High-temperature sterilization method for mung bean seeds

A high-temperature sterilization and seed technology, which is applied in the direction of seed coating/seed dressing, chemicals for biological control, fungicides, etc., can solve the problems of easy occurrence of diseases and insect pests, so as to ensure healthy growth, complete sterilization, reduce The effect of evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

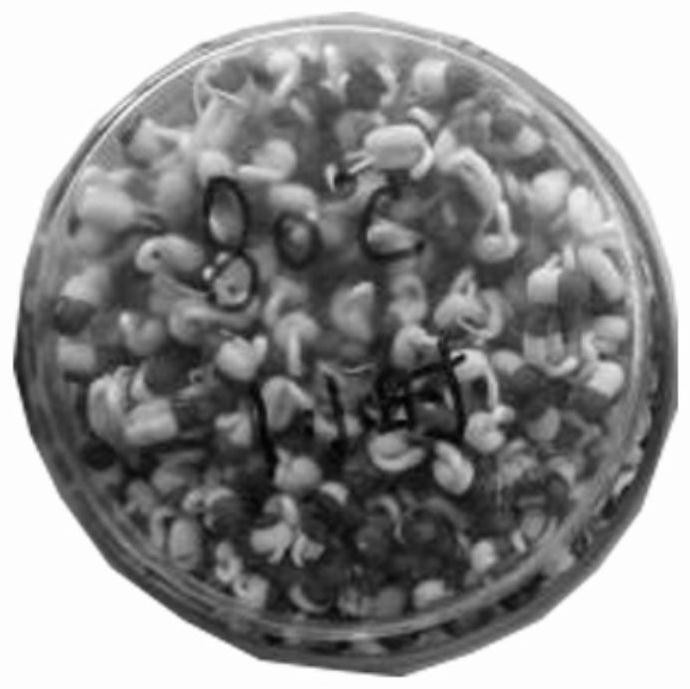

Image

Examples

Embodiment 1

[0033] Dry the mung bean seeds at 40°C to a water content of 3%; put the seeds into an electric constant temperature blast drying oven for high-temperature sterilization, first treat at 70°C for 0.1h, then heat up to 80°C for 1h, and then cool to room temperature; Put the high-temperature sterilized seeds into a sealed bag, vacuumize them, and store them at 4°C.

Embodiment 2

[0035] Dry the mung bean seeds at 40°C to a water content of 3%, immerse in a vegetable oil coating agent, soak at room temperature for 3 minutes, take them out and dry them in the air, put the seeds into an electric constant temperature blast drying oven for high-temperature sterilization, and treat them at 70°C for 0.1 h, then heat up to 80°C for 1h, then cool to room temperature; put the sterilized seeds into a sealed bag, vacuumize, and store at 4°C.

[0036] Wherein, the vegetable oil coating agent includes the following raw materials by weight: 60 g of vegetable oil, 20 g of chitosan, 3 g of modified titanium dioxide nanorods, 2 g of phytoncide, and 1230 g of 1% acetic acid solution by volume fraction. Its preparation method is as follows:

[0037] Weigh the dried titanium dioxide nanorods, add them into isopropanol at a ratio of 1g / 10mL, and disperse with 400W ultrasonic waves for 15min to obtain a titanium dioxide nanorods solution;

[0038] Then weigh 6g of titanate ...

Embodiment 3

[0044] Dry mung bean seeds at 40°C to a water content of 4%, immerse in vegetable oil coating agent, soak at room temperature for 3 minutes, take out and dry, put the seeds into an electric constant temperature blast drying oven for high temperature sterilization, and treat them at 70°C for 0.15 h, then raised the temperature to 80°C for 1.2h, then cooled to room temperature; put the high-temperature sterilized seeds into a sealed bag, evacuated, and stored at 4°C.

[0045] Wherein, the vegetable oil coating agent includes the following raw materials by weight: 70 g of vegetable oil, 30 g of chitosan, 4 g of modified titanium dioxide nanorods, 3 g of phytoncide, and 1845 g of 1% acetic acid solution by volume fraction. The preparation method is as follows:

[0046] Weigh the dried titanium dioxide nanorods, add them into isopropanol at a ratio of 1g / 10mL, and disperse with 400W ultrasonic waves for 15min to obtain a titanium dioxide nanorods solution;

[0047] Then weigh 8g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com