Catalytic cracking catalyst for increasing diesel yield and preparation method of catalytic cracking catalyst

A catalytic cracking and catalyst technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of complex preparation process and improve diesel yield, and achieve simple preparation process, increase diesel yield, and improve the The effect of diesel yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

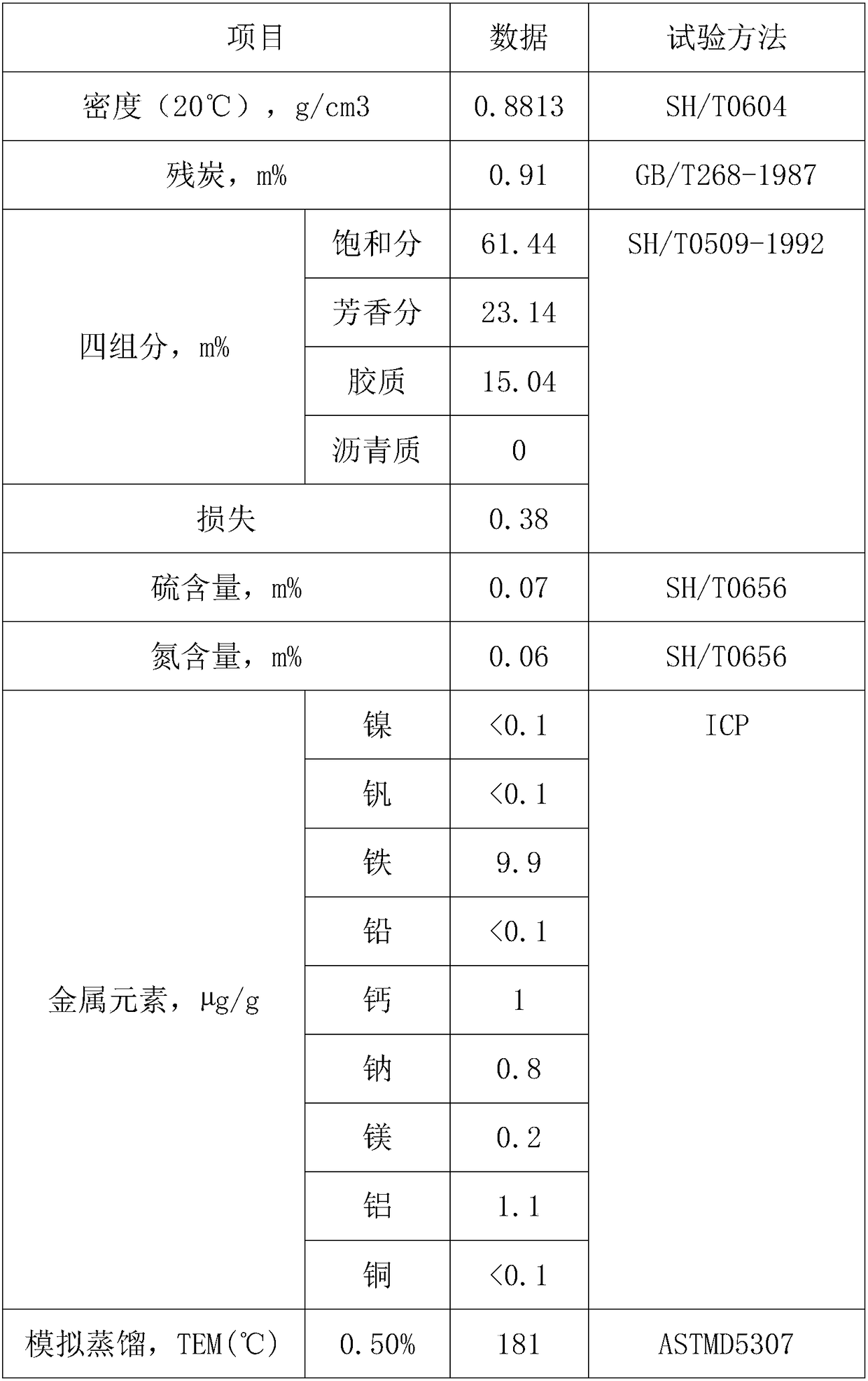

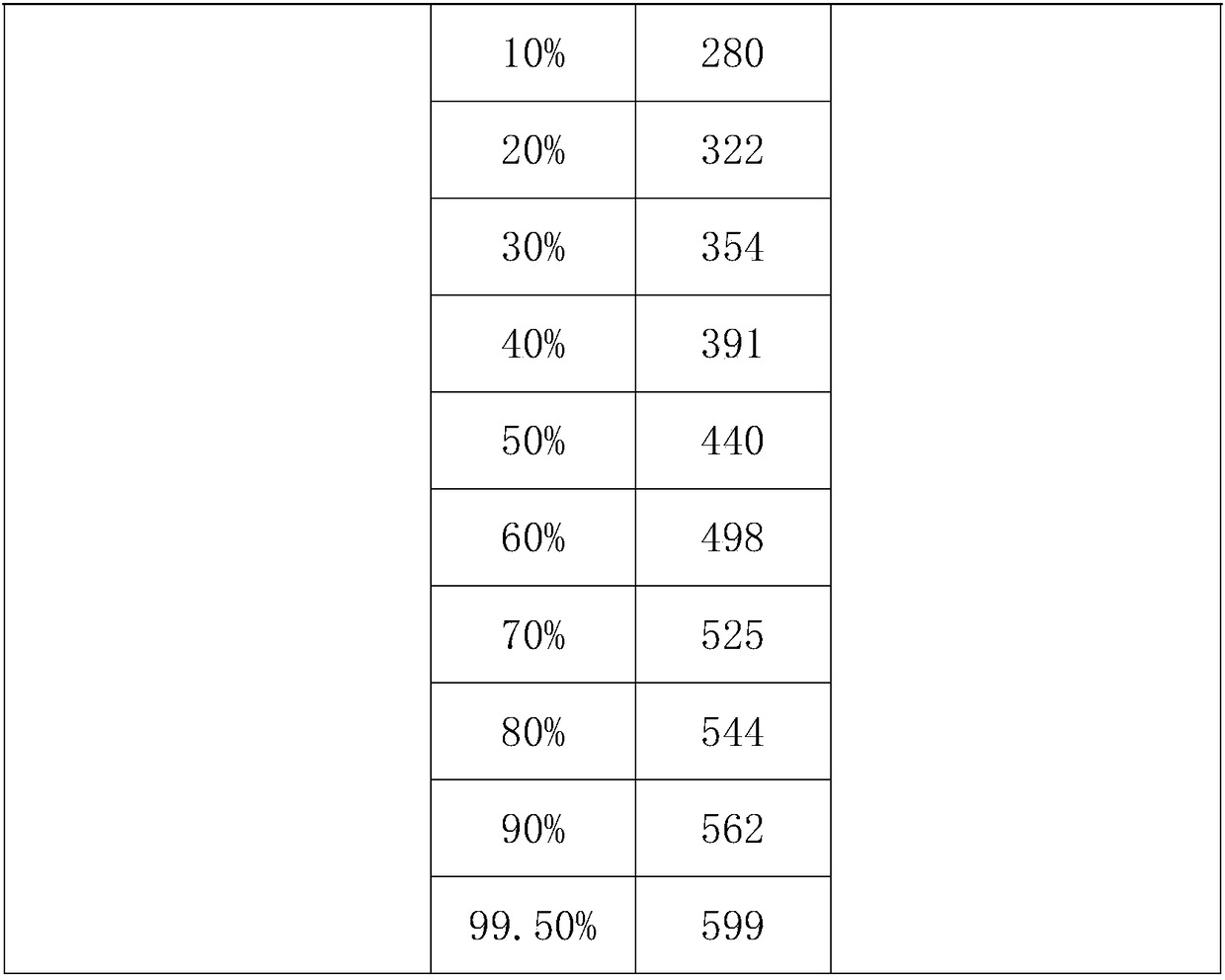

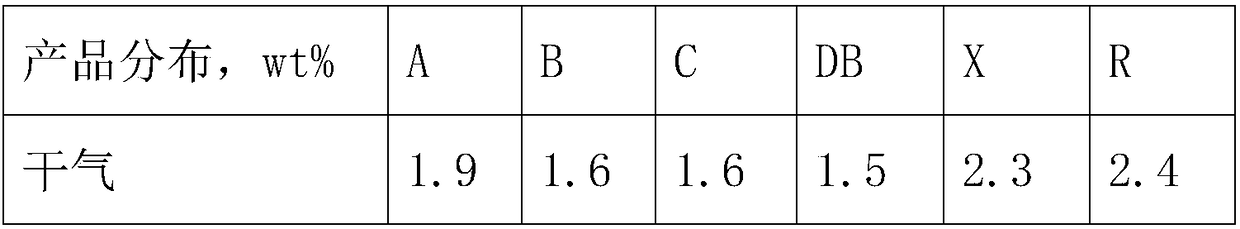

Embodiment 1

[0080] Put 4278g of deionized water, 1207g of kaolin and 198g of boronite into the stirring tank, mix and beat for 30min, then add 2451g of pseudo-boehmite and 166g of concentrated hydrochloric acid, mix and beat for 120min, then add 1150g of USY molecular sieve and 1061g of REY molecular sieve in turn , 1093g of aluminum sol, mixed evenly, sprayed into a gel, and roasted the sprayed microspheres at 450°C for 5 hours, and then used 10000g of deionized water and 60g of ammonium chloride per 1000g of roasted microspheres , the calcined microspheres were washed at 85° C. for 5 minutes, then filtered and dried to obtain the catalytic cracking catalyst for prolific diesel production, which was designated as sample A.

Embodiment 2

[0082] Put 4297g of deionized water, 2042g of pseudoboehmite, 222g of magnesium hexaborate into the stirring tank and beat for 45min, then put in 152g of concentrated hydrochloric acid for 90min, then put in 1590g of kaolin, 1286g of USY molecular sieve, 936g of REUSY molecular sieve, 1312g of Aluminum sol, mixing and beating, spray molding after gelation, roasting the obtained spray microspheres at 500°C for 3.5h, and then using 9000g of deionized water and 100g of ammonium dihydrogen phosphate per 1000g of roasted microspheres, Slurry wash the calcined microspheres at 75° C. for 10 minutes, then filter and dry to obtain the catalytic cracking catalyst for producing diesel oil, which is designated as sample B.

Embodiment 3

[0084] Put 4219g of deionized water, 2009g of kaolin, 1634g of pseudoboehmite into the stirring tank and beat for 60min, then put in 133g of concentrated hydrochloric acid for beating for 60min, then put in 111g of leucumite for beating for 60min, then add 1421g USY molecular sieve, 811g REHY molecular sieve, 1531g aluminum sol, mixed and beaten, gelled and then sprayed into the mold, the obtained spray microspheres were roasted at 550°C for 3h, and then 8000g deionized water and 90g The ratio of diammonium hydrogen phosphate is to wash the calcined microspheres at 70° C. for 15 minutes, then filter and dry to obtain the catalytic cracking catalyst for producing diesel oil, which is designated as sample C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com