Process method for dimethyl ether production wastewater recycled for cooling water

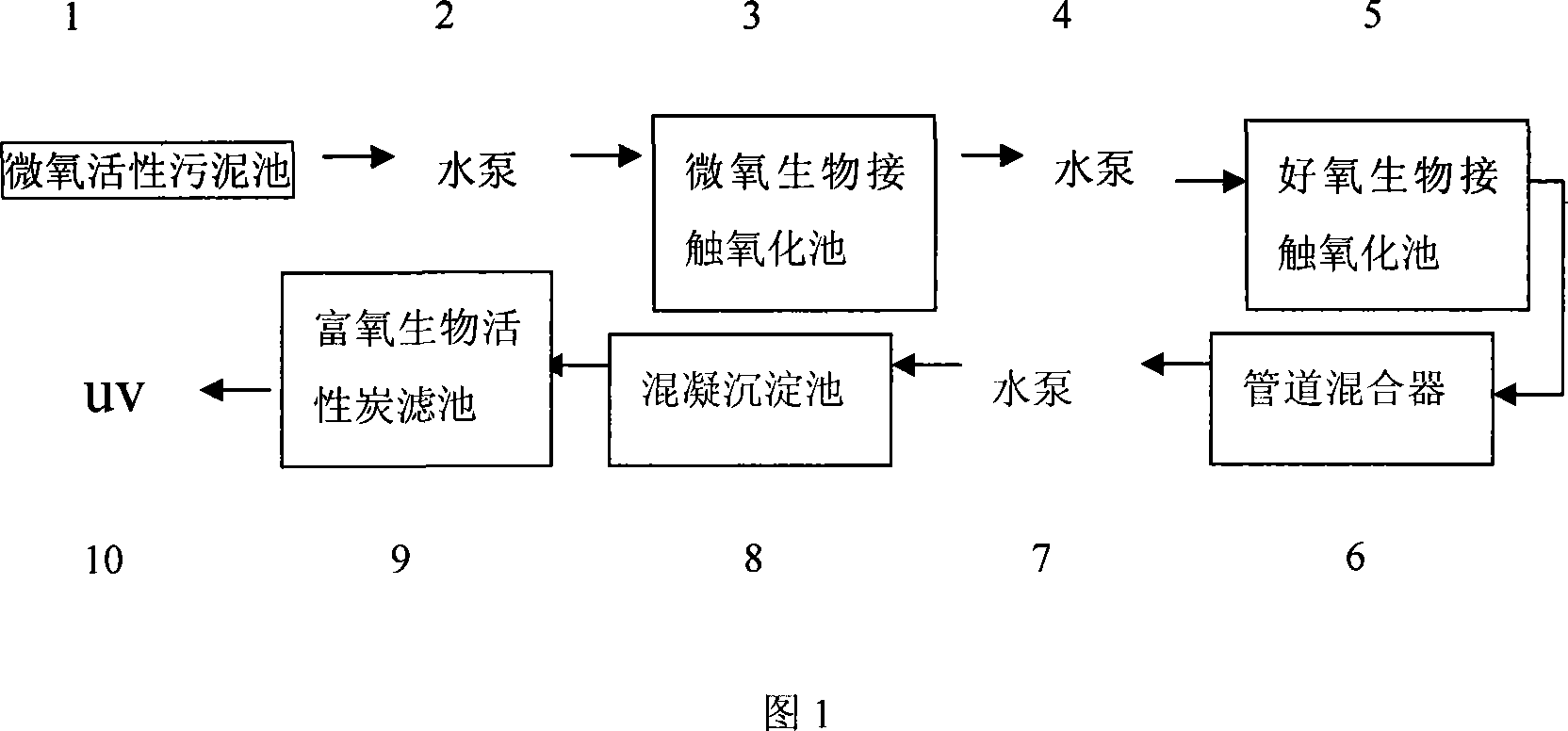

A technology for circulating cooling water and producing waste water, which is applied in the direction of light water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high biomass content, large power consumption, dimethyl ether There are no problems such as reuse of industrial circulating cooling water, and the effects of simple operation, reliable operation, and reduced sludge treatment volume are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Under the normal operating conditions of each process in the wastewater treatment system, the treatment effects of each wastewater treatment process after treatment are shown in Table 1.

[0026] Table 1 The running results of each process (hardness is expressed as CaCO 3 count)

[0027] Water quality project

[0028] It can be seen from Table 1 that the treatment system effluent CODcr, methanol, conductivity, hardness (CaO), pH, turbidity and chromaticity and other water quality indicators all meet the requirements of the industrial circulating cooling water make-up water quality standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com