Production method of flame-retardant reflective warning tape

A reflective warning tape and the technology of the production method, which are applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve the problem of glass bead falling off, poor blocking effect of the grille, aluminum-coated areas and non-aluminized areas Distinguish problems such as fuzzy boundary lines, and achieve the effects of simple preparation process, smooth touch, and good glass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

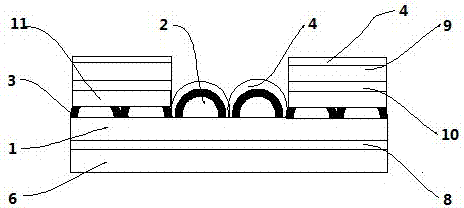

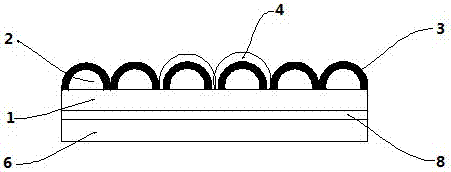

[0041] The PET-PE composite film I in the above-mentioned flame-retardant reflective warning tape includes a PET layer I6, a film-coated adhesive layer I8 and a PE layer I1, the thickness of the PET layer I6 is 25 μm, and the film-coated adhesive layer I8 The thickness is 2 μm, and the thickness of PE layer I 1 is 35 μm.

[0042] Specifically, the non-volatile content in the focusing layer is 1%, and the non-volatiles include the following components:

[0043] Polyurethane glue or polyacrylate adhesive: 8 parts by weight;

[0044] Polyurethane curing agent: 10 parts by weight;

[0045] Ethyl acetate: 110 parts by weight;

[0046] Silane coupling agent: 1 part by weight.

[0047] Specifically, the coating thickness of the adhesive is 50 μm.

[0048] Specifically, the PET-PE composite film II includes a PET layer II 9, an adhesive layer II 10 and a PE layer II 11, the thickness of the PET layer II 9 is 25 μm, the thickness of the adhesive layer II 10 is 2 μm, and the PE laye...

Embodiment 2

[0058] The PET-PE composite film I in the above-mentioned flame-retardant reflective warning tape includes a PET layer I6, a film adhesive layer I8 and a PE layer I1, the thickness of the PET layer I6 is 35 μm, and the film adhesive layer I8 The thickness is 5 μm, and the thickness of PE layer I 1 is 45 μm.

[0059] Specifically, the non-volatile matter content in the adhesive is 5%, and the non-volatile matter includes the following components:

[0060] Polyurethane glue or polyacrylate adhesive: 5 parts by weight;

[0061] Polyurethane curing agent: 6 parts by weight;

[0062] Ethyl acetate: 95 parts by weight;

[0063] Silane coupling agent: 0.6 parts by weight.

[0064] Specifically, the coating thickness of the adhesive is 40 μm.

[0065] Specifically, the PET-PE composite film II includes a PET layer II 9, an adhesive layer II 10 and a PE layer II 11, the thickness of the PET layer II 9 is 25 μm, the thickness of the adhesive layer II 10 is 2 μm, and the PE layer II ...

Embodiment 3

[0075] The PET-PE composite film I in the above-mentioned flame-retardant reflective warning tape includes a PET layer I6, a film adhesive layer I8 and a PE layer I1, the thickness of the PET layer I6 is 30 μm, and the film adhesive layer I8 The thickness is 3 μm, and the thickness of PE layer I 1 is 40 μm.

[0076] Specifically, the non-volatile matter content in the adhesive is 10%, and the non-volatile matter includes the following components:

[0077] Polyurethane glue or polyacrylate adhesive: 3 parts by weight;

[0078] Polyurethane curing agent: 3 parts by weight;

[0079] Ethyl acetate: 80 parts by weight;

[0080] Silane coupling agent: 0.2 parts by weight.

[0081] Specifically, the coating thickness of the adhesive is 30 μm.

[0082] Specifically, the PET-PE composite film II includes a PET layer II 9, an adhesive layer II 10 and a PE layer II 11, the thickness of the PET layer II 9 is 25 μm, the thickness of the adhesive layer II 10 is 2 μm, and the PE layer II...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com