Infrared transmitting germanate glass and preparation method thereof

A technology of germanate glass and infrared transmission, applied in the field of germanate glass, can solve the problems of crystallization performance, mechanical strength stability, poor process performance, low water content, low dispersion, etc., to achieve enhanced physical and chemical properties, Effect of improving glass capacity and reducing group content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

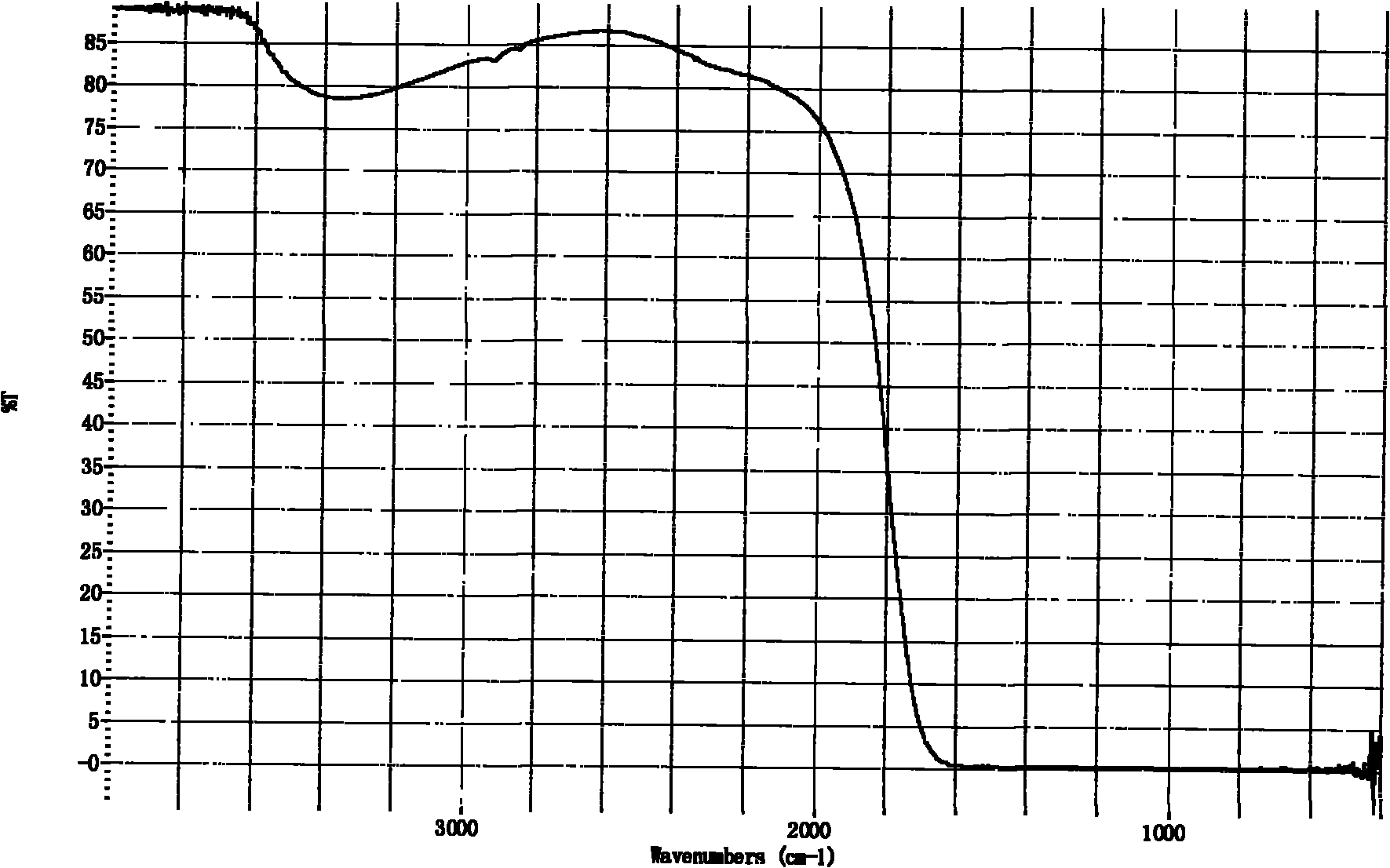

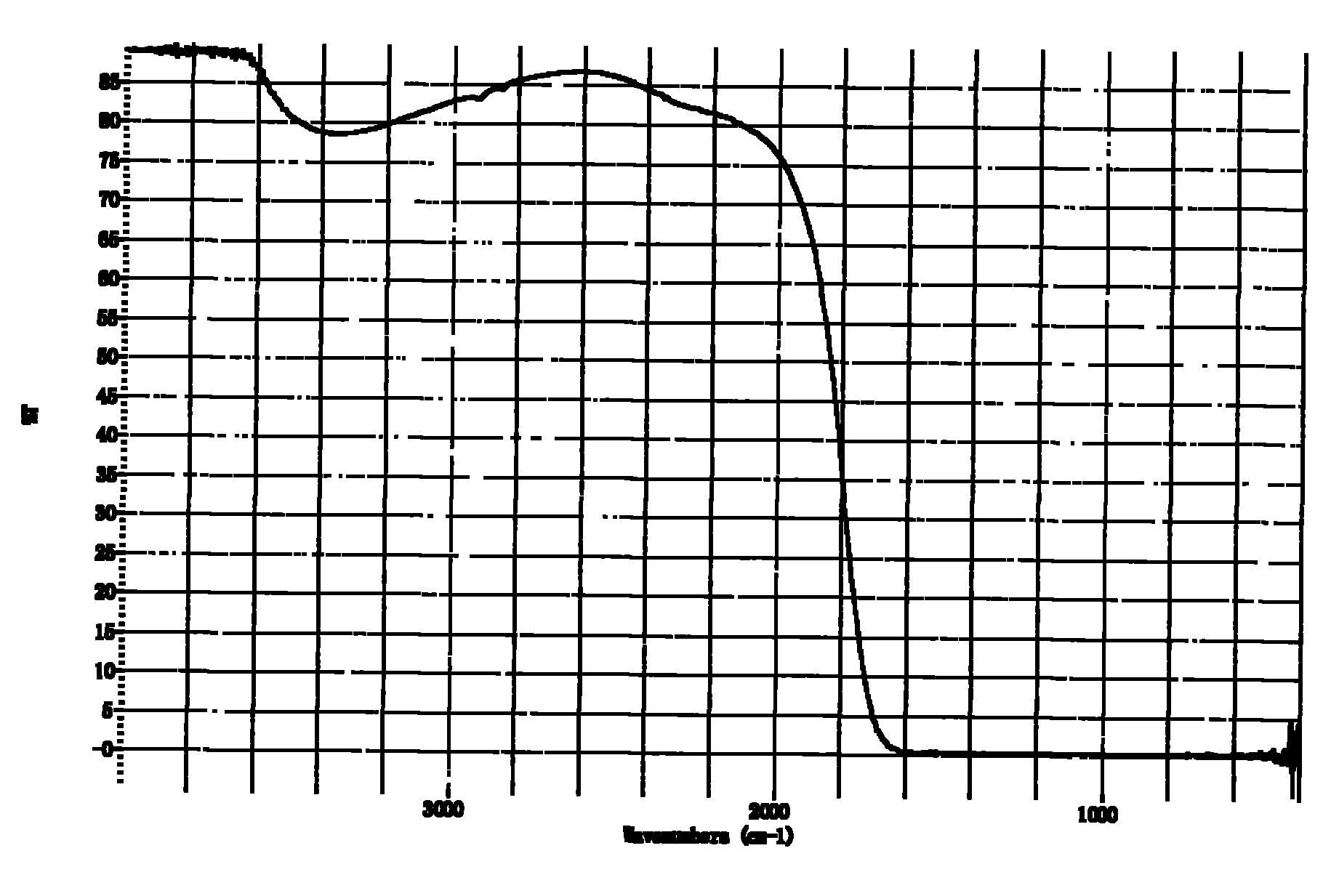

Image

Examples

Embodiment 1

[0024] (1) According to 38% GeO 2 -26%AL 2 o 3 -36%CaO (mol percent) Calculate the weight percent of each component, then take the raw material and mix it uniformly in a ball mill jar;

[0025] (2) Add the mixture into a 0.3L platinum crucible, the feeding temperature is 1480°C, and the feeding time is 1 hour;

[0026] (3) After the glass is melted, the temperature is raised to 1520°C, and a dry gas is introduced on the surface of the molten glass for 6 hours, and at the same time, a platinum stirrer is used to stir, homogenize and clarify;

[0027] (4) After slowly lowering the furnace temperature to 1450°C, pour the molten glass into a preheated mold for molding (casting into a rectangular shape);

[0028] (5) Quickly put the glass into the muffle furnace that has been heated to the transition temperature. After 2 hours of heat preservation, it is annealed at a speed of -10°C / h to 200°C, and then the power is turned off and then lowered to room temperature to obtain a col...

Embodiment 2

[0031] (1) According to 45% GeO 2 -15%Ga 2 o 3 -24%BaO-3%ZrO 2 -10%TiO 2 -3% La 2 o 3 (Mole percent) calculate the weight percent of each component, then take by weighing raw material, mix homogeneously in ball mill jar;

[0032] (2) Add the mixture into a 0.3L platinum crucible, the feeding temperature is 1350°C, and the feeding time is 1 hour;

[0033] (3) After the glass is melted, the temperature is raised to 1400°C, and a dry gas is introduced on the surface of the molten glass for 6 hours. At the same time, a platinum stirrer is used to stir and homogenize and clarify;

[0034] (4) After slowly lowering the furnace temperature to 1300°C, pour the molten glass into a preheated mold for molding (casting into a rectangular shape);

[0035] (5) Quickly put the glass into the muffle furnace that has been heated to the transition temperature. After 2 hours of heat preservation, it is annealed at a speed of -10°C / h to 200°C, then the power is turned off and the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com