Method for improving corrosion resistance of phosphate coating on surface of neodymium-iron-boron permanent magnet

A surface phosphating, permanent magnet technology, applied in the direction of metal material coating process, can solve the problem of low corrosion resistance of phosphating film, and achieve the effect of improving corrosion resistance, simple process and good combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

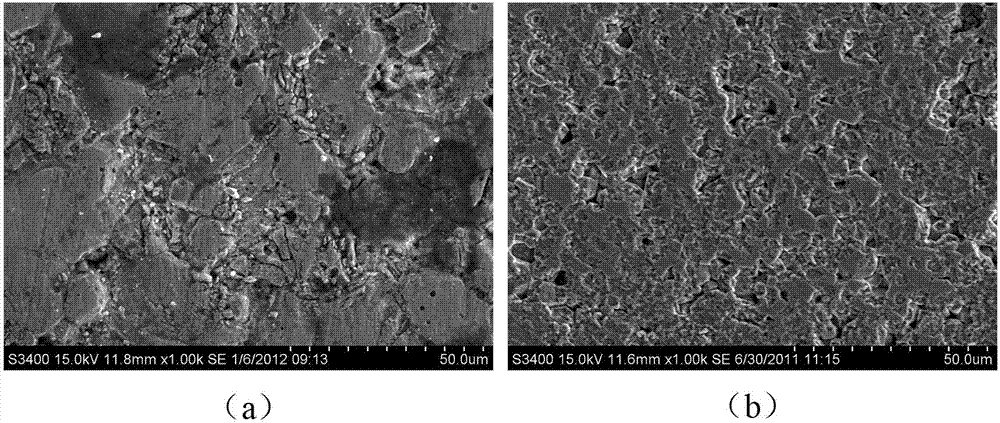

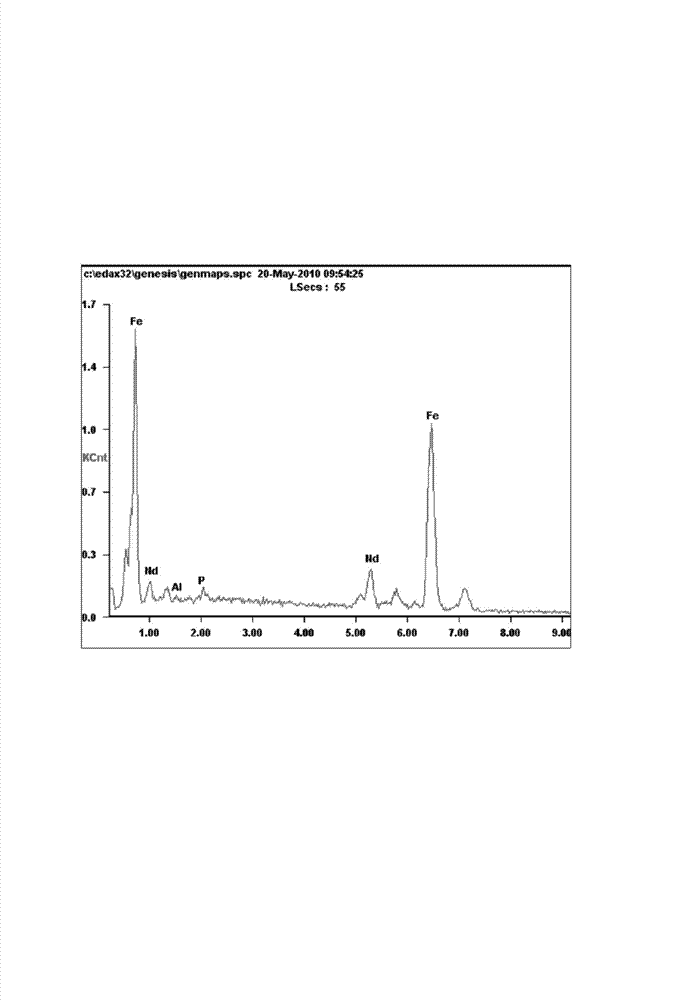

Image

Examples

Embodiment 1

[0038] The substrate is sintered NdFeB permanent magnet (source of sample: Antai Technology Co., Ltd., main composition: 63.95% Fe, 29% Nd, 1.1% B and a small amount of other elements), sample size: 5 cm × 1cm × 0.25cm .

[0039] (1) Alkaline washing and degreasing process conditions: sodium phosphate 60 g / L, sodium carbonate 40 g / L, sodium hydroxide 5g / L, OP-10 emulsifier 0.5g / L, sodium lauryl sulfate 0.1 g / L L, temperature 70°C, processing time: 1min;

[0040] (2) Pickling is carried out after alkaline washing and cleaning, nitric acid 40 mL / L, hexamethylenetetramine 2.0 g / L, sodium lauryl sulfate 0.5 g / L, temperature is 25°C, and treatment time is 15s ;

[0041] (3) The composition and process of phosphating solution are: potassium dihydrogen phosphate 50 g / L, phosphoric acid 5 mL / L, zinc nitrate 1 g / L, sodium nitrate 0.5 g / L, ammonium molybdate 0.5 g / L, dodecyl Sodium sulfate 0.1 g / L, sulfosalicylic acid 0.1 g / L, pH = 1.5, phosphating temperature 25°C, phosphating time ...

Embodiment 2

[0045] The substrate is sintered NdFeB permanent magnet (source of sample: Antai Technology Co., Ltd., main composition: 63.95% Fe, 29% Nd, 1.1% B and a small amount of other elements), sample size: 5 cm × 1cm × 0.25cm .

[0046] (1) Alkaline washing and degreasing process conditions: sodium phosphate 80 g / L, sodium carbonate 60 g / L, sodium hydroxide 10 g / L, OP-10 emulsifier 1.0 g / L, sodium lauryl sulfate 0.5 g / L L, temperature 60°C, processing time: 2min;

[0047] (2) Pickling is carried out after alkaline washing and cleaning, nitric acid 60 mL / L, hexamethylenetetramine 1.0 g / L, sodium lauryl sulfate 0.1 g / L, temperature 15°C, treatment time 25s ;

[0048] (3) The composition and process of phosphating solution are: potassium dihydrogen phosphate 90g / L, phosphoric acid 15mL / L, zinc nitrate 3g / L, sodium nitrate 2.0 g / L, ammonium molybdate 2.5g / L, lauryl sulfate Sodium 0.35 g / L, sulfosalicylic acid 0.5 g / L, pH = 2.5, phosphating temperature 55°C, phosphating time 20 minutes...

Embodiment 3

[0052] The substrate is sintered NdFeB permanent magnet (source of sample: Antai Technology Co., Ltd., main composition: 63.95% Fe, 29% Nd, 1.1% B and a small amount of other elements), sample size: 5 cm × 1cm × 0.25cm .

[0053] (1) Alkaline washing and degreasing process conditions: sodium phosphate 70 g / L, sodium carbonate 50 g / L, sodium hydroxide 7g / L, OP-10 emulsifier 0.8g / L, sodium lauryl sulfate 0.3 g / L L, temperature 65°C, processing time: 1.5min;

[0054] (2) Pickling is carried out after alkaline washing and cleaning, nitric acid 50 mL / L, hexamethylenetetramine 1.5 g / L, sodium lauryl sulfate 0.3 g / L, temperature is 20°C, and treatment time is 20s ;

[0055] (3) The composition and process of phosphating solution are: potassium dihydrogen phosphate 70g / L, phosphoric acid 10mL / L, zinc nitrate 2g / L, sodium nitrate 1.0 g / L, ammonium molybdate 1.5g / L, lauryl sulfate Sodium 0.2 g / L, sulfosalicylic acid 0.3 g / L, pH = 2.0, phosphating temperature 35°C, phosphating time 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com