Low-oxidizability continuous casting covering slag

A technology of continuous casting mold flux and mold flux, which is applied in the field of low-oxidizing continuous casting mold flux, which can solve the problems of high friction coefficient between the mold wall and the slab, easy crystallization of mold flux slag, and weak network formation performance. The effect of stable component performance, improved purity, and reduced possibility of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The low-oxidizing continuous casting mold flux of the present invention will be further described in detail below in conjunction with specific examples.

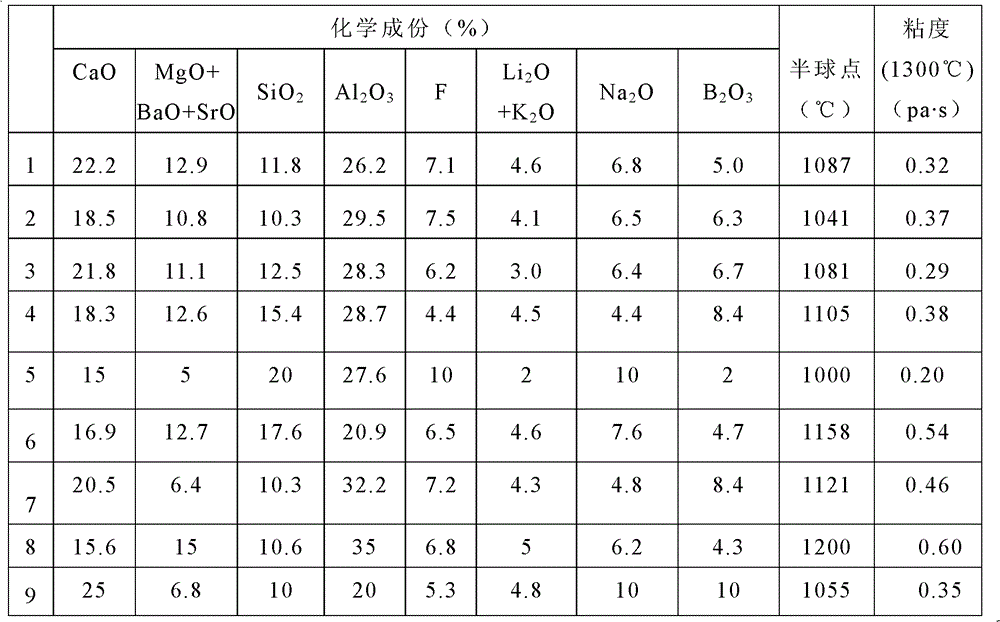

[0022] Table 1 lists the chemical composition weight percentages of nine examples of the low-oxidizing continuous casting mold flux of the present invention (the balance is carbon and unavoidable impurities).

[0023] Its preparation method is as follows: Grind the raw materials containing the above ingredients into powders of less than 200 meshes and mix them with carbonaceous materials with a designed content to make the ingredients and properties meet the design requirements. After melting at high temperature, it can be obtained by crushing and slagging Nine components of low-oxidizing mold flux listed in Table 1.

[0024] The above-mentioned low-oxidizing mold slag was tested, and it was found that it was quenched after melting, and the slag glass phase was more, indicating that the crystallization temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com