Patents

Literature

43 results about "Methoprene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

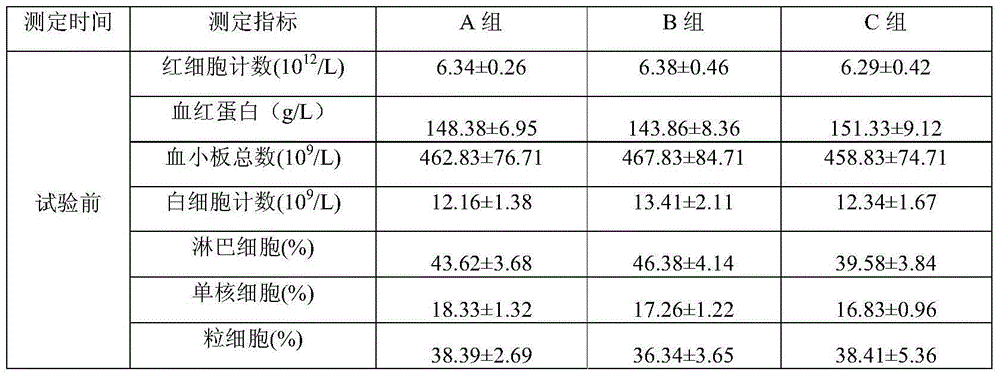

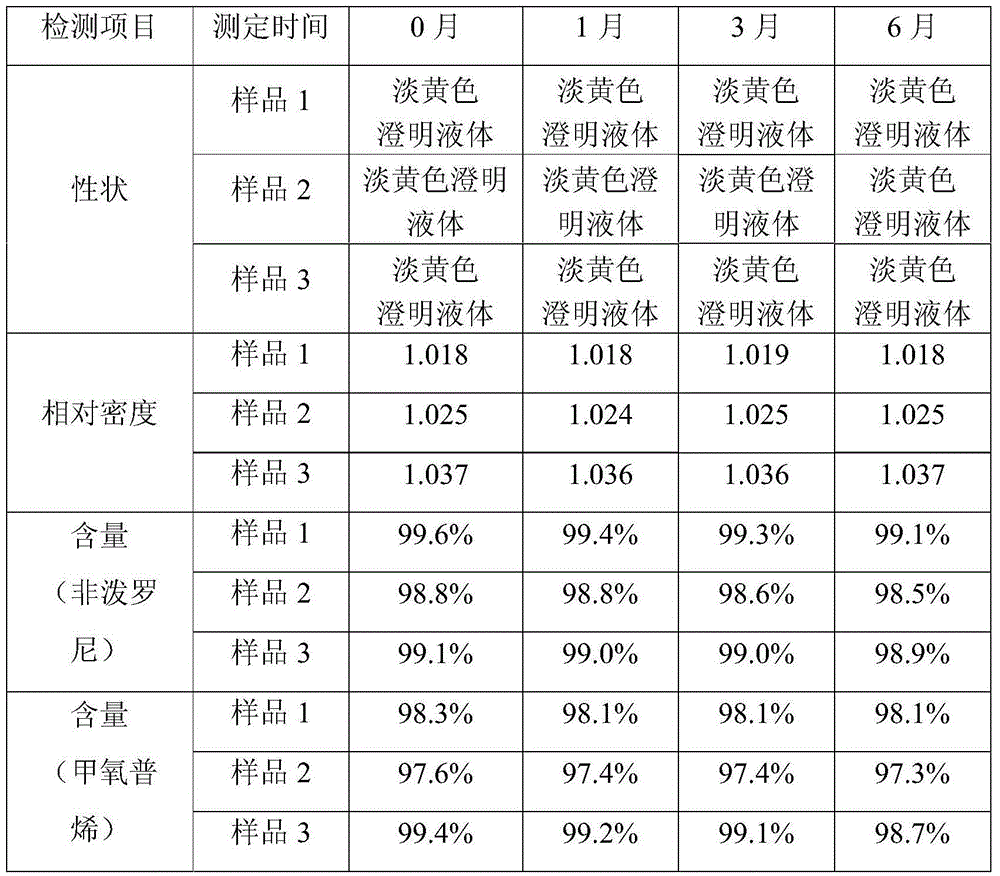

Methoprene is a juvenile hormone (JH) analog which acts as a growth regulator when used as an insecticide. It is an amber-colored liquid with a faint fruity odor. According to the MSDS, methoprene is a material that may be irritating to the mucous membranes and upper respiratory tract, may be harmful by inhalation, ingestion, or skin absorption, may cause eye, skin, or respiratory system irritation and is very toxic to aquatic life. The GHS signal word is "Warning," with notes such as P273 Avoid release into the environment and P391 collect spillage. It is used in drinking water cisterns to control mosquitoes which spread dengue fever and malaria.

High concentration dinotefuran formulations containing methoprene

InactiveUS6889632B2Reduce the amount requiredReduce efficacyBiocideDead animal preservationMethopreneHigh concentration

Owner:CEVA ANIMAL HEALTH

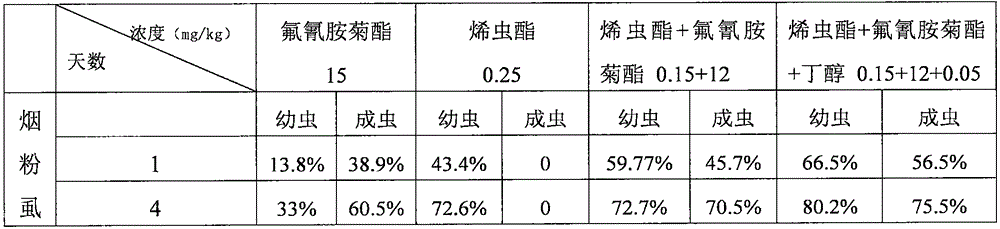

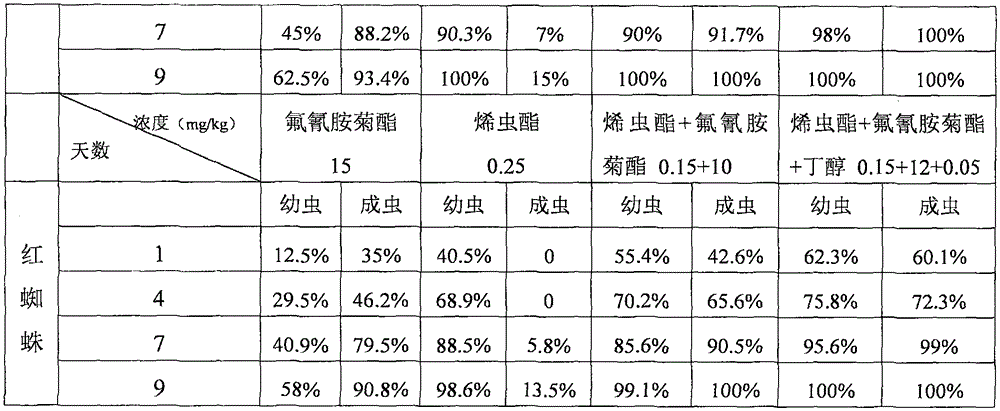

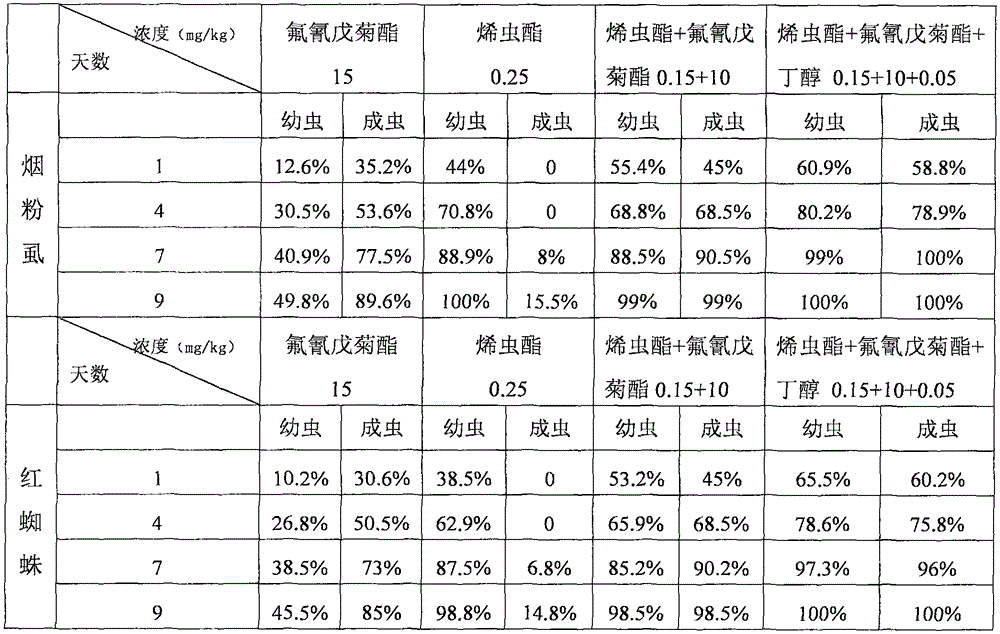

Biological insecticide containing methoprene as well as preparation and application methods thereof

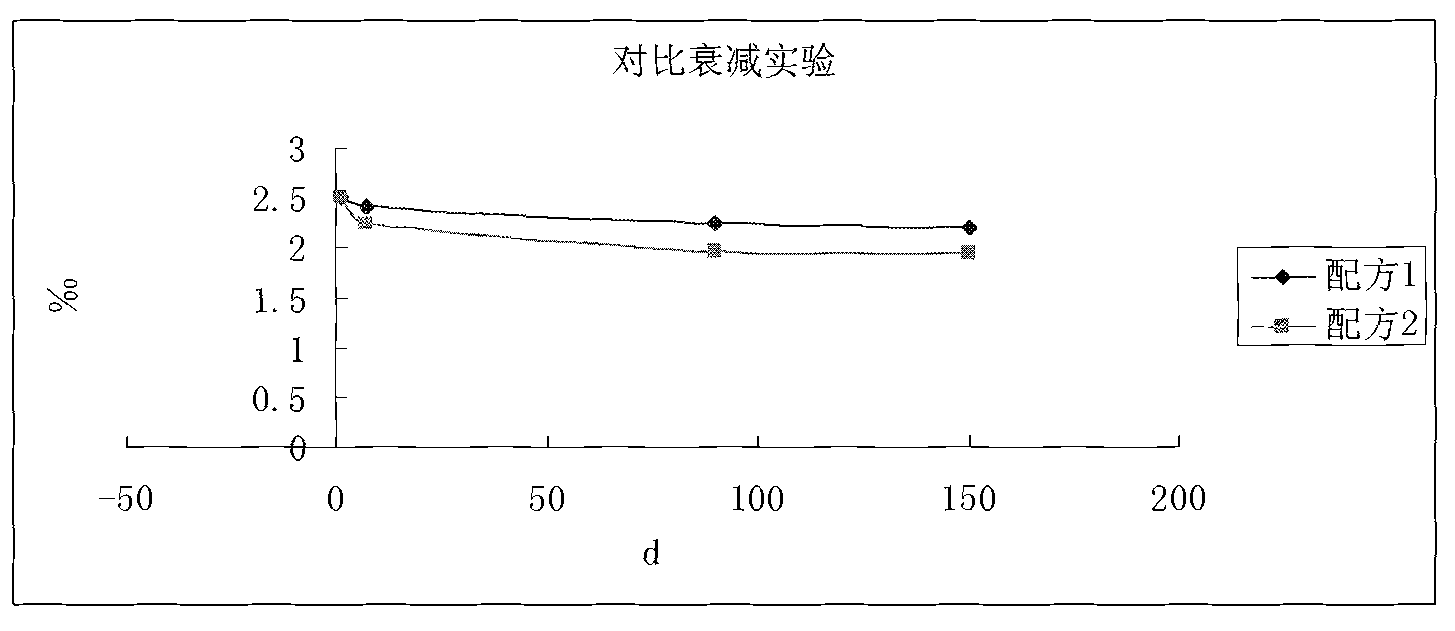

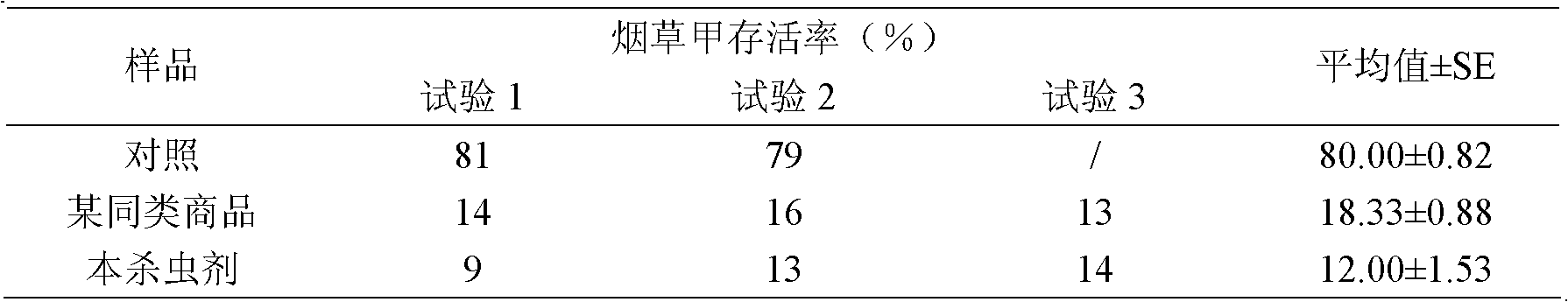

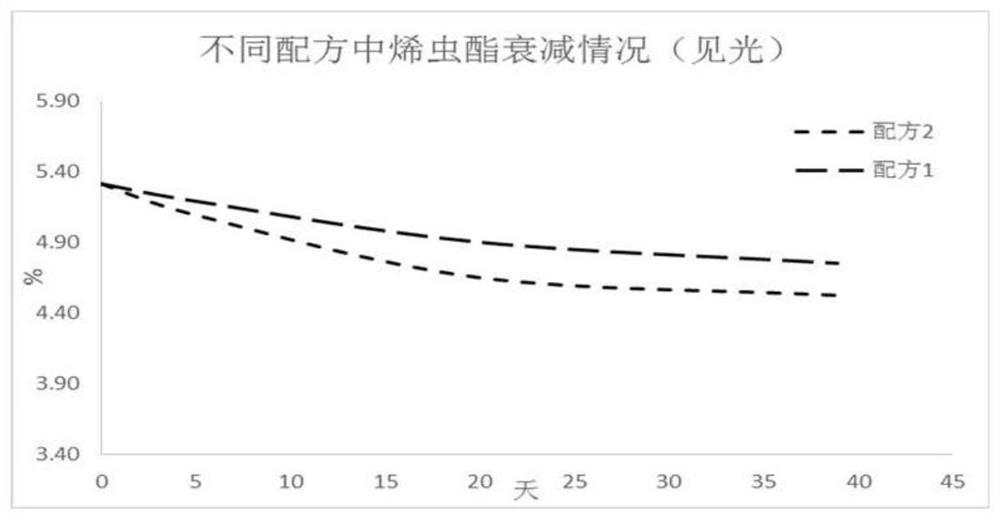

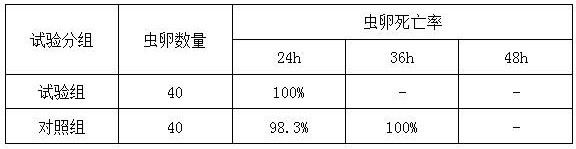

The invention provides a biological insecticide containing methoprene as well as preparation and application methods thereof. The biological insecticide is prepared from the following components: 0.01-10% of methoprene, 0.01-5% of surfactant, 0.01-10% of light stabilizer and 75-99% of solvent. The biological insecticide has the advantages that: by adopting the mixed solvent and the surfactant at the same time, the effective ingredients can be uniformly dispersed in the solution, and the uniformity of the effective ingredients in the using process can be ensured; the light stabilizer is added, thus the attenuation rate of methoprene is obviously reduced, the storage life of the insecticide is prolonged, and the using effect of the insecticide is enhanced; and the biological insecticide has very obvious killing effects on mosquitoes and flies in water as well as beetles, flour moths and other lepidoptera, diptera, coleoptera, homoptera and other insects in grain and tobacco, and can be applied to prevention and control of mosquitoes and flies in tap water, storage of grain and tobacco as well as disinfection and insect disinfection of carpets and the like.

Owner:CHINA TOBACCO HUNAN INDAL CORP

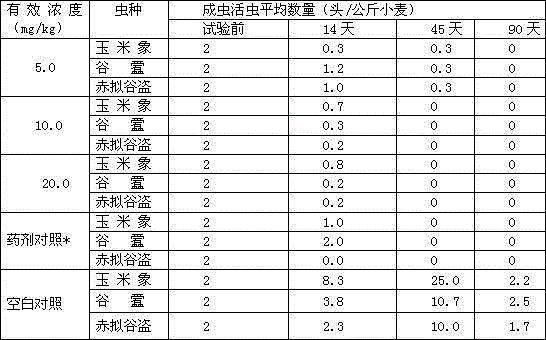

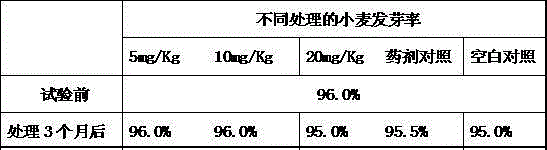

5% S-methoprene wettable powder, and preparation method and application thereof

InactiveCN104026122AUnderstand the effect of prevention and controlUnderstanding InhibitionBiocideAnimal repellantsBiotechnologyMethoprene

The invention provides a 5% S-methoprene wettable powder and a preparation method and application thereof. The wettable powder is mainly used for inhibition of grain storage insects. The 5% S-methoprene wettable powder is prepared from S-methoprene, a carrier, a surfactant, a dispersant and an anti-oxidant. The prepared wettable powder is nontoxic, green and environment-friendly, has high activity on target insects and a ppm-grade application concentration and is a novel green grain storage insect inhibitor.

Owner:苏衡

Long-acting low-toxicity high-efficiency insecticidal composition

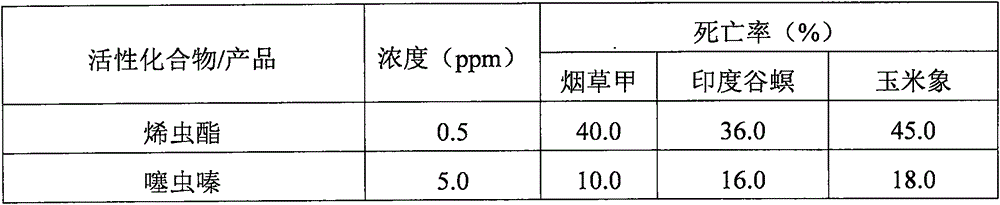

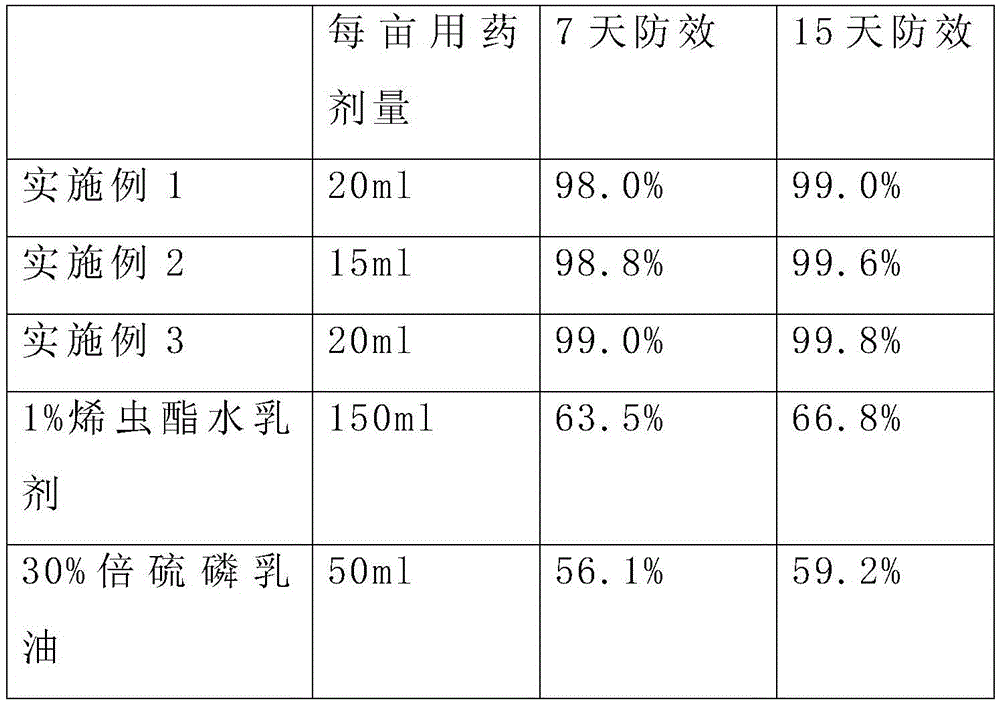

ActiveCN105379749AExpand the target of prevention and controlBroaden the field of applicationBiocideAnimal repellantsMethopreneApplication areas

The invention provides a long-acting low-toxicity high-efficiency insecticidal composition. The composition comprises methoprene and at least one chloronicotinyl insecticide. Through synergism between methoprene and the chloronicotinyl insecticide, the scope of control objects and application fields of the insecticide is broadened; different existing forms of insects in each stage of the whole life cycle can be effectively controlled; the effective utilization rate of the insecticide is increased; cost for the insecticide is reduced for peasants; the service life of chemical pesticide is prolonged; and resistance generation is delayed.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

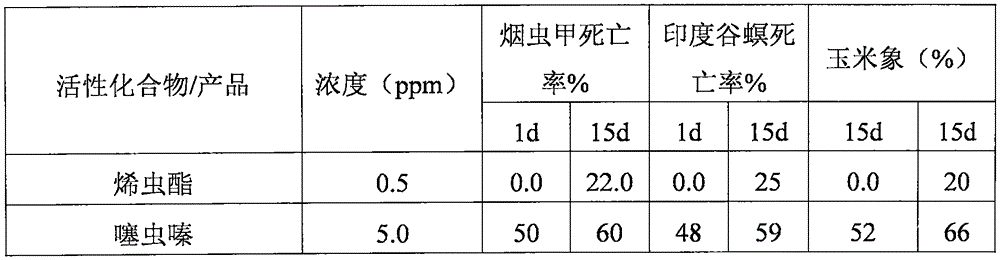

High concentration dinotefuran formulations containing methoprene

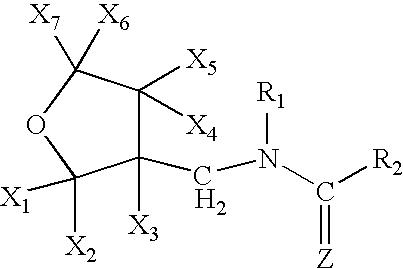

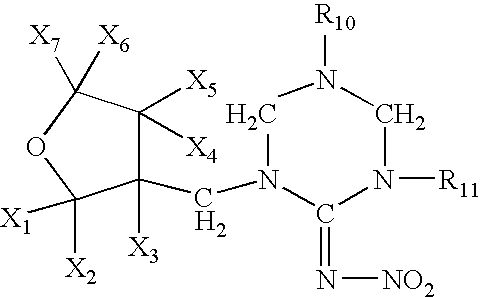

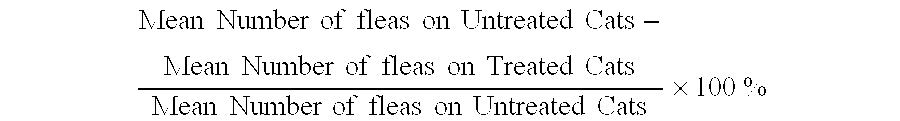

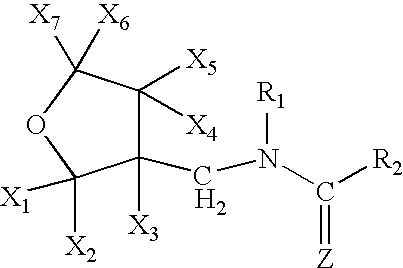

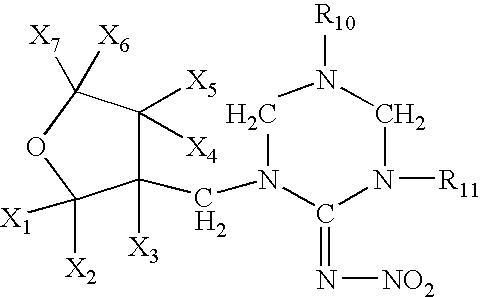

A topical insecticide is provided which can be safe to use and avoids many common deleterious side effects of conventional topical insecticides. In one preferred embodiment of the invention, the active ingredient of the insecticide formulation is an amine derivative, having a nitro-methylene group, a nitroamino group or a cyanoamino group, which can be formulated to have low toxicity and excellent insecticidal activity. One particularly suitable insecticide is 1-{(tetrahydro-3-furanyl)methyl}-2-nitro-3-methylguanidine (dinotefuran), an aldulticide that will kill adult fleas combined with methoprene.

Owner:CEVA ANIMAL HEALTH

Safe, environment-friendly and efficient insecticidal composition and use thereof

The invention provides a safe, environment-friendly and efficient insecticidal composition, which comprises methoprene and at least one pyrethroid insecticide. The two insecticides have different modes of action, and through the synergistic effect of the two, the insecticidal composition can play an insecticidal role more quickly and more completely, effectively controls different insect body shapes at various stages in the whole life cycle of pests, at the same time also reduces the frequency of drug administration by farmers, lowers the pharmacy cost, and delays the generation of resistance.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Methods and compositions for treating ectoparasite infestation

Compositions and methods for killing ectoparasites on a subject. Compositions containing a fatty acid ester, e.g., isopropyl myristate, effective for killing ectoparasites is described. Also described are compositions containing a fatty acid ester and a siloxane (e.g. decacyclomethicone). The compositions can also contain a mectin and / or a mycin, and S-methoprene. The compositions are useful against a variety of ectoparasites that afflict humans, animals, and plants, e.g., head lice, fleas, body lice, crab lice, scabies mites, ticks, and plant parasites.

Owner:NUVO PHARMA IRELAND DESIGNATED ACTIVITY CO

Parasite prevention and/or treatment pharmaceutical composition and preparation method and application thereof

ActiveCN105687188AEfficient removalEffective/or killOrganic active ingredientsAntiparasitic agentsMethopreneDisease

Owner:LUOYANG HUIZHONG ANIMAL MEDICINE

Juvenile Hormone Analogs for Control of Leafhopper and Treehopper Pests

The present invention pertains to compounds and methods for controlling treehopper and leafhopper pests, such as the glassy-winged sharpshooter (GWSS), while conserving their parasites (such as parasitoid wasps). In one embodiment, the compound is a juvenile hormone analog such as methoprene, kinoprene, and hydropene. The invention also concerns pesticidal compositions comprising the compounds of the invention and a pesticidally acceptable carrier. The invention further concerns methods for controlling pests, such as GWSS, while conserving their parasites, by applying a compound or composition of the invention to the pest or pest-inhabited locus.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Methods and Compositions for Treating Ectoparasite Infestation

Compositions and methods for killing ectoparasites on a subject. Compositions containing a fatty acid ester, e.g., isopropyl myristate, effective for killing ectoparasites is described. Also described are compositions containing a fatty acid ester and a siloxane (e.g., decacyclomethicone). The compositions can also contain a mectin and / or a mycin, and S-methoprene. The compositions are useful against a variety of ectoparasites that afflict humans, animals, and plants, e.g., head lice, fleas, body lice, crab lice, scabies, ticks, and plant parasites.

Owner:NUVO PHARMA IRELAND DESIGNATED ACTIVITY CO

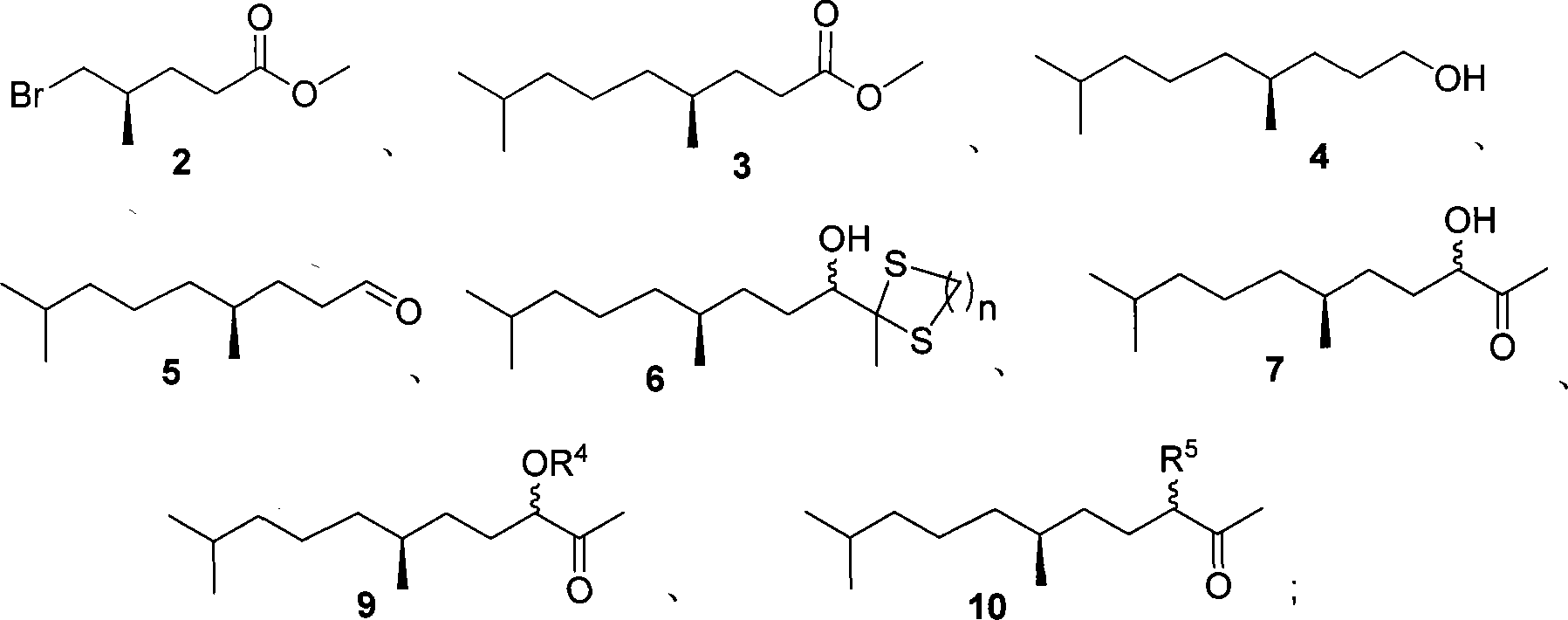

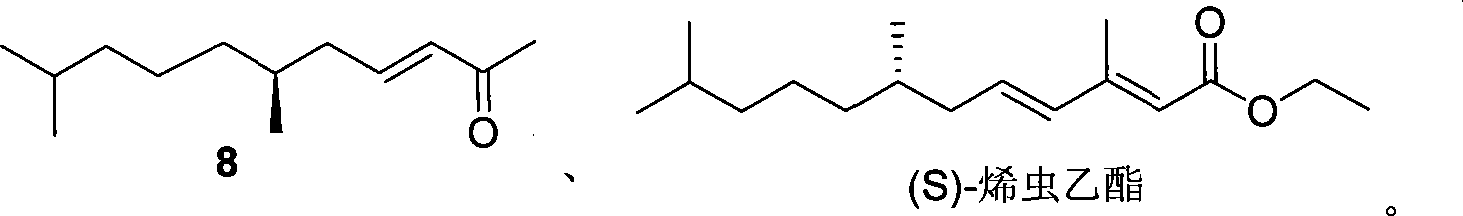

(6S)-6-methyl-2-ketone derivant, synthesizing method and use in synthesis of (S)-methoprene

InactiveCN101134754AEasy to manufactureShort stepsOrganic compound preparationCarboxylic acid esters preparationMethopreneEthyl ester

The present invention provides one kind of (6S)-6-methyl-2-ketone derivatives in novel structure. The (6S)-6-methyl-2-ketone derivatives may prepared with (4R)-methyl caprolactone obtained easily from steroid sapogenin oxidizing and degrading waste as material, and may be applied in synthesizing optical pure (S)-ethyl methoprene. The present invention can raise the utilization rate of steroid sapogenin, reduce environmental pollution, prepare thioketal compounds in the structure as shown and expand the application range of steroid sapogenin oxidizing and degrading waste.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

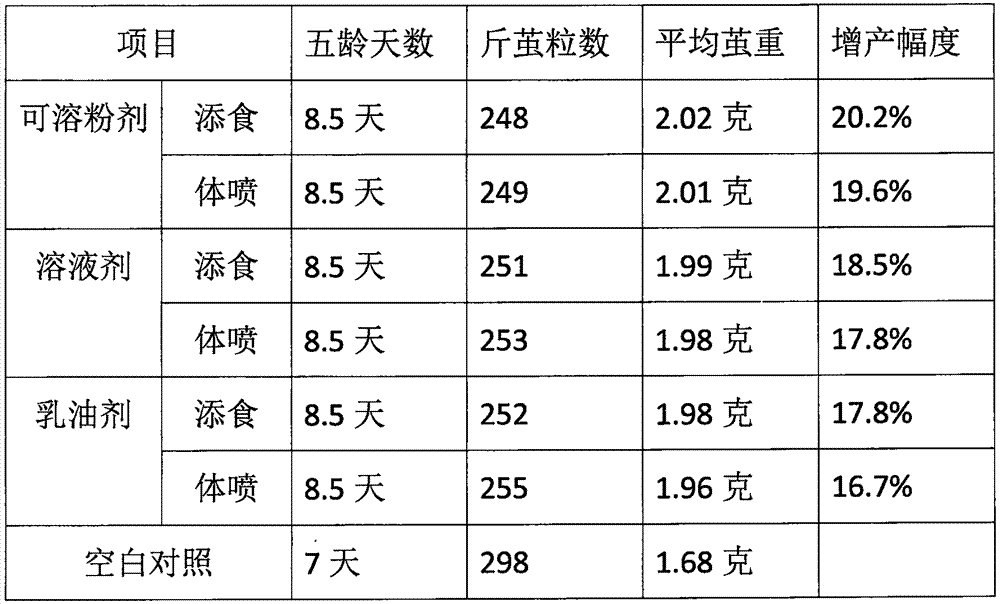

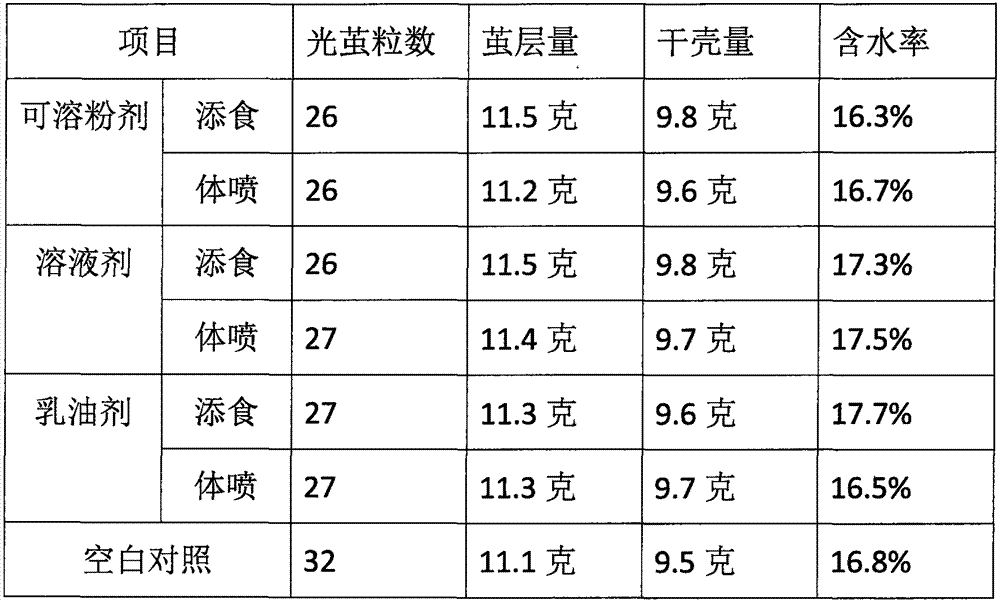

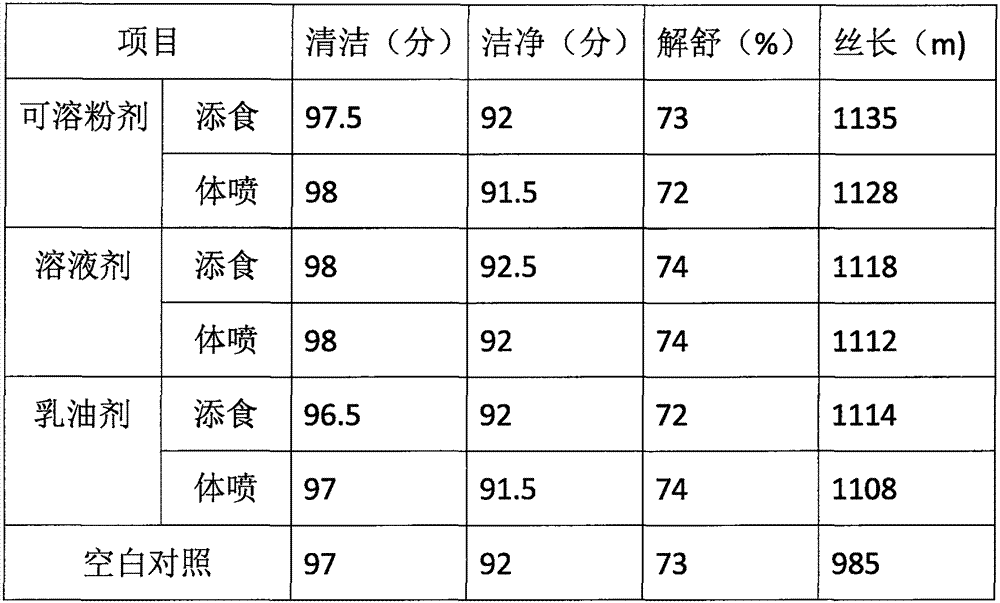

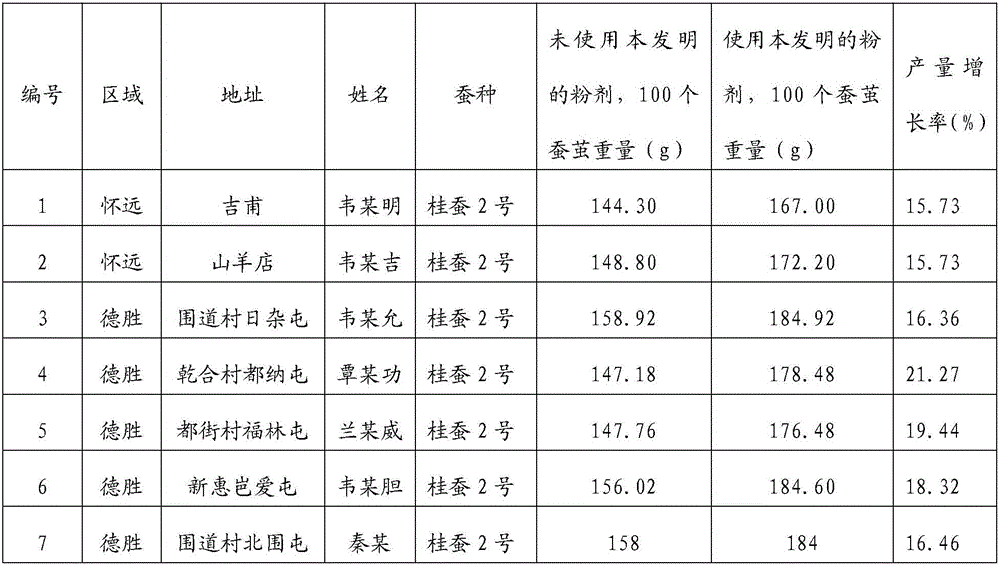

Application of methoprene in preparation of silkworm drug

PendingCN106955283AExtend ageIncrease food intakeOrganic active ingredientsDrug compositionsMethopreneBombyx mori

The invention discloses a new silkworm drug. S-methoprene is prepared into soluble powder, solution agent and oil concentrate agent which are suitable for silkworms to eat; the silkworm drug is used for regulating growth development of domestic silkworms and extending age so that the silkworms eat more mulberry leaves in a silk gland development stage, thus, the conversion of silk leaves is promoted, the yield of silkworm cocoons is increased, the adverse effect in the cocoon quality and the silk quality is avoided, and the cocoon quality and the silk quality are improved relatively. The silkworm drug is stable in pesticide effect and convenient to use, and is beneficial for improving the efficiency of breeding silkworms for silkworm raisers.

Owner:周元铎

Method of raising the yield of insect baculovirus with insect juvenoid

InactiveCN1403573AIncrease infection mortalityIncrease total outputPeptide/protein ingredientsViruses/bacteriophagesMethopreneHormone analog

The present invention relates to the application of insect juvenoid analog in the proliferation of insect baculovirus, and is especially the method of raising the yield of insect baculovirus with insect juvenoid. The method includes treating effective insect larva in its initial end period with insect juvenoid analog while virus infection, and further feeding of the insect until its death of virus infection. According to the said method, juvenoid analog ZR-515 (Methoprene) is used to treat beet armyworm larva to raise the death rate of beet armyworm caused by nuclear polyhedron virus infection, raise monocephalic virus content and total virus yield. The method of the present invention can raise virus yield for pesticide.

Owner:SUN YAT SEN UNIV

Harmless mosquito larva killing composition and preparation method thereof

InactiveCN109090116ANo pollution in the processHigh vegetation penetrationBiocideAnimal repellantsMethopreneHormone analog

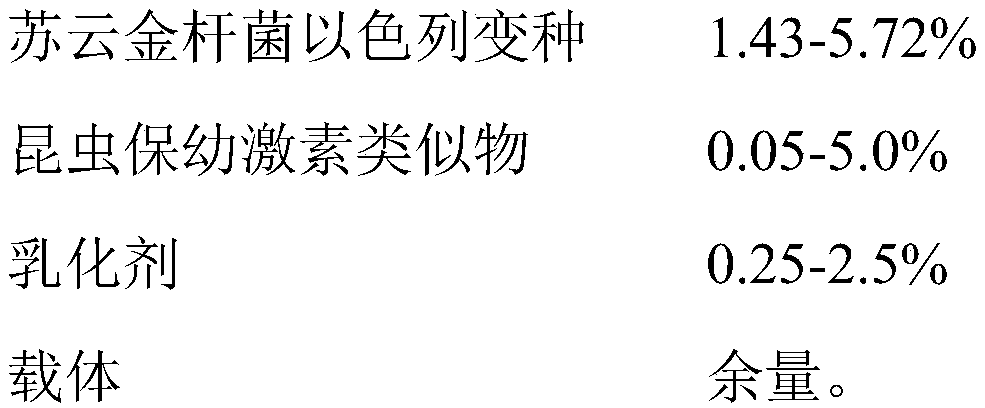

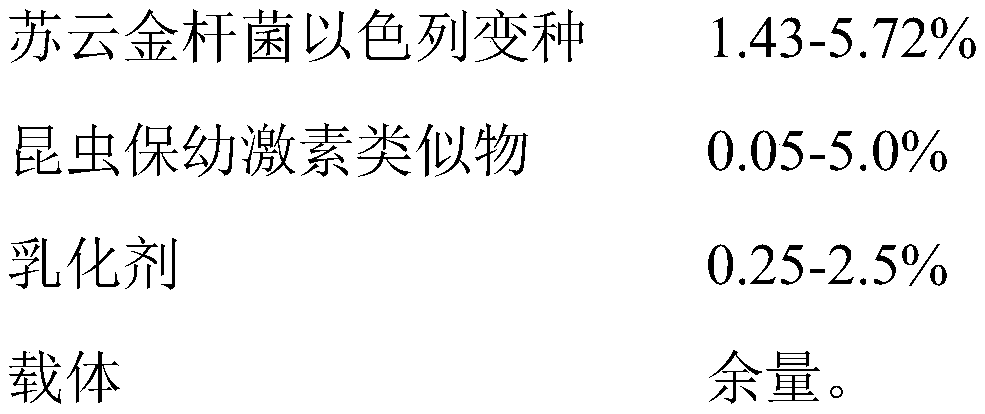

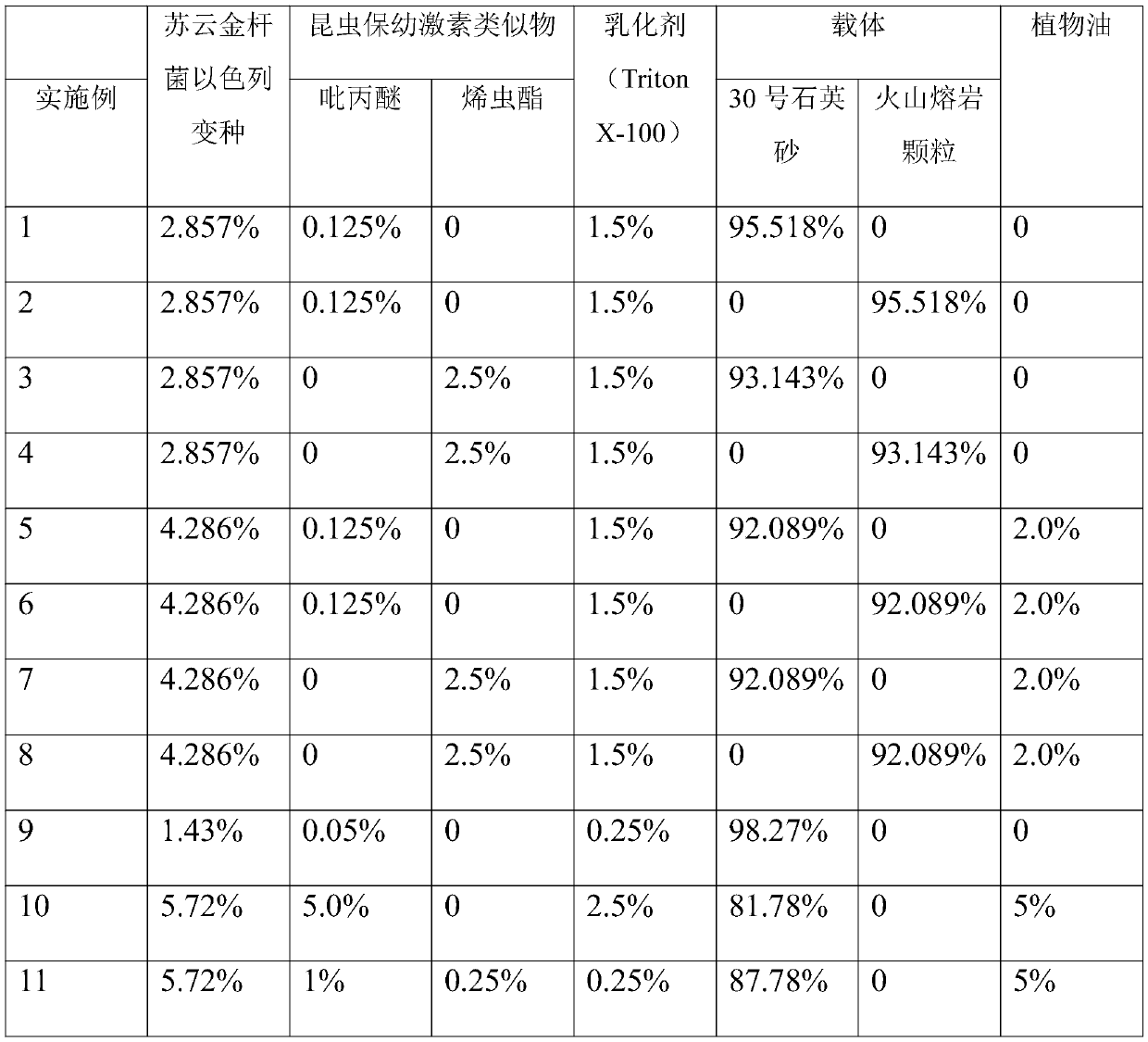

The invention discloses a harmless mosquito larva killing composition and a preparation method thereof. The composition comprises bacillus thuringiensis vav israelensis, insect juvenoid, an emulsifier, a carrier and optional plant oil, wherein the carrier is quartz sand or volcanic lava granules; the insect juvenoid is pyriproxyfen and / or methoprene. The preparation method comprises steps of emulsification, spraying, mixing, stirring, covering and the like. The composition disclosed by the invention is prepared by compounding purely natural soil bacterium products and artificially synthesizedinsect juvenoid, has the beneficial effects of quick-acting effects and slow effects, non-target bio-safety and no drug resistance, is free of pollution or residue in environment protection, and has high plant permeability. After vacuum sealing and packaging, a finished product of the composition disclosed by the invention can be preserved for two years under the condition of the room temperature.

Owner:广东惠利民有害生物防制工程有限公司 +1

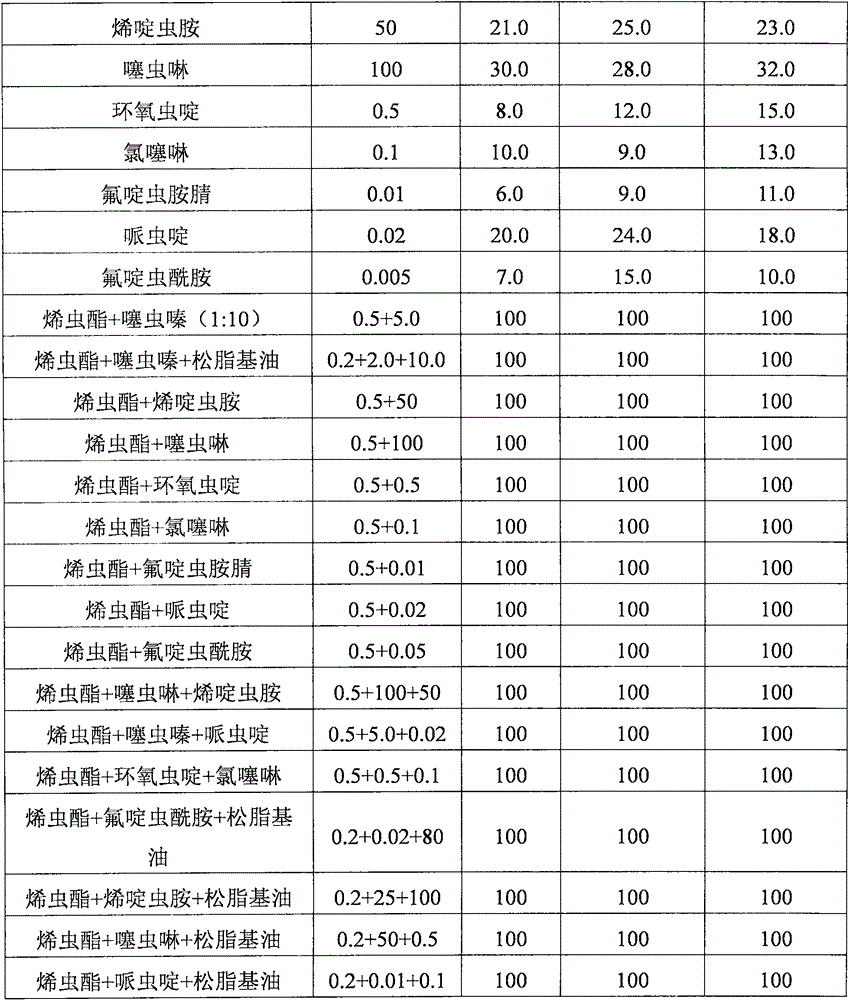

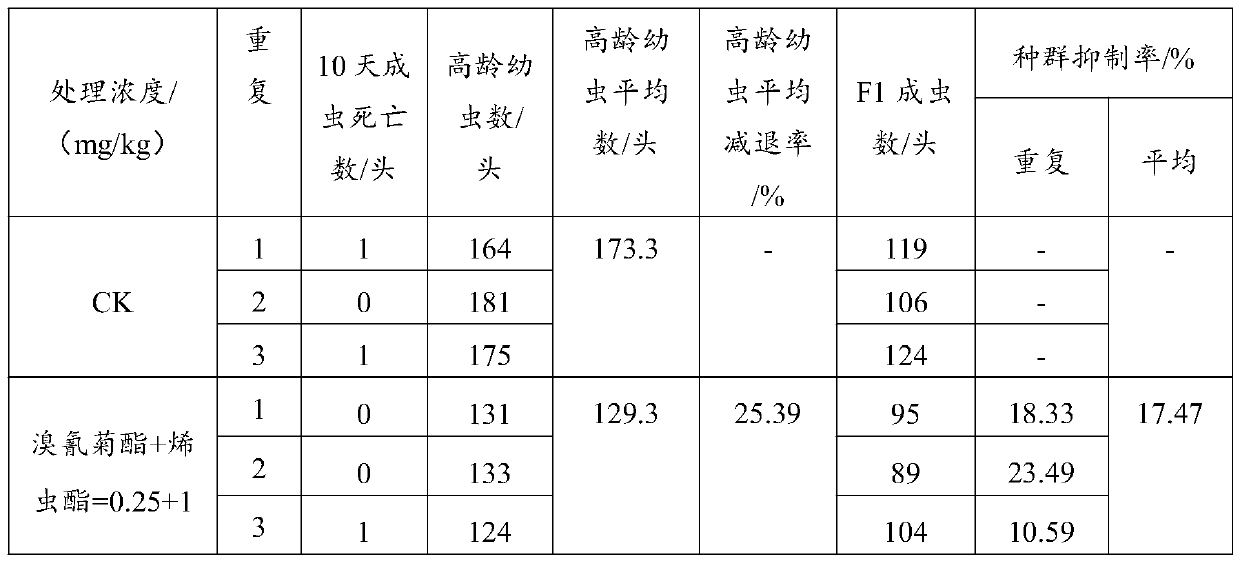

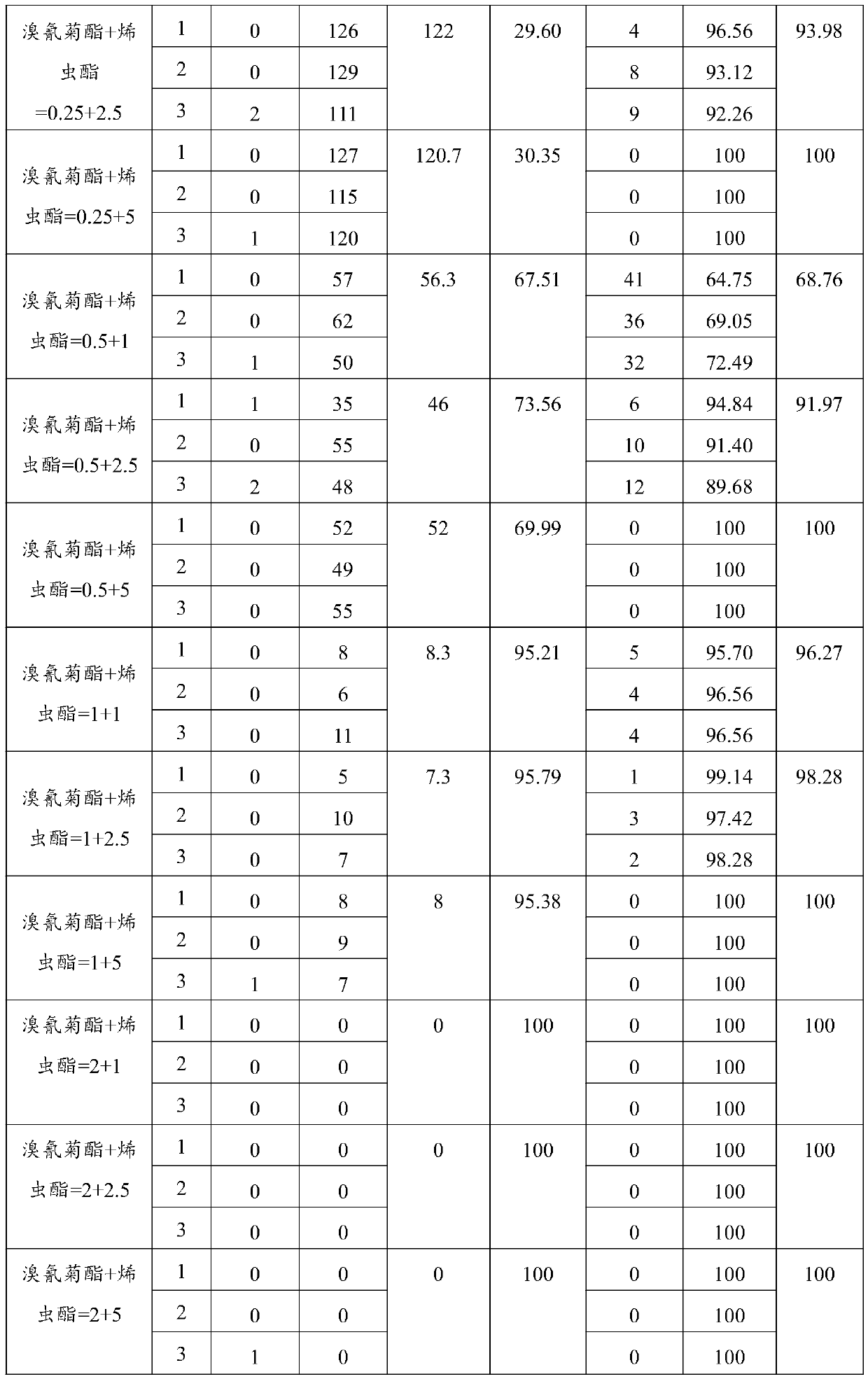

Insecticide composition for controlling stored grain pest population

The invention discloses an insecticide composition for controlling the stored grain pest population. The insecticide composition comprises active components of illicium verum essential oil, deltamethrin and methoprene. The mass ratio of the illicium verum essential oil to the deltamethrin to the methoprene is 1:(1-4):(4-20). The application amount of the illicium verum essential oil in stored grain is larger than or equal to 0.25 mg / kg, the application amount of the deltamethrin in the stored grain is 0.25-1 mg / kg, and the application amount of the methoprene in the stored grain is 1-5 mg / kg.According to the insecticide composition, based on the characteristics of the three kinds of pesticides of the methoprene, the deltamethrin and the illicium verum essential oil in prevention and treatment of stored grain pests, the advantages of the three kinds of pesticides are sufficiently used, the defects of the three kinds of pesticides are overcome, the three kinds of pesticides are scientifically and reasonably combined, and the insecticide composition has a synergistic function and is used for prevention and treatment for the stored grain pests; particularly for controlling the population of coleoptera and lepidoptera stored grain pests such as tribolium castaneum, the insecticide composition has a good fast-acting property, the aim of controlling pest dangers for a long time can also be achieved, and the insecticide composition is safe and free of pollution and has important application popularization value.

Owner:GUANGXI NORMAL UNIV

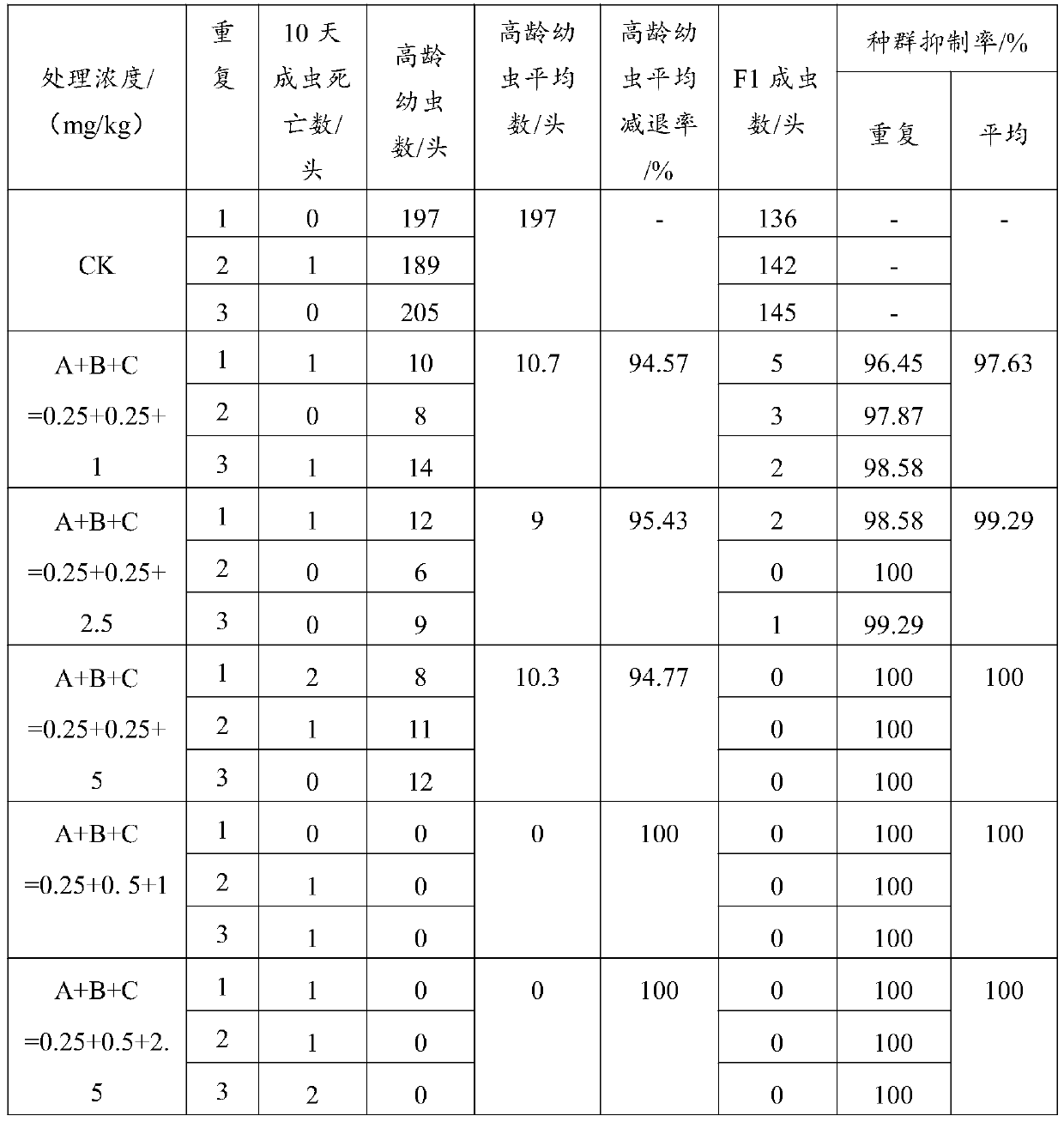

Nutrient solution for gaining weight of domestic silkworms and application of nutrient solution

The invention provides a nutrient solution for gaining weight of domestic silkworms and an application of the nutrient solution. The nutrient solution is composed of the following active ingredients such as S-methoprene, antioxidants, and carriers. The nutrient solution is an aqueous liquid, and each part of the nutrient solution can be used for feeding 25 thousand silkworms, and can achieve the effect of 10% or above of weight gain of silkworm cocoons.

Owner:常州胜杰生命科技股份有限公司

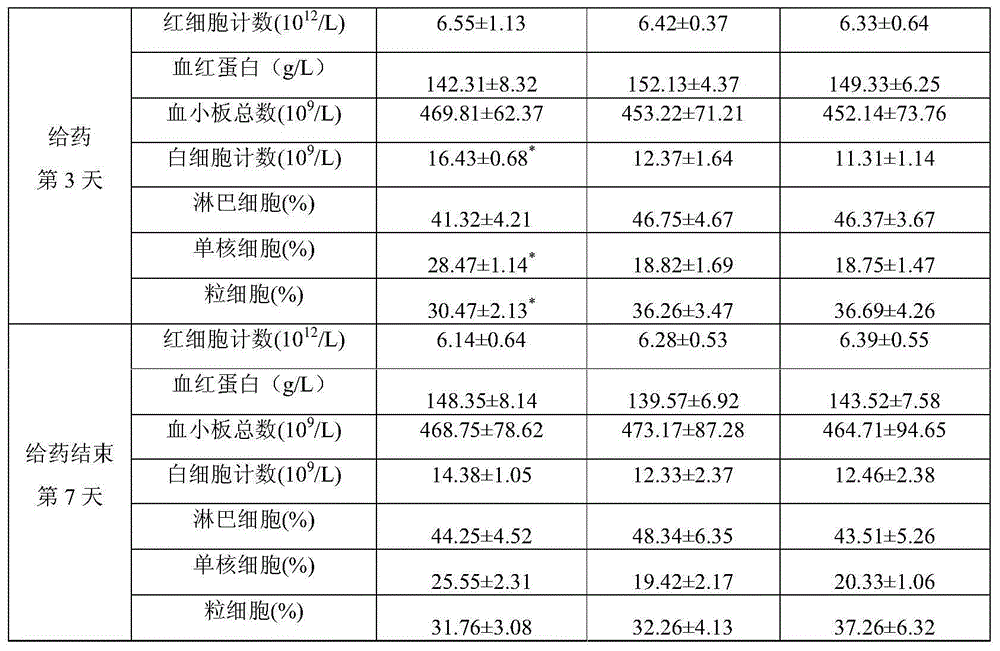

20-percent S-methoprene microcapsule suspension and preparing method of 20-percent S-methoprene microcapsule suspension

The invention provides a 20-percent S-methoprene microcapsule suspension and a preparing method of the 20-percent S-methoprene microcapsule suspension. The invention provides a pesticide product capable of being applied and used in the field in a large scale for killing mosquito larvae from sources. The active ingredient of the pesticide product is S-methoprene; the S-methoprene is of a long-chain unsaturated aliphatic ester structure; and the S-methoprene is used as juvenile hormone and can interfere the growth period of pests, so the pests cannot realize successful eclosion, and a pest killing goal is achieved. The pesticide product is nontoxic and green and is environmentally friendly; the activity on target pests is high; the use concentration is at the ppb level (1ppm=1000ppb); the pesticide product can be spread in the field in a large scale for controlling the mosquito density from sources; and the outbreak of epidemic diseases spread by mosquito vectors can be prevented.

Owner:苏衡

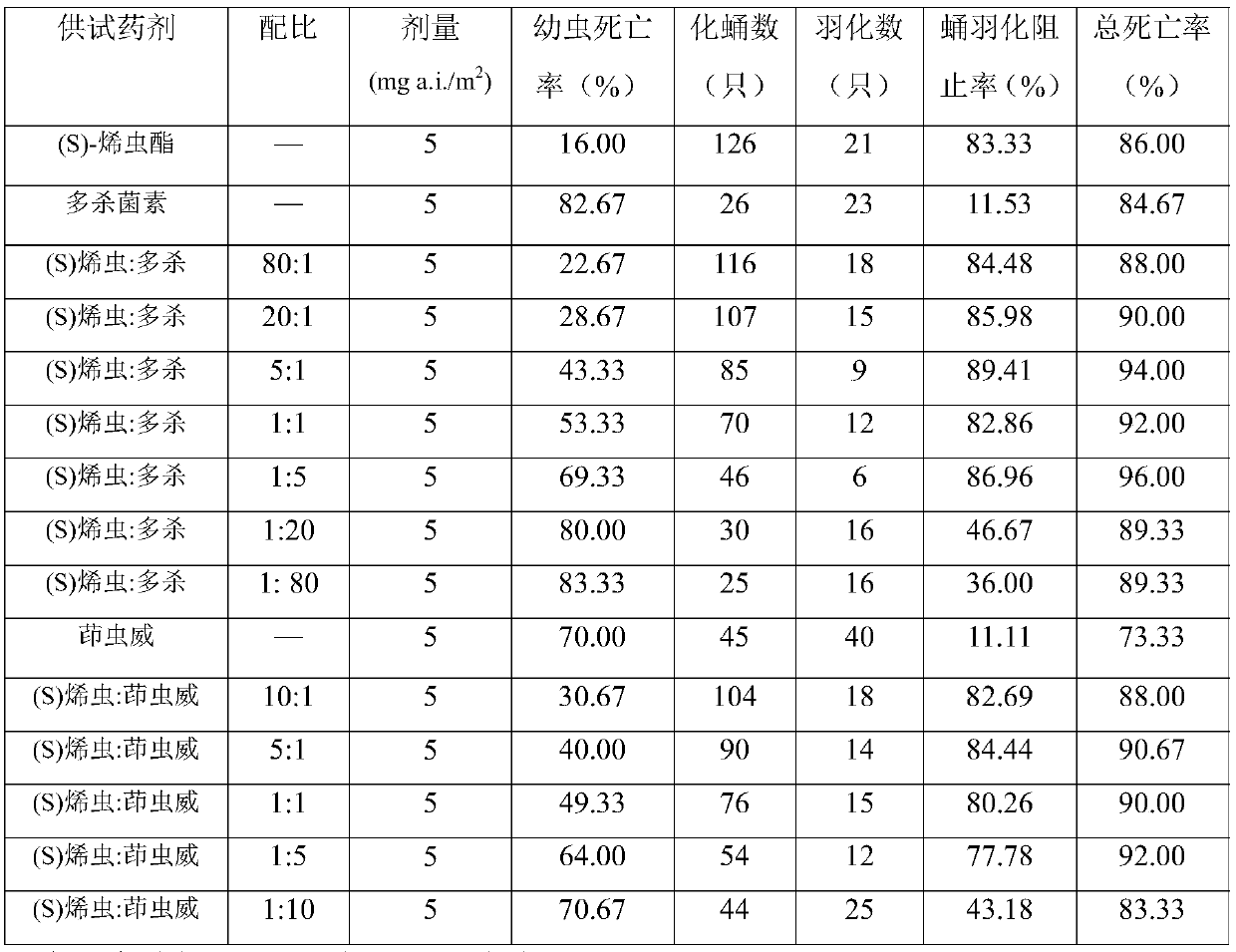

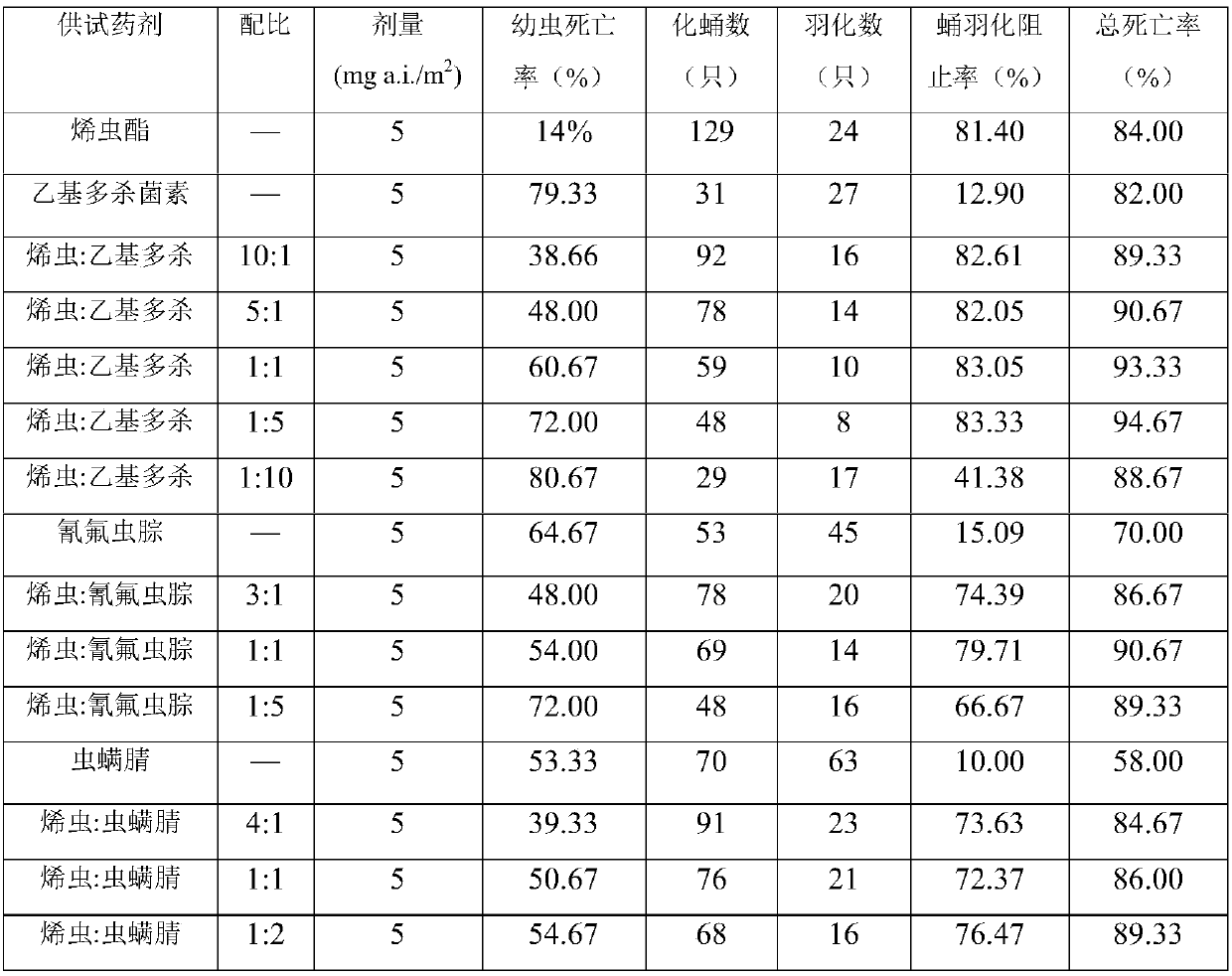

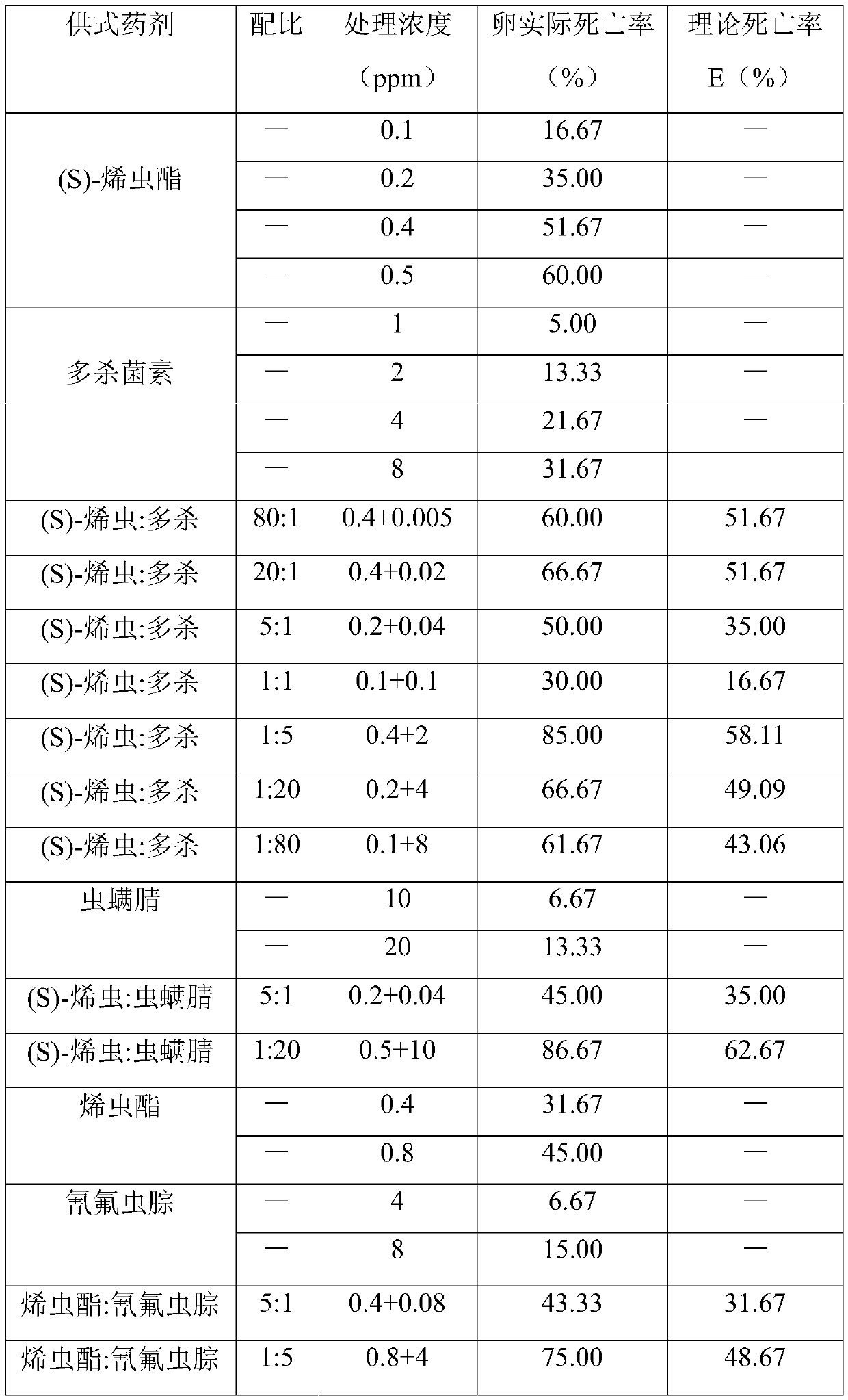

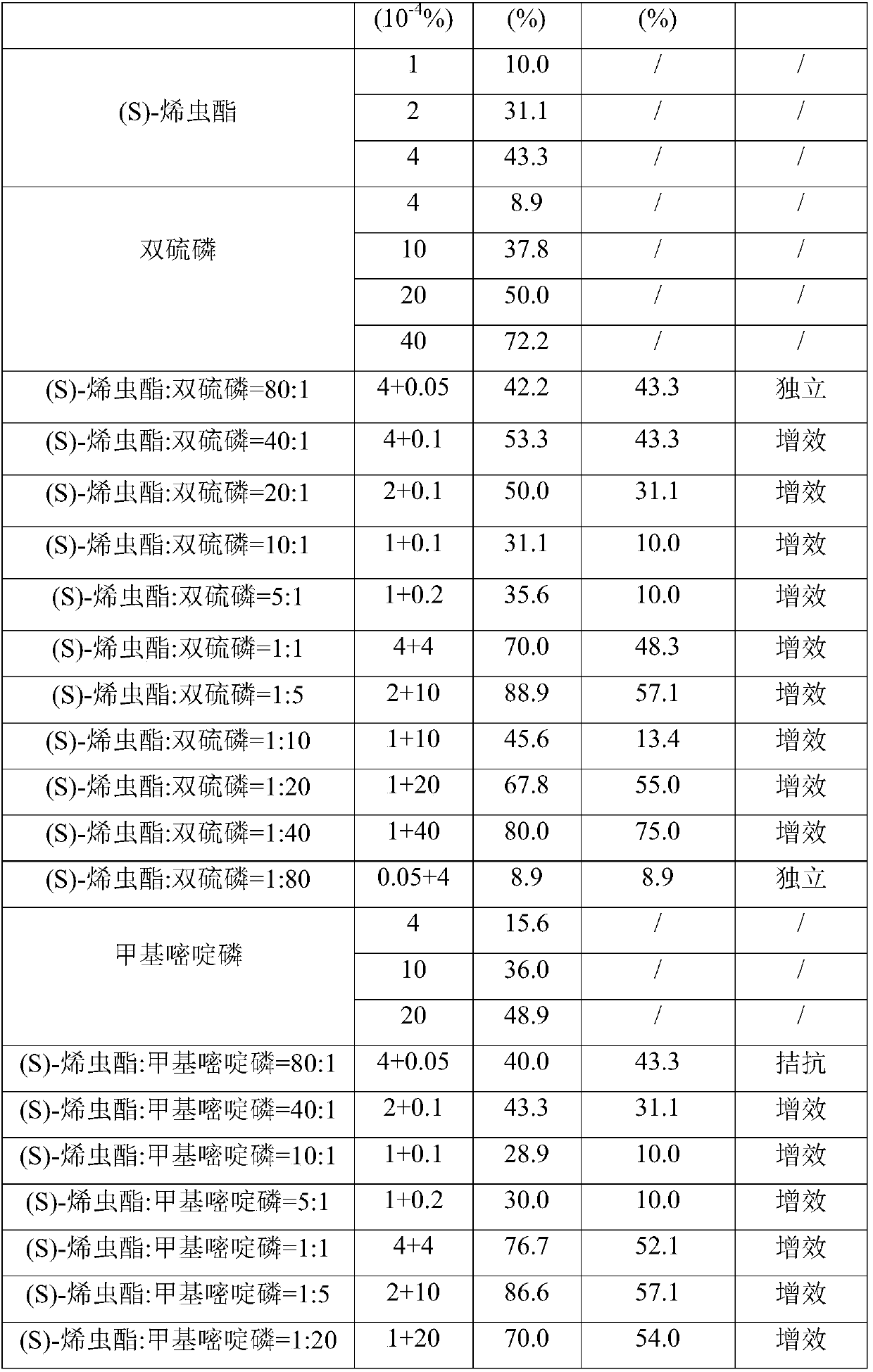

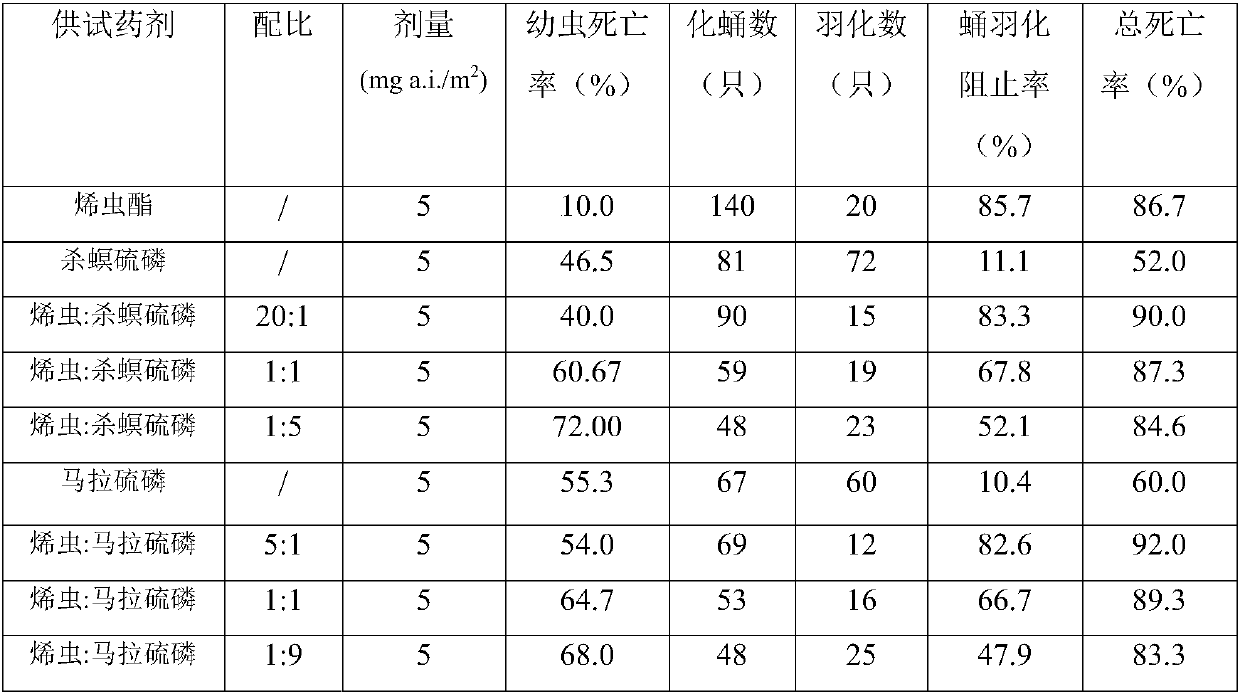

Insecticidal composition containing methoprene compound, and application of insecticidal composition

The invention relates to an insecticidal composition containing a methoprene compound, and application of the insecticidal composition. The composition comprises an active component A and an active component B, wherein the active component A is one selected from (S)-methoprene and methoprene, the active component B is one selected from indoxacarb, metaflumizone, spinosad, spinetoram and chlorfenapyr, and the weight ratio of the active component A to the active component B is 80:1-1:80. According to the invention, the action mechanisms of the two active components in the composition are greatlydifferent, the composition has an obvious synergistic effect on mosquitoes, hyphantria cunea, locusts, solenopsis invicta and other pests after being compounded, and the production and application value is high.

Owner:江苏功成生物科技有限公司

Insecticidal composition containing methoprene

Owner:江苏功成生物科技有限公司

Nutrient solution used for increasing cocoon weight and silk yield of silkworms

The invention provides a nutrient solution used for increasing cocoon weight and silk yield of silkworms. The nutrient solution used for increasing cocoon weight and silk yield of the silkworms is composed of the following ingredients: an active ingredient S-methoprene, an antioxidant, a carrier, and the like. The nutrient solution used for increasing cocoon weight and silk yield of the silkwormsis aqueous liquid capable of achieving the effect of increasing weight of silkworm cocoons by 10% or above at an addition amount of 1 part for per 25 thousand of silkworms.

Owner:常州胜杰生命科技股份有限公司

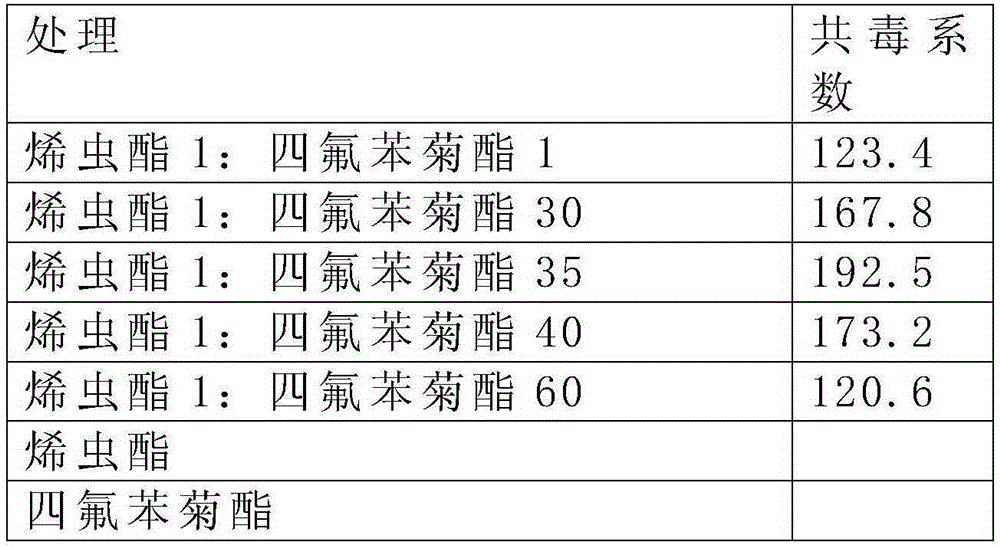

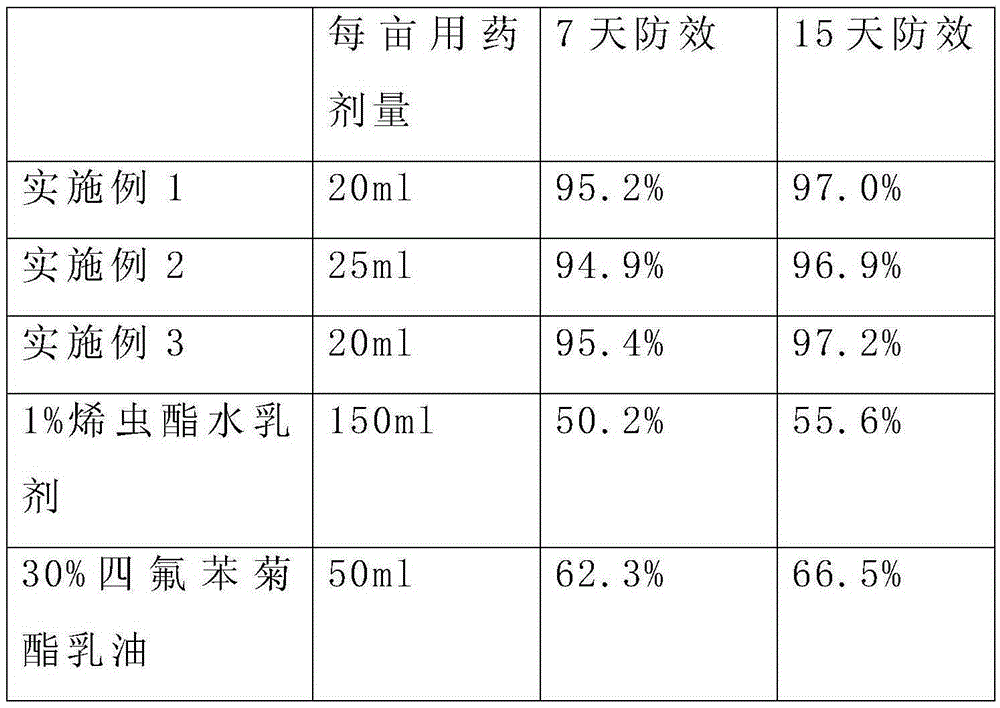

Ultra-low volume spray containing methoprene and transfluthrin and application

The invention belongs to the technical field of pesticide insecticide compounding and particularly relates to an ultra-low volume spray containing methoprene and transfluthrin and application. Active components of the composition are methoprene and transfluthrin, and the ratio of the active component methoprene to transfluthrin is 1:1-60. An efficient formulation is provided, the synergy is obvious after the compounding, the control effect is remarkable, the pesticide use amount is greatly reduced, the pesticide application cost is reduced, the ultra-low volume spray is convenient to spray, the environmental pollution is small, and the ultra-low volume spray adapts to a large-area cultivation mode.

Owner:JINAN SHUNHAO BIOTECH CO LTD

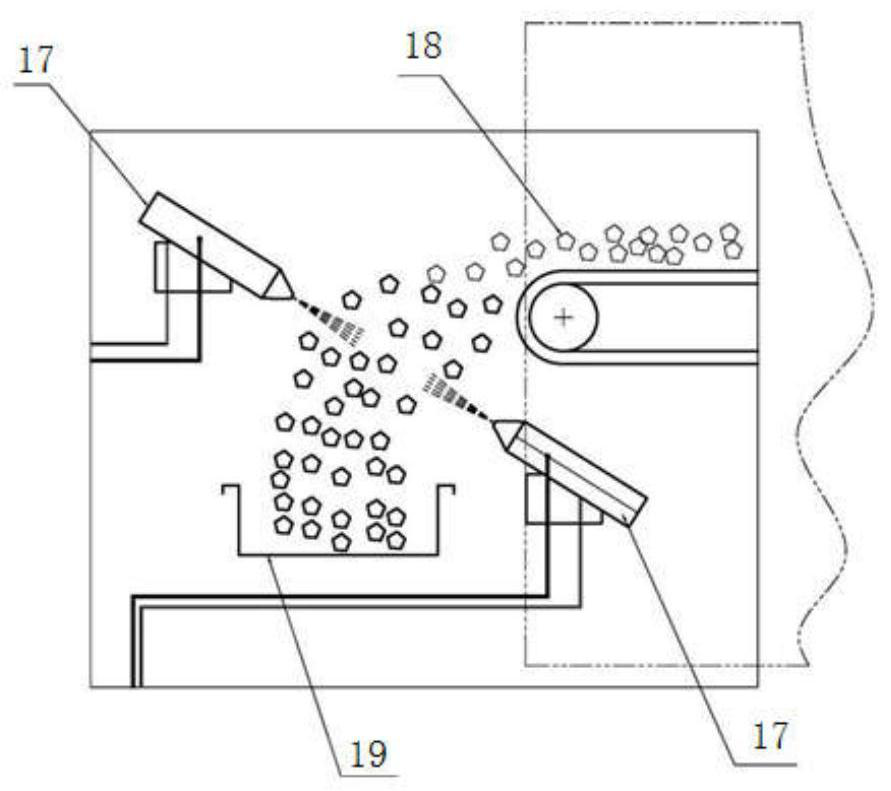

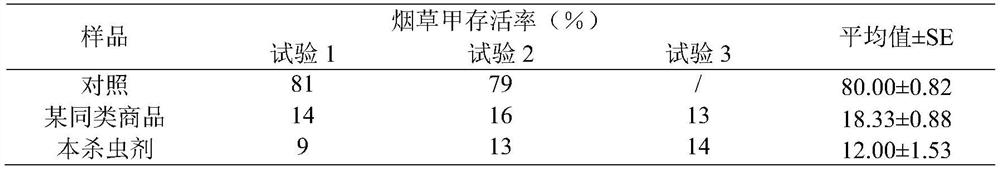

Biological insecticide containing methoprene, preparation method and spraying device

The invention discloses a biological insecticide containing methoprene, a preparation method and a spraying device. The insecticide is prepared from the following components in percentage by mass: 0.01-10% of methoprene, 0.01-5% of a surfactant, 0.01-10% of a light stabilizer, a proper amount of an isomer stabilizer and 75-99% of a solvent. The mixed solvent and the surfactant are adopted at the same time, so that the effective components can be uniformly dispersed into a solution, and the uniformity of the effective components can be ensured during use; the light stabilizer and the isomer stabilizer are added, so that the decay speed of methoprene in the insecticide is obviously slowed down, the storage period of the insecticide is prolonged, and the use effect of the insecticide is enhanced; and the biological insecticide has a very obvious killing effect on mosquitoes and flies in water and various insects such as lepidoptera, diptera, coleoptera and homoptera such as beetles and powder borers in grains and tobaccos, and can be applied to prevention and control of mosquitoes and flies in tap water, storage of grains and tobaccos, disinfection and insect killing of carpets and the like.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Silkworm cocoon weighing and whitening powder as well as preparation method and use method thereof

ActiveCN106667991AImprove securityReduce shipping costsOrganic active ingredientsPowder deliveryMethopreneDisease

The invention discloses a silkworm cocoon weighing and whitening powder as well as a preparation method and use method thereof, and belongs to the technical field of silkworm medicines. The silkworm cocoon weighing and whitening powder is made of brown sugar or white sugar and a methoprene emulsion in water, wherein the weight ratio of the brown sugar or white sugar to the methoprene emulsion in water is (100:9)-(100:18); the mass percentage of methoprene in the methoprene emulsion in water is 4-4.5%. The invention further discloses a preparation method and a use method of the silkworm cocoon weighing and whitening powder. By adopting the powder disclosed by the invention, defects of a methoprene liquid agent in the prior art can be overcome, the methoprene is prepared into a powder agent for the first time in China, in addition, the expiration date can be greater than or equal to 9 months. The powder disclosed by the invention is high in security and low in transportation cost. The powder can be applied to fifth instar larvae, the silkworm cocoon amount can be increased by 15-20%, in addition, the silkworm cocoon is good in whiteness, the silkworm cocoon grade is high, the price of the silkworm cocoon can be increased, and remarkable economic benefits can be made; moreover, the disease ratio or death ratio of the fifth instar larvae can be reduced.

Owner:GUANGXI HAOWANG BIOTECH

Ultralow-volume spraying agent containing fenthion and application thereof

InactiveCN105532718AReduce dosageReduce pollutionBiocideDead animal preservationMethopreneAdditive ingredient

The invention belongs to the technical field of pesticide and insecticide compounding, and in particular, relates to an ultralow-volume spraying agent containing fenthion and an application thereof. The composition has the effective ingredients of methoprene and fenthion, wherein the ratio of the effective component methoprene to the effective component fenthion is (1-20) to 2. The invention provides an efficient dosage form, after compounding, synergy is significant, the prevention and treatment effects are prominent, the pesticide use amount is greatly reduced, the cost of pesticide application is reduced, moreover, spraying is convenient, and the spraying agent has less pollution to the environment and adapts to large-area farming ways.

Owner:JINAN SHUNHAO BIOTECH CO LTD

Antiparasitic formulations

Fipronil formulations and fipronil / S-methoprene co-formulations are provided herein. These formulations optionally contain one or more additional active ingredient(s). The formulations comprise an organic solvent, an alcohol co-solvent, and one or more antioxidants and without any crystallization inhibitor. The formulations provided herein are antiparasitic, and can be used, for example, to combat dog and cat parasites, such as, fleas and ticks.

Owner:FIDOPHARM

Insecticidal fumigant for cigarette making machine set and fumigating and killing method

The invention discloses an insecticidal fumigant for a cigarette making machine set and a fumigating and killing method, belonging to the field of pest control of cigarette production equipment. The insecticidal fumigant for the cigarette making machine set is prepared from the following components in percentage by weight: 19 to 36% of sulfuryl fluoride, 54 to 76% of carbon dioxide and 5 to 10% ofS-methoprene. A preparation method of the insecticidal fumigant comprises the step of sequentially filling a pressure-resistant container with the sulfuryl fluoride, the carbon dioxide and the S-methoprene according to a sequence from a low vapor pressure from to a high vapor pressure. The fumigating and killing method comprises the following steps: sealing a cigarette making machine set, injecting the insecticidal fumigant into the cigarette making machine set, conducting fumigating and killing for 36-48 hours at a temperature of 15-35 DEG C, and recovering the insecticidal fumigant after the fumigating and killing are finished. The fumigant disclosed by the invention is low in toxicity, small in adsorption capacity, fast in analysis, strong in permeability and high in safety, can be used for effectively killing hidden insects and worm eggs in the unit, and has the advantages of thorough insect killing, short fumigating and killing period and no adverse effect on a cigarette unit.

Owner:陕西新金叶烟草科技有限公司

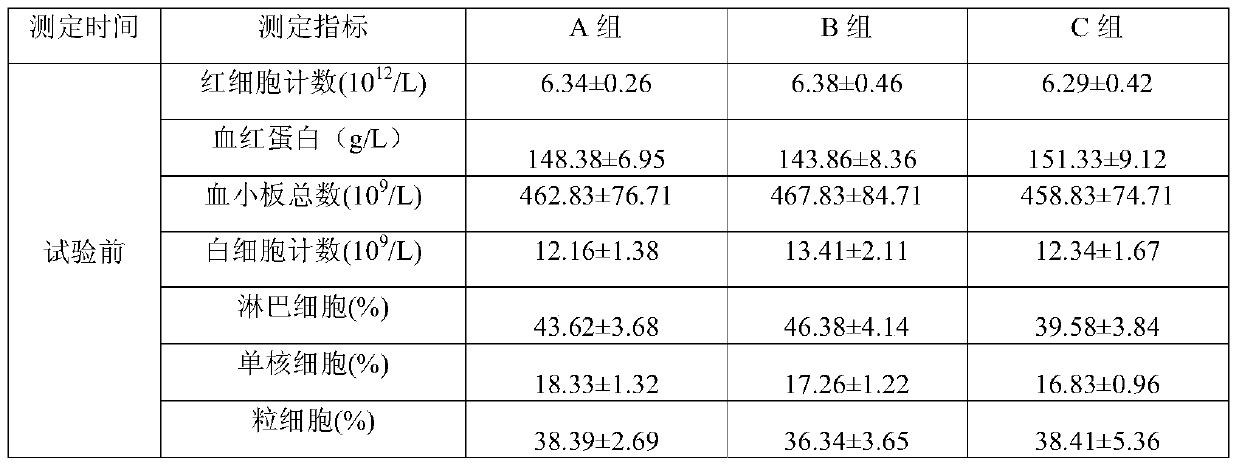

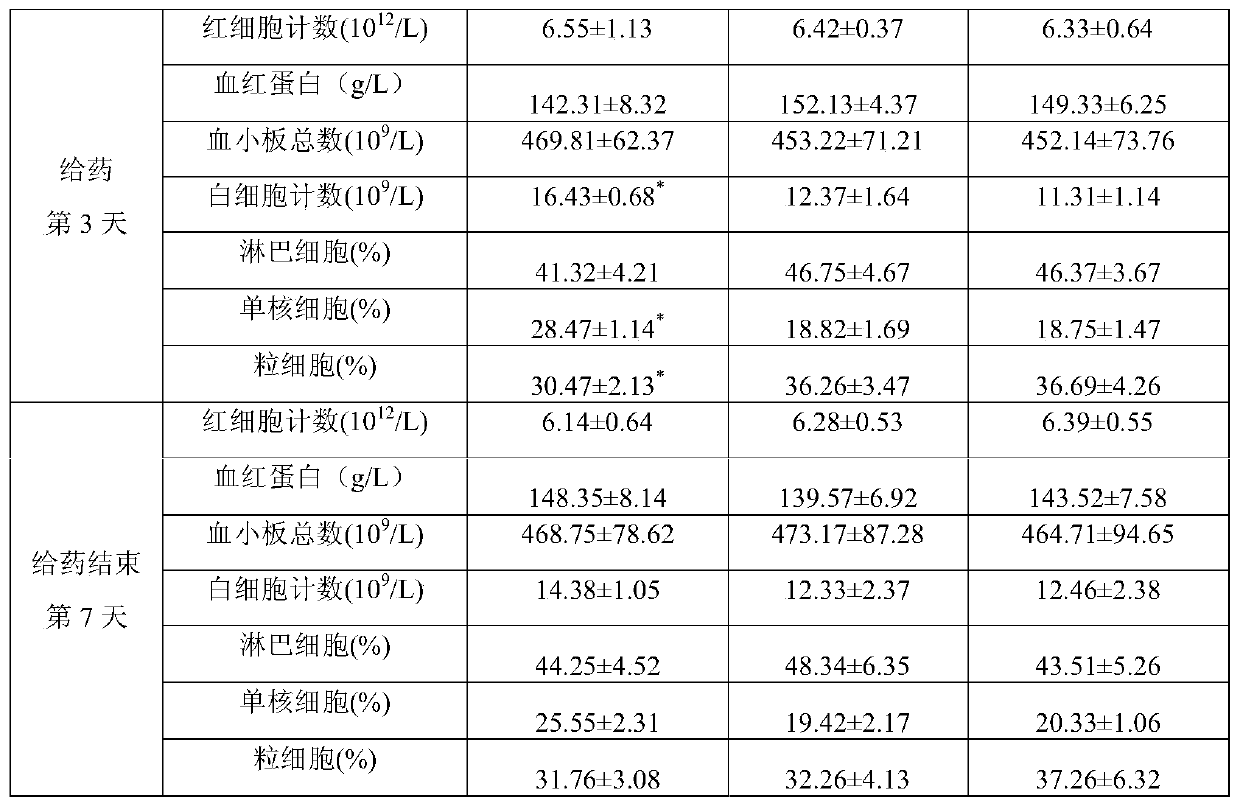

Pharmaceutical composition for preventing and/or treating parasites and its preparation method and application

ActiveCN105687188BEfficient removalSmall side effectsOrganic active ingredientsAntiparasitic agentsDiseaseMethoprene

The present invention relates to a parasite prevention and / or treatment pharmaceutical composition, and the pharmaceutical composition comprises the following components: 5-20% of Fipronil, 4-18% of methoprene, 2-10% of an emollient, and the balance of a pharmaceutically acceptable carrier. The present invention also relates to a preparation method and application of the pharmaceutical composition in preparation of drugs for the prevention and / or treatment of pet diseases.

Owner:LUOYANG HUIZHONG ANIMAL MEDICINE

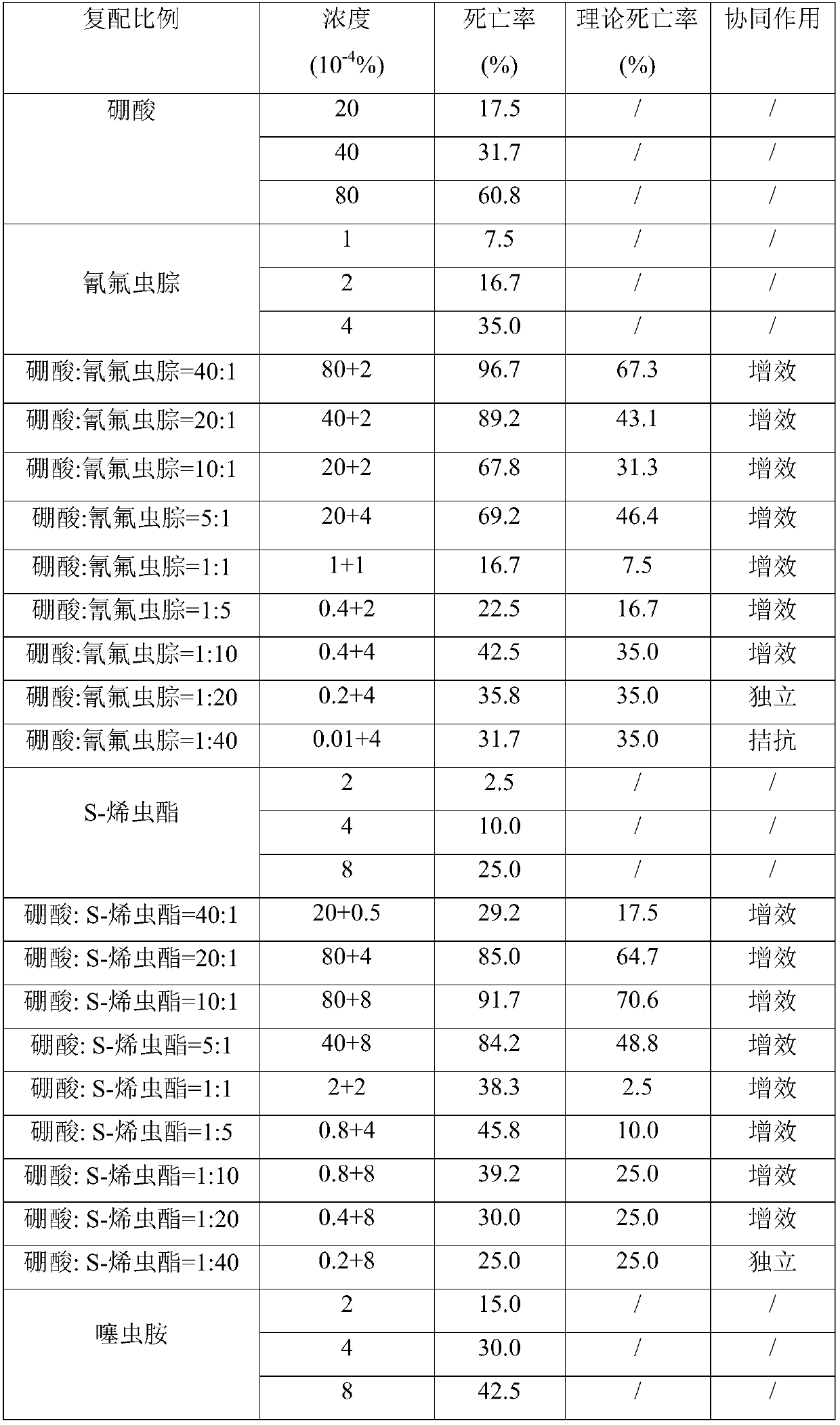

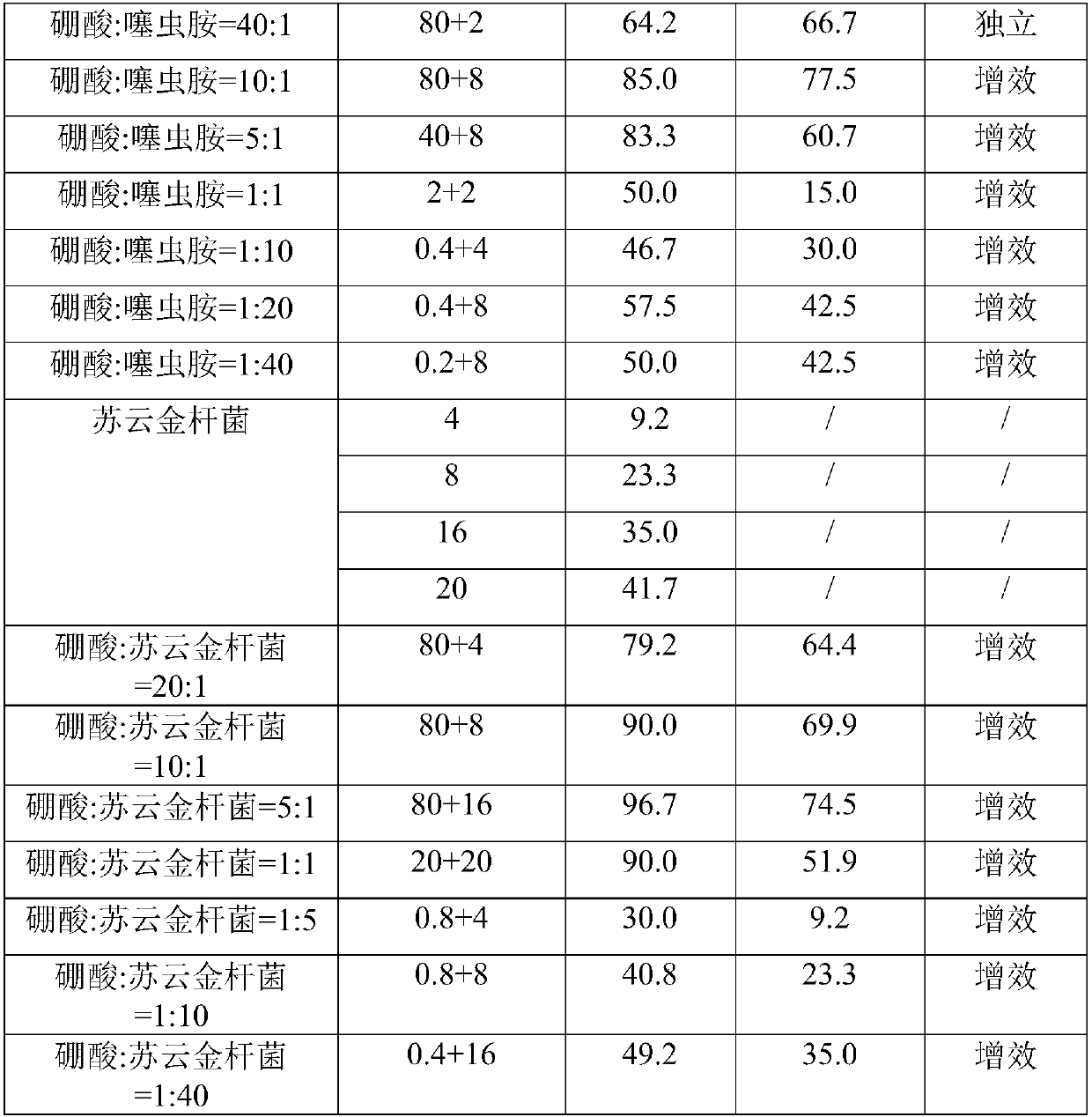

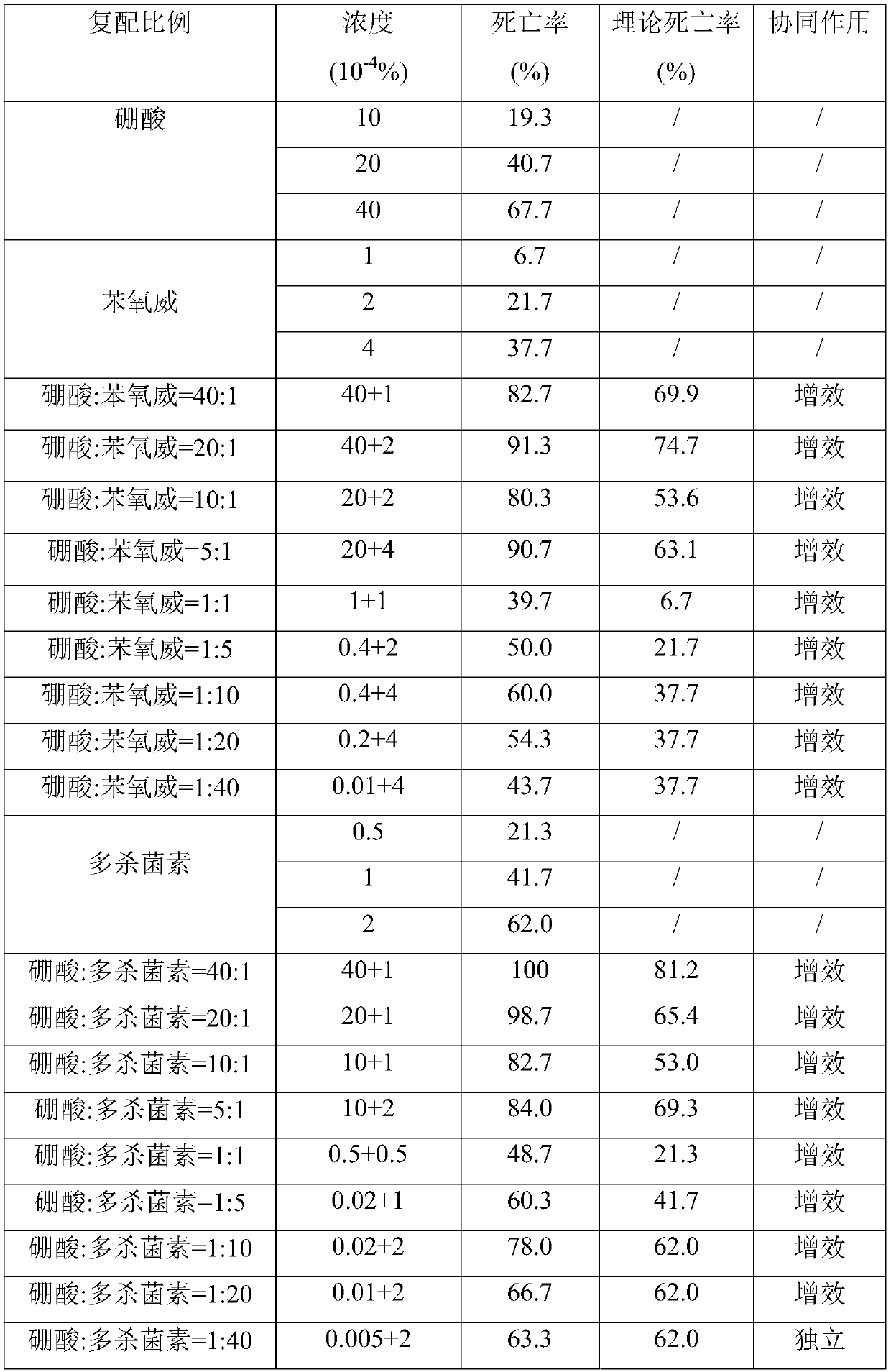

Insecticidal composition containing boric acid, and application thereof

InactiveCN111296478ADifficult to produce food refusalEnsure feedingBiocideAnimal repellantsMethopreneBacillus thuringiensis

The invention relates to an insecticidal composition, which is composed of an active component A and an active component B, wherein the active component A is boric acid, the active component B is oneselected from fenoxycarb, S-methoprene, indoxacarb, metaflumizone, clothianidin, acetamiprid, spinosad and bacillus thuringiensis, when the active component B is selected from fenoxycarb, S-methoprene, clothianidin, acetamiprid and bacillus thuringiensis, the weight ratio of the active component A to the active component B is 40:1-1:40, and when the active component B is selected from indoxacarb,metaflumizone and spinosad, the weight ratio of A to B is (40: 1)-(1:20). According to the invention, the composition is dominated by an inorganic salt boric acid, the lethal rate is not high, solenopsis invicta is not prone to producing food refusal, it is ensured that queen ant and breeding ants eat the lethal dosage, the prevention and control rate is increased, and after boric acid and the specific active component B are compounded, the synergistic effect is achieved, and the production practicability is achieved.

Owner:江苏功成生物科技有限公司

Preparation method for methoprene microcapsules

The invention relates to a preparation method for methoprene microcapsules. The preparation method comprises the following steps: firstly, carrier preparation is carried out, namely, a polymerization reaction with a mol ratio of succinic acid, butylene glycol and lactic acid being 1:1:0.2-0.3 is carried out, and a carrier PBS-co-PLA is obtained; secondly, oil phase preparation is carried out, namely, PBS-co-PLA, methoprene and dichloromethane are weighed with a mass ratio of PBS-co-PLA, methoprene and dichloromethane being 3.5-4.5:1:10, the PBS-co-PLA carrier is dissolved in dichloromethane, after the PBS-co-PLA is dissolved in dichloromethane fully, the methoprene active compound is added and dissolved and an oil phase is obtained; thirdly, water phase preparation is carried out, deionized water is measured and taken with a mass ratio of the oil phase to the water phase being 1:5-7, an emulsifier dispersant is added in water and dissolved and a water phase is obtained; fourthly, microcapsule preparation is carried out, namely, the oil phase is added in the water phase, an oil and water mixed emulsion is obtained, an antifoaming agent is added, microcapsule suspension is prepared after curing, water washing is carried out, the supernatant is removed, and a finished product is obtained after drying. The method is simple in technology and is environmentally friendly. The obtained methoprene microcapsules have a good form, the encapsulation efficiency is 78%, the drug loading capacity is 50%, the effective release period is 30 days, the drug release amount is 94%, and the methoprene microcapsule is an ideal pesticide sustained release agent.

Owner:周德志

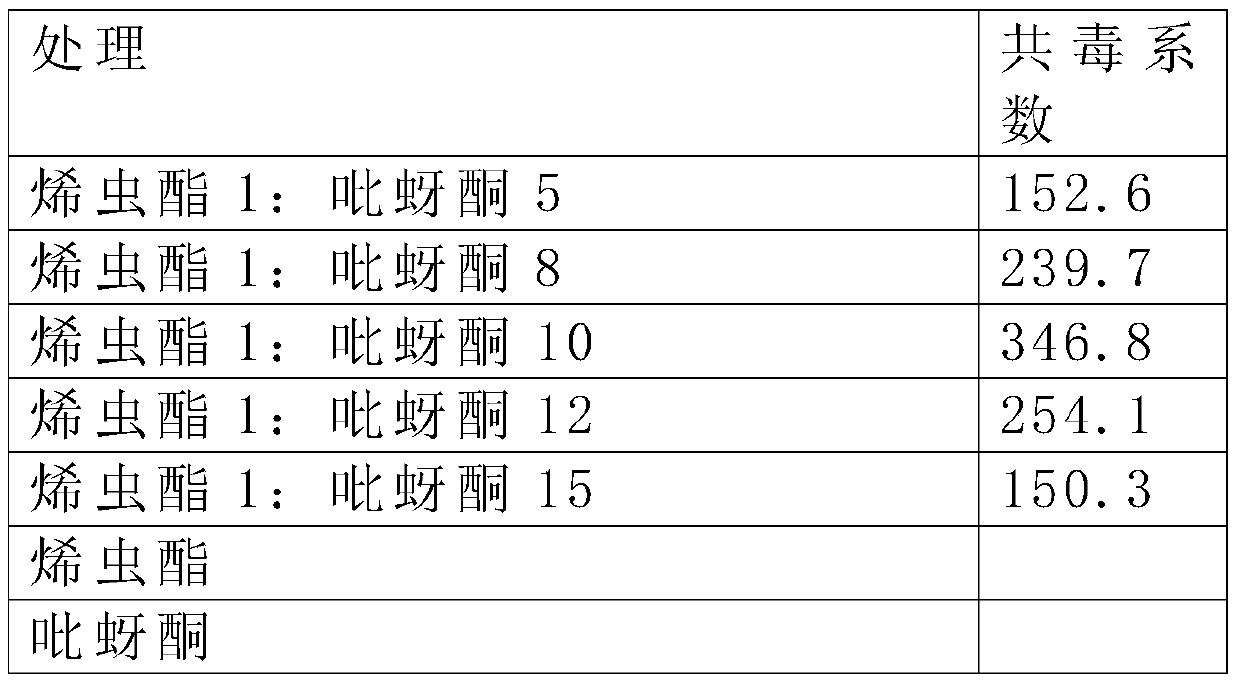

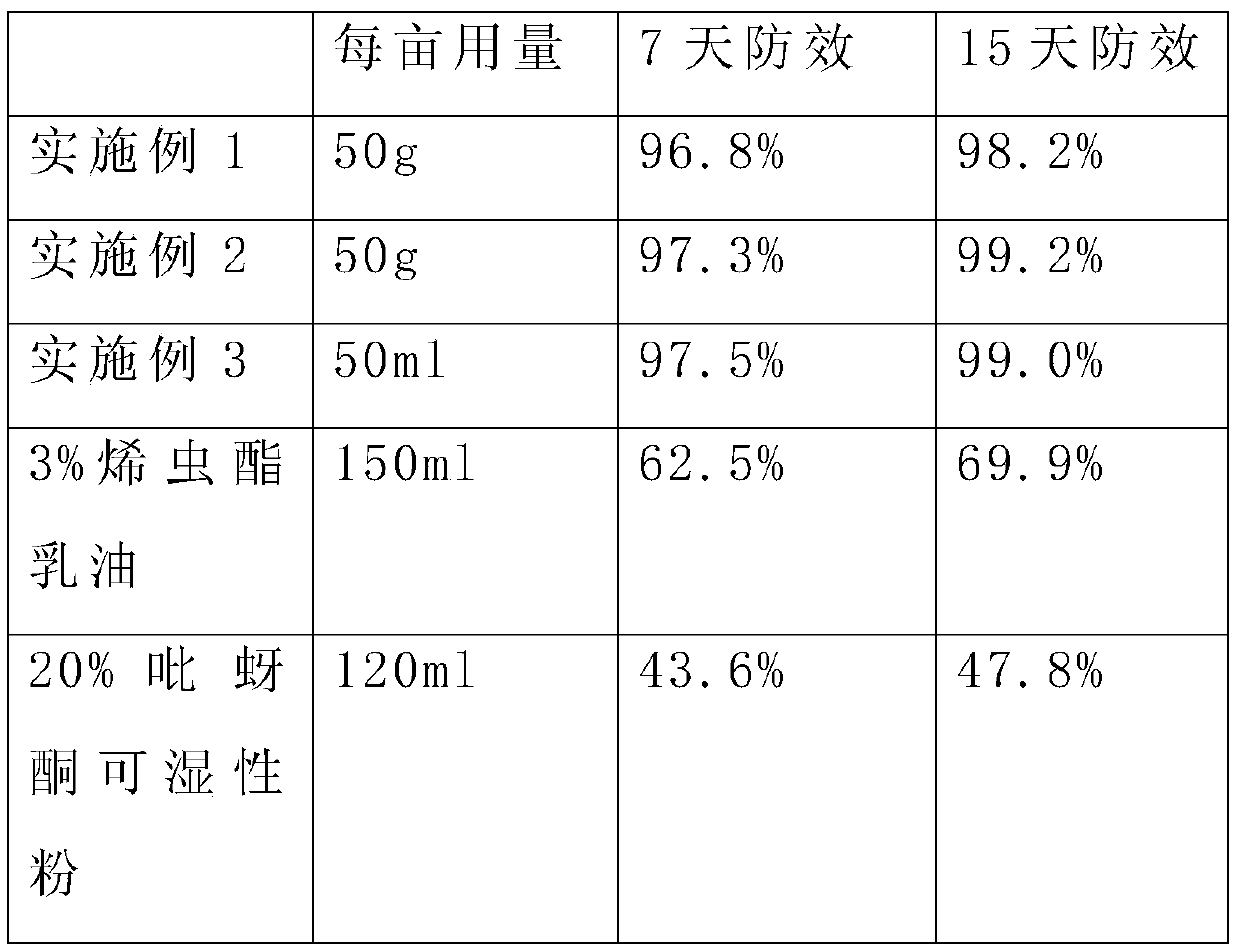

Composition containing pymetrozine and application

InactiveCN105494362AMitigate the problem of drug resistanceReduce dosageBiocideDead animal preservationMethopreneHas active ingredient

The invention belongs to the technical field of agricultural insecticide compounding and particularly provides a composition containing pymetrozine and application. The effective components of the composition are methoprene and pymetrozine, wherein the mass ratio of the effective components, namely the methoprene to the pymetrozine, is 1: (5-15). The effect can be obviously improved. The composition has a remarkable prevention and control effect, relieves the problem of pest resistance to insecticides to the most degree, accordingly the dosage of agricultural insecticides is decreased, and the prevention and control costs are reduced. In addition, the composition is convenient to spray and apply and small in environmental pollution and is suitable for a large-area tillage mode.

Owner:JINAN SHUNHAO BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com