Composite particle material and radiant panel for shielding neutron gamma radiation by high strength

A composite particle, high-strength technology, used in shielding, synthetic resin layered products, layered products, etc., can solve the problems of unsatisfactory radiation protection effect, single function, can not meet the shielding mixed radiation field and other problems, achieve strong gamma Shielding effect, increase extrusion rate, increase compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

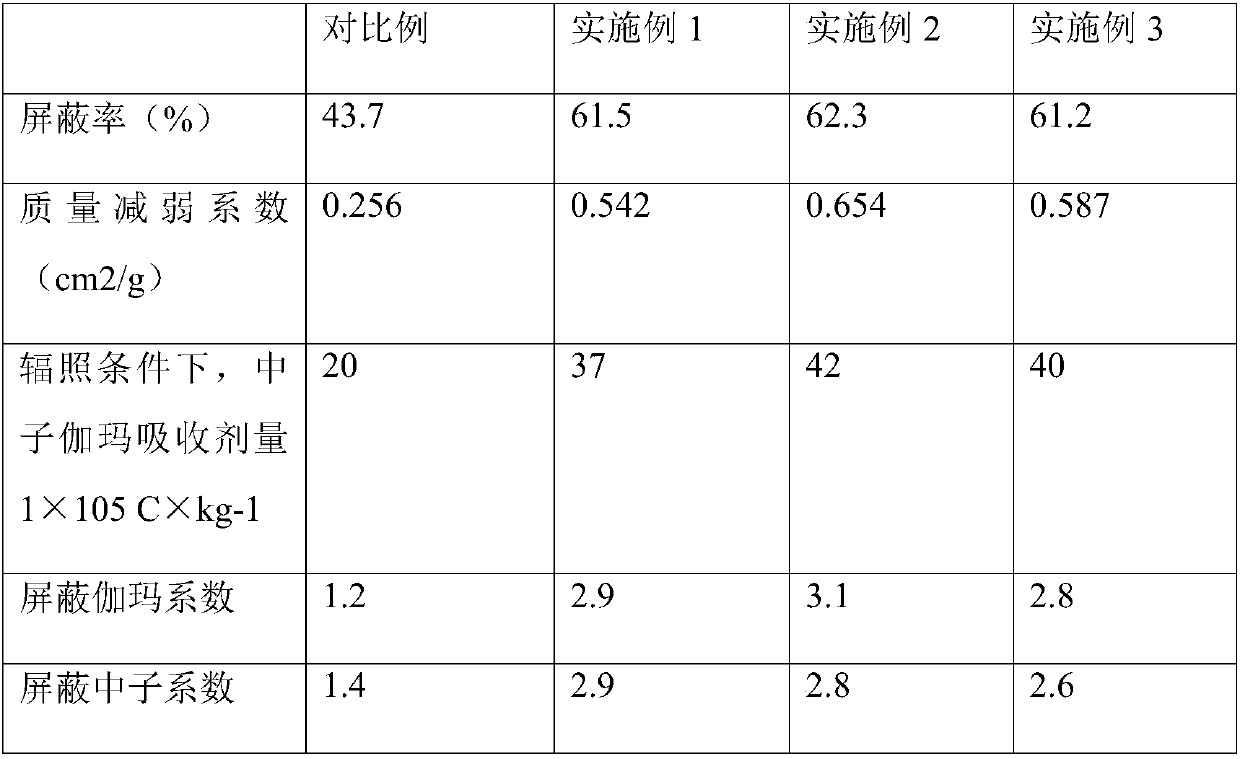

Embodiment 1

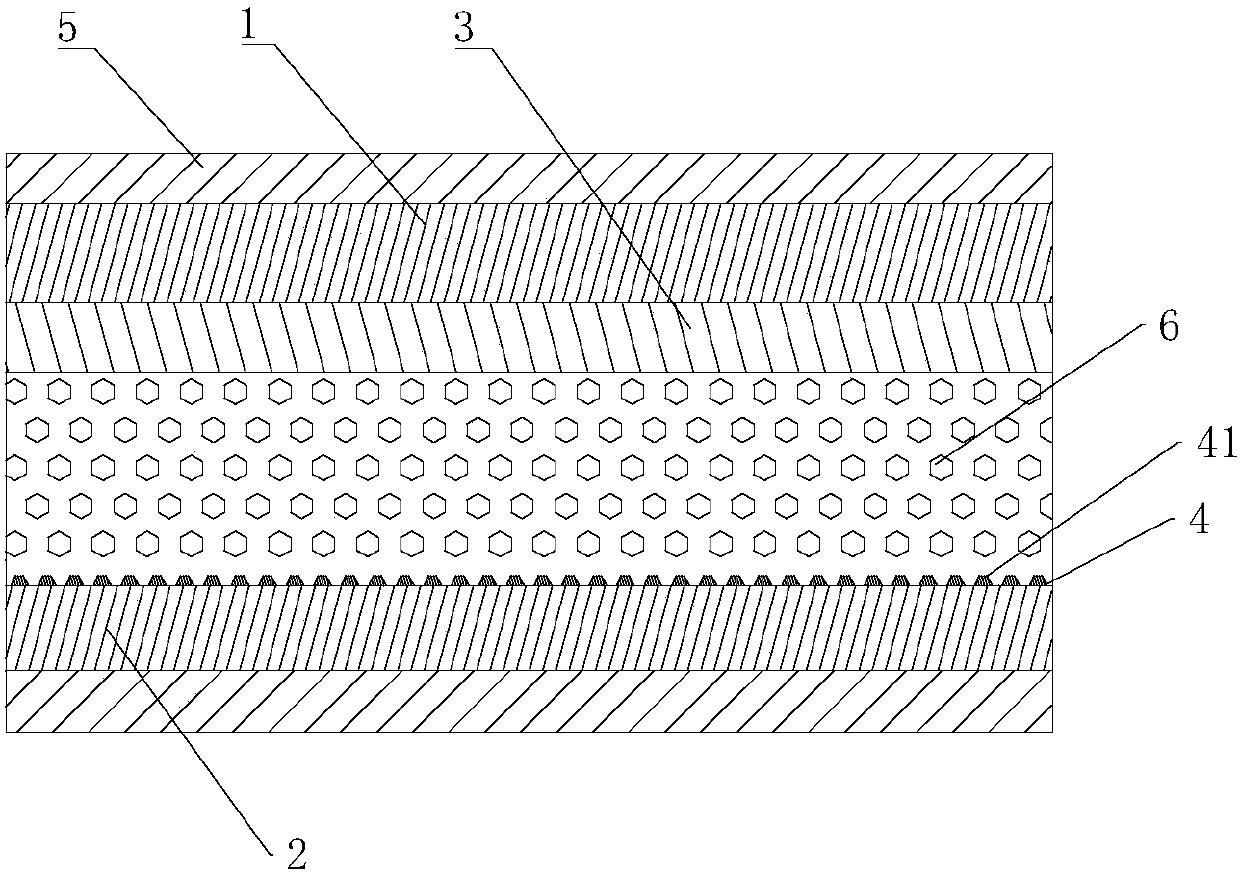

[0030] Embodiment 1: This embodiment provides a new type of neutron gamma radiation shielding sheet with a structure such as figure 1 As shown in and 2, it includes a composite absorbing layer 6, which is filled with composite particle materials, a first lead layer 1 and a second lead layer 2 are respectively provided on both sides of the composite absorbing layer 6, and the first lead layer 1 is provided On the side of the composite absorption layer 6 close to the radiation source, that is, the radiation first passes through the first lead layer 1, then through the composite absorption layer 6, and finally passes through the second lead layer 2.

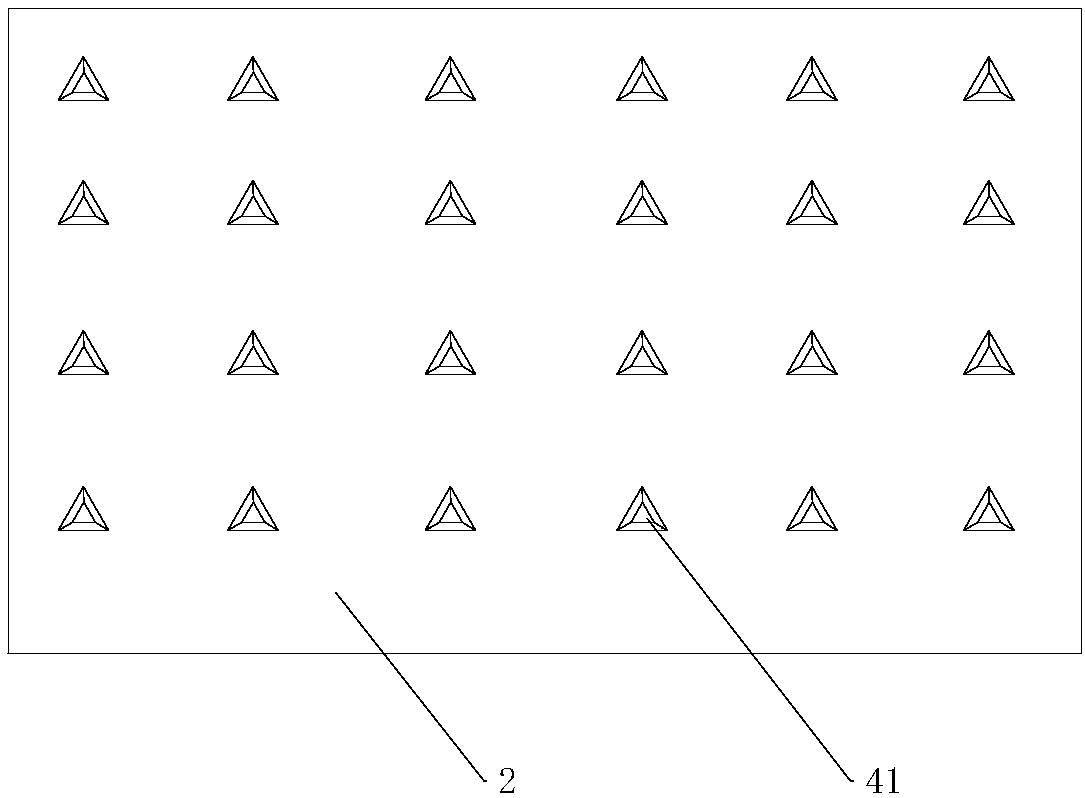

[0031] The second lead layer 2 is provided with a reflective layer 4 on the side close to the first lead layer 1. The reflective layer 4 includes a number of evenly distributed ridges. The ridges are triangular ridges 41, and the triangular ridges 41 are made of lead blocks. The bottom surface of the prism is fixedly connected to the s...

Embodiment 2

[0043] Embodiment 2: This embodiment provides a new type of neutron gamma radiation shielding sheet with a structure such as figure 1 As shown in and 2, it includes a composite absorbing layer 6, which is filled with composite particle materials, a first lead layer 1 and a second lead layer 2 are respectively provided on both sides of the composite absorbing layer 6, and the first lead layer 1 is provided On the side of the composite absorption layer 6 close to the radiation source, that is, the radiation first passes through the first lead layer 1, then through the composite absorption layer 6, and finally passes through the second lead layer 2.

[0044] The second lead layer 2 is provided with a reflective layer 4 on the side close to the first lead layer 1. The reflective layer 4 includes a number of evenly distributed ridges. The ridges are triangular ridges 41, and the triangular ridges 41 are made of lead blocks. The bottom surface of the prism is fixedly connected to the s...

Embodiment 3

[0057] Embodiment 3: This embodiment provides a new type of neutron gamma radiation shielding sheet with a structure such as figure 1 As shown in and 2, it includes a composite absorbing layer 6, which is filled with composite particle materials, a first lead layer 1 and a second lead layer 2 are respectively provided on both sides of the composite absorbing layer 6, and the first lead layer 1 is provided On the side of the composite absorption layer 6 close to the radiation source, that is, the radiation first passes through the first lead layer 1, then through the composite absorption layer 6, and finally passes through the second lead layer 2.

[0058] The second lead layer 2 is provided with a reflective layer 4 on the side close to the first lead layer 1. The reflective layer 4 includes a number of evenly distributed ridges. The ridges are triangular ridges 41, and the triangular ridges 41 are made of lead blocks. The bottom surface of the prism is fixedly connected to the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com