Method for removing powder and attaching glue for tab locations of pole pieces

A pole piece and tab technology, which is applied in the direction of electrical components, circuits, battery pack components, etc., can solve the problems of high packaging requirements, large environmental pollution, strong corrosion, etc., and achieve low processing cost, high control precision, and eliminate dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

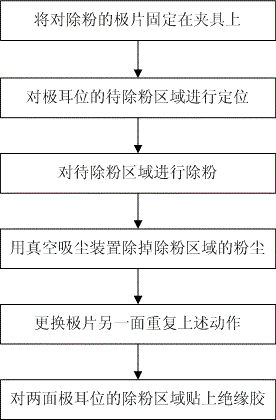

Image

Examples

Embodiment 1

[0030] Embodiment 1 uses a laser to burn the powder-removing area at the tab of the pole piece; first, the laser is focused according to the distance from the laser source to the powder-removing area at the tab of the pole piece and the depth of the powder-removing area, so that the powder to be removed The powder area is within the Rayleigh length of the laser, ensuring that the burning range of each depth in the powder removal area is within a controllable normal range; then accurately locate the powder removal area to prevent multiple removals due to inaccurate positioning The problem of powder or non-powder removal; finally, laser burning is used to complete the powder removal of the area to be removed at the ear of the pole piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com