Concrete and preparing system and preparing method thereof

A technology for preparing a system and concrete, which is applied to clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve the problems that bagged concrete cannot be evenly turned, and bagged concrete cannot be laid equally, and achieves the effect of being easy to place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

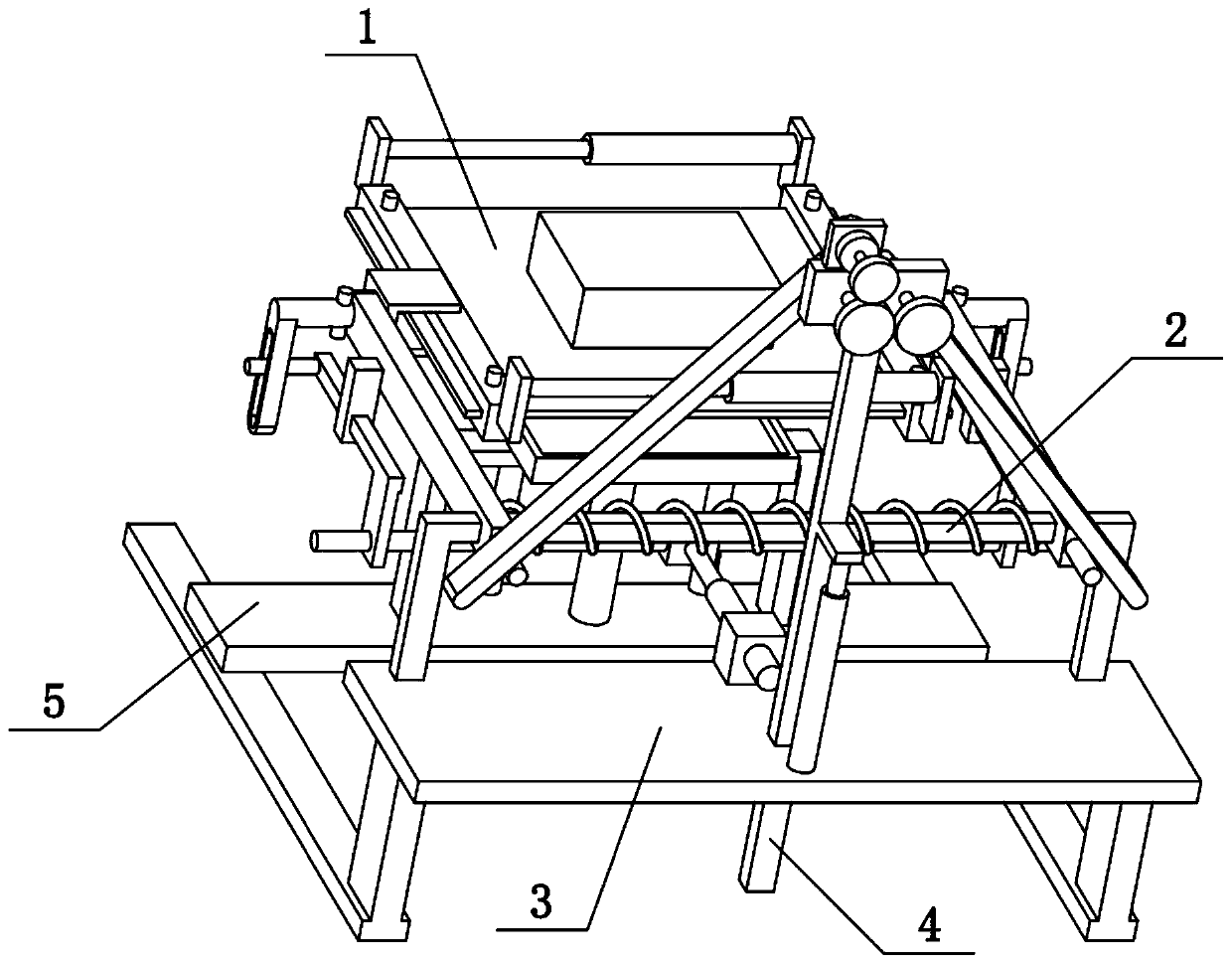

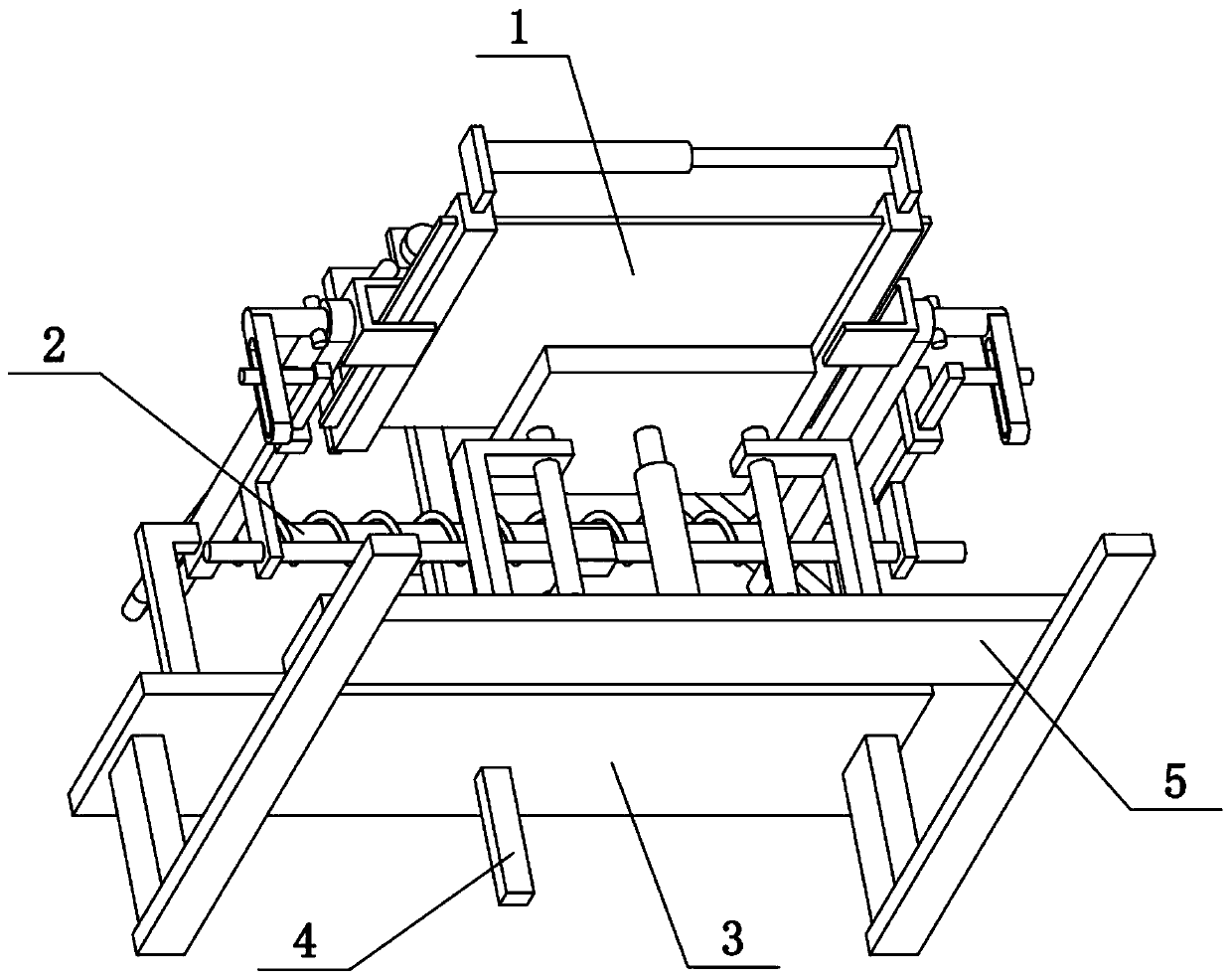

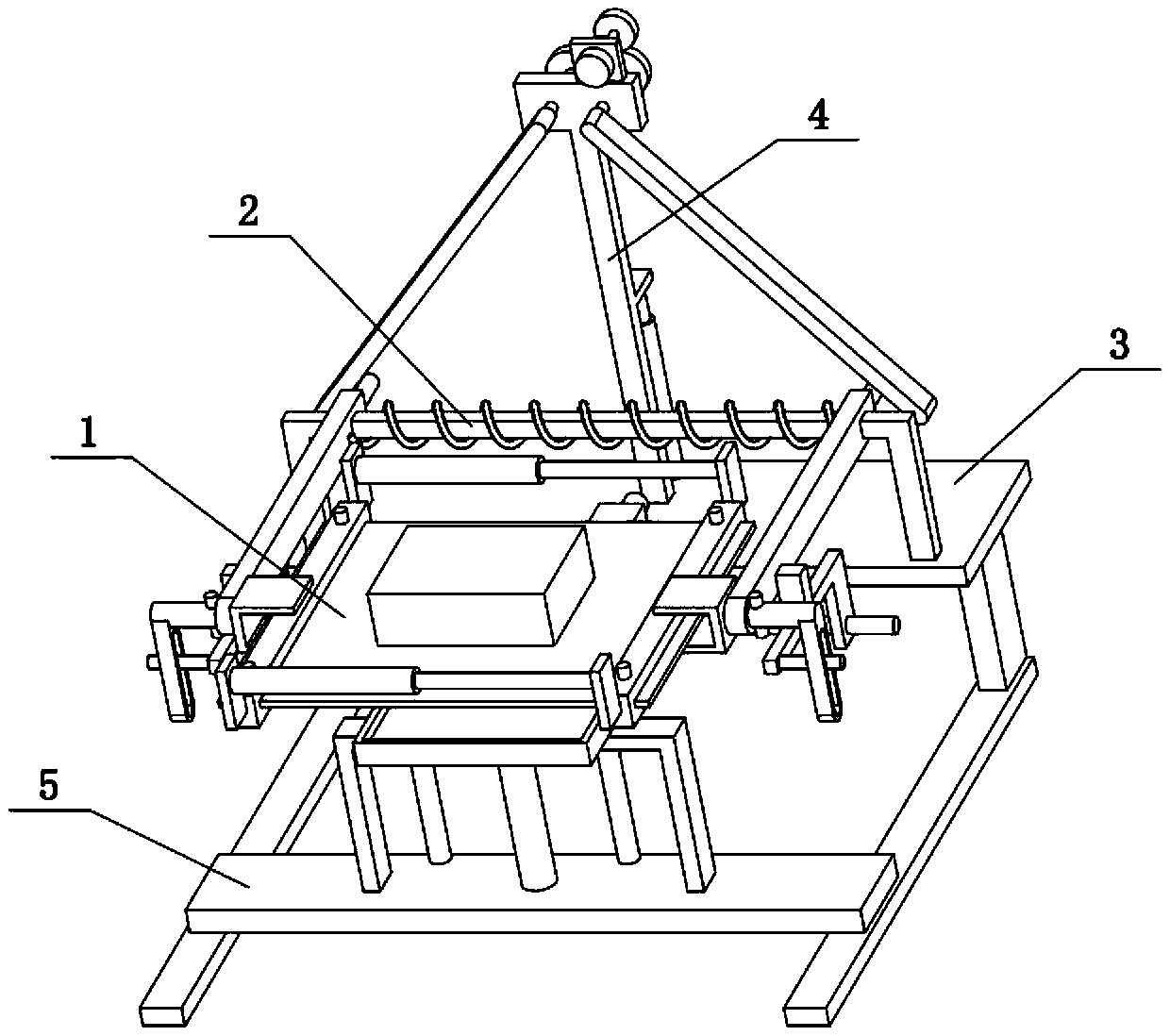

[0035] Combine below Figure 1-10 Describe this embodiment, the present invention relates to the field of concrete preparation, more specifically a concrete preparation system, including textile cloth 1, protruding piece 101, hollow tube 102, solid rod 103 and edge strip 104, the present invention can pack The concrete is further shaken evenly, and the bagged concrete can be paved to facilitate the placement of the bagged concrete.

[0036]There are two side strips 104 left and right, the left and right sides of the textile cloth 1 are respectively inserted on the two side strips 104, and fastening screws are arranged on the two side strips 104 to fix the textile cloth 1 on the side strips 104 , the front and rear ends of the two side bars 104 are fixedly connected with lugs 101, the two lugs 101 at the left end are fixedly connected with a solid rod 103, and the two lugs 101 at the right end are fixedly connected with a hollow cylinder 102, The two solid rods 103 are sliding...

specific Embodiment approach 2

[0038] Combine below Figure 1-10 To illustrate this embodiment, the concrete preparation system further includes a door-shaped piece 105, a stop pin 106, a fixed shaft 107, a cross bar 2 and a left and right moving rod 206, and the outer middle parts of the two side bars 104 are fixedly connected with the door-shaped piece 105 , the outer sides of the two door-shaped parts 105 are fixedly connected with fixed shafts 107, and one end of the two left and right moving rods 206 is respectively slidably connected to the left and right ends of the cross bar 2, and the cross bar 2 between the two left and right moving rods 206 A compression spring is sleeved, and the two fixed shafts 107 are respectively rotatably connected to the front ends of the two left and right moving rods 206, and the two fixed shafts 107 are fixedly connected with stop pins 106, and the two stop pins 106 are respectively located on the two left and right moving rods. 206 outside. The two left and right movi...

specific Embodiment approach 3

[0040] Combine below Figure 1-10 To illustrate this embodiment, the concrete preparation system also includes a sliding hole rod 108, a sliding hole 109, a pillar 202, a front and rear moving rod 203, a sliding cylinder 204, a fixed seat 205, a flat plate 3, an electric push rod 1301 and a push-pull rod 303. The left and right ends of the rod 2 are fixedly connected with pillars 202, the lower ends of the two pillars 202 are fixedly connected on the flat plate 3, the outer ends of the two fixed shafts 107 are fixedly connected with the sliding hole rods 108, and the two sliding hole rods 108 Sliding holes 109 are arranged on the top, and two fixed seats 205 are fixedly connected on the two left and right moving rods 206. One end of each is fixedly connected with a sliding cylinder 204, and the two sliding cylinders 204 are respectively slidably connected to two sliding holes 109, an electric push rod I301 is fixedly connected to the plate 3, and the other end of the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com