Continuous casting crystallizer mold powder of sheet billet at high casting speed

A mold powder and thin slab continuous casting technology, applied in the field of continuous casting mold mold powder, can solve the problems of steel breakout, poor lubrication, longitudinal cracking of the casting billet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

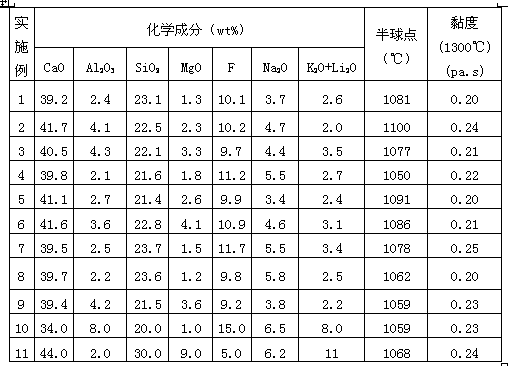

[0020] The present invention will be further described in detail below in conjunction with specific examples. Examples 1-11 are mold fluxes for high-speed thin slab continuous casting, using the following preparation methods and chemical components.

[0021] Preparation method: Grind the raw materials containing the above ingredients to a powder of less than 200 meshes, add the carbonaceous material with the designed content, make the ingredients meet the design requirements, melt at high temperature, crush and slag to obtain the surface Mold flux with nine components listed in 1.

[0022] Chemical composition: the weight percent of chemical composition of each embodiment is shown in Table 1, balance carbon and unavoidable impurity.

[0023] Table 1: Chemical composition of each embodiment

[0024]

[0025] Application test:

[0026]The above examples of the present invention have been carried out application test on the thin slab continuous casting machine of Tangshan Ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com