Amido boron phosphate and preparation method of amido boron phosphate

A technology of amine borophosphate and dibutyl phosphite, applied in the field of amine borophosphate and its preparation, can solve the problem of poor stability, inability to achieve product performance, and inability to meet the requirements of water-based metalworking fluid lubrication and rust prevention and other problems, to achieve the effect of strong anti-hydrolysis ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

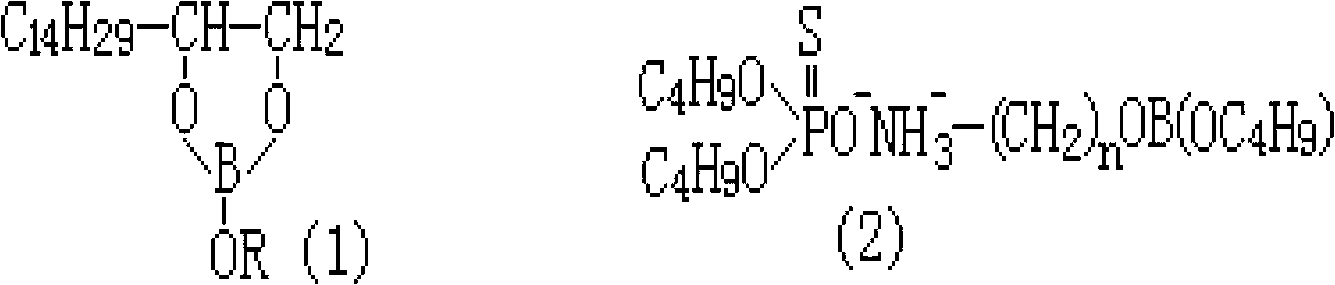

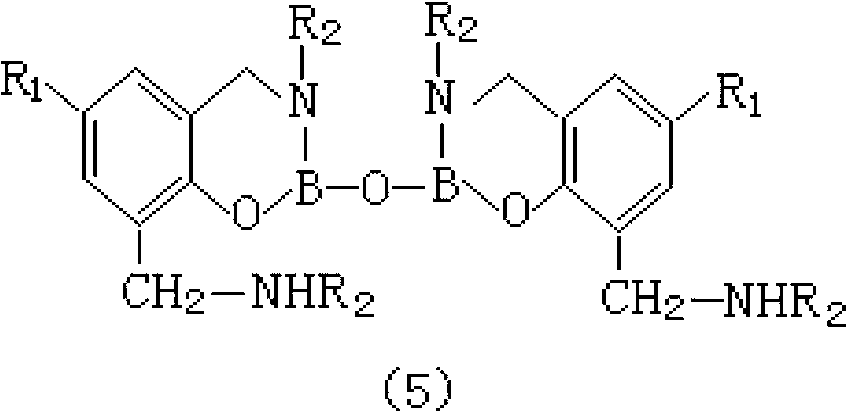

Method used

Image

Examples

Embodiment 1

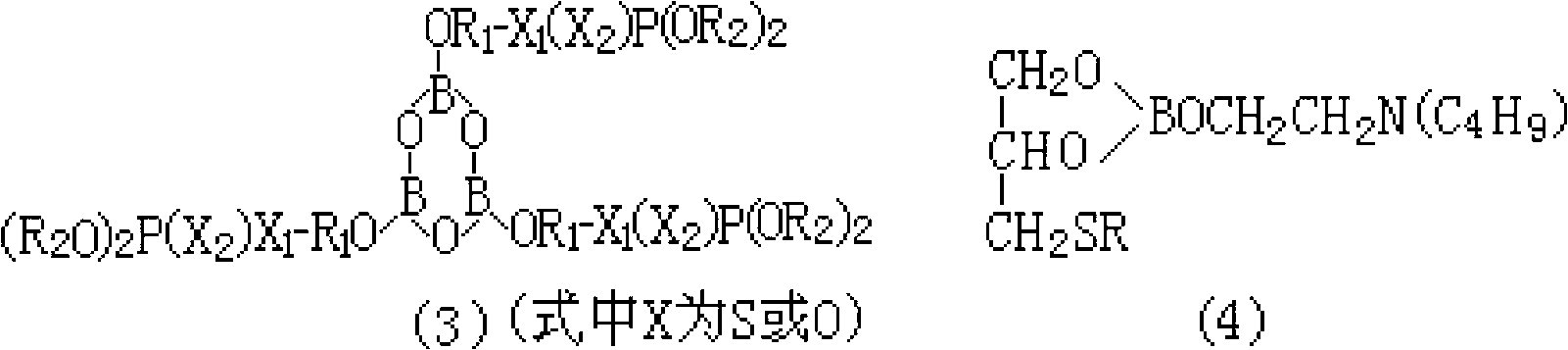

[0030] Dibutyl phosphite (38.8g, 0.2mol) and 36% formaldehyde (16.7g, 0.2mol) were added to the reactor, and ethylenediamine (6.1g, 0.1mol) was gradually added dropwise to the reactor while stirring In the process, control the temperature in the reactor to ≤30°C, and continue to stir for 1.5h when the temperature in the reactor no longer rises; Reflux reaction at 110°C for 4 hours. When the liquid level of water in the water separator no longer increases, the reaction ends. Cool to room temperature to obtain the target product. The chemical reaction formula is as follows:

[0031]

Embodiment 2

[0033] Dibutyl phosphite (58.2g, 0.3mol) and 36% formaldehyde (25.0g, 0.3mol) were added to the reaction kettle, and diethylenetriamine (10.3g, 0.1mol) was gradually added dropwise to the reaction vessel under stirring. In the kettle, control the temperature in the reactor to ≤30°C, and continue to stir for 2 hours when the temperature in the kettle no longer rises; Reflux reaction at 130°C for 5 hours. When the liquid level of water in the water separator no longer increases, the reaction ends. Cool to room temperature to obtain the target product. The typical chemical reaction formula is as follows:

[0034]

[0035] Organic synthesis is a complicated chemical reaction process, and its boronation reaction can obtain monobasic and dibasic two kinds of structures of aminoborophosphate substances in terms of embodiment 2, and the amount of each substance is mainly determined by the ratio of raw materials (i.e. mol ratio) and the process conditions of the reaction, the separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com