Insecticidal fumigant for cigarette making machine set and fumigating and killing method

A fumigant and unit technology, applied in the direction of insecticides, botanical equipment and methods, biocides, etc., can solve the problems of long fumigation time, high dose of insect eggs, large dosage, etc., and achieve short fumigation cycle and safety High toxicity, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

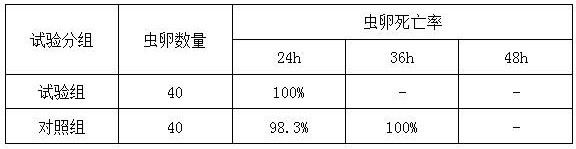

Examples

Embodiment 1

[0033] This embodiment 1 provides a method for fumigating and killing hidden pests inside a cigarette unit, specifically adopting an insecticidal fumigant composed of 25% sulfuryl fluoride, 70% carbon dioxide and 5% S-methoprene in percentage by weight. Cigarette unit No. 8 ZJ19-ZB25 unit (referred to as 8 # unit) and No. 9 cigarette unit ZJ19-ZB25 unit (referred to as 9 # crew) for fumigation, the 8 # Crew and 9 # The volume of the unit is 315m 3 , including the following steps:

[0034] Before the present embodiment 1 carried out fumigating and killing, arranging trapping boards was carried out by a definite period of one month to monitor the insect situation, and the monitoring result was 8 # Crew 3 tobacco beetles / week, 9 # Unit 4 tobacco beetles / week;

[0035] Adopt the plastic film that thickness is 0.15mm to describe 8 # Crew and 9 # The unit is sealed on five sides, and the contact part between the plastic film and the ground is sealed with sealing tape;

[00...

Embodiment 2

[0041] This embodiment 2 provides a method for fumigating and killing hidden pests inside the cigarette unit, specifically using a fumigant composed of 20% sulfuryl fluoride, 70% carbon dioxide and 10% S-methoprene in percentage by weight to treat Hanzhong cigarettes Cigarette unit No. 10 ZJ17-ZB47 cigarette unit (referred to as 10 # unit), No. 12 ZJ17-ZB47 cigarette unit (referred to as 12 # unit) and No. 14 ZJ17-ZB25 cigarette unit (referred to as 14 # crew) for fumigation, the 10 # Crew and 12 # The volume of the unit is 310m 3 , 14 # Unit volume 317m 3 , including the following steps:

[0042] Before the present embodiment 2 carried out fumigation and killing, arranging trapping boards was carried out by a definite period of one month to monitor the insect situation, and the monitoring result was 10 # Crew and 12 # Crew 5 tobacco beetles / week, 14 # The unit has 3 tobacco beetles per week;

[0043] The plastic film with a thickness of 0.12mm is used to seal the th...

Embodiment 3

[0049] This embodiment 3 provides a method for fumigating and killing hidden pests inside the cigarette unit, specifically using an insecticidal fumigant composed of 35% sulfuryl fluoride, 57% carbon dioxide and 8% S-methoprene in percentage by weight. Cigarette unit No. 4 ZJ17-ZB25 cigarette unit (referred to as 4 # unit) and No. 5 ZJ17-ZB25 cigarette unit (referred to as 5 # crew) for fumigation, the 4 # Crew and 5 # The volume of the unit is 318m 3 , including the following steps:

[0050] Before the fumigation in this embodiment 3, trapping boards were arranged to monitor the insect situation for a period of one month, and the monitoring results were 4 # Crew 11 tobacco beetles / week, 5 # The unit has 7 tobacco beetles per week;

[0051] The plastic film with a thickness of 0.12mm is used to seal the five sides of the two groups of units respectively, and the contact part between the plastic film and the ground is sealed with a sealing tape;

[0052] The insecticidal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com