Neutron protective body plug and material thereof

A protective body and neutron technology, applied in the field of neutron protective body plugs and their materials, can solve problems such as unfavorable production, high processing and molding temperature, and difficult production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

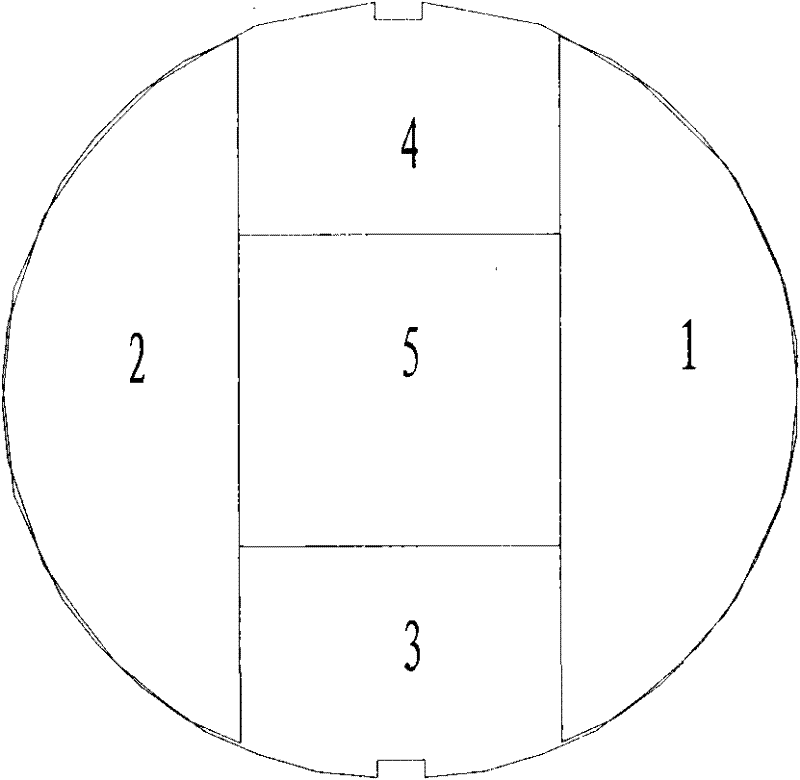

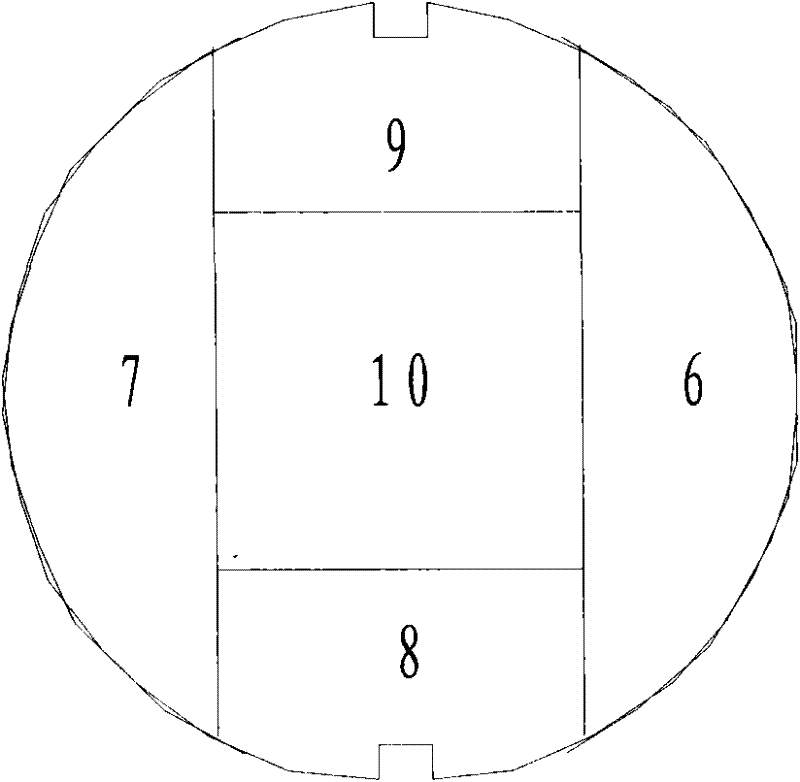

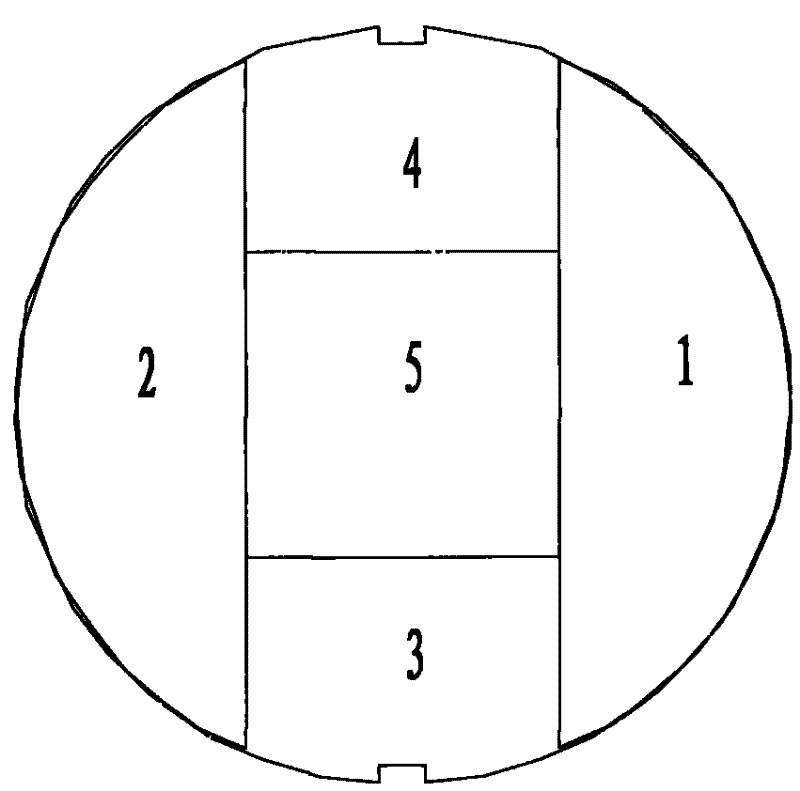

Image

Examples

Embodiment 1

[0014] The material for producing the neutron shield plug is the following components by weight: 32% polyethylene, 20% chlorinated polyethylene, 10% polyvinyl alcohol, 31% aluminum hydroxide, 7% colemanite, The corresponding element composition and content are: aluminum=10.73%, boron=1.12%, calcium=1.36%, carbon=43.49%, chlorine=7.0%, hydrogen=8.4%, oxygen=27.08%, impurity=0.82%.

Embodiment 2

[0016] The material for producing the neutron shield plug is the following components by weight: 30% polyethylene, 15% chlorinated polyethylene, 14% polyvinyl alcohol, 35% aluminum hydroxide, 6% colemanite; The ingredients and their contents are: aluminum=12.12%, boron=0.95%, calcium=1.17%, carbon=41.31%, chlorine=5.25%, hydrogen=8.41%, oxygen=30.37%, impurity=0.42%.

Embodiment 3

[0018] The material for producing the neutron shield plug is the following components by weight percentage: polyethylene 40%, chlorinated polyethylene 10%, polyvinyl alcohol 12%, aluminum hydroxide 28%, colemanite 10%; The ingredients and their contents are: aluminum=9.69%, boron=1.58%, calcium=1.95%, carbon=46.13%, chlorine=3.5%, hydrogen=8.9%, oxygen=27.82%, impurity=0.43%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com