Nano-grade boron phosphate rapid preparation method with microwave radiation low-temperature solid-phase reaction method

A technology of boron phosphate and microwave devices, which is applied in the direction of nanotechnology, boron compounds, chemical instruments and methods, etc., can solve the problems of high energy consumption, high price and complexity of boron phosphate, and achieve no material loss, simple production process, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

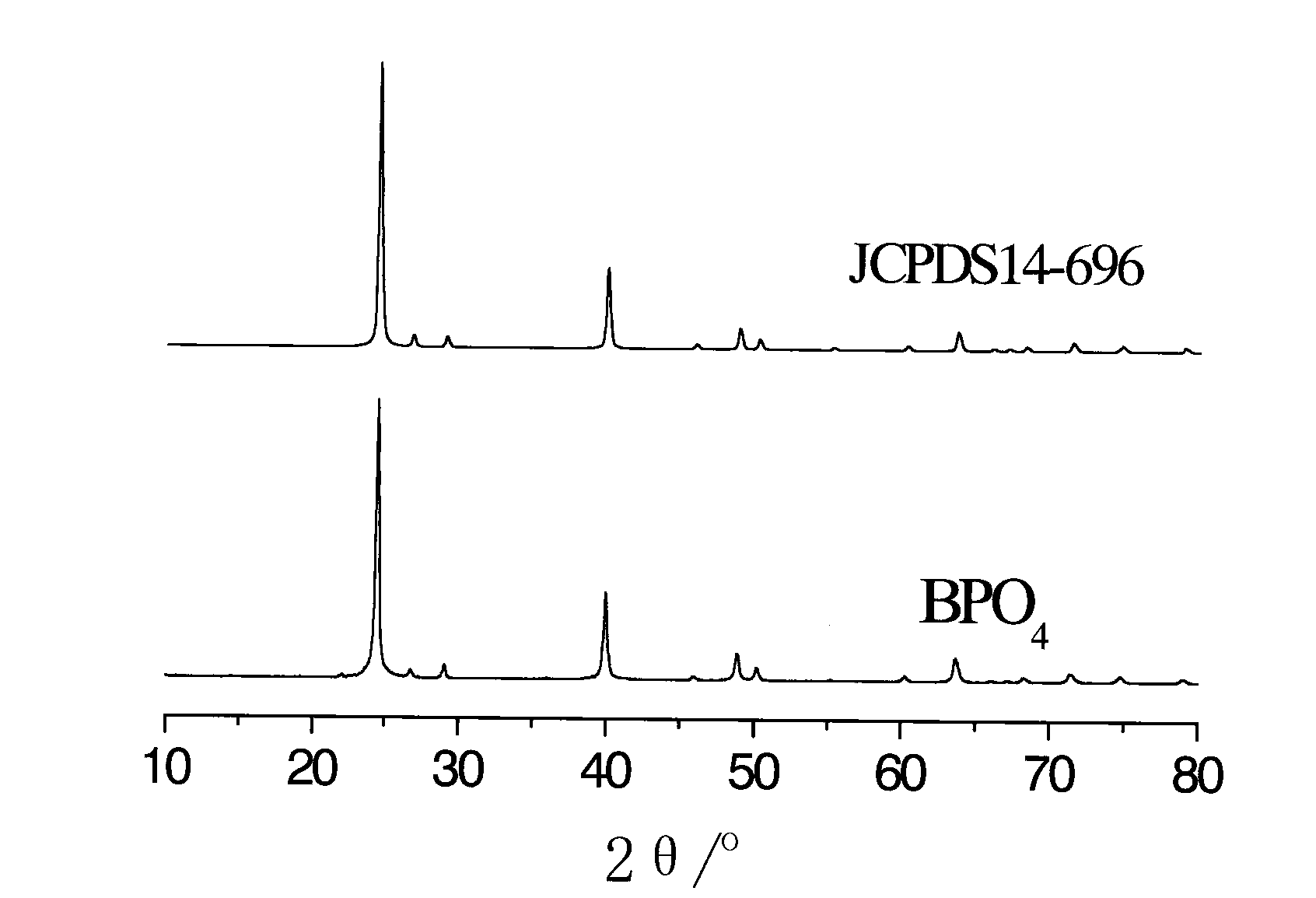

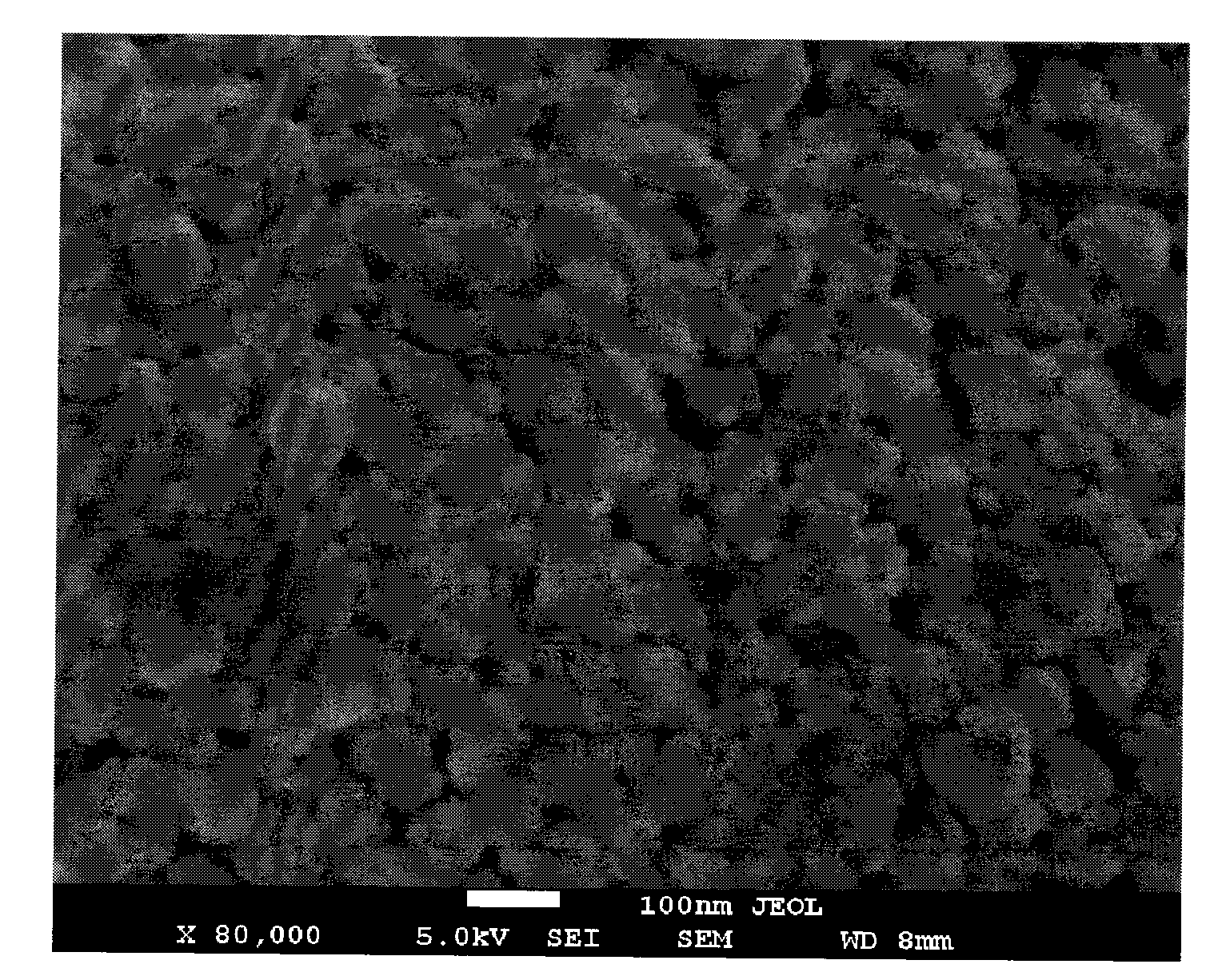

[0021] In the crucible, directly weigh phosphoric acid (85%) 5.76g, boric acid 2.81g, P 2 o 5 and B 2 o 3 The matching ratio is 1.1:1. Place the crucible in an ultrasonic generator to vibrate and disperse for 10 minutes, put it in a household microwave oven, and microwave it for 8 minutes under a microwave power of 400W, then take out the crucible to obtain boron phosphate. The XRD spectrum of this product is completely consistent with the standard spectrum (JPDS 14-1696) (see attached figure 1 ), it can be explained that what is obtained is pure boron phosphate. Measure the B content in boron phosphate (in B 2 o 3 In terms of) and P content (in P 2 o 5 Count) are B 2 o 3 =32.63%, P 2 o 5 = 66.95%. SEM image shows the prepared BPO 4 The particle diameter is between 20-100nm.

Embodiment 2

[0023] Press P 2 o 5 :B 2 o 3 =0.9:1 ratio weighing P 2 o 5 3.55g, 3.44g boric acid, grind in a mortar, add 1mL water to make a paste, dry under an infrared lamp, put it into a crucible, and microwave it in a microwave oven at a power of 800W for 20min to obtain boron phosphate. B in the measured product 2 o 3 =32.81%, P 2 o 5 = 66.34%.

Embodiment 3

[0025] Weigh phosphoric acid (85%) 5.76g directly in the crucible, B 2 o 3 1.74g, P 2 o 5 and B 2 o 3 The ratio is 1:1. Place the crucible in an ultrasonic generator to oscillate and disperse for 30 minutes, then place it in a household microwave oven, microwave for 12 minutes under a microwave power of 640W, and then take out the crucible to obtain boron phosphate. B in the measured product 2 o 3 =32.78%, P 2 o 5 = 66.85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com