Patents

Literature

104results about How to "Excellent mothproof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mildewproof and mothproof composite fabric

InactiveCN102058189AImprove breathabilityKeep warmLayered productsProtective garmentKapok fiberEngineering

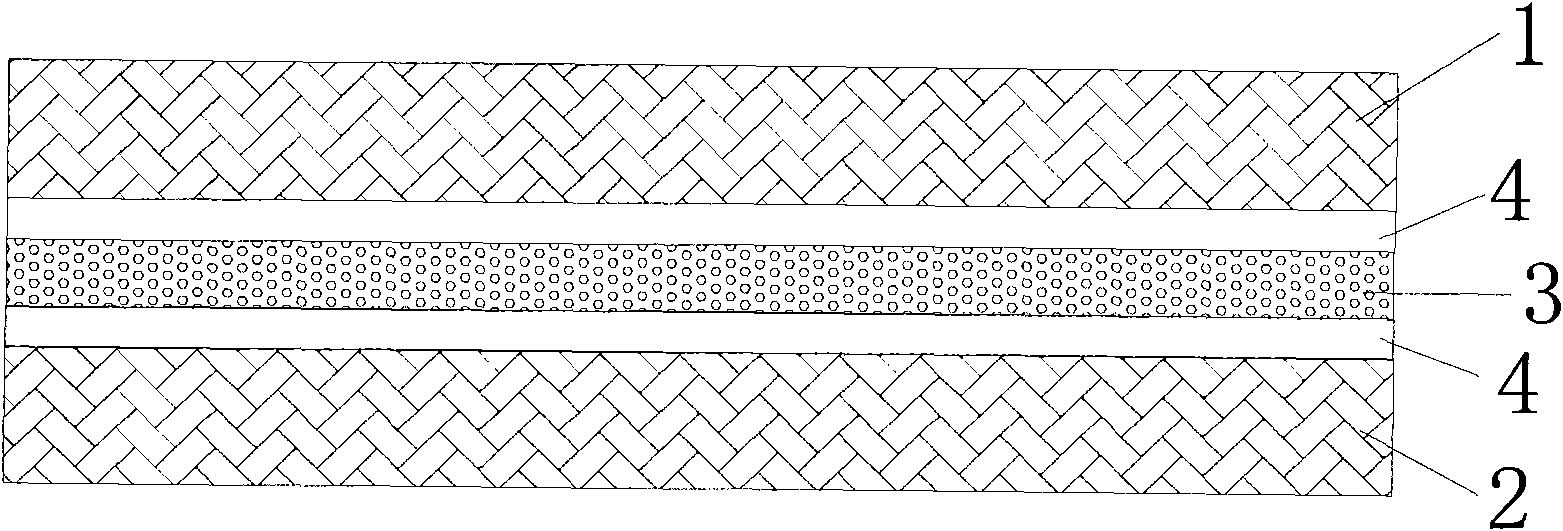

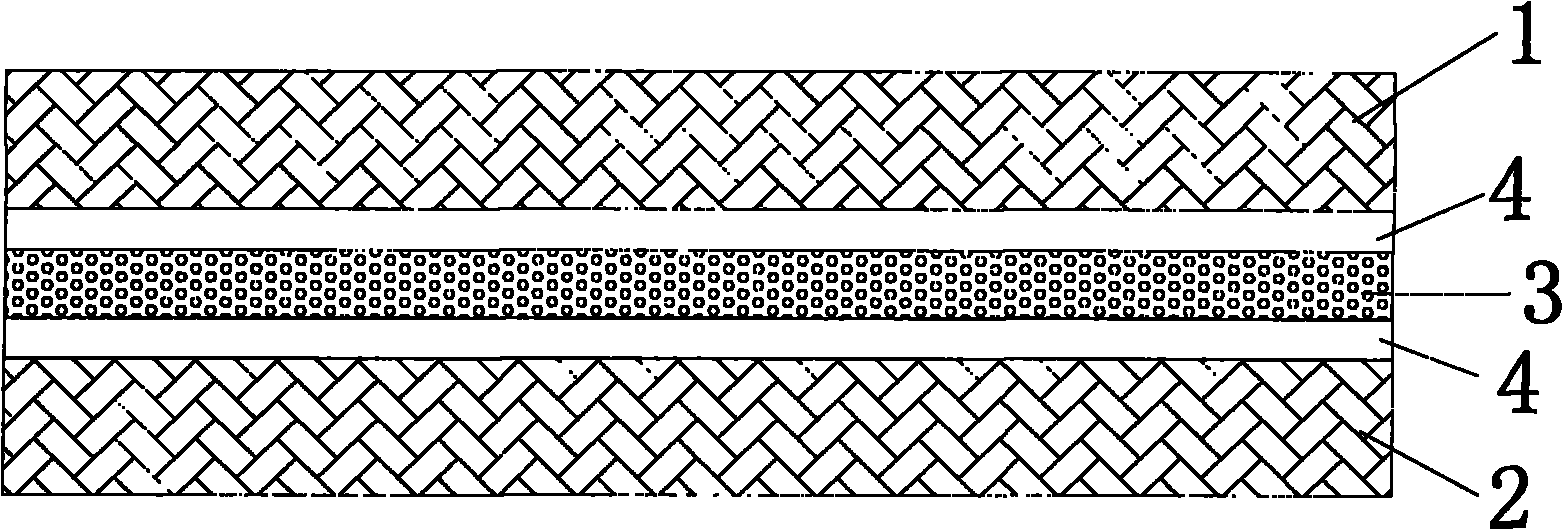

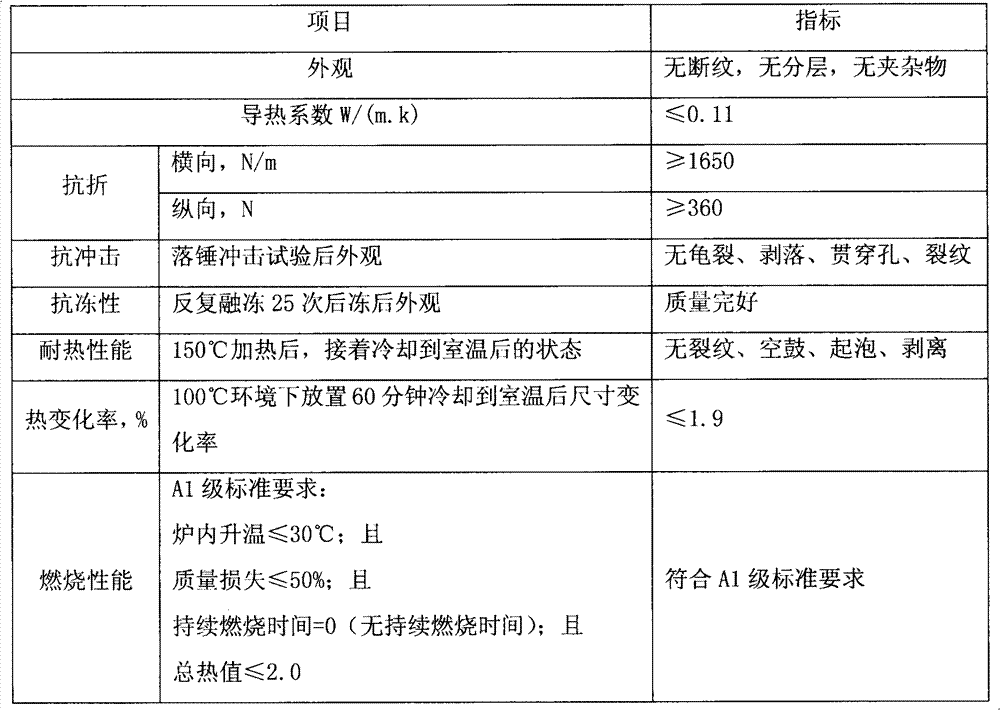

The invention discloses a mildewproof and mothproof composite fabric, which comprises an outer layer, an inner layer and a middle layer, wherein both the outer layer and the inner layer are made of fabric blended with kapok fibers and other fibers; the middle layer is a membrane layer; and the two sides of the membrane layer are combined with the outer layer and the inner layer through glue layers. The composite fabric disclosed by the invention is a kapok fiber-containing fabric, has excellent breathing, warming, dampness conducting, mildewproof and mothproof effects, is environmentally-friendly, has the characteristic of being softer, lighter and more environmentally-friendly than fabrics made of other fibers, and mainly solves the problem that the mildewproof and mothproof effects of other fibers are undesirable.

Owner:CHANGSHU HUABO WOOLEN TEXTILE

Antique tusche and new preparation method thereof

InactiveCN101787234AIncrease the sense of thicknessAvoid ambiguityInksGranularityTraditional medicine

The invention relates to an antique tusche and a preparation method thereof. The antique tusche comprises the components by weight percent: 75-85 bone glue solution, 3-25 oily fume, 0.05-0.5 powdery spice and 0.5-5 traditional Chinese medicine liquid, wherein the bone glue solution is prepared by mixing bone glue and water according to a certain mass ratio, heating to 110-120 DEG C, decocting for 20-50h, and filtering; the oily fume is light powder solid and has the granularity less than 1 micron; the powdery spice is prepared by grinding musk and borneol with the mass ration of 2: 8 and sieving by a 200-mesh sieve; the traditional Chinese medicine liquid is prepared by decocting Chinese herbal medicines; and the preparation method of the antique tusche comprises the steps of: evenly mixing the bone glue solution, the oily fume, the musk, the borneol and the traditional Chinese medicine liquid, and dispersing the mixture into paste with the fineness less than 15 microns and the viscosity of 0.01-200 Pa. S; and the antique tusche is used for writing or printing painting and calligraphy works.

Owner:北京今鼎新化文化有限公司 +1

Process for preparing biological specimen

The invention discloses a biological specimen preparation method as follows: a specimen is pressed, shaped and dried; and then a shallow tray is made with a transparent organic plate and three narrow same organic plates; three surfaces of the shallow tray are enclosed and one surface is vacated; the depth of the tray depends on the thickness of the specimen; and then a layer of transparent unsaturated polyester resin with curing agent added is brushed in the tray; the plant or insect specimen is put into the resin in the shallow tray, and a label is put in together; a transparent organic plate is adhered to the shallow tray to form a flat box with an opening arranged on one side end; after the resin is cured, the opening is upward, transparent resin is poured in to embed the specimen in; after the product is cured, the biological specimen is prepared. The product prepared through the method has high transparency, good aging resistant, corrosion resistant, damp proof, mildew proof and moth proof performance. Because of the technical proposal, the invention has the advantages of simple operation, capability of greatly reducing the production cost and leading an embedding method to be convenient for mass production.

Owner:杜静磊

Embossed nonwoven fabric

InactiveCN108103669AImproves UV resistanceImprove sound insulationCoatingsNon-woven fabricsNonwoven fabricPolypropylene

The invention discloses an embossed nonwoven fabric which is formed integrally. The embossed nonwoven fabric comprises a nonwoven fabric base layer with embossed patterns and is produced by steps: subjecting a polypropylene raw material and additives to mixed melting and spun-laid process, adopting a hot-pressing embossing roller for one-time hot rolling forming, and spraying glitters to single orboth surfaces of the embossed nonwoven fabric to improve surface quality. By one-time forming of the embossed nonwoven fabric, production efficiency is remarkably improved while outstanding 3D effects are achieved, and high visual and tactile quality of the embossed nonwoven fabric is realized.

Owner:嘉兴市宏景无纺面料有限公司

Mothproof antibacterial essential oil

InactiveCN104642405AGood antibacterialExcellent mothproofBiocidePest repellentsCampheneAlpha-humulene

The invention discloses mothproof antibacterial essential oil which is used for solving the problems that a mothproof function and an antibacterial function cannot be combined very well in the prior art, and the smell is pungent. The mothproof antibacterial essential oil comprises the following components in percentage by weight: 5%-70% of natural camphor, 0-10% of lavender essential oil, 0-10% of pyrethrin, 10%-40% of other components, and 10%-85% of 1,8 cineole and / or aromatic alcohol, based on 100% in total, wherein the other components comprise one or more of p-cymene, alpha-pinene, beta-pinene, geraniolene, alpha-terpene alcohol, camphene, limonene, caryophyllene, alpha-humulene, borneol and alpha-phellandrene. According to the technical scheme adopted by the invention, the problems in the prior art can be solved very well.

Owner:肖正君

Multiple-effect timber fire retardant and its preparation method and treatment process

InactiveCN104647537AGood anti-loss performanceGood flame retardant performancePressure impregnationWood impregnation detailsPhosphoric acidAmmonium polyphosphate

The invention discloses a multiple-effect timber fire retardant and its preparation method and treatment process. The multiple-effect timber fire retardant comprises, by mass, 20-40% of phosphoric acid, 10-20% of dicyandiamide, 10-20% of melamine, 5-10% of boric acid, 5-20% of ammonium polyphosphate, 5-20% of silica sol, 3-8% of a smoke inhibitor, 0.5-3% of a surfactant and 0.1-2% of a mildew inhibitor. Compared with the existing timber fire retardant, the multiple-effect timber fire retardant has good fire retardant performances, good smoke inhibition performances, good loss resistance performances, large timber impregnation depth and good corrosion-resistant, mildew-resistant and mothproof effects. The preparation method has simple processes. The multiple-effect timber fire retardant has good timber protection and processing effects and is economical and practical.

Owner:高天红

Finishing process of flax fabric

InactiveCN105568680AGood antibacterialImprove mildew resistanceHeat resistant fibresGrip property fibresPolyethylene glycolSilicon dioxide

The invention discloses a finishing process of a flax fabric. The finishing process comprises the following steps: (1) sequentially adding 1-2 weight parts of butyl naphthalene sulfonate, 0.7 weight part of titanium dioxide, 1.9 weight parts of castor oil, and 0.8 weight part of ammonium propionate into 20 mass parts of deionized water, and uniformly stirring; (2) simultaneously adding 0.2 weight part of nano superfine soft silicon dioxide, 0.8 weight part of tri(2,3-dibromopropyl) isocyanurate, 1.1 weight parts of polyethylene glycol terephthalate, and 1.7 weight parts of bi alkyl imidazoline amide, and stirring continuously till all the components are fully and uniformly mixed, thereby obtaining a finishing agent; and (3) padding the fabric in the finishing agent, and drying the fabric taken out of the finishing agent at constant temperature. The fabric processed by the finishing process has excellent properties of bacteria resistance, mildewing prevention, flaming retardance, moth prevention and static resistance, and has strong washability and soft handfeeling.

Owner:CHANGSHU ZHONGHONG KNITTING MILL

Method for purifying plant fumigation matter

The invention belongs to the plant pyrolysis field, which particularly relates to a method for purifying plant fumigation matter. The invention is characterized in that the method for purifying comprises the following three steps: distilling primary liquid, adsorbing and filtering, and adsorbing and filtering again. The purifying method of the invention is simple, production cost is low, and degree of purity of products is high. Plant fumigation matter which is prepared by the invention is colourless and transparent, which has no peculiar smell and toxicity, and has the functions of killing viruses, sterilizing, killing acari, resisting oxidation, deodorizing, resisting moth, relieving itch and beautifying. The invention can be extensively applied in the fields such as food, medicine, daily chemical, environmental protection and the like.

Owner:叶礼奎

Preparation method for fabrics antibacterial finishing liquid

InactiveCN105401408AGood hydrophilicityGood permeabilityBiochemical treatment with wool-protecting/anti-moth agentsHeat resistant fibresIonSodium silicate

A disclosed preparation method for a fabrics antibacterial finishing liquid comprises the following steps: 1) successively adding 1-2 parts by weight of glycerin monostearate, 1.4 parts by weight of sodium silicate, 0.8 part by weight of an acrylamide, 0.7 part by weight of potassium thiocyanate into 19 parts by mass ofdeionized water, and stirring uniformly; and 2) then simultaneously pouring 1.5 parts by weight of Ixeris denticulate extraction liquid, 2.3 parts by weight of sorbic acid, 1.1 parts by weight of dimetyl terephthalate, and 0.9 part by weight of boron phosphate, and continuing to stir until the mixture is uniformly mixed, so as to prepare the finishing liquid. The prepared finishing liquid is good in hydrophilicity and good in permeability, and fabrics finished by using the finishing liquid possesses excellent flame retardation performance, mildew resistance, moth prevention performance, bacteria resistance and static electricity resistance, and is strong in washing fastness and soft in handfeel.

Owner:SUZHOU FUMEI TEXTILE TECH

Straw-fiber-reinforced polyester tile and manufacturing method thereof

InactiveCN102951870AEfficient use ofGood sound and heat insulationSolid waste managementFiberEcological environment

The invention discloses a straw-fiber-reinforced polyester tile and a manufacturing method thereof. The manufacturing method comprises the following steps: evenly stirring and mixing straw fiber, metaphenylene polyester resin, mica powder, wollastonite powder and other raw materials according to a certain formula, and carrying out hot compacting. The straw-fiber-reinforced polyester tile has the characteristics of sound insulation, heat insulation and long service life in the colored steel tile and synthetic resin tile which are commonly used at present, can effectively utilize the straw resources, is beneficial to protecting the ecological environment, and lowers the production cost and use cost.

Owner:北京传树建材科技集团有限公司

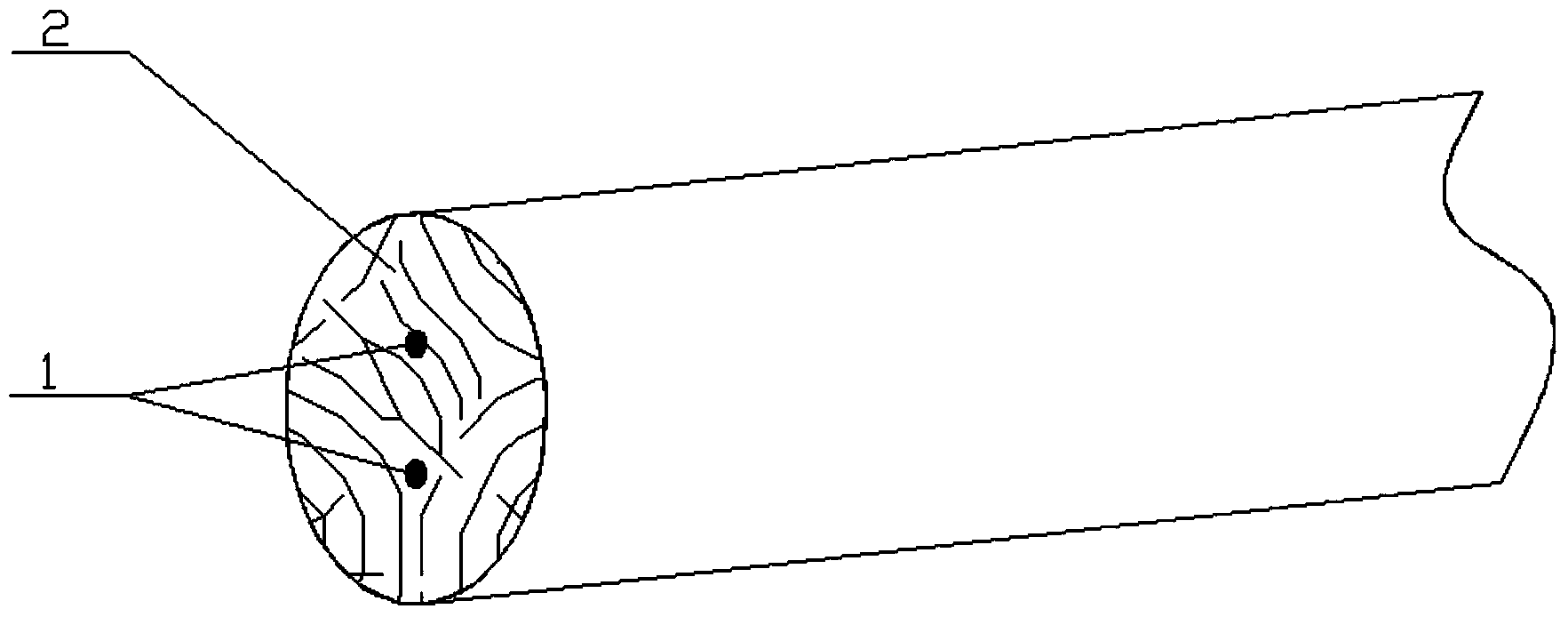

Production method of agricultural greenhouse framework

The invention discloses a production method of an agricultural greenhouse framework. According to the production method, a metal material is taken as a framework lining, and conveyed into a co-extrusion mould, the material extruded by a plastic extruder and a framework basic material are synchronously conveyed onto a sizing mould and a traction machine, and the agricultural greenhouse framework is obtained through co-extrusion, traction, cooling and sizing, and cutting, wherein the metal material can be iron wires, steel wires, cold-rolled round steel or flat iron; the basic material is produced by mixing the following components in parts by weight: 100 parts of plastic, 30-50 parts of plant fiber powder, 3-5 parts of a heat stabilizer, 5-10 parts of a plasticizer, 1-3 parts of a lubricant, 5-10 parts of a modifier ACR-401, 0-3 parts of a compatilizer, 1-3 parts of a coupling agent, 0.5-3 parts of a foaming agent, 3-10 parts of a foaming regulator ZB-530, 10-20 parts of a nucleating agent and 10-20 parts of an inorganic material, and then granulating the components; the inorganic material is the combination of magnesium chloride and magnesium oxide. According to the production method disclosed by the invention, the operation is simple and easy and the cost is low, and the produced greenhouse framework is good in bending resistance and compression resistance.

Owner:GUILIN SHUKANG BUILDING MATERIAL

Healthy paddy rice and production method

InactiveCN1600111AGood for healthAvoid absorptionSeed preservation by coatingCholesterolAdditive ingredient

A health-care rice for decreasing blood fat, blood sugar and cholesterin, lowering blood pressure and delaying sanility is prepared through immersing in the liquid containing chitosan, and drying.

Owner:杨建华

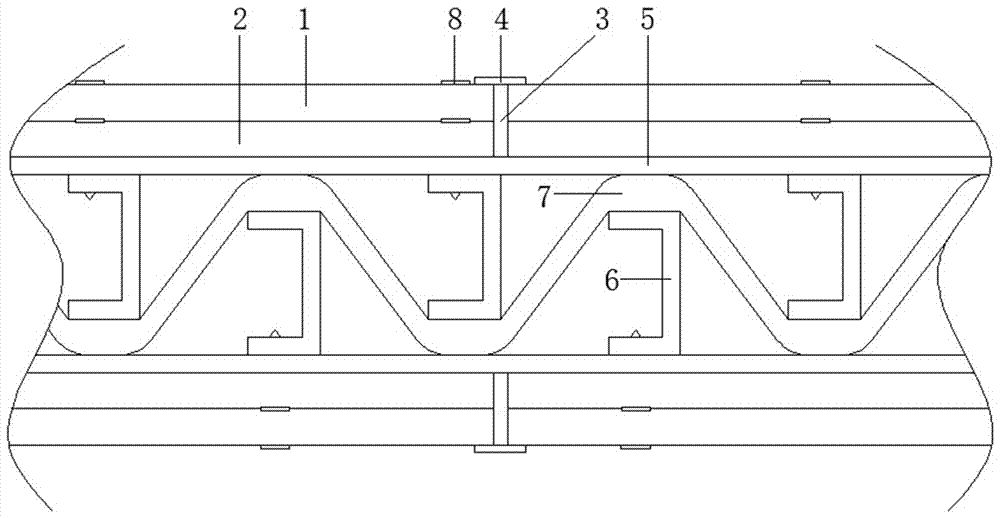

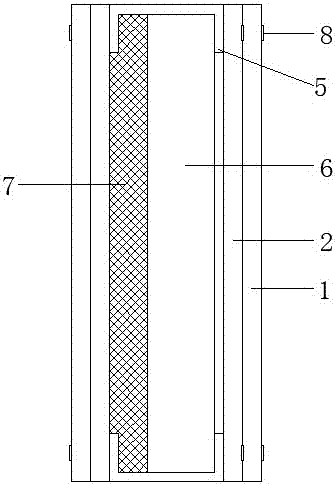

Wall with sound insulation function

The invention belongs to the technical field of walls and discloses a wall with a sound insulation function. The wall comprises a U-shaped keel. An inner cavity of the U-shaped keel is provided with sound absorption cotton; the sound absorption cotton is in a sine shape, and D-shaped keels are arranged in the wave crest and wave trough positions of the sound absorption cotton correspondingly; inner gypsum boards are mounted on the left portion and the right portion of the top end and the bottom end of the U-shaped keel correspondingly; outer gypsum boards are arranged on the outer walls of thefour inner gypsum boards correspondingly; self-tapping screws are mounted on the outer walls of the inner gypsum boards and the outer gypsum boards correspondingly; and the inner gypsum boards and the outer gypsum boards are connected with the U-shaped keel and the D-shaped keels through the self-tapping screws correspondingly. The parts, between the gypsum boards, of the sound absorption cottonand the D-shaped keels form a plurality of spaces similar to resonant chambers, sound waves are reflected and absorbed in the multiple resonant chambers, so that energy is cooled and consumed, and thesound insulation effect is excellent; and in addition, the gypsum boards are light, high in strength, easy to process, fireproof and mothproof, and the sound insulation effect of the wall is furtherimproved through the two sets of gypsum boards.

Owner:徐州逸刻新型墙体材料有限公司

Dyeing and finishing process of knitted fabric

InactiveCN105421057AExcellent flame retardantExcellent mothproofHeat resistant fibresGrip property fibresIsothiazolinoneSodium acetate

The invention discloses a dyeing and finishing process of knitted fabric which comprises the following steps of firstly, pretreating; secondly, dying; thirdly, finishing: sequentially feeding 1 to 2 parts by weight of gamma-(methacryloyloxyethy) propyltrimethoxysilane, 0.4 part by weight of dimethylformamide, 1.3 parts by weight of 4,5-dichloro-2-n-octyl-3-isothiazolinone and 0.9 part by weight of sodium acetate into 15 parts by mass of deionized water and uniformly stirring; then simultaneously feeding 0.7 part by weight sodium pentachlorophenate, 0.5 part by weight of 1,3,5- triglycidylisocyanurate, 1,4 parts by weight of dimethyl terephthalate and 0.9 part by weight of octamethylcyclotetrasiloxane, and continuously stirring until the materials are fully and uniformly mixed to obtain a finishing liquid; subsequently performing padding treatment on fabric in the finishing liquid, taking out and then drying the treated fabric at constant temperature. According to the dyeing and finishing process of the knitted fabric, disclosed by the invention, the dyed and finished fabric has excellent flame-retardant, mothproof, mouldproof, antibacterial and antistatic properties; in addition, the dyed and finished fabric is high in washability and is soft in hand feeling.

Owner:常熟市大唐王子服饰厂

Dyeing and finishing process of underwear fabric

InactiveCN105421046AExcellent flame retardantExcellent mothproofHeat resistant fibresGrip property fibresPolymer scienceBromine

The invention discloses a dyeing and finishing process of underwear fabric, which comprises the following steps: (1) pretreatment; (2) dyeing; (3) finishing: adding 1-2 parts by weight of gamma-(3-glycidoxypropyl) trimethoxysilane, 1.2 parts by weight of 4-Br-2-n-octylisothiazolinone, 0.9 part by weight of salicylanilide and 3.6 parts by weight of acrylic acid into 15 parts by mass of deionized water, and stirring uniformly; then adding 0.9 part by weight of bioresmethrin, 0.7 part by weight of isocyanuric acid triallyl ester, 0.9 part by weight of polyamide and 1.4 parts by weight of 3-(2-aminoethyl)-aminopropyl methyl dimethoxy silane, and continuously stirring till full and uniform mixing to prepare finishing liquid; then padding the fabric in the finishing liquid, taking out and drying at constant temperature.The fabric dyed and finished by the dyeing and finishing process has excellent mildewproof, mothproof, antibacterial, antiflaming and antistatic performances, and is high in washing resistance and soft in handfeel.

Owner:常熟市大唐王子服饰厂

Dyeing and finishing process for knitted fabric

InactiveCN105484020AGood antibacterialStrong washabilityBiochemical fibre treatmentHeat resistant fibresPhosphoric acidEthylenediamine

The invention discloses a dyeing and finishing process for knitted fabric. The dyeing and finishing process comprises the steps of 1, pretreatment; 2, dyeing; 3, finishing, wherein 1-2 parts by weight of N-methyl pyrrolidone, 2.7 parts by weight of ethyl alcohol, 1.1 parts by weight of tea polyphenol and 0.7 part by weight of artemisinin are put into 25 parts by mass of deionized water in sequence, the mixture is stirred uniformly, 1.4 parts by weight of phenyl salicytate, 0.9 part by weight of phosphoric acid ethylenediamine, 1.2 parts by weight of aromatic diester and 0.9 part by weight of diethanol amine are added at the same time, stirring continues to be conducted till the raw materials are mixed fully and uniformly, and a finishing solution is prepared; the fabric is padded in the finishing solution, and the fabric is taken out and then dried at a constant temperature. According to the dyeing and finishing process for the knitted fabric, the fabric dyed and finished through the process has outstanding antibacterial, mould-proof, mothproof, flame-retardant and antistatic performance, is high in washability and feels soft.

Owner:常熟市庄丹奴服饰有限公司

Afterfinish process of wool knitted fabric

InactiveCN106283657AImprove wrinkle resistanceImprove wear resistanceBiochemical fibre treatmentHeat resistant fibresMethacrylatePhenol

The invention discloses an afterfinish process of wool knitted fabric. The afterfinish process includes the following steps that 1, by weight, 1-2 parts of zinc borate, 1.7 parts of imidazoline, 0.9 part of coated red phosphorus, 1.4 parts of N,N-bis(acylaminoethyl)-methyl quaternary ammonium salt, 2.9 parts of polyoxyethylene sorbitan tallate are sequentially put into 48 parts of deionized water and stirred uniformly; 2, by weight, 2.3 parts of sodium hexametaphosphate, 3.5 parts of maleic anhydride modified polyethylene, 4.1 parts of nonyl phenol polyoxyethylene ether, 3.1 parts of 2-(diethylamino)ethyl methacrylate and 1.1 parts of monosodium maleate are sequentially added and continue to be stirred to be fully and uniformly mixed to prepare finish liquid; padding is carried out on the fabric in the finish liquid, and the fabric is taken out and dried at constant temperature. The finished fabric is high in performance and soft in handfeel.

Owner:常熟市大正纺织制版有限公司

Plush fabric

The invention discloses a plush fabric which is subjected to dyeing and finishing treatment including the following steps: 1) pretreatment; 2) dyeing; 3) finishing: successively adding 1-2 parts by weight of N-acyl amino acid salt, 0.8 parts by weight of polypropylene glycol, 1.8 parts by weight of acetic acid, 0.7 parts by weight of a lavender extract liquid and 1.3 parts by weight of cobalt aluminate to 13.5 parts by mass of deionized water with uniform stirring, and adding 0.9 parts by weight of chlorothalonil, 1.2 parts by weight of glycerin monostearate and 1.4 parts by weight of octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate at the same time, continuously stirring the materials until the components are fully and uniformly mixed to obtain a finishing liquid, padding the fabric in the finishing liquid, and drying the fabric at constant temperature. The plush fabric is excellent in mildew-proofing, anti-moth, antibacterial, flame-retarding and anti-static properties, is strong in washability and has a soft hand feel.

Owner:SUZHOU XIN GE HOUSEHOLD PROD CO LTD

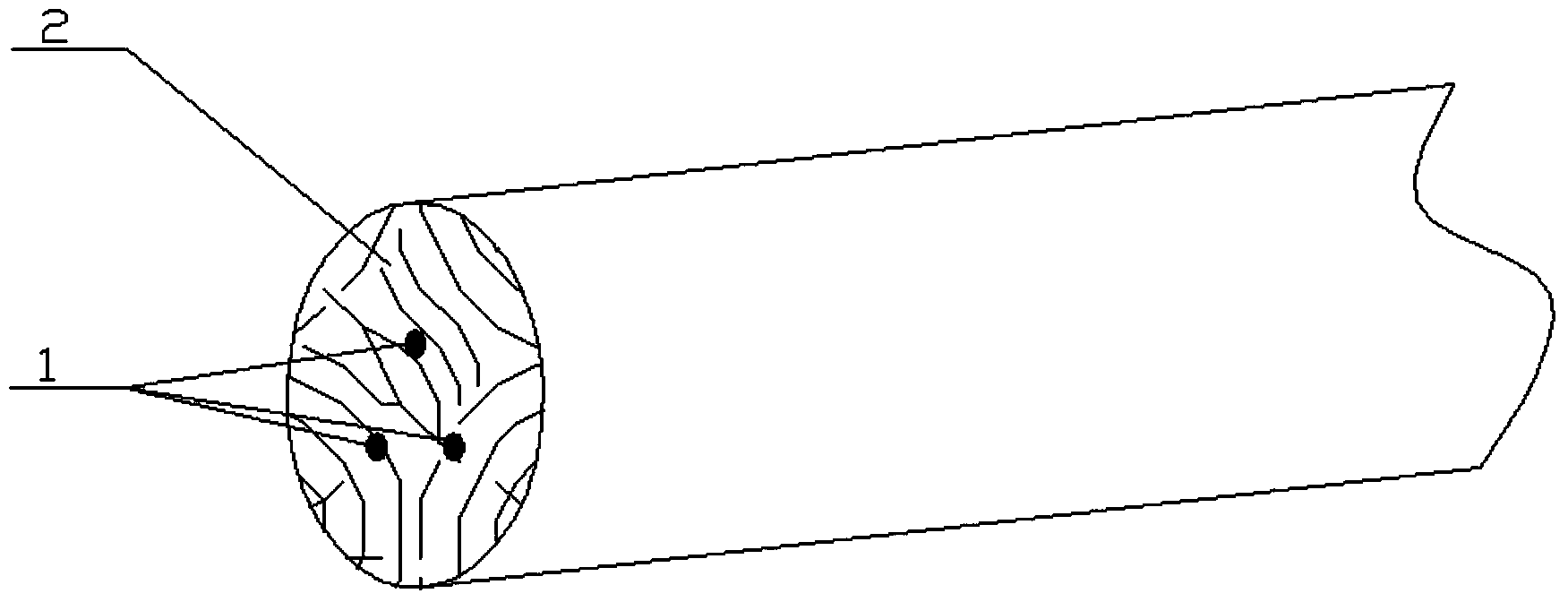

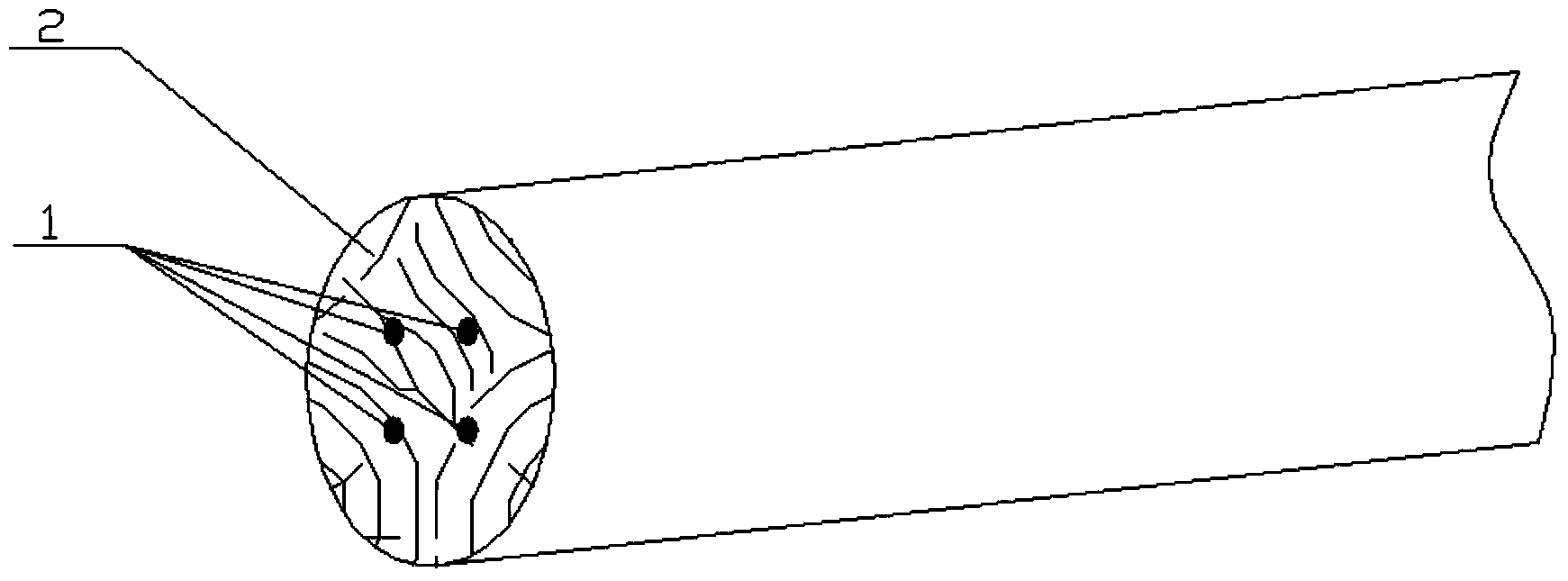

Antibacterial wool product, antibacterial agent and production process of antibacterial wool product

PendingCN107354750AGood antibacterialExcellent mothproofBiochemical fibre treatmentShrinking resistant fibresAntibacterial agentWool fiber

The invention provides an antibacterial wool product. The antibacterial wool product comprises wool fiber, wherein a mixed source antibacterial and mothproof layer is arranged on the surface of the wool fiber. Correspondingly, the invention further provides a production process of the antibacterial wool product. Wool fiber is subjected to surface pretreatment through an oxidizing agent and a reducer, so that wool fiber is rapidly bound with a following antibacterial agent and has a good binding strength, and the good antibacterial effect, shrink-proof and moth-proof effects are obtained.

Owner:JIAXING ZHULANG CLOTHING CO LTD

Antibacterial blended yarn

InactiveCN105463838AGood antibacterialImprove mildew resistanceHeat resistant fibresYarnChinese hawthorn

The invention discloses an antibacterial blended yarn which is subjected to padding treatment, wherein the padding treatment comprises the following steps: (1) putting 1 to 2 parts by weight of aliphatic amine polyoxyethylene ether, 1.2 parts by weight of polyacrylic acid, 2.3 parts by weight of sorbic acid and 0.9 part by weight of sodium chloride into 12.6 parts by weight of deionized water, and stirring uniformly; (2) then simultaneously and slowly adding 0.9 part by weight of diethylenetriamine, 0.7 part by weight of cortex phellodendri extracting solution, 0.6 part by weight of Chinese hawthorn seed extracting solution and 0.9 part by weight of dimethyl octadecyl hydroxy ethyl quaternary ammonium nitrate, and continuously stirring until fully mixed, so as to prepare finishing liquor; (3) performing padding treatment on the blended yarn in the finishing liquor, and drying at constant temperature after taking out. The antibacterial blended yarn provided by the invention has excellent mould proof, mothproof, antibacterial, inflaming retarding and anti-static performances.

Owner:常熟市明达腈纺有限公司

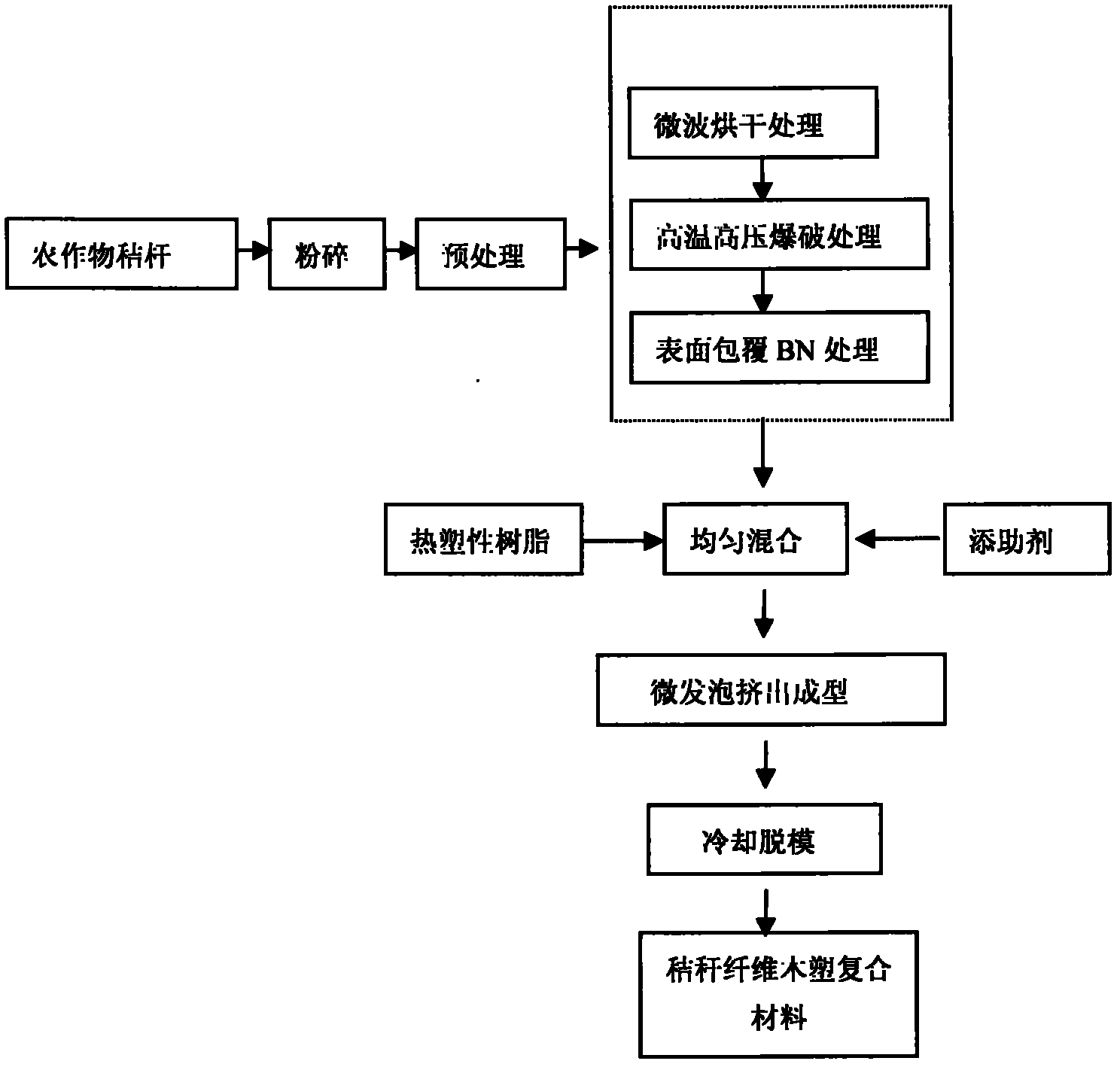

Preparing technology of high-performance straw fiber plastic-wooden composite material

The invention discloses a preparing technology of a high-performance straw fiber plastic-wooden composite material, and relates to the technical field of straw fiber-based plastic-wooden composite materials. The preparing technology comprises the following steps of: carrying out microwave drying treatment, high-temperature high-pressure steam explosion modifying treatment and inorganic boron nitride nanopowder coating modification pretreatment on rice straws which serve as the raw material, uniformly mixing the treated rice straws with thermoplastic resin, an interfacial modifier and other additives, carrying out microcellular-foaming extrusion molding on the mixture in a mould after uniform mixing, cooling and demoulding to obtain the high-performance straw fiber plastic-wooden composite material. According to the invention, a preparing method capable of effectively obtaining the high-performance straw fiber-based plastic-wooden composite material can be obtained by proceeding from the principle of interfacial atom combination and a microcellular foaming technology, planning to use a high-temperature high-pressure steam explosion technology and adopting a microwave drying technology and inorganic boron nitride nanopowder lubricant surface coating, so that harmless treatment of crop straws and efficient comprehensive utilization of resources can be realized.

Owner:南通升环木业有限公司

Finishing process of knitted fabric

InactiveCN105568681AGood antibacterialImprove mildew resistanceHeat resistant fibresGrip property fibresMagnesium stearateSodium salt

The invention discloses a finishing process of a knitted fabric. The finishing process comprises the following steps: (1) sequentially adding the following components into 20 parts of deionized water by mass in parts by weight: 1-2 parts of petroleum sulfonate, 0.5 part of calcium carbonate, 0.9 part of p-hydroxybenzoic acid ethyl ester sodium salt and 0.1 part of magnesium stearate; uniformly stirring; (2) simultaneously adding the following components in parts by weight in sequence: 1.2 parts of Chinese mugwort leaf extract, 0.9 part of 2-methyl-5-oxocyclopent-1-enyl propionate, 1.4 parts of sodium carbonate and 1.5 parts of butanone; continually stirring until the components are sufficiently and uniformly mixed to prepare a finishing solution; carrying out padding treatment on the cloth in the finishing solution; and taking out the cloth and drying the cloth at a constant temperature. According to the finishing process of the knitted fabric, disclosed by the invention, the finished fabric has excellent antibacterial, mildew-proof, inflaming-retarding, mothproof and antistatic performances, strong washing fastness and a soft hand feeling.

Owner:CHANGSHU ZHONGHONG KNITTING MILL

Natural mothproof scented powder and preparation method thereof

InactiveCN102870827AExcellent mothproofImprove mildew resistanceBiocidePest repellentsActive carbonCypress

The invention discloses natural mothproof scented powder and a preparation method thereof; the mothproof scented powder mainly comprises the following components by weight: 10-90 parts of camphorwood powder, 10-90 parts of cypress powder, 10-90 parts of active carbon powder, 2-20 parts of camphorwood oil, and 2-20 parts of essence. The natural mothproof scented powder provided by the invention has a simple preparation method, and significant mothproof effect.

Owner:陈文灿

Dyeing and finishing process of home textile fabric

InactiveCN105421032AExcellent mildew resistanceStrong washabilityBiochemical treatment with wool-protecting/anti-moth agentsHeat resistant fibresIonDiammonium phosphate

The invention discloses a dyeing and finishing process of home textile fabrics, which includes the following steps: 1) pretreatment; 2) dyeing; 3) finishing: successively adding 1-2 parts by weight of imidazoline, 3.5 parts by weight of ethylene glycol, 1.9 parts by weight of hydroxyl silicone oil and 1.9 parts by weight of dimethylolpropionic acid to 14.5 parts by mass of deionized water with uniform stirring, and adding 0.3 parts by weight of an extract of perilla, 1.2 parts by weight of sodium dehydroacetate, 0.9 parts by weight of fluorinated alkyl sulfonate and 1.1 parts by weight of diammonium hydrogen phosphate at the same time, continuously stirring the materials until the components are fully and uniformly mixed to obtain a finishing liquid, padding the fabric in the finishing liquid, and drying the fabric at constant temperature. The fabric treated through the dyeing and finishing process is excellent in mildew-proofing, anti-moth, antibacterial, flame-retarding and anti-static properties, is strong in washability and has a soft hand feel.

Owner:常熟市格林染整有限公司

Preparation method for fabric flame-retardant finishing liquor

InactiveCN105484040AImprove hydrophilicityImprove permeabilityBiochemical fibre treatmentHeat resistant fibresSodium lactateSulfonate

The invention discloses a preparation method for fabric flame-retardant finishing liquor. The preparation method comprises the steps of firstly, putting 1-2 parts of fatty acid methyl ester sulfonate, 1.2 parts of polypropylene glycol, 0.9 part of dimethylaminoethyl methacrylate and 1.1 parts of sodium lactate into 14 parts by mass of deionized water in sequence to be stirred uniformly; secondly, putting 1.2 parts of dark plum extract liquor, 0.9 part of sodium dichloroisocyanurate, 1.7 parts of methyl methacrylate and 0.4 part of antimonous oxide into the mixture, and continuing to stir till the mixture is mixed fully and uniformly to prepare the finishing liquor. The finishing liquor prepared through the method is good in hydrophilia and permeability; fabric finished through the finishing liquor has outstanding antistatic, flame retardant, mothproof, mould-proof and antibacterial performance, is high in washability and feels soft.

Owner:成路凯尔服装(苏州)有限公司

Dyeing and finishing process for composite fabric

InactiveCN105506976AExcellent flame retardantExcellent mothproofHeat resistant fibresGrip property fibresDiethylenetriaminePropyl hydroxybenzoate

The invention discloses a dyeing and finishing process for a composite fabric. The dyeing and finishing process comprises the following steps of 1 preprocesing; 2 dyeing; 3 finishing, wherein 1-2 parts by weight of oleic acid polyoxyethylene ester, 1.3 parts by weight of propylparaben, 0.9 part by weight of sodium dehydroacetate and 0.9 part by weight of ammonium phosphate are sequentially put into 15 parts by mass of deionized water, the materials are stirred to be uniform, 1.3 parts by weight of resmethrin, 0.4 part by weight of phosphonic acid ester, 0.9 part by weight of dimethyl sulfate and 1.5 parts by weight of diethylenetriamine are simultaneously put, the materials are continuously stirred until the materials are fully mixed to be uniform, finishing liquid is prepared, and the fabric is processed through padding in the finishing liquid and then taken out to be dried at constant temperature. According to the dyeing and finishing process for the composite fabric, the dyed and finished fabric has the excellent flame retardance, mothproof property, mouldproof property, antibacterial property and anti-static property and is high in washability and flexible in handfeel.

Owner:常熟市大唐王子服饰厂

Finishing process for cotton and linen fabric

InactiveCN105350336AGood antibacterialImprove mildew resistanceBiochemical fibre treatmentHeat resistant fibresHydrogen phosphateDiammonium phosphate

The invention discloses a finishing process for cotton and linen fabric. The finishing process comprises the following steps: (1) sequentially feeding the following raw materials in parts by weight: 1-2 parts of sodium alkylarysulfonate, 0.9 part of vermiculite power, 2.2 parts of dimethicone and 1.3 parts of prochloraz to 20 parts by mass of deionized water, and mixing and stirring the raw materials evenly; (2) simultaneously feeding the following raw materials in parts by weight: 0.9 part of fluorophenoxy phenylsilane, 1.2 parts of diammonium hydrogen phosphate, 0.2 part of acetylene black and 1.7 parts of di(butter acylamino ethyl)-2-hydroxy ethyeneamine, and further stirring the raw materials until the raw materials are fully mixed evenly, so as to prepare a finishing liquid; and (3) carrying out padding treatment on the fabric in the finishing liquid, and taking out and drying the fabric at a constant temperature. According to the finishing process for the cotton and linen fabric, the finished fabric has excellent antibacterial property, anti-mold property, flame retardant property, mothproof property and antistatic property, high washability and soft hand feeling.

Owner:CHANGSHU ZHONGHONG KNITTING MILL

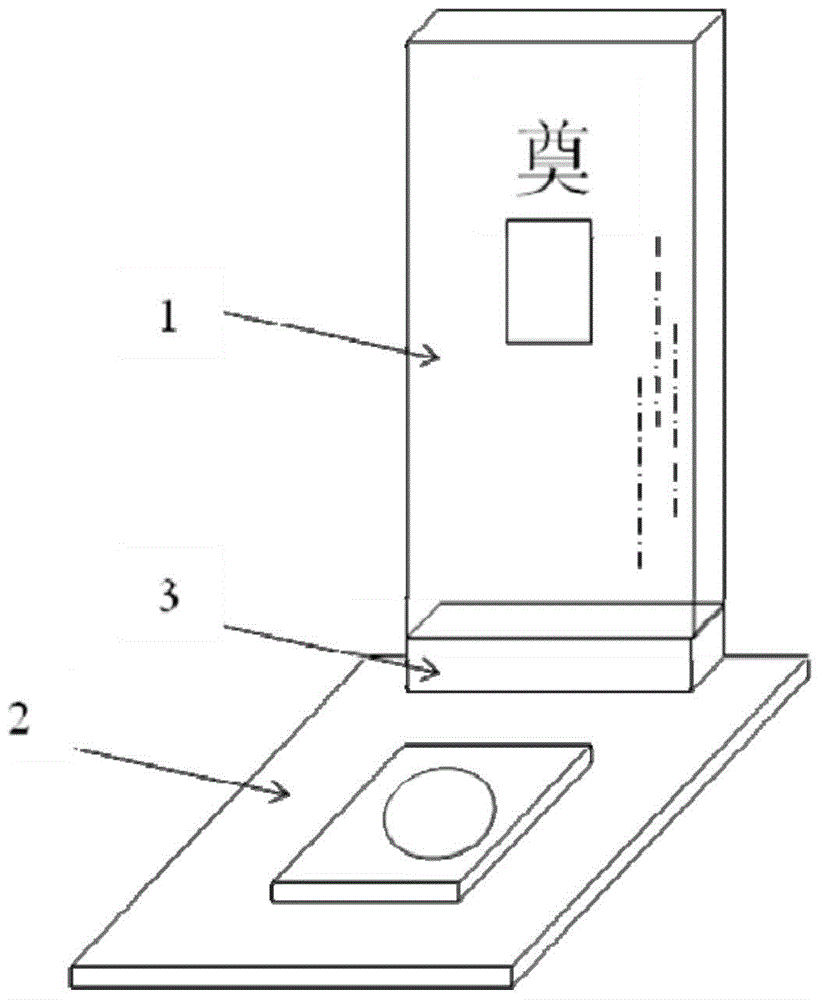

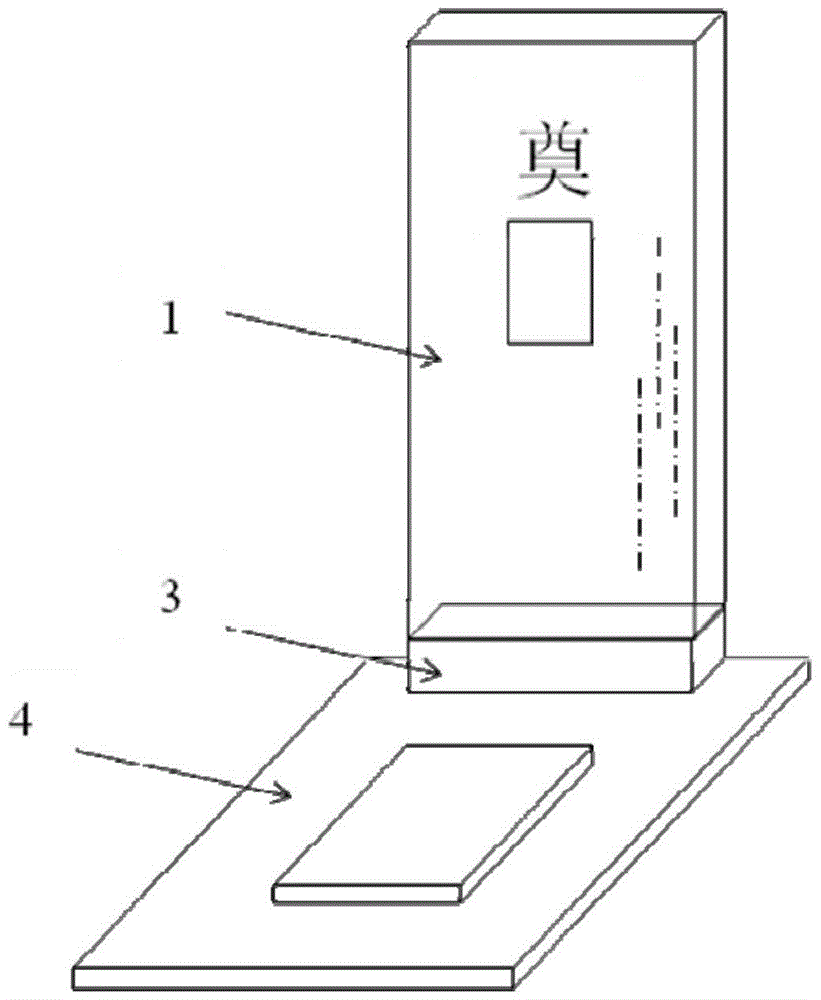

Crystal tombstone and manufacturing method thereof

InactiveCN105696841AFast processingImprove machining accuracyBurial vaultsMonumentsTransmittanceEngineering

The invention discloses a crystal tombstone and a manufacturing method thereof. The crystal tombstone is manufactured through artificial crystals. A tombstone body of the crystal tombstone is solid. The surface of the tombstone body of the crystal tombstone is provided with a plane and / or three-dimensional colored or colorless patterns and / or characters, wherein the plane is carved through a laser carving machine and / or a rotating carving machine. The surface of the tombstone body is further provided with a colored or colorless departed saint picture carved through the laser carving machine. According to the crystal tombstone, a traditional stone or artificial stone tombstone is replaced with artificial crystal glass, the tombstone body is completely transparent and can reflect sunlight, a fashionable sunny tombstone group with the modern characteristics and the innovated idea is made, the visual impact, the good light transmittance, the whole shocking sense and the obvious image are achieved, a deep impression is given to people, the people will feel conspicuous, and a forerunner path is developed for the future funeral and interment industry. The patterns, the characters and the picture can be carved on the tombstone body and never fade, the crystal tombstone is exquisite and is like artware, the personal character is demonstrated, and people are made to be reluctant to leave.

Owner:段然

Preparation method for fabrics finishing liquid

InactiveCN105401437AImprove hydrophilicityImprove permeabilityHeat resistant fibresGrip property fibresDiethylenetriamineAntimony trioxide

A disclosed preparation method for a fabrics finishing liquid comprises the following steps: 1) successively adding 1-2 parts by weight of polyoxyethylene oleate, 1.3 parts by weight of sodium polyacrylate, 1.6 parts by weight of diethylenetriamine, 2.6 parts by weight of acetic acid into 18 parts by mass of deionized water, and stirring uniformly; and 2) simultaneously pouring 1.3 parts by weight of lithospermum extraction liquid, 1.1 parts by weight of iodopropynyl butylcarbamate, 0.8 parts by weight of diantimony trioxide, and 0.9 part by weight of cyanuric acid, and continuing to stir until the mixture is uniformly mixed, so as to prepare the finishing liquid. The prepared finishing liquid is good in hydrophilicity and good in permeability. The fabrics finished by using the finishing solution possesses excellent static electricity resistance, flame resistance, moth resistance, mildew resistance and bacteria resistance, and is strong in washing fastness and soft in handfeel.

Owner:成路凯尔服装(苏州)有限公司

Dyeing and finishing process for garment materials

InactiveCN105350290AGood antibacterialImprove mildew resistanceBiochemical treatment with wool-protecting/anti-moth agentsHeat resistant fibresEthylenediamineCoconut diethanolamide

The invention discloses a dyeing and finishing process for garment materials. The process comprises the following steps: 1) preprocessing; 2) dyeing; 3) finishing: sequentially putting 1 to 2 parts by weight of polyvinylpyrrolidone, 1.4 parts by weight of sodium pyrophosphate, 1.1 parts by weight of cinnamon oil and 0.9 parts by weight of schisantherin into 25 parts by mass of deionized water, and uniformly stirring; simultaneously putting 1.3 parts by weight of sandalwood powder, 0.7 parts by weight of piperazine phosphate, 1.3 parts by weight of coconut diethanolamide and 0.7 parts by weight of hydroxyethyl ethylenediamine into the mixture, continuously stirring, till being fully uniformly mixed, so that finishing liquor is prepared; then enabling the garment materials to be subjected to padding treatment in the finishing liquor, taking the garment materials out, and drying at a constant temperature. By adopting the dyeing and finishing process for the garment materials, the dyed and finished garment materials have the excellent performances of being antibacterial, mildew-proof, mothproof, flame retardant and antistatic, are strong in washability and soft in hand feel.

Owner:常熟市庄丹奴服饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com