A kind of mold slag for continuous casting mold for p91 steam pipeline steel and its preparation method

A continuous casting crystallizer and steam pipeline technology, applied in the field of metallurgical materials, can solve the problems of poor fluidity of slag, low binary alkalinity, uneven inflow, etc., and achieve the reduction of shell scratches, full crystallization, Effect of preventing sticky slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with some specific embodiments.

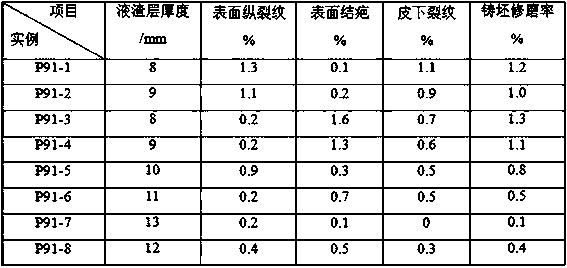

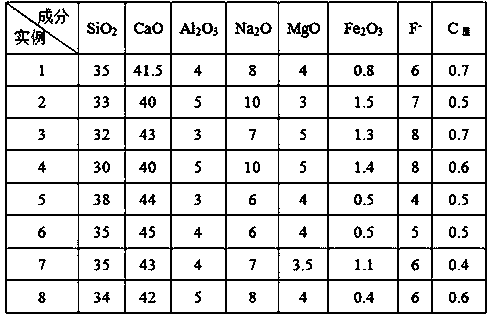

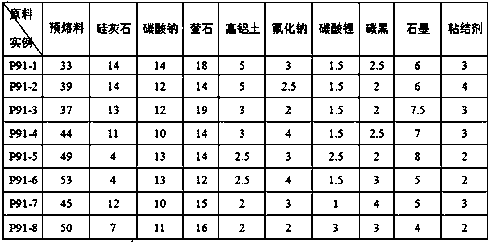

[0035] The chemical composition and weight percentage of P91 mold flux for continuous casting in Examples 1 to 8 of the present invention are shown in Table 1, the weight percentage of each raw material is shown in Table 2, and the chemical composition and weight percentage of the premelt used The contents are shown in Table 3.

[0036] The preparation method of mold flux for P91 continuous casting mold in Example 1 of the present invention comprises the following steps: crush each raw material to 200-mesh fine powder, add it to a mold flux ball mill, and then add clear water to make the pulping concentration 60%, and grind The slurry time is 60 minutes, and it enters the hot air spray tower through the pressure pump for 600 ℃ spray granulation to obtain hollow granular mold powder with a particle size range of 0.15-1.0mm and a moisture content of ≤0.30%.

[0037] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com