Pre-hydrogenation catalyst for preparing 1,4-butanediol, preparation method and application thereof

A catalyst, pre-hydrogenation technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem of catalyst poisoning, incomplete esterification, power consumption, etc. increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The prehydrogenation catalyst, the Al 2 o 3 Three types of Al with particle diameters of 200-500 μm, 50-200 μm, and 10-50 μm 2 o 3 The gradation of the powder is conducive to improving the pore volume of the catalyst, especially the pore volume of large pores with a pore diameter between 100 and 1000 nm; the preparation method of the prehydrogenation catalyst comprises the following steps:

[0020] (1) According to the mass ratio of 50-70:10-20:10-40, weigh three kinds of Al with particle diameters ranging from 200-500 μm, 50-200 μm, and 10-50 μm, respectively 2 o 3 powder; then weighed Al 2 o 3 The total mass of the powder is 2% of the binder hydroxypropyl methylcellulose, and mixed evenly to obtain material Ⅰ;

[0021] (2) Add an aqueous solution containing an alkali metal oxide precursor to the material I, knead and extrude it into a strip, dry and roast to obtain the material II;

[0022] (3) The material II is impregnated with an aqueous solution containing ...

Embodiment 1

[0034] Catalyst preparation:

[0035] (1) According to the ratio of mass ratio of 50:10:40, respectively weigh Al with particle diameter ranges of 200-500 μm, 50-200 μm, and 10-50 μm 2 o 3 powder; then weighed Al 2 o 3 The total mass of the powder is 2% of the binder hydroxypropyl methylcellulose, and mixed evenly to obtain material Ⅰ;

[0036] (2) Add an aqueous solution containing KOH to the material I, knead and extrude into strips with a diameter of 2mm, dry at 100°C for 10 hours, and roast at 600°C for 4 hours to obtain material II;

[0037] (3) The material II was impregnated with an aqueous solution containing copper nitrate, dried at 100°C for 10 hours, and calcined at 400°C for 4 hours to obtain the catalyst of this example.

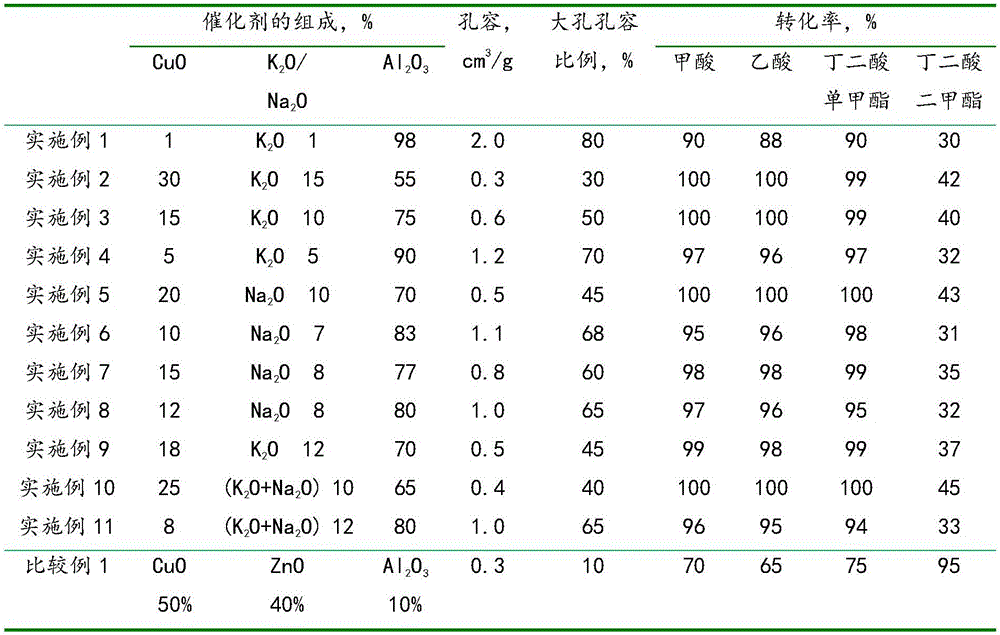

[0038] The composition, pore volume, and ratio of macropore (100-1000 nm) pore volume of the catalyst obtained in this example are shown in Table 1.

[0039] Catalyst evaluation:

[0040] In addition to dimethyl succinate, the dimethyl suc...

Embodiment 2

[0043] Catalyst preparation:

[0044] (1) According to the ratio of mass ratio of 70:20:10, respectively weigh Al with particle diameters ranging from 200 to 500 μm, 50 to 200 μm, and 10 to 50 μm 2 o 3 powder; then weighed Al 2 o 3 The total mass of the powder is 2% of the binder hydroxypropyl methylcellulose, and mixed evenly to obtain material Ⅰ;

[0045] (2) Add KNO containing KNO to material Ⅰ 3 After kneading, it was extruded into strips with a diameter of 2mm, dried at 100°C for 10 hours, and roasted at 600°C for 4 hours to obtain material II;

[0046] (3) The material II was impregnated with an aqueous solution containing copper acetate, dried at 100°C for 10 hours, and calcined at 400°C for 4 hours to obtain the catalyst of this example.

[0047] The composition, pore volume, and ratio of macropore (100-1000 nm) pore volume of the catalyst obtained in this example are shown in Table 1.

[0048] Catalyst evaluation:

[0049] In addition to dimethyl succinate, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com