Method for preparing rare earth oxide dispersion strengthened copper

A technology for dispersion strengthening of copper and rare earth oxides, applied in the field of metal matrix composite materials and preparation, can solve the problems of difficult to achieve strengthening effect, small solid solubility, and insufficient strengthening effect, and achieve excellent high temperature softening performance, The effect of improving performance and life, excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A Cu-0.4Y (%, mass fraction, the same below) alloy sample with a thickness of 1 mm and a size of 20 mm × 70 mm was subjected to liquid phase in-situ reaction, and the process steps were as follows.

[0018] (1) Surface treatment: Polish the surface of the sample with 360# sandpaper, remove the surface oxide layer, and clean it with alcohol.

[0019] (2) Liquid phase in-situ reaction: In the atmosphere protection furnace, heat the alloy sample to the liquidus temperature of 1080°C for 2 hours, the protection gas is industrial nitrogen, and the partial pressure of oxygen in nitrogen is 10 -3 ~10 -6 Pa.

[0020] (3) Reduction: in an atmosphere protection furnace, hydrogen reduction, 600℃×1h.

[0021] (4) Flatten the sample.

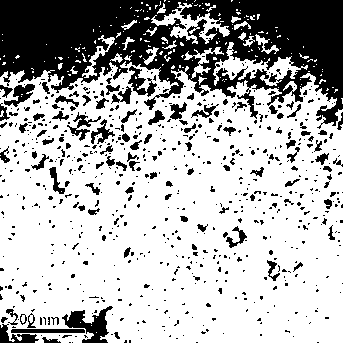

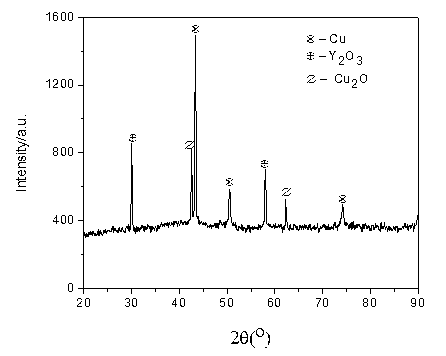

[0022] Yttrium oxide dispersion strengthened copper matrix composite material was prepared through the above process, Y 2 o 3 The particles are evenly distributed on the copper substrate, the average particle size is 7nm, and the average particle...

Embodiment 2

[0024] A Cu-0.6Y alloy sample with a thickness of 1 mm and a size of 20 mm × 70 mm was subjected to liquid phase in-situ reaction, and the process steps were as follows.

[0025] (1) Surface treatment: Polish the surface of the sample with 360# sandpaper, remove the surface oxide layer, and clean it with alcohol.

[0026] (2) Liquid-phase in-situ reaction: In an atmosphere protection furnace, heat the alloy sample to the liquidus temperature of 1078°C for 3 hours, the protection gas is industrial nitrogen, and the partial pressure of oxygen in nitrogen is 10 -3 ~10 -6 Pa.

[0027] (3) Reduction: in an atmosphere protection furnace, hydrogen reduction, 600℃×1h.

[0028] (4) Flatten the sample.

[0029] The properties of yttrium oxide dispersion strengthened copper prepared through the above process are: tensile strength 618MPa, electrical conductivity 92.7%IACS, softening temperature 895°C.

Embodiment 3

[0031] A Cu-0.8Y alloy sample with a thickness of 1 mm and a size of 20 mm × 70 mm was subjected to liquid phase in-situ reaction, and the process steps were as follows.

[0032] (1) Surface treatment: Polish the surface of the sample with 360# sandpaper, remove the surface oxide layer, and clean it with alcohol.

[0033] (2) Liquid-phase in-situ reaction: In an atmosphere-protected furnace, heat the alloy sample to the liquidus temperature of 1075°C for 4 hours, the protective gas is industrial nitrogen, and the partial pressure of oxygen in nitrogen is 10 -3 ~10 -6 Pa.

[0034] (3) Reduction: in an atmosphere protection furnace, hydrogen reduction, 600℃×1h.

[0035] (4) Flatten the sample.

[0036] The properties of yttrium oxide dispersion strengthened copper prepared by the above process are: tensile strength 667MPa, electrical conductivity 90.2%IACS, softening temperature 910°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com