Steel slag radiation shield concrete and preparation method thereof

A radiation protection and concrete technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of poor solidification safety effect of nuclear waste, sustainable utilization of unfavorable resources, soil, water and air pollution, etc. Achieve significant economic benefits, good compactness, and the effect of saving natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

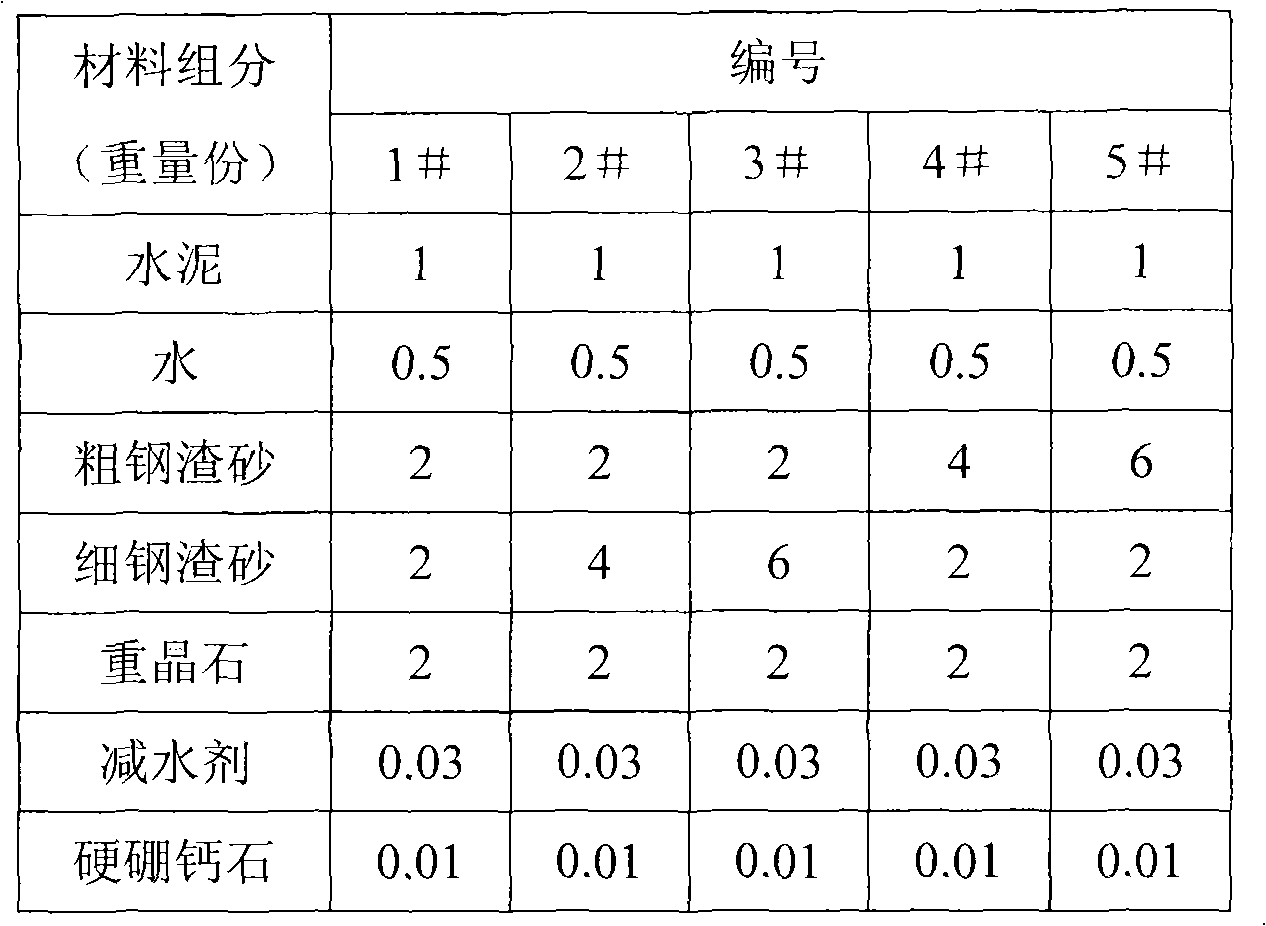

[0028] Five groups of optimization experiments were carried out using the composition ratio shown in Table 3, and the preparation process was the same as above.

[0029] In Table 3, fine steel slag sand refers to steel slag sand with a particle size range of 0-5 mm, and coarse steel slag sand refers to steel slag sand with a particle size range of 5-25 mm.

[0030] Table 3 Test raw material formula

[0031]

[0032] Table 4 shows the various indicators of the radiation-proof concrete prepared in the five groups of tests, including apparent density, compressive strength, flexural strength and other items.

[0033] Table 4 Comparison of trial production of products

[0034] make up

[0035] As can be seen from Table 4, the steel slag sand in the two particle size ranges of 0-5mm and 5-25mm has the best effect in every index of the radiation-proof concrete prepared by the proportioning ratio of 1:1. Therefore, the present invention is effective in preparing radiatio...

Embodiment 5

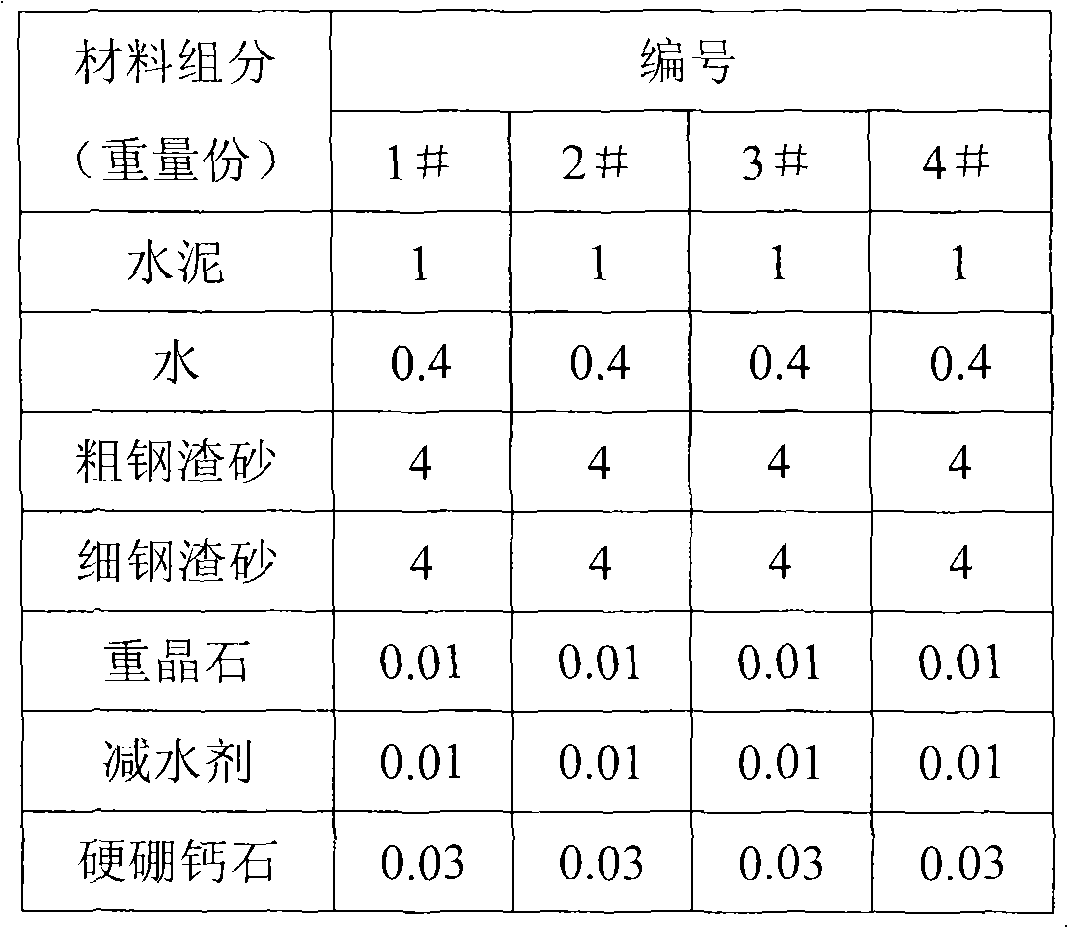

[0037] Adopt the composition ratio shown in Table 5 to carry out 4 groups of comparative tests, the preparation process is carried out as follows:

[0038] (1) crushing the steel slag to below 40 mm, and then passing through a screen with an aperture of 35 mm to obtain steel slag sand with a particle size range of 35-40 mm and steel slag sand with a particle size less than 35 mm;

[0039] (2) passing the steel slag sand with a particle diameter less than 35mm obtained in the step (1) through a screen with an aperture of 30mm to obtain a steel slag sand with a particle size range of 30-35mm and a steel slag sand with a particle size less than 30mm;

[0040] (3) passing the steel slag sand with a particle diameter less than 30mm obtained in the step (2) through a screen with an aperture of 25mm to obtain a steel slag sand with a particle size range of 25-30mm and a steel slag sand with a particle size less than 25mm;

[0041] (4) passing the steel slag sand with a particle diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com