has the advantages of simple operation, low running expenses, small device investment and zero exhausting of waste water, and without secondary pollution.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

Insecticidal aerosol with multi-bactericidin

InactiveCN101278670AReduce pollutionImprove insecticidal effectBiocideArthropodicidesSpinosadMedicine

The invention belongs to a pesticide, which more particularly relates to a spinosad desinsection aerosol which consists of propellant and liquid medicine that are contained inside a gas spray vessel, wherein, the liquid medicine comprises the pesticide, knocking down agent, solvent, synergistic agent, etc. which are compounded by proportion, wherein the spinosad is selected as the pesticide. The invention solves the problems that mosquitoes, insects, etc. can produce drug resistance easily; the pollution to the environment is serious, etc. which exist in the product of the prior art. The pesticide which is the product of the invention has the advantages of simple preparation technical process, low toxicity, little pollution to the environment, better comprehensive desinsection effect, good stability, etc.

Owner:保定蕴生生物科技有限公司

Method for producing enramycin by fermenting

ActiveCN102943101ARaise the level of fermentationSolve the problem of insufficient dissolved oxygenMicroorganism based processesFermentationBactericidinOxygen

The invention relates to a method for producing enramycin by fermenting. According to the method, bactericidin streptomycete FYFJ03 is taken as a fermenting strain; during a fermenting process for constant temperature culturing, different sugar concentrations are fed under different stages; the dissolved oxygen of fermentation liquor is improved; and the fermentation level of the enramycin is increased. The method is simple and easy to carry out. After the fermentation is performed according to the method during the fermenting culturing process, the fermentation level of the enramycin is increased by about 20%.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

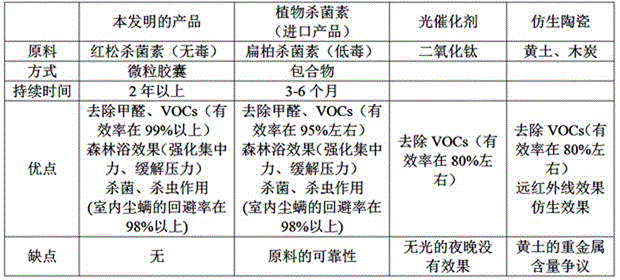

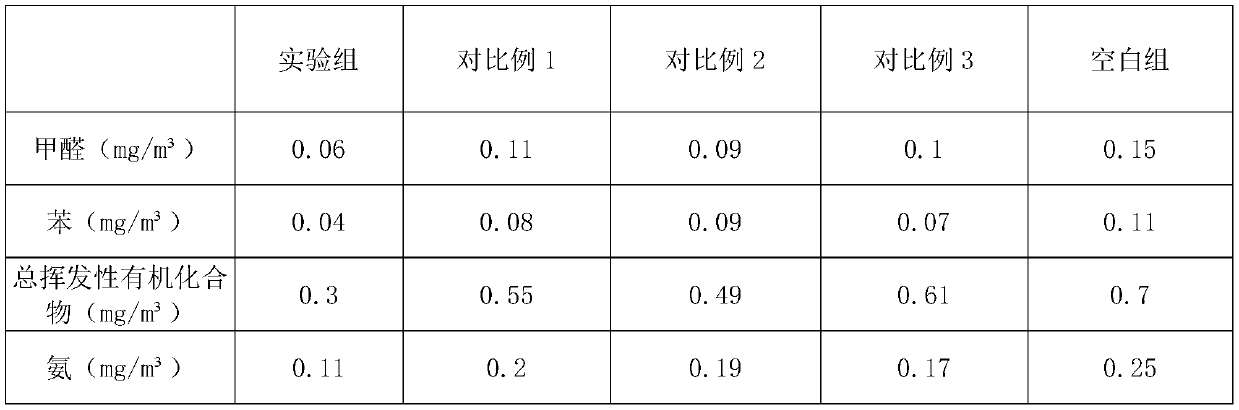

Environment-friendly coating containing pinus koraiensis phytoncide

InactiveCN105623343ABactericidalHas insecticidal effectAntifouling/underwater paintsPaints with biocidesBiotechnologyIndoor air quality

The invention discloses environment-friendly coating containing pinus koraiensis phytoncide. The environment-friendly coating contains 1-3 wt% of pinus koraiensis phytoncide. The coating has the effects of removing formaldehyde and VOCs, the effective rate is 99% or above, the coating further has the effects of killing bacteria and dust mites, removing ammonia gas and improving the indoor air quality, the indoor dust mite avoiding rate is 98% or above, meanwhile, pressure of people can be relieved, concentration is strengthened, and the learning efficiency is improved. Because the micro capsulation technology is adopted, the medicine efficiency can lasts for a long time (three years or above), and the market prospects are quite broad.

Owner:FUJIAN LESHIBI ENVIRONMENTAL TECH CO LTD

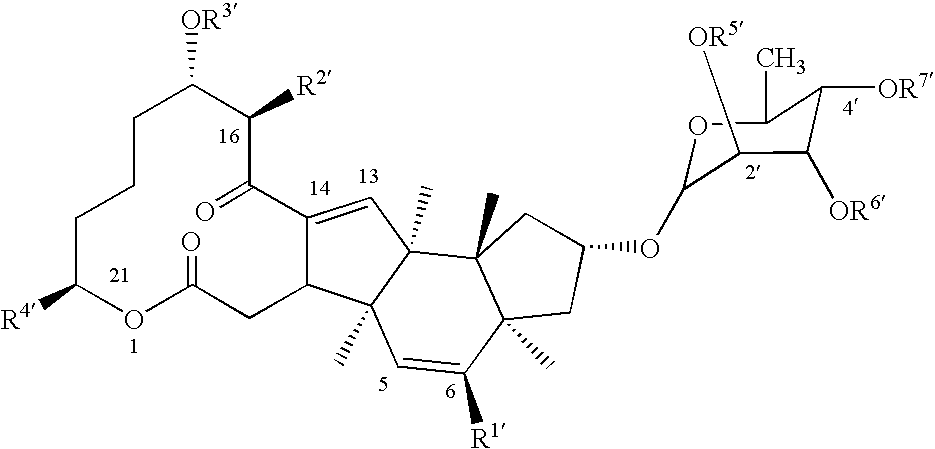

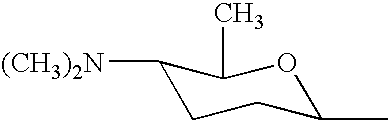

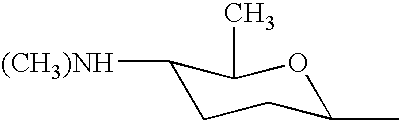

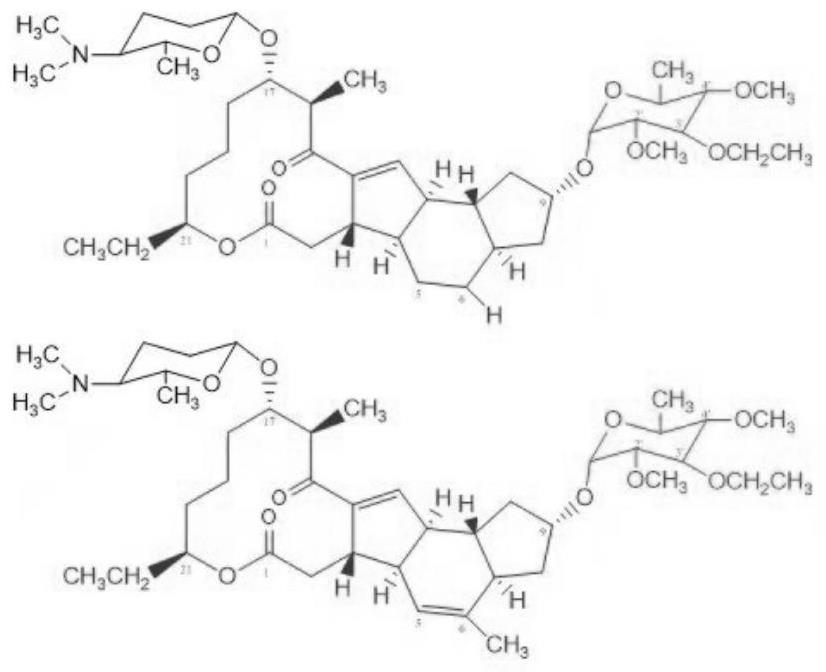

Biosynthetic genes for spinosyn insecticide production

InactiveUS20040023343A1Altered spinosyn synthesisInhibit productionFungiBacteriaBiotechnologySpinosad

Spinosyn biosynthetic genes, spinosyn producing microorganisms transformed with the biosynthetic genes, methods using the biosynthetic genes to increase production of spinosyn insecticidal macrolides, and methods using the genes or fragments thereof to change the products produced by spinosyn-producing microorganisms.

Owner:DOW AGROSCIENCES LLC

Itching-relieving cream for mosquito bites

InactiveCN107669573AAnti-inflammatoryFast swellingAntibacterial agentsCosmetic preparationsVitamin CMedicine

The invention discloses an itching-relieving cream for mosquito bites. The itching-relieving cream is prepared from the following raw materials: turmeric powder, garlic, Houttuynia cordata, coptis, hawthorn, Folium Isatidis, vitamin C, coconut oil, vaseline and glycerin. The itching-relieving cream is viscous paste-like cream, and a proper amount of a preservative is added in the preparation process of the cream. As the VC with a certain concentration is smeared onto parts affected by mosquito bites, rapid itching-relieving effect is produced; the turmeric powder, garlic and the like with powerful bactericidin are added on the basis of the VC for sterilization of skin having suffered from mosquito bites, so recovery is accelerated; and Houttuynia cordata, coptis and Folium Isatidis have anti-inflammation effect and are cooperated with VC to rapidly eliminate swelling caused by mosquito bites while relive itching.

Owner:广西钱隆投资管理有限公司

Biological agent for air purification and preparation method thereof

The invention relates to a biological agent for air purification. The biological agent for air purification is prepared from a mint extract, a lemon extract, a ginger extract, a shaddock peel extract,an orange jessamine extract, a tea extract and probiotics. The invention has the following beneficial effects: the biological agent for air purification is a pure plant natural air purifying agent, contains no chemical additives, is safe and nontoxic, and is natural and fragrant. In addition, the biological agent also contains bactericidin and probiotics, can effectively kill harmfull substancesand harmful bacteria in the air, can be used for eliminating harmful substances such as formaldehyde, etc. in a general home or in indoor public places, and also can be used for removing offensive odor from factories, sewage treatment plants, livestock farms and the like.

Owner:厦门市民安创享实业有限公司

Insecticidal composition consisting of spinosad and fenobucarb

InactiveCN102027958AReduce pollutionWide range of insecticidalBiocideAnimal repellantsSpinosadBactericidin

The invention relates to an insecticidal composition consisting of spinosad and fenobucarb. The insecticidal composition comprises 0.5 to 10 percent of spinosad and 1 to 35 percent of fenobucarb. The insecticidal composition has good prevention and control effects on plutella xylostella, reduces using amount, delays medicament resistance, reduces pollution to the environment and does not cause chemical injury easily.

Owner:BEIJING YOLOO BIO TECH CORP

Active substance combinations having insecticidal and acaricidal properties

Owner:BAYER IP GMBH

Method for producing enramycin by fermenting

ActiveCN102943101BRaise the level of fermentationSolve the problem of insufficient dissolved oxygenMicroorganism based processesFermentationEnramycinBactericidin

The invention relates to a method for producing enramycin by fermenting. According to the method, bactericidin streptomycete FYFJ03 is taken as a fermenting strain; during a fermenting process for constant temperature culturing, different sugar concentrations are fed under different stages; the dissolved oxygen of fermentation liquor is improved; and the fermentation level of the enramycin is increased. The method is simple and easy to carry out. After the fermentation is performed according to the method during the fermenting culturing process, the fermentation level of the enramycin is increased by about 20%.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

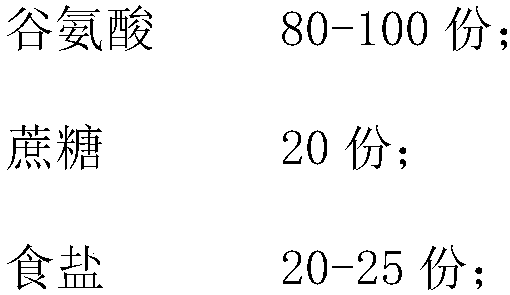

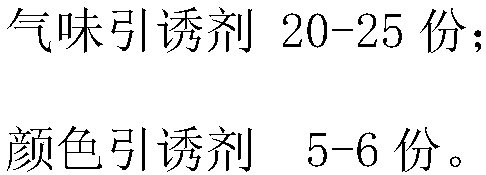

Attractant for Drosodhila suzukii Matsumura and application method thereof

InactiveCN107889829ALure effect is stableGood lure effectBiocidePest attractantsCypermethrinHigh concentration

The invention discloses an attractant for Drosodhila suzukii Matsumura and an application method thereof. The attractant is prepared by mixing glutamic acid, cane sugar, table salt, an odor attractantand a color attractant according to a weight ratio of (80-100): 20: (20-25): (20-25): (5-6). The attractant starts to exert an attracting effect when the concentration of an attractant aqueous solution is 3 g / L or above, has stronger attractive force with higher concentration, and achieves an effective distance of 5 to 30 meters. According to the invention, the Drosodhila suzukii Matsumura has acharacteristic of needing to supplement a great amount of nutrients in a period of time during the process of development; the tendency of the Drosodhila suzukii Matsumura to some colors and smells iscomprehensively utilized; the attractant is used by cooperating with pesticides like avermectin, spinosad and highly-efficient cypermethrin; thus, trap-killing and toxic-killing effects are greatly improved, and the number of a Drosodhila suzukii Matsumura population can be greatly reduced.

Owner:福州市琅岐经济区万叶园农业开发有限公司 +1

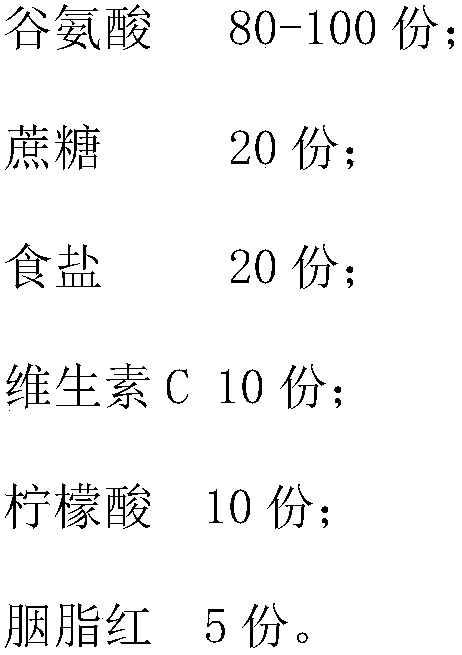

Polysaccharide and protein conjugate

InactiveCN102580073AImprove immunityRaise antibody levelsAntibacterial agentsAntibody medical ingredientsBactericidal antibodyBactericidin

The invention discloses a polysaccharide and protein conjugate. The polysaccharide and protein conjugate is formed by coupling vibrio cholerae lipopolysaccharide and cholera toxin non-toxic subunit protein, wherein the vibrio cholerae lipopolysaccharide is from vibrio cholerae 0139, the protein content in the vibrio cholerae lipopolysaccharide is not more than 2 percent, the nucleic acid content is not more than 5 percent, and the molecular weight of the vibrio cholerae lipopolysaccharide is 8Kd. The immune effect of the polysaccharide and protein conjugate is higher than that of common rBS-WC (recombinant B subunit-killed whole-cell cholera) vaccine, single LPS (lipopolysaccharide) vaccine or single CTB (cholera toxin B-subunit) vaccine, the conjugate can enhance the immunogenicity of LPS to make an induced immunity reaction have immunologic memory and potentiation effect to generate massive bactericidin, is suitable for various kinds of people, and can initiate mucosal immunity of a body to realize IgA (immunoglobulin A) antibodies massively exist in intestinal secretion fluid and bile.

Owner:INST OF BIOENG ACAD OF MILITARY MEDICAL SCI OF THE CHINESE

Broad-spectrum bactericidal medical surgical towel

The invention relates to a broad-spectrum bactericidal medical surgical towel. The broad-spectrum bactericidal medical surgical towel comprises a towel layer composed of interwoven weft and warp yarns; the surface layer and the bottom layer of the towel layer are provided with knitted fabric material layers, and the knitted fabric material layers are covered by broad-spectrum bactericidin surface yarn layers. According to the broad-spectrum bactericidal medical surgical towel, broad-spectrum bactericidin and a towel are combined with each other, the powerful broad-spectrum bactericidin can powerfully kill virus, bacteria, fungi and mycotic spores, have low skin irritation and toxicity, durable in effects and safe and convenient to use.

Owner:JIANGSU PROVINCE JIANERKANG MEDICAL DRESSING CO LTD

Industrial plating wastewater treatment process

InactiveCN105967385AEasy to separateEmission complianceWater treatment compoundsWater contaminantsSodium metabisulfiteBactericidin

The invention provides an industrial plating wastewater treatment process. The process sequentially comprises the following operating steps that the PH value of plating wastewater is adjusted to be 3 to 4; 1-20 g / L of hydrogen peroxide, 2-20 g / L of sodium metabisulphite and 0.1-10 g / L of bactericidin are added to the wastewater, stirring is conducted for 20 min to 30 min, and precipitation is conducted. According to the industrial plating wastewater treatment process, the treated plating water can be discharged up to standard, complexes can be completely decomposed, harmful impurities can be removed, and operation is easy.

Owner:JIANGSU SERO ANTICORROSION EQUIP

Red date probiotics fermented feed additive

InactiveCN110269144APromote proliferationObvious biological antagonismAnimal feeding stuffBiotechnologyFood additive

The invention discloses a red date probiotics fermented feed additive. The additive is prepared from, by mass, 95% of whole red date powder, 2% of radix astragali, 2% of radix angelicae sinensis and 1% of herba leonuri through fermentation through a beneficial viable bacteria preparation. By sufficiently using the medicine and food homologous functions of tonifying spleen, nourishing stomach and tonifying qi and blood and the advantages of high energy, high sugar content and high vitamins of red dates, the feed palatability, livestock growth rate and immunity are greatly improved. A large amount of metabolisms are generated in the fermentation process, intestinal disorder can be quite well adjusted, and the supplementing of normal flora of intestines or the promoting of the proliferation of beneficial bacteria is realized; the beneficial flora generates hydrogen peroxide, organic acid, bactericidin and the like, so the growth and plantation of aerobic bacteria and foreign pathogens are not facilitated, the remarkable biological antagonism effect is realized on pathogenic bacteria, lots of beneficial flora is provided for the health of animal intestines, and therefore balance is reached.

Owner:YANGLING VOCATIONAL & TECHN COLLEGE

Method for manufacturing special mosquito net for infants

InactiveCN107080401AHas mosquito repellent and antibacterial functionImprove adsorption capacityChildren furnitureInsect netsDracaena arboreaBactericidin

Owner:南宁东印时代广告有限公司

Child toothpaste

InactiveCN108158952APromote healthy growthInhibit tooth decayCosmetic preparationsToilet preparationsTO-18Foaming agent

The invention provides child toothpaste. The child toothpaste is characterized by being prepared from the following raw materials in parts by weight: 2 to 8 parts of xylitol, 2 to 4 parts of a naturalpreservative, 4 to 6 parts of tea polyphenol, 3 to 7 parts of citric acid, 10 to 18 parts of de-ionized water, 8 to 12 parts of glycerol, 6 to 10 parts of bactericidin, 5 to 9 parts of black sesame,2 to 4 parts of honey, 4 to 7 parts of a friction agent and 1 to 3 parts of a foaming agent. The child toothpaste provided by the invention has the advantages of inhibiting decayed teeth and protecting the teeth to grow healthily.

Owner:李思敏

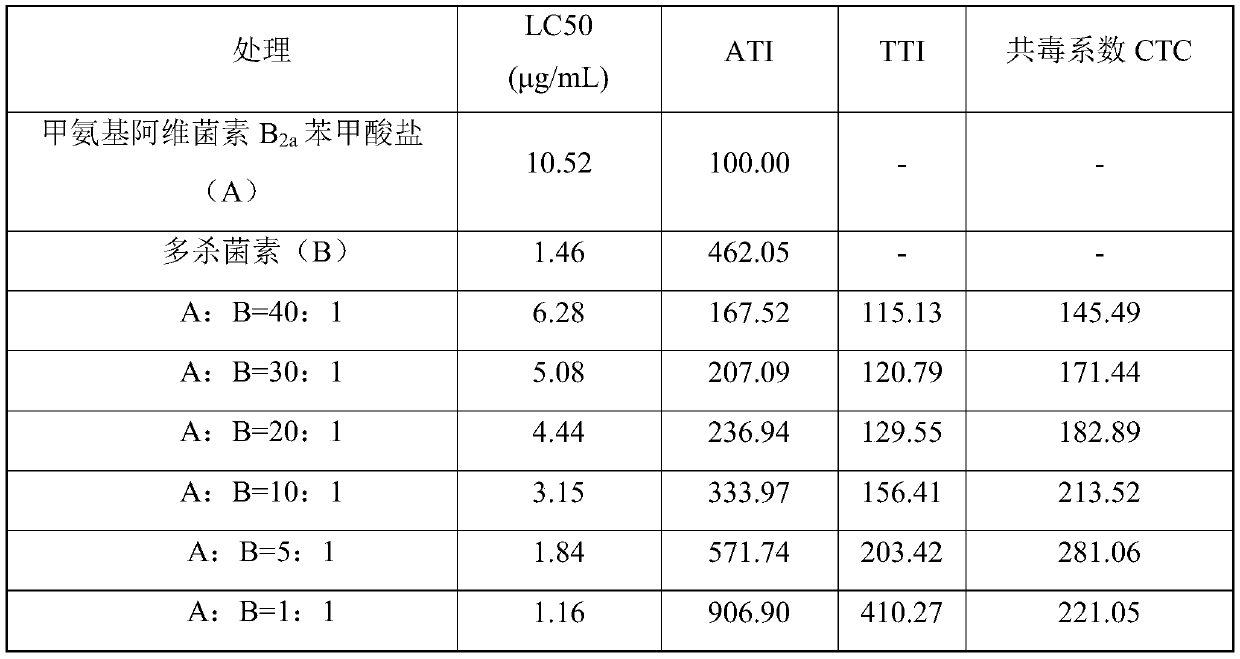

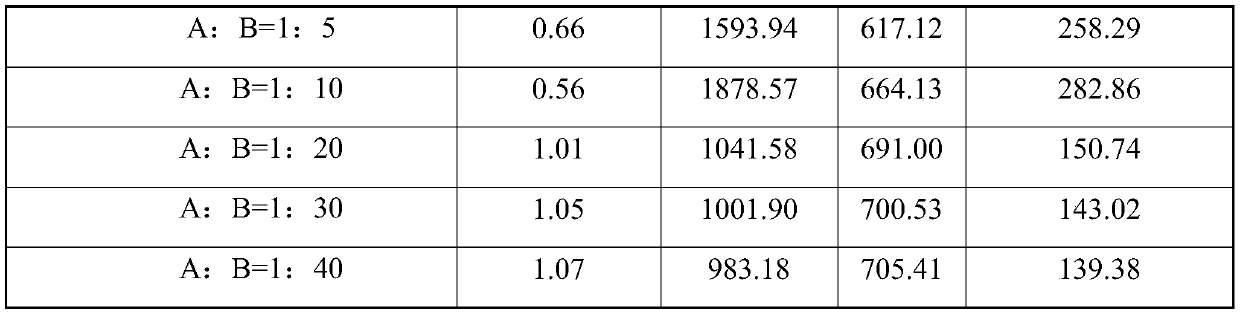

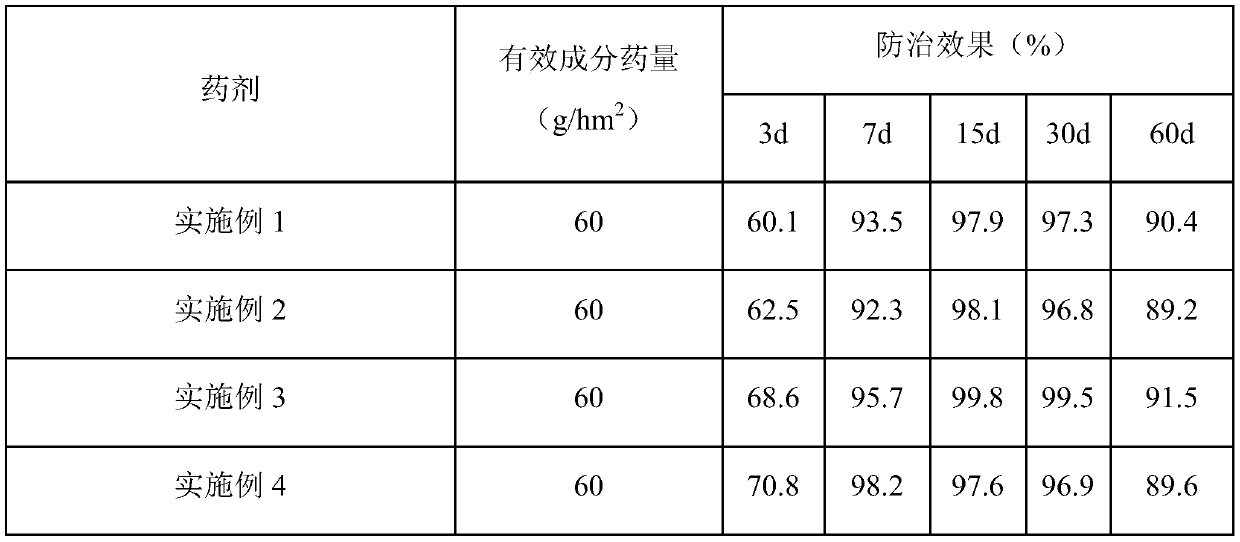

Insecticidal composition as well as preparation and application thereof

ActiveCN111466396ALower resistanceImprove the effect of prevention and controlBiocideAnimal repellantsBenzoic acidSteviolmonoside

The invention relates to the technical field of preparation of farm chemicals, and particularly discloses an insecticidal composition as well as a preparation and application thereof. According to thecomposition, emamectin B<2a> benzoate, pleocidin and steviol glycoside are compounded, wherein the emamectin B<2a> benzoate and the pleocidin are synergistic, the plant extract steviol glycoside is further added as a synergist, the synergistic interaction effect is achieved through the plant extract steviol glycoside, the emamectin B<2a> benzoate and the pleocidin; meanwhile, the special structure and fragrant and sweet taste of the steviol glycoside can attract the feeding behavior of pests, and the pesticide effect is further improved. According to the insecticidal composition provided by the invention, by selecting and compounding the raw materials with different action mechanisms, the prevention and treatment effect on thrips pests is remarkably improved, the lasting period is long, environmental compatibility is good, drug resistance of the pests is not easy to generate after long-term use, and the insecticidal composition has a great popularization value.

Owner:HEBEI VEYONG BIO CHEM

Saccharopolysporaspinosa with high yield of spinosad

ActiveCN113444659AHigh yield in shake flasksBacteriaMicroorganism based processesBiotechnologyMicroorganism

The invention discloses Saccharopolysporaspinosa with high-yield of spinosad, and belongs to the technical field of microorganisms. The Saccharopolysporaspinosa with high-yield of the spinosadis SaccharopolysporaspinosaWHU1107 with the preservation number of CCTCC NO: M 2021307, the strain is obtained after mutagenesis, the yield of the spinosad is up to 4 g / L or above after fermentation culture is conducted on the strain in a culture flask containing 25 mL of a fermentation culture medium, the yield is far higher than that of existing reported strains, and the Saccharopolysporaspinosa can be used for producing the spinosad. The invention provides a new material for industrial production of the spinosad.

Owner:WUHAN UNIV

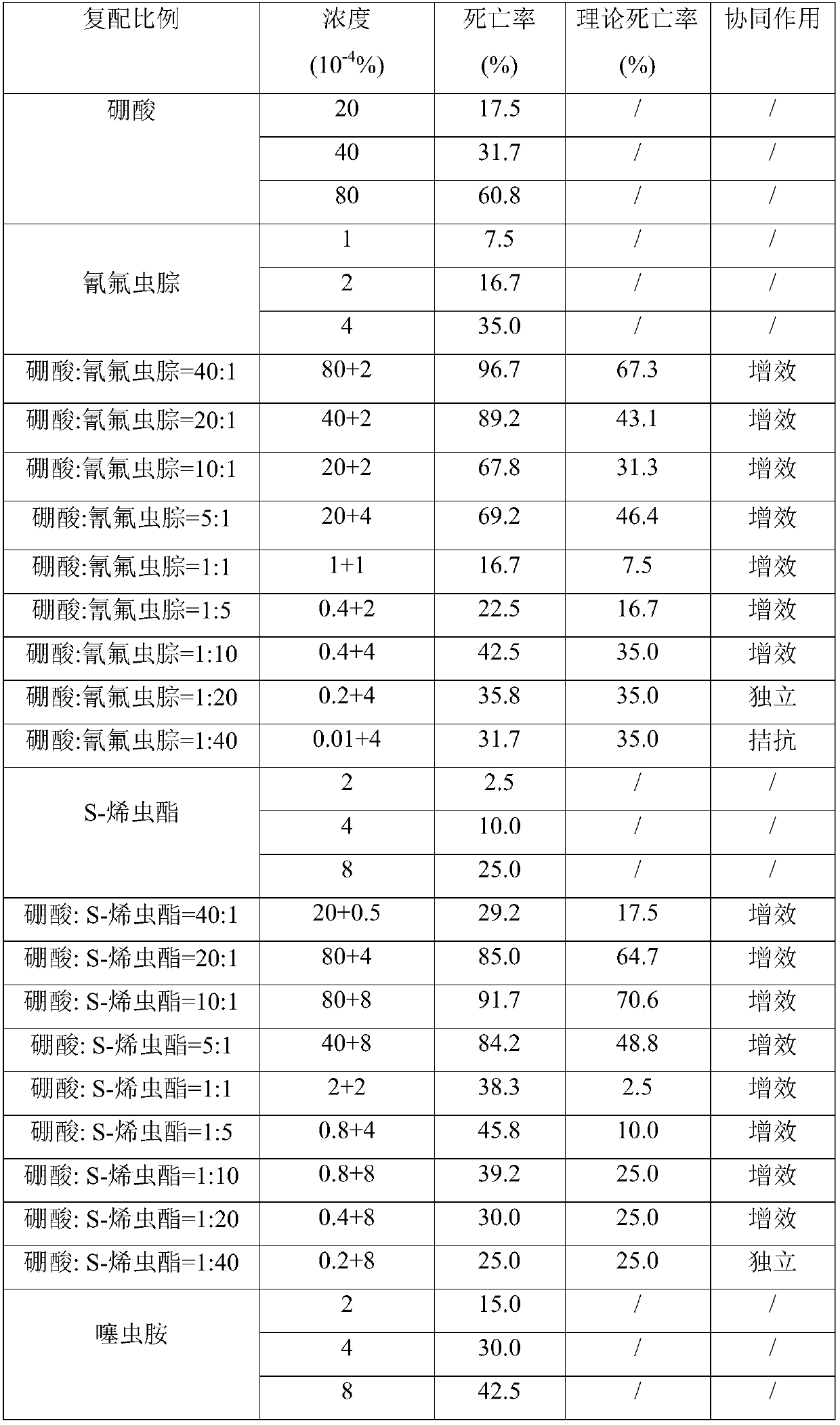

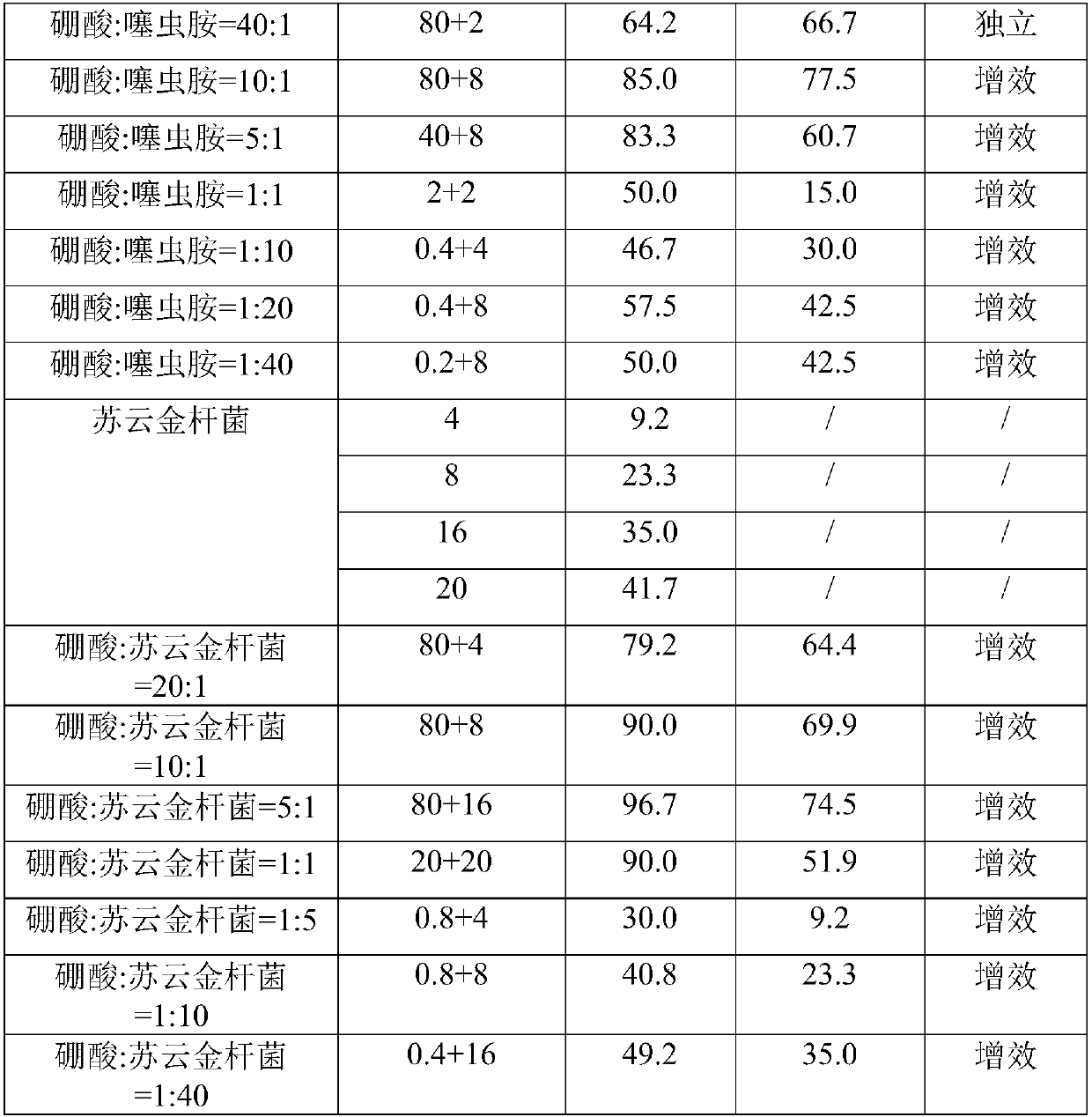

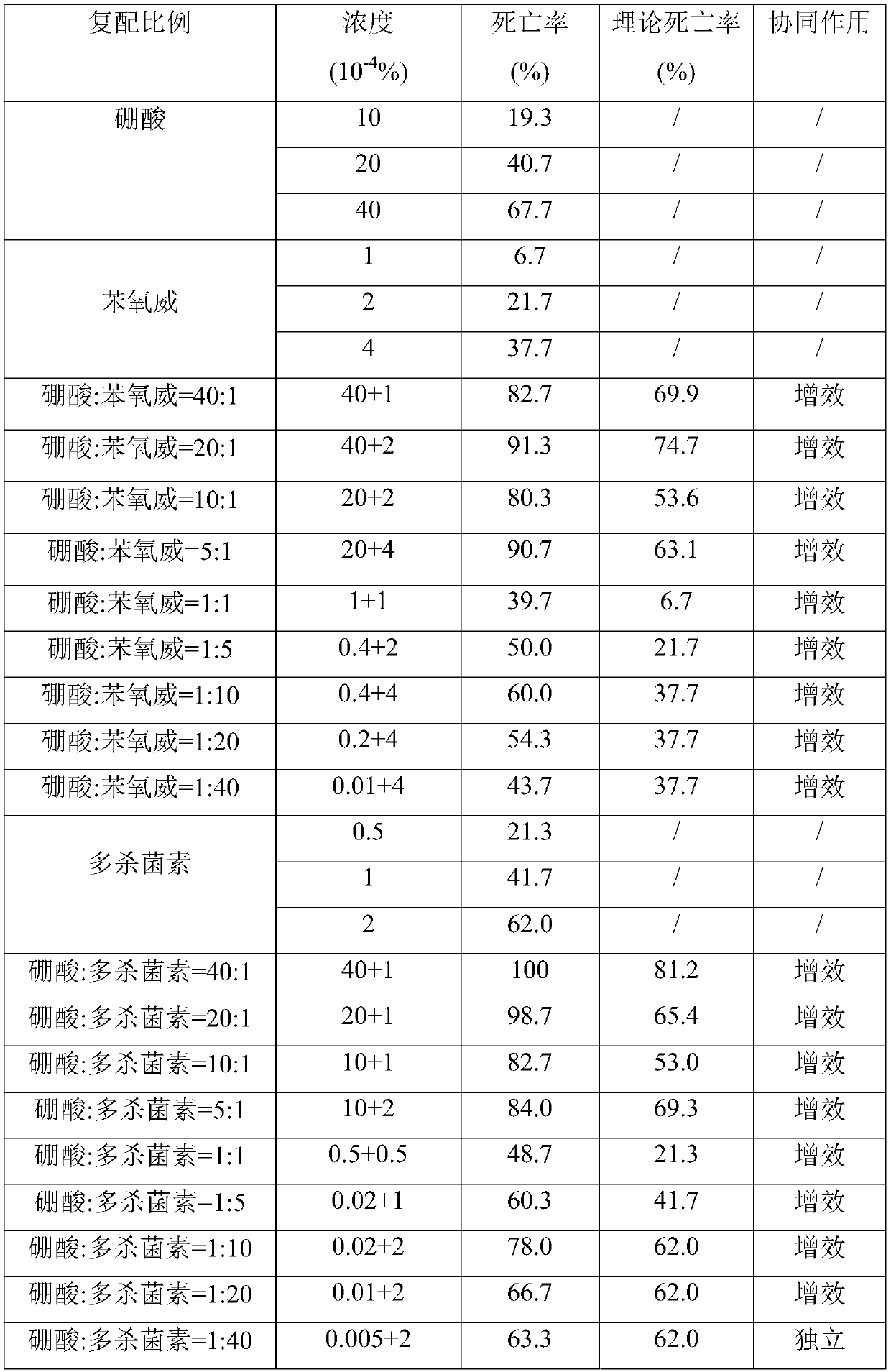

Insecticidal composition containing boric acid, and application thereof

InactiveCN111296478ADifficult to produce food refusalEnsure feedingBiocideAnimal repellantsMethopreneBacillus thuringiensis

The invention relates to an insecticidal composition, which is composed of an active component A and an active component B, wherein the active component A is boric acid, the active component B is oneselected from fenoxycarb, S-methoprene, indoxacarb, metaflumizone, clothianidin, acetamiprid, spinosad and bacillus thuringiensis, when the active component B is selected from fenoxycarb, S-methoprene, clothianidin, acetamiprid and bacillus thuringiensis, the weight ratio of the active component A to the active component B is 40:1-1:40, and when the active component B is selected from indoxacarb,metaflumizone and spinosad, the weight ratio of A to B is (40: 1)-(1:20). According to the invention, the composition is dominated by an inorganic salt boric acid, the lethal rate is not high, solenopsis invicta is not prone to producing food refusal, it is ensured that queen ant and breeding ants eat the lethal dosage, the prevention and control rate is increased, and after boric acid and the specific active component B are compounded, the synergistic effect is achieved, and the production practicability is achieved.

Owner:江苏功成生物科技有限公司

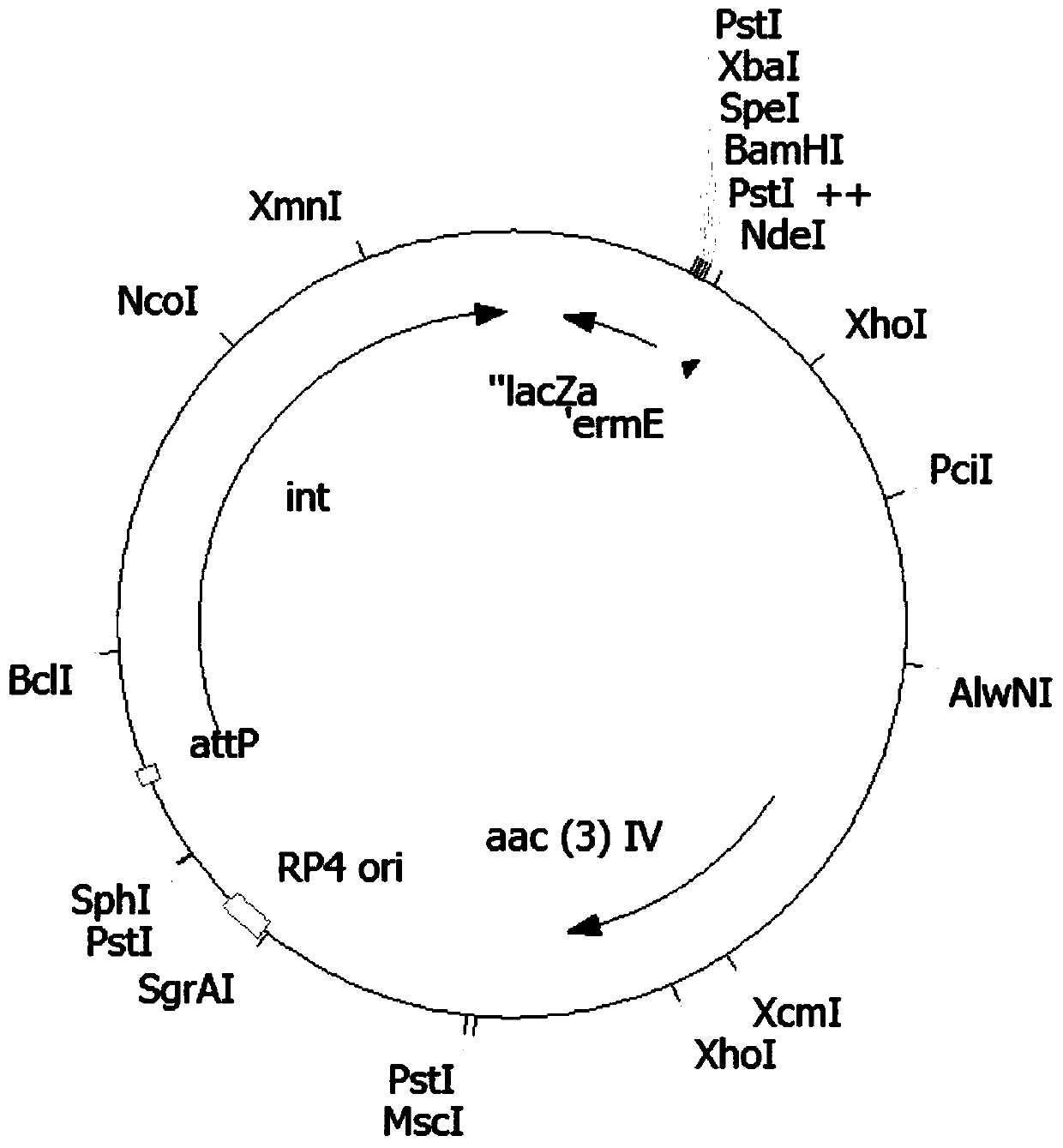

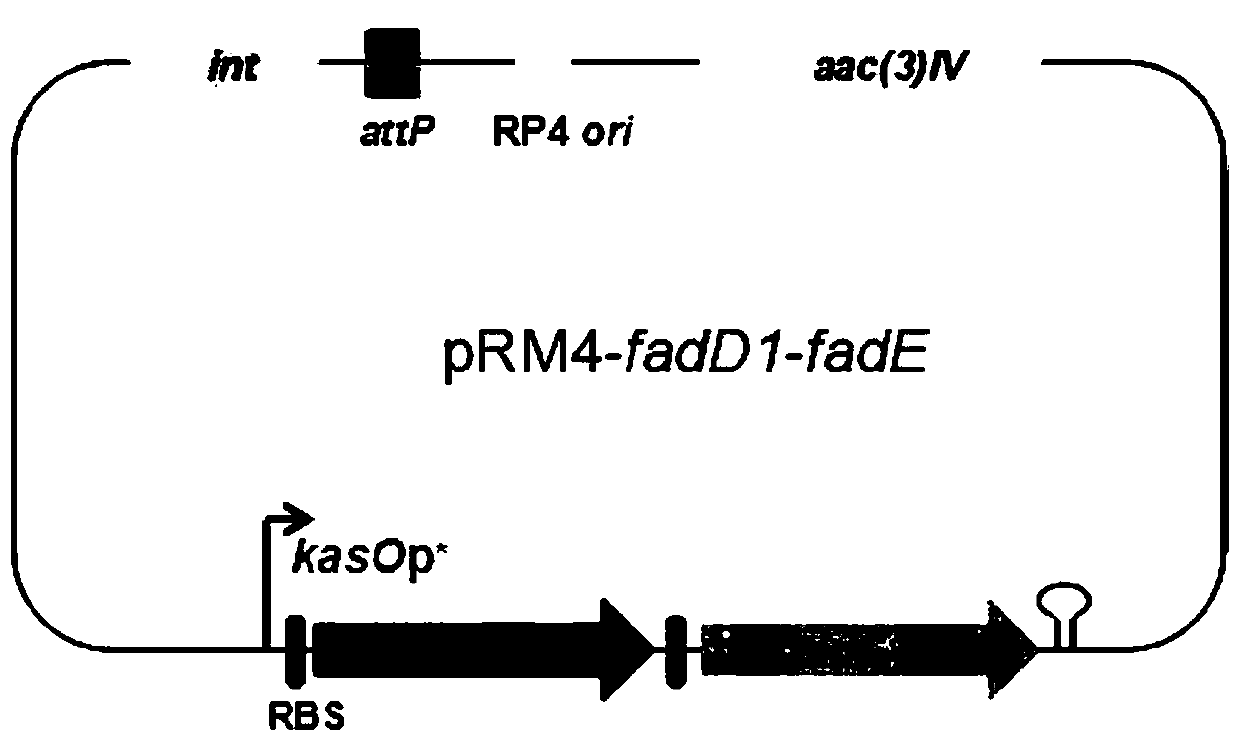

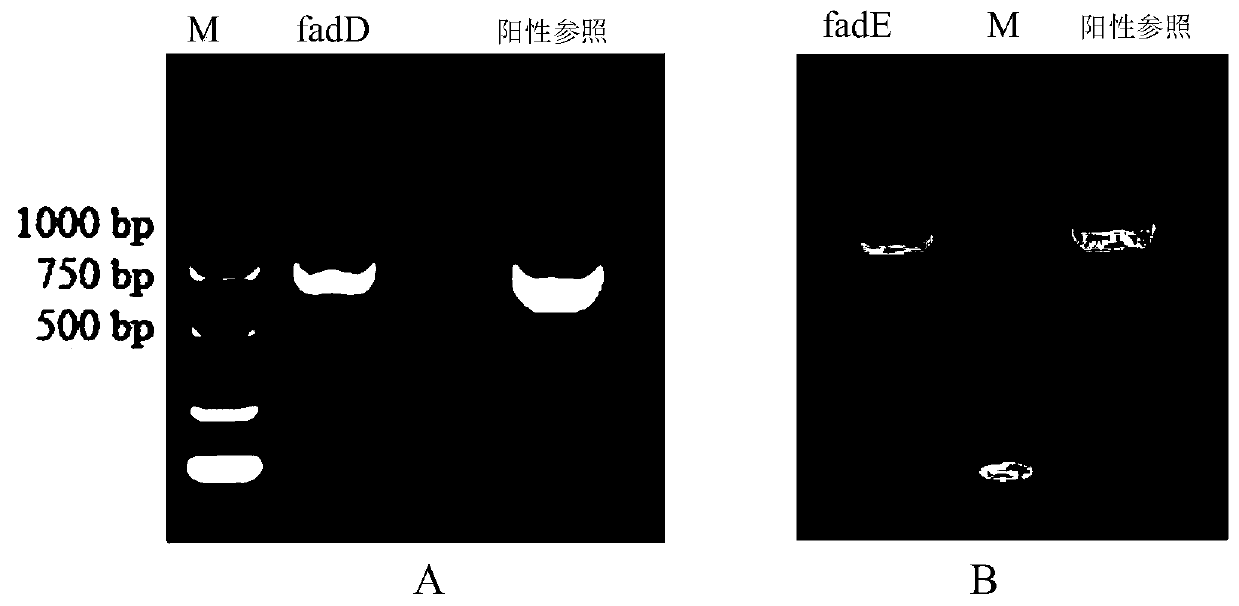

Spinosad high-yield genetically engineered bacteria and its construction method and application

ActiveCN107418925BIncrease supplyImprove utilizationBacteriaMutant preparationBiotechnologyBactericidin

The invention discloses a spinosad high-yield gene engineering bacterium. The preservation number of the gene engineering bacterium is CGMCC No. 14193. The invention further discloses a method by enhancing a fatty acid metabolism pathway to construct the spinosad high-yield gene engineering bacterium and application of the engineering bacterium to produce spinosad. According to the construction method, by conducting expression enhancement on the oxidation pathway of fatty acid Beta of saccharopolyspora spinosa, supply for the spinosad to biosynthesize the important precursor of acetyl coenzyme A is improved, and compared with original strains, the yield of the spinosad of obtained gene engineering strains is improved obviously.

Owner:ACAD OF NAT FOOD & STRATEGIC RESERVES ADMINISTRATION

Insecticidal aerosol with multi-bactericidin

InactiveCN101278670BReduce pollutionImprove insecticidal effectBiocideArthropodicidesSpinosadMedicine

The invention belongs to a pesticide, which more particularly relates to a spinosad desinsection aerosol which consists of propellant and liquid medicine that are contained inside a gas spray vessel, wherein, the liquid medicine comprises the pesticide, knocking down agent, solvent, synergistic agent, etc. which are compounded by proportion, wherein the spinosad is selected as the pesticide. The invention solves the problems that mosquitoes, insects, etc. can produce drug resistance easily; the pollution to the environment is serious, etc. which exist in the product of the prior art. The pesticide which is the product of the invention has the advantages of simple preparation technical process, low toxicity, little pollution to the environment, better comprehensive desinsection effect, good stability, etc.

Owner:保定蕴生生物科技有限公司

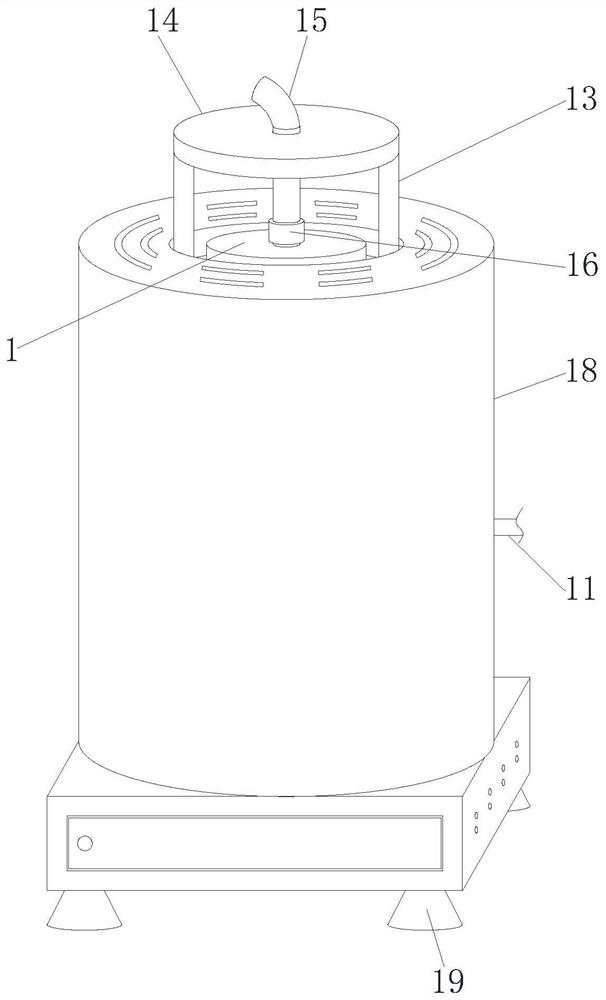

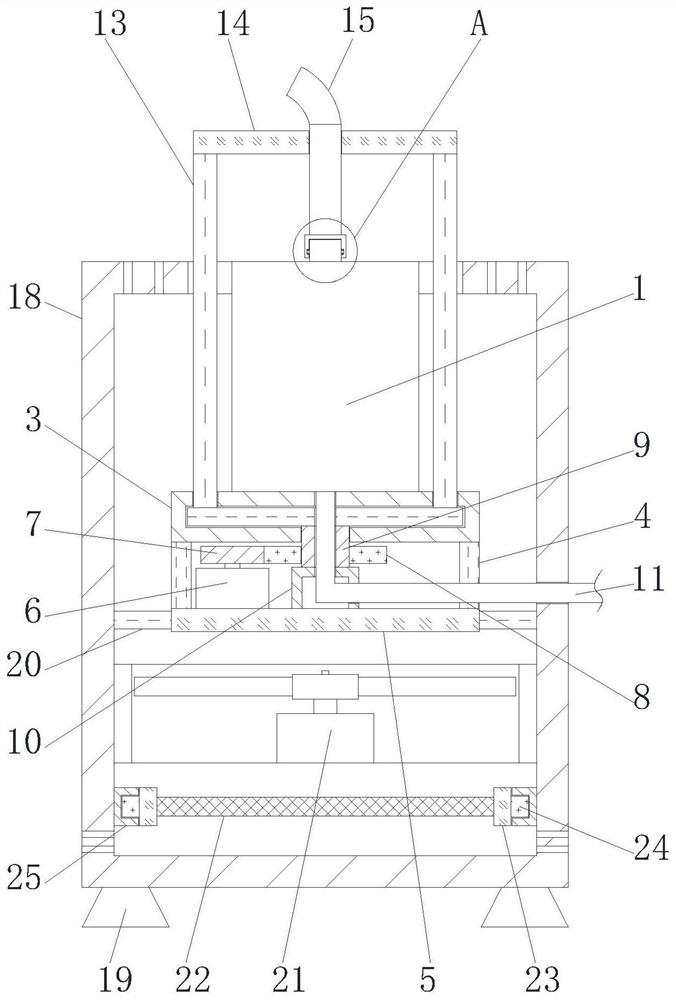

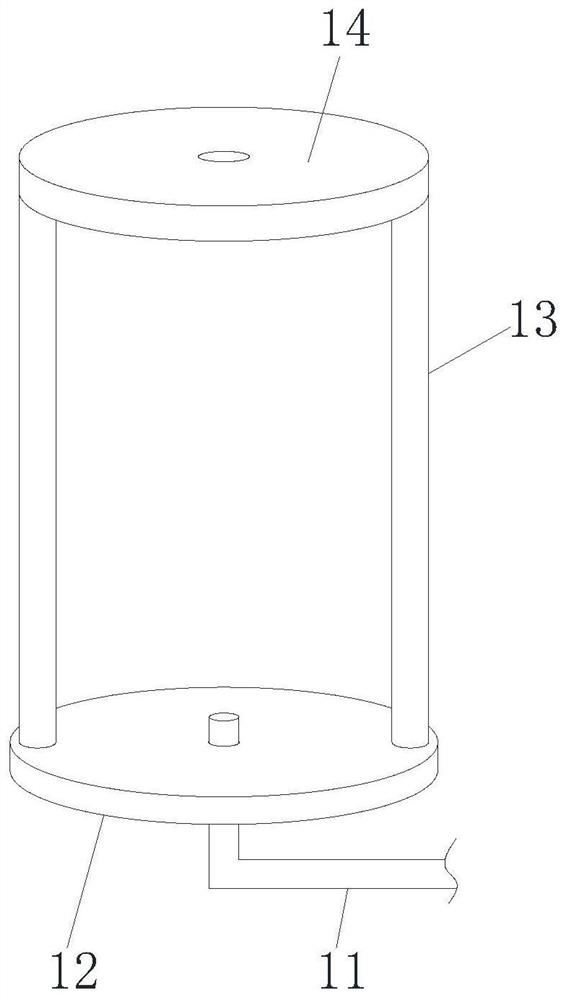

Bacteriostatic and sterilizing biological agent and application of bacteriostatic and sterilizing biological biological agent in humidifiers

PendingCN113973852AEasy to useGood antibacterial effectBiocideMechanical apparatusBiotechnologySophocarpidine

The invention discloses a bacteriostatic and sterilizing biological biological agent and application of the bacteriostatic and sterilizing biological biological agent in humidifiers. The biological agent comprises 38% of water, 30% of ethanol, 10% of essential oil, 5% of synergist, 6% of a plant concentration solution and 11% of phytoncide, wherein the synergist is mainly composed of thymol, the plant concentration solution is composed of tea trees, eucalyptus, pine trees and pine nuts, and the phytoncide is prepared from cnidium lactone, sophocarpidine, clover, manuka and aloe. According to the invention, the bacteriostatic and antibacterial effects of the biological agent can be improved through the phytoncide, the synergist and the plant concentration solution while the health-care effect of the biological agent can be improved, so that the biological agent has better fragrance and is convenient to use.

Owner:佛山市天恩生物科技有限公司

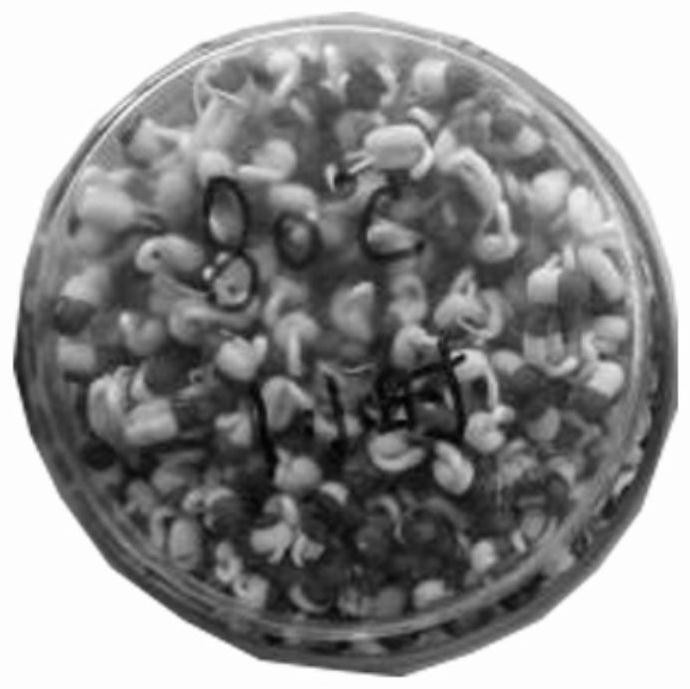

High-temperature sterilization method for mung bean seeds

InactiveCN111727688AEvenly heatedAffect germination rateBiocideFungicidesBactericidinPathogenic bacteria

The invention discloses a high-temperature sterilization method for mung bean seeds, and relates to the technical field of treatment of crop seeds. The high-temperature sterilization method comprisesthe following steps: drying the mung bean seeds at the temperature of 40 DEG C until the water content reaches 3-5%, placing the seeds into an electric heating constant-temperature air blast drying oven, carrying out high-temperature sterilization, treating the seeds at the temperature of 70 DEG C for 0.1-0.2 hour, then heating the seeds to the temperature of 80 DEG C to be treated for 1-1.5 hours, cooling the seeds to room temperature, filling a sealed bag with the seeds, carrying out vacuumizing, and storing the seeds at the temperature of 4 DEG C. According to the method disclosed by the invention, a film layer is formed on the surface of each of the mung bean seeds, so that the mung bean seeds are uniformly heated in the sterilization process; and moreover, plant bacteriocins are addedinto the film layers, pathogenic bacteria can be thoroughly killed in cooperation with high temperature, and the pathogenic bacteria carried on the seeds can be fully killed. Meanwhile, by the film layers, the evaporation rate of seed moisture can be reduced, and the germination rate of the seeds is guaranteed.

Owner:榆林市农业科学研究院

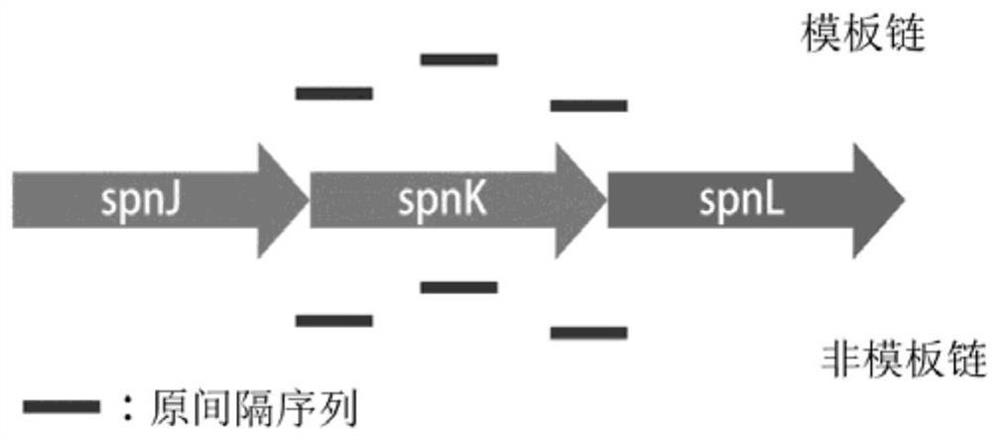

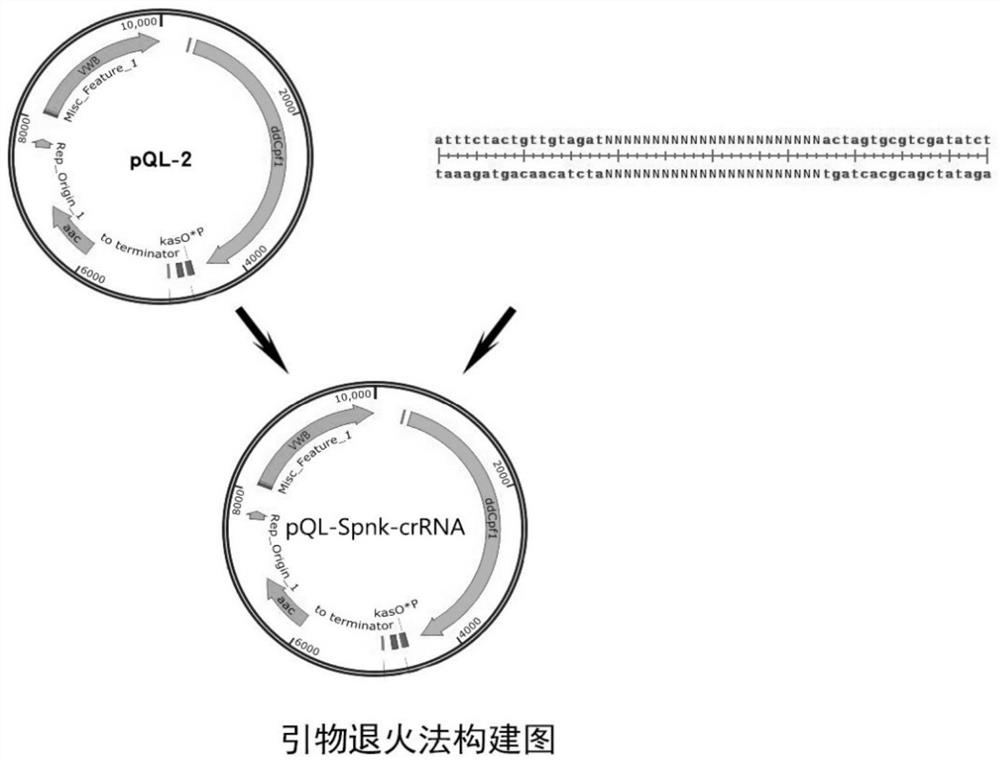

Engineering bacterium for high-yield production of spinosad J/L as well as construction method and application of engineering bacterium

PendingCN113999868AHigh level expressionStable passageBacteriaHydrolasesBiotechnologyHigh level expression

The invention relates to an engineering bacterium for high-yield production of spinosad J / L as well as a construction method and application of the engineering bacterium. Saccharopolyspora spinosa QL-1 is used as an original strain, crRNA is inserted to inhibit the spnK gene expression of the Saccharopolyspora spinosa QL-1 until the spnK gene is inactivated, and the QL-1 / pQL-spnK-crRNA genetically engineering bacterium with high-yield production of spinosad J / L is constructed. The CRISPRi technology is introduced into the saccharopolyspora spinosa for the first time, and the spnK gene is inhibited and inactivated by a CRISPR / ddcpf1 method, so that the high-level expression of the spinosad J / L is realized, and the purpose of high yield of the spinosad J / L is achieved. The constructed QL-1 / pQL-spnK-crRNA engineering bacterium can be stably passaged, and the yield of spinosad J / L of the saccharopolyspora spinosa can be obviously improved and is 8-9 times that of wild saccharopolyspora spinosa.

Owner:QILU PHARMA INNER MONGOLIA

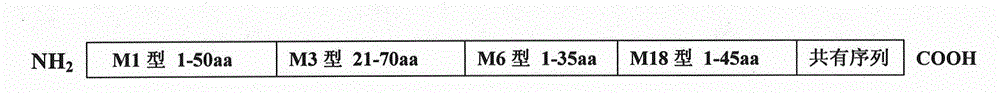

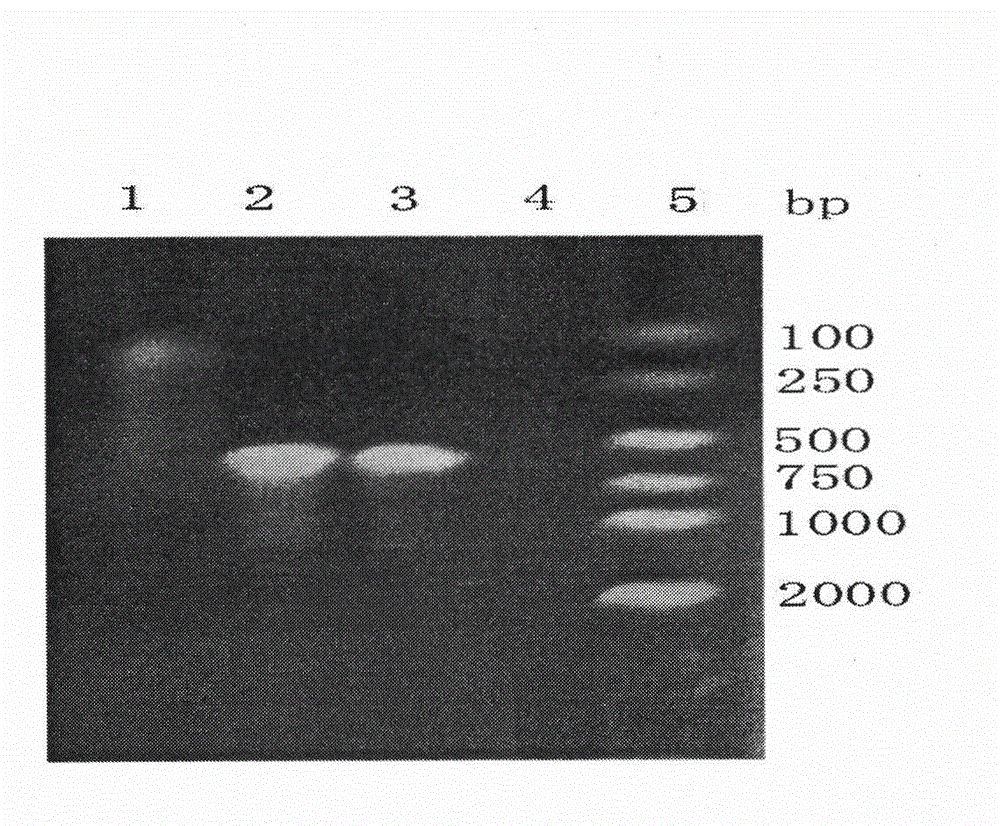

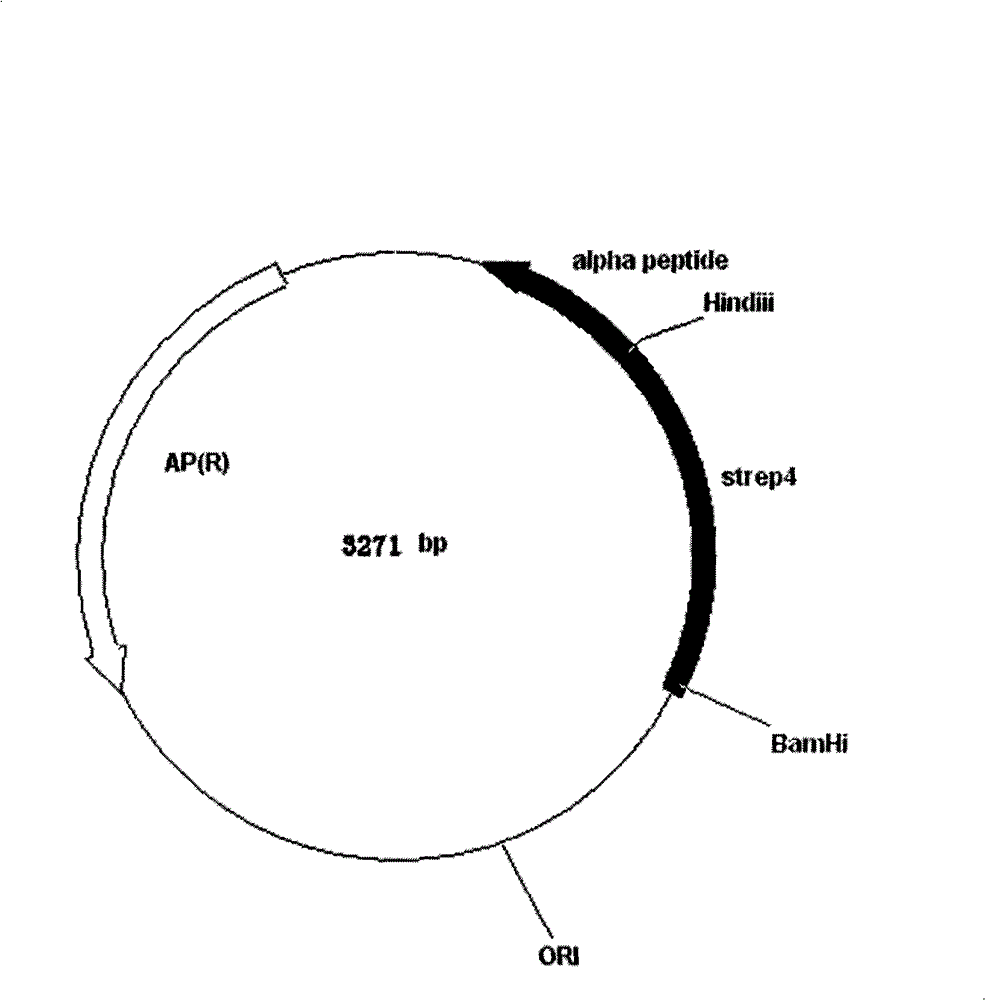

Recombination polypeptide serving as group A streptococcic tetravalent vaccine protective antigen

The invention provides recombination polypeptide, which is prepared by gene recombination technology. The recombination polypeptide is prepared by splicing type-specific amino acid sequences of M1, M3, M6 and M18 serological-type M proteins of rheumatic fever immunogenic group A streptococcus prevailing in the Guangdong province of China, and a common section of conservative amino acid sequence of the C ends of the four serological-type M proteins, wherein the N ends of the four serological-type M proteins comprise protective antigen epitopes and do not comprise human cross reaction epitopes.The recombination polypeptide is experimentally proved to be capable of inducing the generation of bactericidins for the type specificity of the M1, M3 and M6 proteins of the A-group streptococcus soas to be used for preparing recombination polypeptide vaccines for the A-group streptococcus.

Owner:WUHAN INST OF BIOLOGICAL PROD CO LTD

Suspended seed coating for preventing and treating peanut diseases and insects and preparation method thereof

The invention belongs to the field of agricultural seed treatment agents, and particularly relates to an environment-friendly peanut seed coating agent and a preparation method thereof. Biological source insecticides (spinetoram and azadirachtin) and biological bactericides (phenazino-1-carboxylic acid and zhongshengmycin) are taken as effective components, polyvinyl alcohol is taken as a film-forming agent, and auxiliaries including a thickening agent and the like are taken as auxiliary materials to prepare the peanut seed coating. The seed coating can prevent the peanut diseases and insectsin the seedling stage and barely influences the environment.

Owner:INST OF PLANT PROTECTION FAAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com