Fluoride glass and a preparing method thereof

A fluoride and glass technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of difficult and efficient preparation of fluoride glass, low chemical stability, high theoretical loss, etc., to achieve good chemical stability, Increased transmittance and low theoretical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

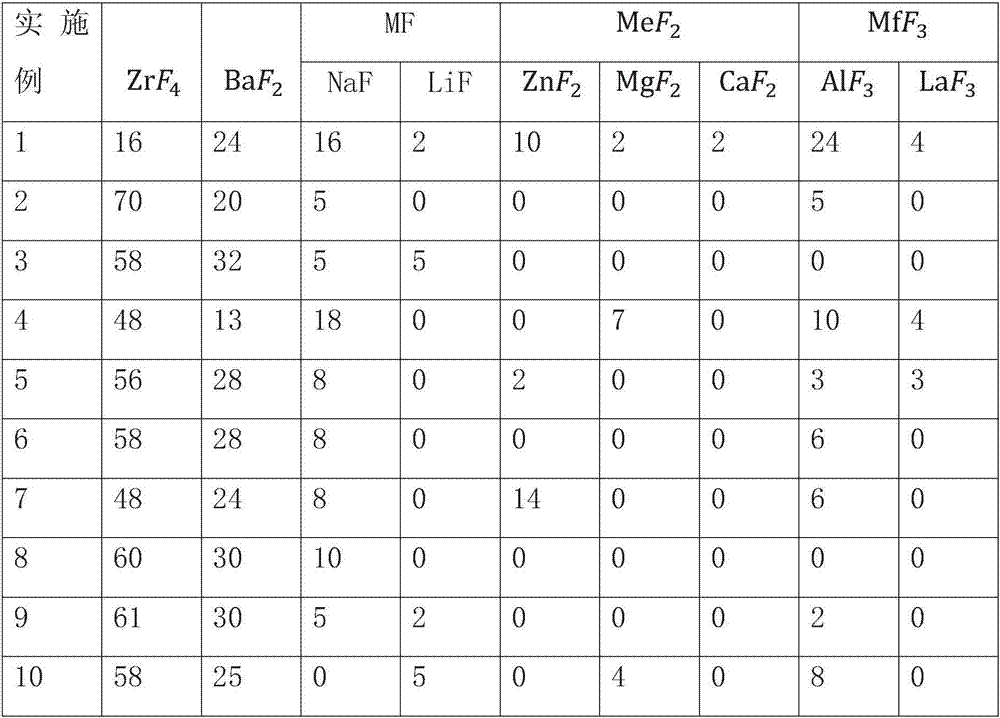

[0027] The molar percentage of the glass raw materials are 16% ZrF 4 , 24% BaF 2 , 16% NaF, 2% LiF, 10% ZnF 2 , 2% MgF 2 , 2%CaF 2 , 24%AlF 3 and 4% LaF 3 , according to the proportion of 20% of the total mass of glass raw materials, add auxiliary reagent NH 4 HF 2 , before the auxiliary reagent is added to the raw material, it needs to be heated for 10 minutes at a temperature of 200°C. After cooling, put it into the raw material, and then rise to 320°C. 4 HF 2 Thermal decomposition produces hydrogen fluoride and ammonia atmosphere, which is maintained for 40 minutes; then, the fluorinated atmosphere is maintained, and the temperature is raised to 850°C for 40 minutes to complete the melting process. Place the mold in a muffle furnace at 100°C and preheat it separately for 30 minutes to heat the mold fully and evenly; after the raw materials are completely melted, quickly pour the molten glass into the mold, return to the furnace, heat at 100°C for 100 minutes, then s...

Embodiment 2

[0029] The molar percentage of glass raw materials are 70% ZrF 4 , 20% BaF 2 , 5% NaF and 5% AlF 3 , add the auxiliary reagent NH according to the proportion of 30% of the total mass of the glass raw material 4 HF 2 , before the auxiliary reagent is added to the raw material, it needs to be heated for 20 minutes, the temperature is 180 ° C, put it into the raw material after cooling, and then rise to 350 ° C, during this process 4 HF 2 Thermal decomposition produces hydrogen fluoride and ammonia atmosphere, which is maintained for 30 minutes; then, the fluorinated atmosphere is maintained, and the temperature is raised to 950 ° C for 30 minutes to complete the melting process. Place the mold in a muffle furnace at 150°C and preheat it separately for 20 minutes to fully and evenly heat the mold; after the raw materials are completely melted, quickly pour the molten glass into the mold, return to the furnace, and stop heating after heating at 150°C for 80 minutes to allow T...

Embodiment 3

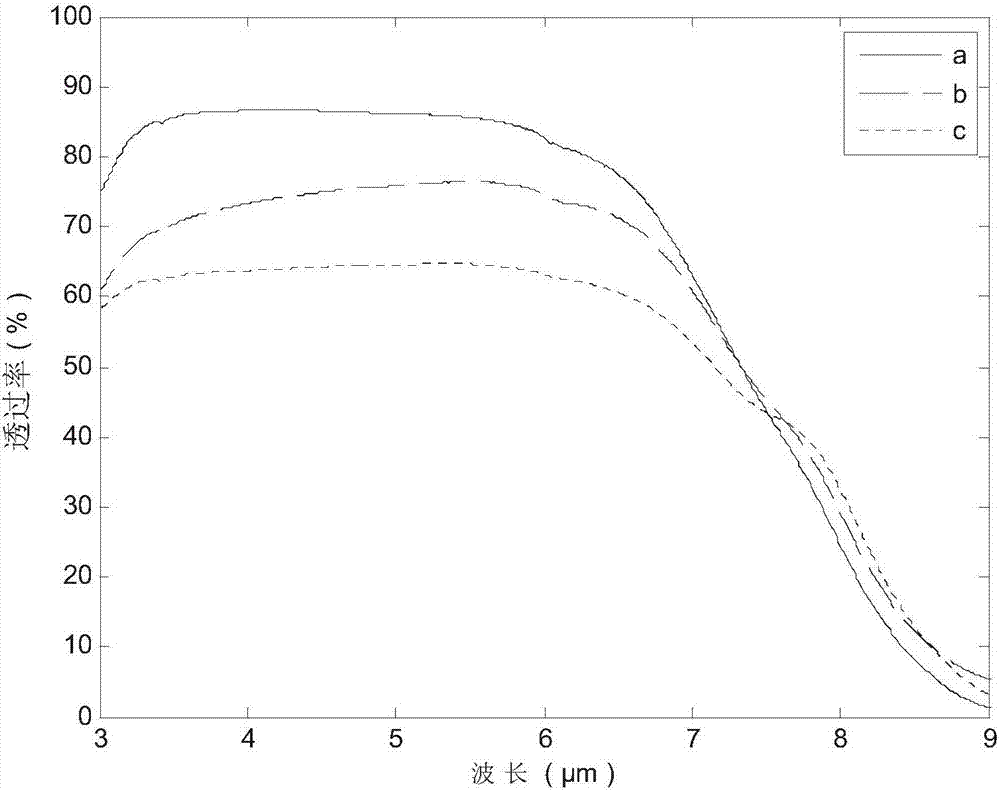

[0031] The molar percentage of the glass raw material is 58% ZrF 4 , 32% BaF 2 , 5% NaF and 5% LiF, add the auxiliary reagent NH according to the proportion of 40% of the total mass of glass raw materials 4 HF 2 , before the auxiliary reagent is added to the raw material, it needs to be heated for 40 minutes at a temperature of 100°C. 4 HF 2 Thermal decomposition produces hydrogen fluoride and ammonia atmosphere, which is maintained for 20 minutes; then, the fluorinated atmosphere is maintained, and the temperature is raised to 1200 ° C for 20 minutes to complete the melting process. Place the mold in a muffle furnace at 250°C, and preheat it separately for 10 minutes to heat the mold fully and evenly; after the raw materials are completely melted, quickly pour the molten glass into the mold, return to the furnace, heat at 250°C for 30 minutes, then stop heating, let The mold and molten glass are naturally cooled to room temperature. The transmittance of the obtained fluo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com