Laser stripping method applied to automobile lamp

A laser peeling and car light technology, which is applied in laser welding equipment, devices for applying liquid to the surface, coatings, etc., can solve the problems of easily damaged substrates and low paint removal rate, reducing damage and improving peeling. The effect of reducing the removal rate and binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A laser stripping method applied to car lights mainly includes the following processing steps:

[0039] (1) Car lamp painting treatment;

[0040] (2) acid treatment;

[0041] (3) nano bombardment treatment;

[0042] (4) Assisted laser peeling.

[0043] As an optimization, the processing steps are:

[0044] (1) Car lamp painting treatment:

[0045] (a) Cleaning: After washing the surface of the lamp with water for 8 times, dry it at 60°C for 2 hours;

[0046] (b) Pre-spraying: Spray blue silver powder paint with a thickness of 40 μm on the surface of the car lamp after cleaning, and dry at 50°C for 20 minutes;

[0047] (c) Re-spraying: Spray a 50 μm thick high-gloss varnish on the surface of the pre-sprayed car lamp, level it at room temperature for 15 minutes, and then dry it;

[0048] (2) acid treatment:

[0049] Mix the painted car lamp obtained in step (1) with hydrochloric acid with a mass fraction of 15% at a mass ratio of 1:12, soak for 3 hours at room temp...

Embodiment 2

[0063] A laser stripping method applied to car lights mainly includes the following processing steps:

[0064] (1) Car lamp painting treatment;

[0065] (2) acid treatment;

[0066] (3) nano bombardment treatment;

[0067] (4) Laser peeling.

[0068] As an optimization, the processing steps are:

[0069] (1) Car lamp painting treatment:

[0070] (a) Cleaning: After washing the surface of the lamp with water for 8 times, dry it at 60°C for 2 hours;

[0071] (b) Pre-spraying: Spray blue silver powder paint with a thickness of 40 μm on the surface of the car lamp after cleaning, and dry at 50°C for 20 minutes;

[0072] (c) Re-spraying: Spray a 50 μm thick high-gloss varnish on the surface of the pre-sprayed car lamp, level it at room temperature for 15 minutes, and then dry it;

[0073] (2) acid treatment:

[0074] Mix the painted car lamp obtained in step (1) with hydrochloric acid with a mass fraction of 15% at a mass ratio of 1:12, soak for 3 hours at room temperature, ...

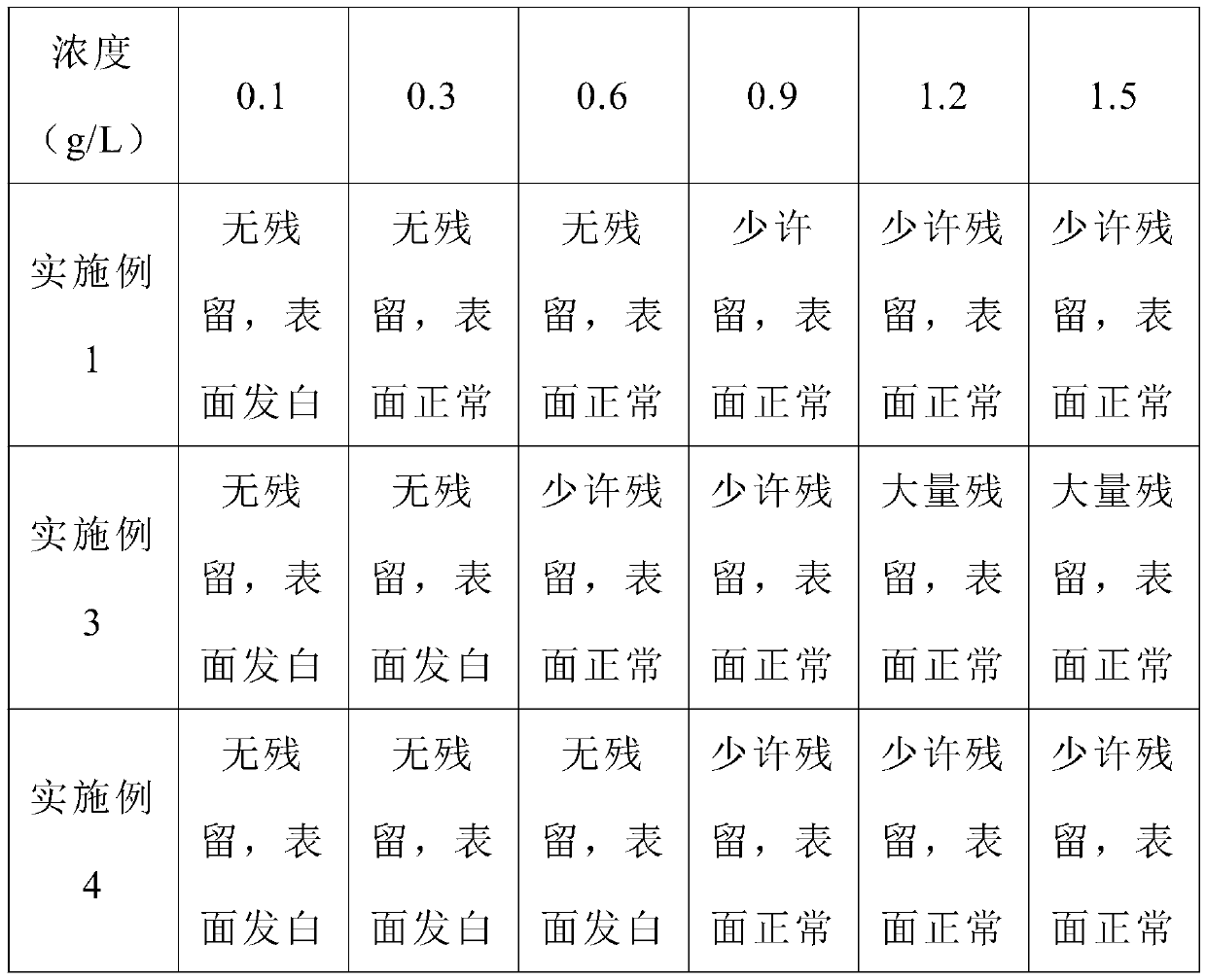

Embodiment 3

[0085] A laser stripping method applied to car lights mainly includes the following processing steps:

[0086] (1) Car lamp painting treatment;

[0087] (2) acid treatment;

[0088] (3) Assisted laser peeling.

[0089] As an optimization, the processing steps are:

[0090] (1) Car lamp painting treatment:

[0091] (a) Cleaning: After washing the surface of the lamp with water for 8 times, dry it at 60°C for 2 hours;

[0092] (b) Pre-spraying: Spray blue silver powder paint with a thickness of 40 μm on the surface of the car lamp after cleaning, and dry at 50°C for 20 minutes;

[0093] (c) Re-spraying: Spray a 50 μm thick high-gloss varnish on the surface of the pre-sprayed car lamp, level it at room temperature for 15 minutes, and then dry it;

[0094] (2) acid treatment:

[0095] Mix the painted car lamp obtained in step (1) with hydrochloric acid with a mass fraction of 15% at a mass ratio of 1:12, soak for 3 hours at room temperature, and filter to obtain a filter cak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com