A kind of high-strength glass fiber and its preparation method

A glass fiber, high-strength technology, applied in glass manufacturing equipment, glass fiber drawing devices, manufacturing tools, etc., can solve problems such as difficulty in supplying raw materials, and achieve the effects of improving yield, uniformity, and melting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

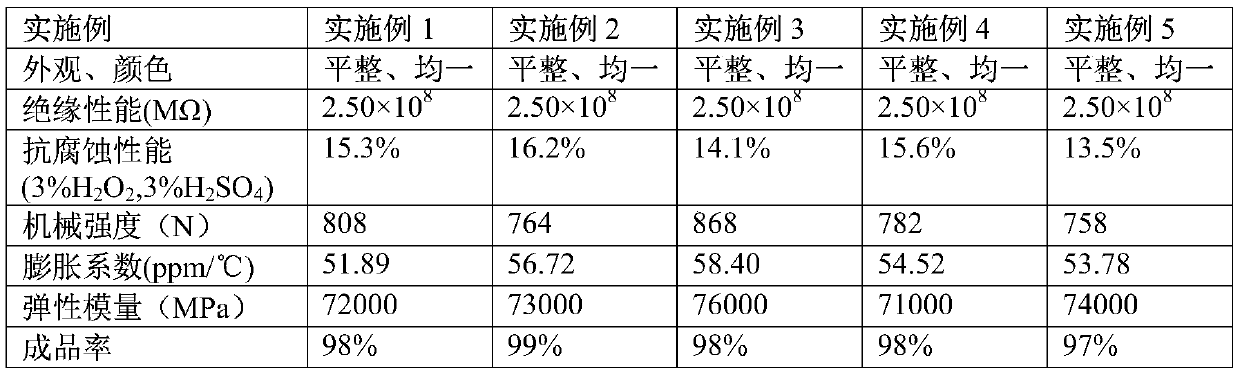

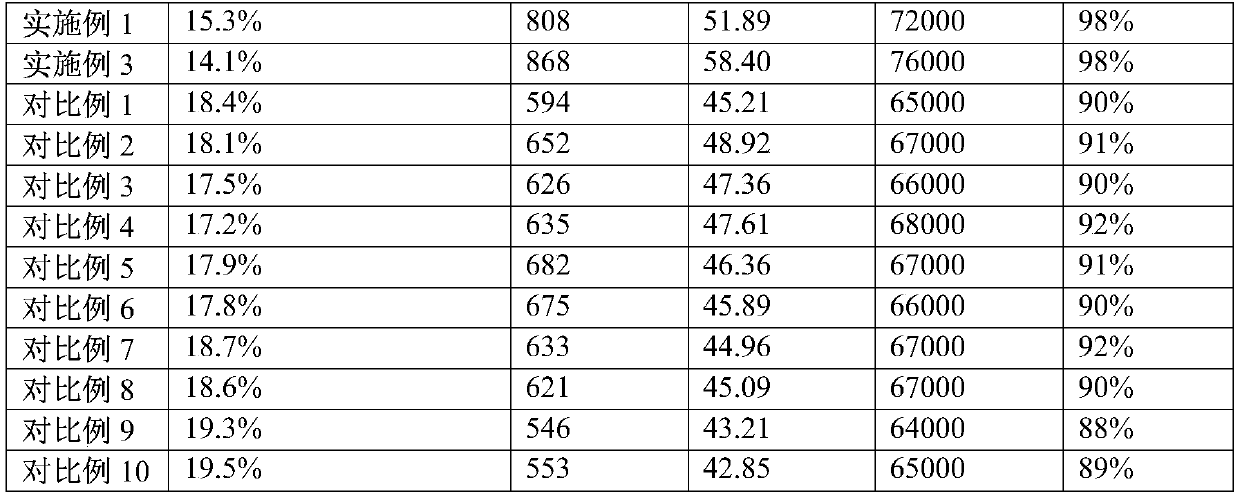

Examples

Embodiment 1

[0035] Embodiment 1 A kind of high-strength glass fiber and preparation method thereof

[0036] Formula: by weight percentage, the main components include:

[0037] Silica sand 29.33%, kaolin 30.31%, calcite 23.92%, fluorite 2.30%, boronite 13.52%, Glauber's salt 0.27% and soda ash 0.35%.

[0038] Preparation method: the specific steps are:

[0039] (1) Weigh various raw materials according to the formula weight, and after drying, pulverize and pass through a 200-mesh sieve to obtain pulverized materials, and mix the pulverized materials uniformly to obtain mixture A;

[0040] (2) Put the mixture A obtained in the step (1) into the kiln pool at a rate of 0.5 tons / h, burn natural gas to make the mixture A heated and melted into glass liquid in the kiln pool, and the combustion temperature of natural gas is 1600 ° C, in the kiln pool The molten glass forms heat convection due to uneven heating, so that the molten glass is mixed evenly to obtain a uniform molten glass;

[0041...

Embodiment 2

[0042] Embodiment 2 A kind of high-strength glass fiber and preparation method thereof

[0043] Formula: by weight percentage, the main components include:

[0044] Silica sand 32.25%, kaolin 27.39%, calcite 25.76%, fluorite 2.33%, boronite 11.68%, Glauber's salt 0.24% and soda ash 0.35%.

[0045] Preparation method: the specific steps are as follows:

[0046] (1) Weigh various raw materials according to the formula weight, and after drying, pulverize them and pass through 300 sieves to obtain pulverized materials, and mix the pulverized materials uniformly to obtain mixture A;

[0047] (2) Put the mixture A obtained in step (1) into the kiln pool at a rate of 0.5 tons / h, burn natural gas to make the mixture A heated and melted into glass liquid in the kiln pool, and the combustion temperature of natural gas is 1800 ° C, in the kiln pool The molten glass forms heat convection due to uneven heating, so that the molten glass is mixed evenly to obtain a uniform molten glass;

...

Embodiment 3

[0049] Embodiment 3 A kind of high-strength glass fiber and preparation method thereof

[0050] Formula: by weight percentage, the main components include:

[0051] Silica sand 30.36%, kaolin 29.12%, calcite 24.86%, fluorite 2.56%, boronite 12.46%, Glauber's salt 0.30% and soda ash 0.34%.

[0052] Preparation method: the specific steps are as follows:

[0053] (1) Weigh various raw materials according to the formula weight, and after drying, pulverize them and pass through 200 sieves to obtain pulverized materials, and mix the pulverized materials uniformly to obtain mixture A;

[0054] (2) Put the mixture A obtained in the step (1) into the kiln at a rate of 0.5 tons / h, burn natural gas to make the mixture A heated and melted into glass liquid in the kiln, and the combustion temperature of natural gas is 2000 ° C, in the kiln The molten glass forms heat convection due to uneven heating, so that the molten glass is mixed evenly to obtain a uniform molten glass;

[0055] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com