Anti-deformation heat preservation compound ethylene propylene diene monomer cable material and preparation method thereof

A technology of EPDM rubber and cable materials, which is applied in the direction of rubber insulators and organic insulators, can solve the problems of scratch resistance, poor flame retardancy, resistance to humidity, cold and heat, etc., achieve excellent performance, and improve vulcanization Performance and Utilization Improvement Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

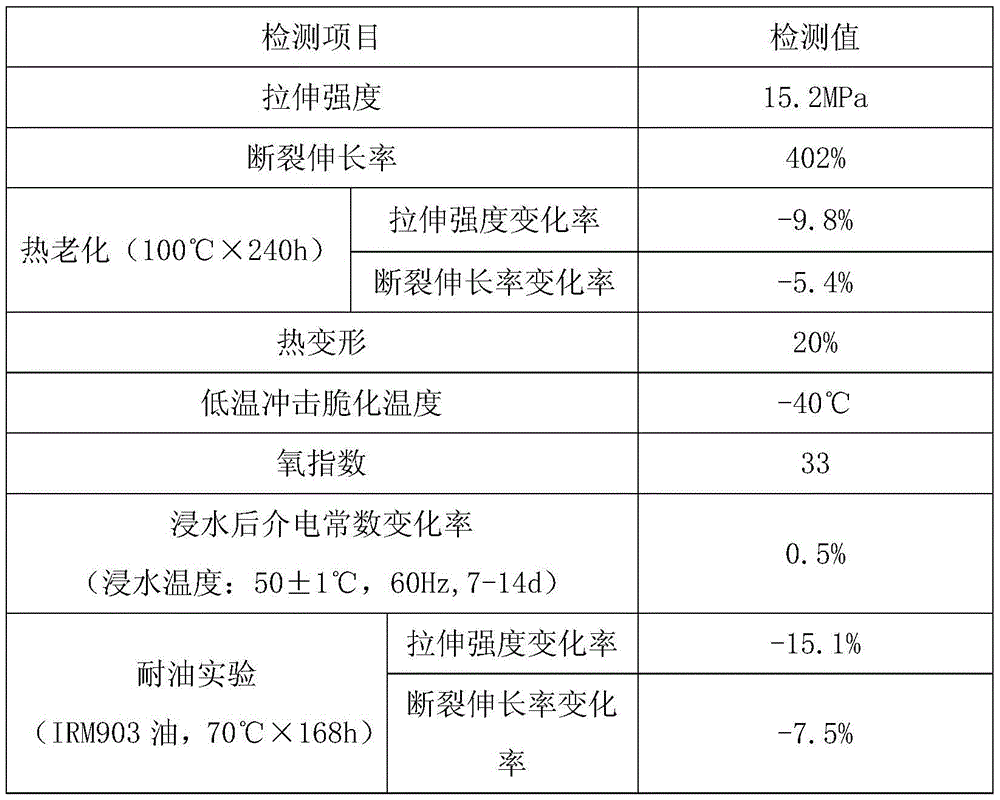

Examples

Embodiment

[0012] The cable material of this embodiment is made of the following raw materials in parts by weight: nano silver 0.01, colemanite powder 25, white carbon black 13, magnesium oxide 4, methacrylic acid 2, magnesium tourmaline 8, EPDM rubber 50 , Silane coupling agent KH-5600.8, antimony trioxide 5, tetrabutyl titanate 8, dioctyl phthalate 5, nitrile rubber 28, accelerator CBS1, color masterbatch 7, diisopropyl peroxide Benzene 2, auxiliary agent 2.

[0013] The auxiliary agent is made of the following raw materials in parts by weight: absolute ethanol 8, aluminum nitride powder 15, zinc stannate 3, vinyl silane coupling agent 2, triethanolamine borate 3, the preparation method is: first Mix and disperse zinc stannate, vinyl silane coupling agent, triethanolamine borate and absolute ethanol evenly, then put aluminum nitride powder into the mixed solution, grind and disperse for 30 minutes, dry the powder at room temperature, remove anhydrous Ethanol, additives.

[0014] Desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com